Anti-winding yacht lifting belt conveying structure

An anti-winding, lifting belt technology, applied in the direction of winding strips, transportation and packaging, load hanging components, etc., can solve problems such as sling wrinkles, achieve the effect of increasing flatness, increasing contact area, and reducing slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

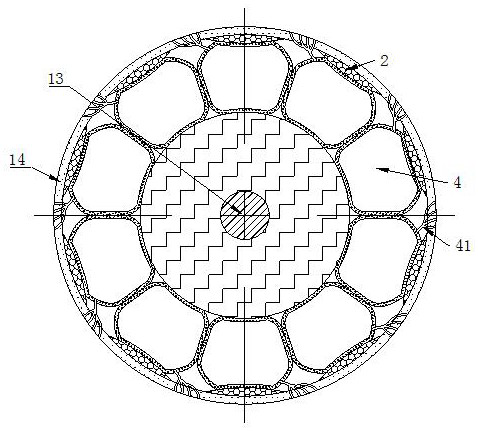

[0040] see Figure 6 As shown in Comparative Example 1, as another embodiment of the present invention, an elastic rod 9 is affixed to the side of the extruded flexible strip 31 away from the pulling flexible thorn 5; Multiple groups of pulleys 91; by being provided with pulleys 91 on the side wall of the extruded flexible strip 31, when the extruded flexible strip 31 is in contact with the flexible stretching roller 14, the sliding friction can be converted into rolling friction, reducing the pressure of the extruded flexible strip 31. The wear of the flexible stretching roller 14 further increases the service life of the second rotating shaft 13 and the flexible stretching roller 14 .

[0041] There are many sets of Y-shaped elastic support sheets 92 fixedly connected on the elastic rod 9; the Y-shaped elastic support sheet 92 is arranged on the elastic rod 9 near the side of the extruded flexible strip 31; The Y-shaped elastic supporting piece 92 can support the elastic ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com