Cylindrical power battery module

A technology for power batteries and cylindrical batteries, which is applied to battery pack components, circuits, electrical components, etc., can solve problems such as potential safety hazards, low modularization, and low space utilization, and achieve improved vibration resistance and impact resistance. The effect of strong versatility and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals.

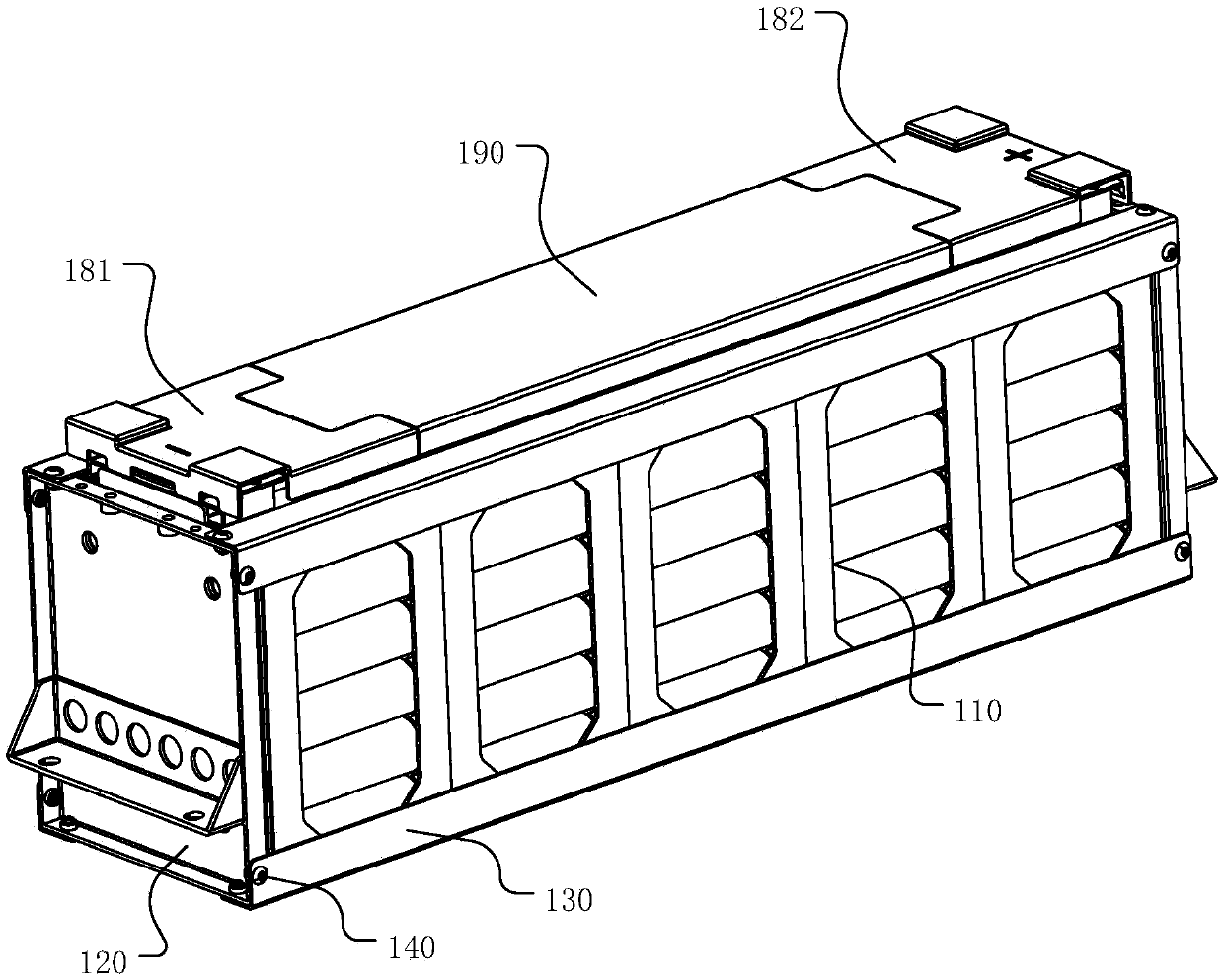

[0025] figure 1 A schematic diagram showing a three-dimensional structure of a cylindrical power battery module according to an embodiment of the present invention.

[0026] The cylindrical power battery module in the embodiment of the present invention includes: a battery module 110 , an end plate 120 , an angle steel 130 , a rivet 140 , a negative upper cover 181 , a positive upper cover 182 and a middle upper cover 190 .

[0027] figure 1 Shown is a schematic diagram of the assembly of the cylindrical power battery module. The battery module includes a plurality of battery modules 110 connected in series, which are fixed by a module frame composed of angle steel 130 and end plates 120 on both sides. Rivet holes are provided on the end plates 120 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com