Novel forklift hydraulic pipeline tee joint

A technology for hydraulic pipelines and tee joints, which is applied in the direction of pipes/pipe joints/fittings, branch pipelines, pipes, etc. It can solve problems such as loosening, oil circuit interruption, and low action sensitivity, so as to achieve rapid action and avoid oil pressure. The effect of high shock and motion sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

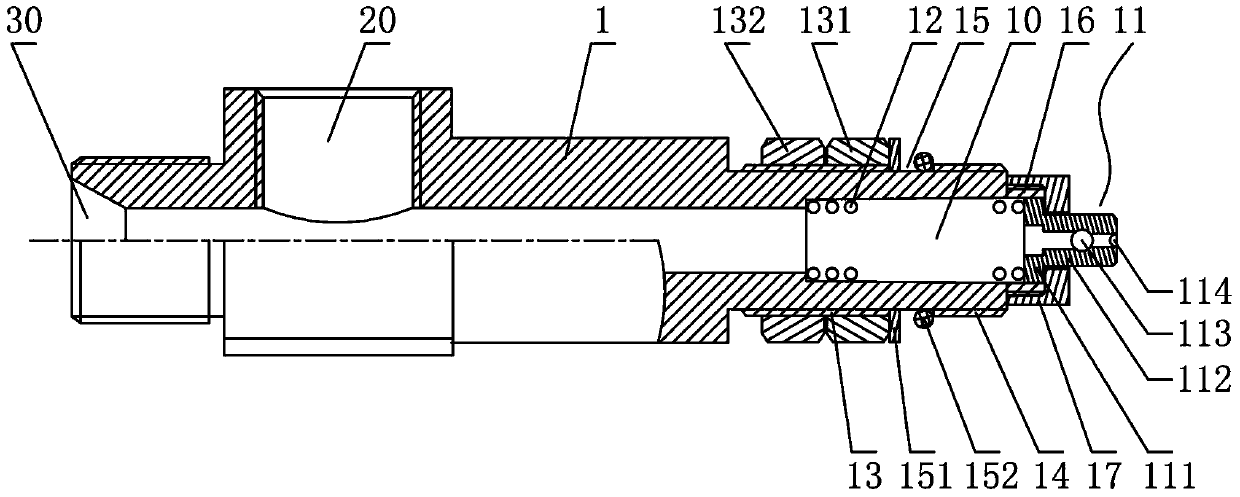

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

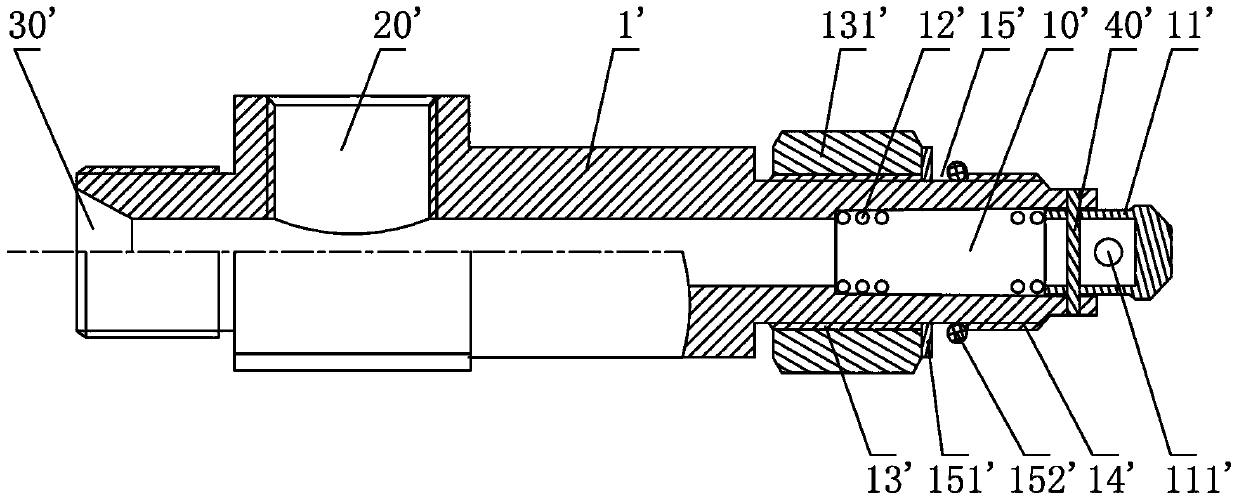

[0019] Such as figure 2 The new forklift hydraulic pipeline tee joint shown includes a joint body 1, and the joint body 1 is respectively provided with an oil cylinder interface 10, an oil inlet 20 and a diversion port 30, and a slide valve is movable in the oil cylinder interface 10 11. A spring 12 is connected between the slide valve 11 and the joint body 1, and a rear external thread section 13 and a front external thread section 14 are provided on the outer circular wall of the oil cylinder interface 10, and the rear external thread section 13 An annular groove 15 is provided between the front external thread section 14 and a gasket 151 and an annular sealing ring 152 are nested in the annular groove 15 .

[0020] The end of the oil cylinder interface 10 is extended with a small-diameter connecting portion 16, and the small-diameter connecting portion 16 is fitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com