A mold with a diversion groove connected with a T-shaped groove

A diversion groove and mold technology, applied in the direction of metal extrusion molds, etc., can solve problems such as affecting production and use, broken joints, insufficient material supply, etc., to achieve low manufacturing difficulty, stable size, and simple and reasonable mold structure design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

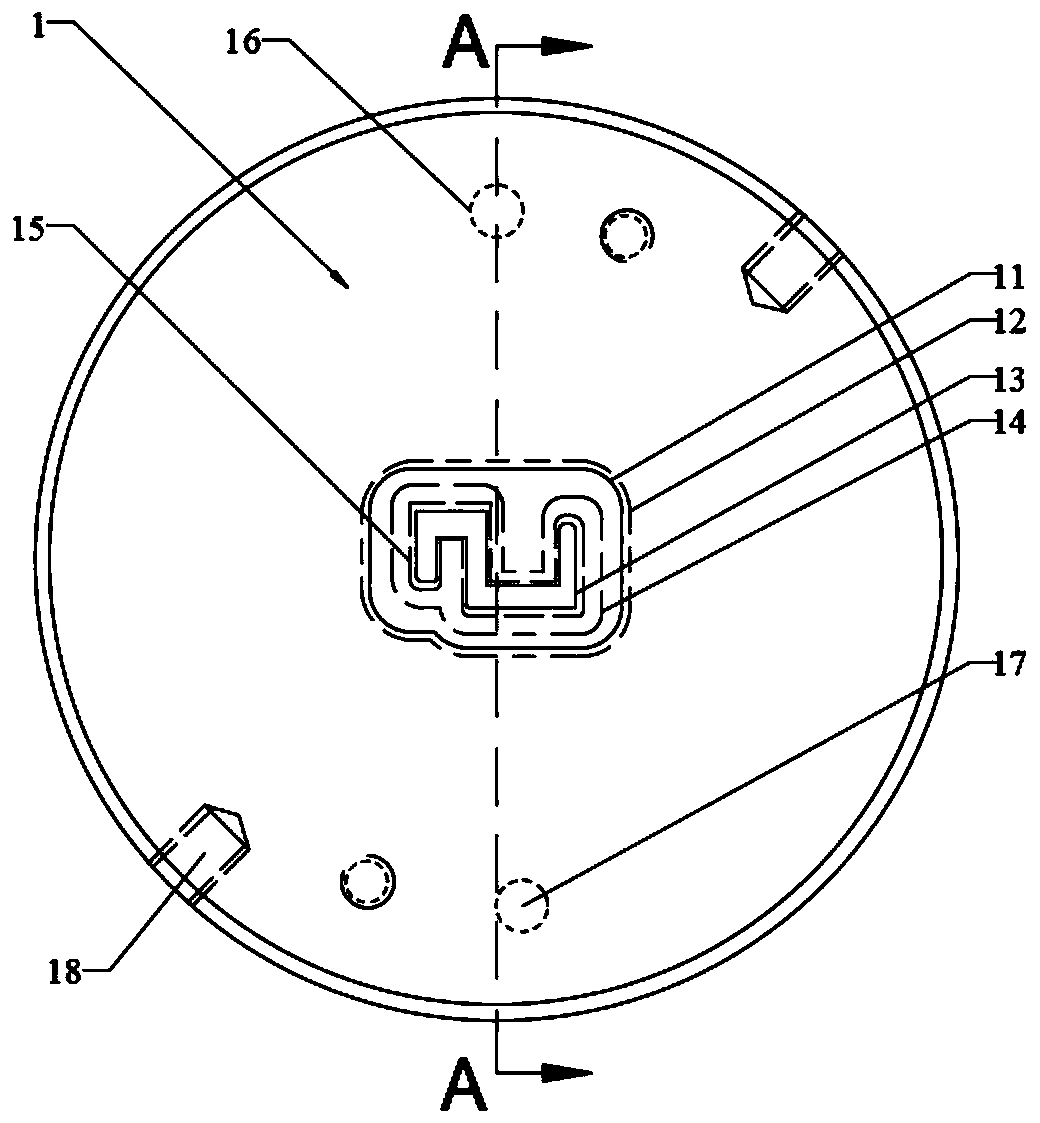

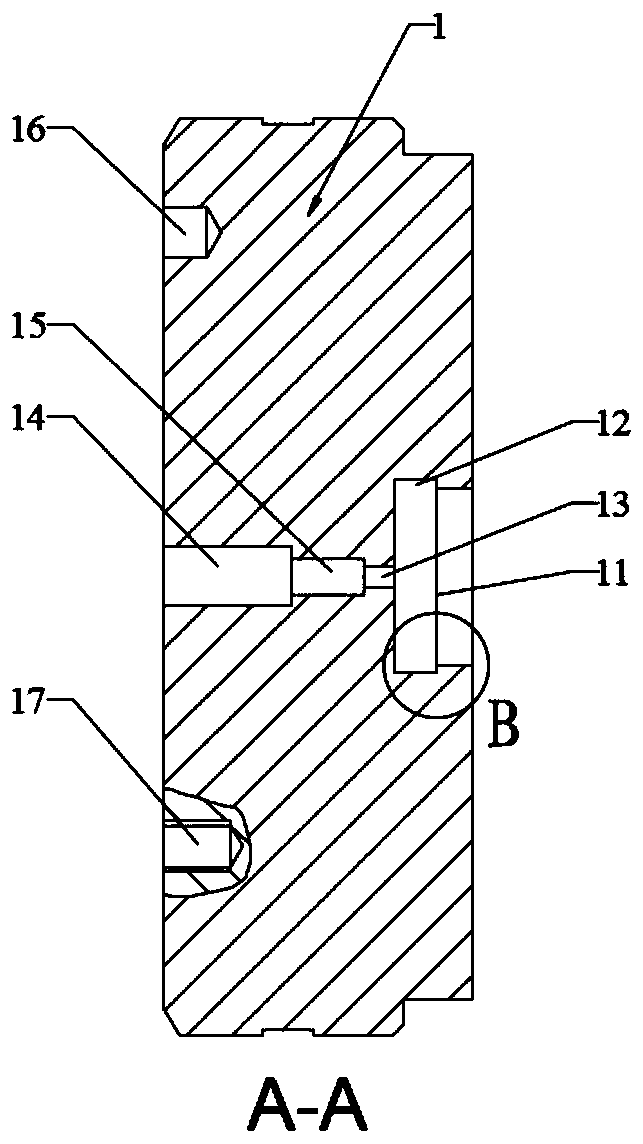

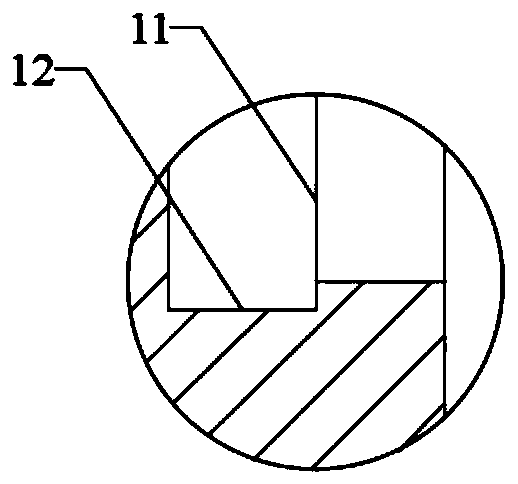

[0036] Please refer to Figure 1 to Figure 4 Shown, embodiment one of the present invention is:

[0037] A kind of mold that diversion groove is connected with T-shaped groove, comprises guide mold 1, and the shape of described guide mold 1 is cylinder; Described guide mold 1 is from the feed end of guide mold 1 to guide mold The axis of the discharge end of 1 is provided with diversion groove 11, T-shaped groove 12, working belt 13 and discharge port 14 in sequence;

[0038] The diversion groove section of the guide groove 11 along the axial direction of the guide mold 1 is rectangular, and the T-shaped groove cross section of the T-shaped groove 12 along the axial direction of the guide mold is rectangular; the T-shaped groove cross section and the flow guide The vertical line of the long side of the groove cross-section coincides with the axis of the guide mold 1; the length of the short side of the T-shaped groove cross-section is greater than the length of the short side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com