Ring extruder for chain ring of round-link chain

A technology of round link chain and chain link, which is applied in the direction of metal chains, etc., can solve the problems of large reactive power consumption, low mechanical efficiency, and high equipment failure rate, so as to reduce operating costs and equipment failure rates, improve mechanical efficiency, and improve product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

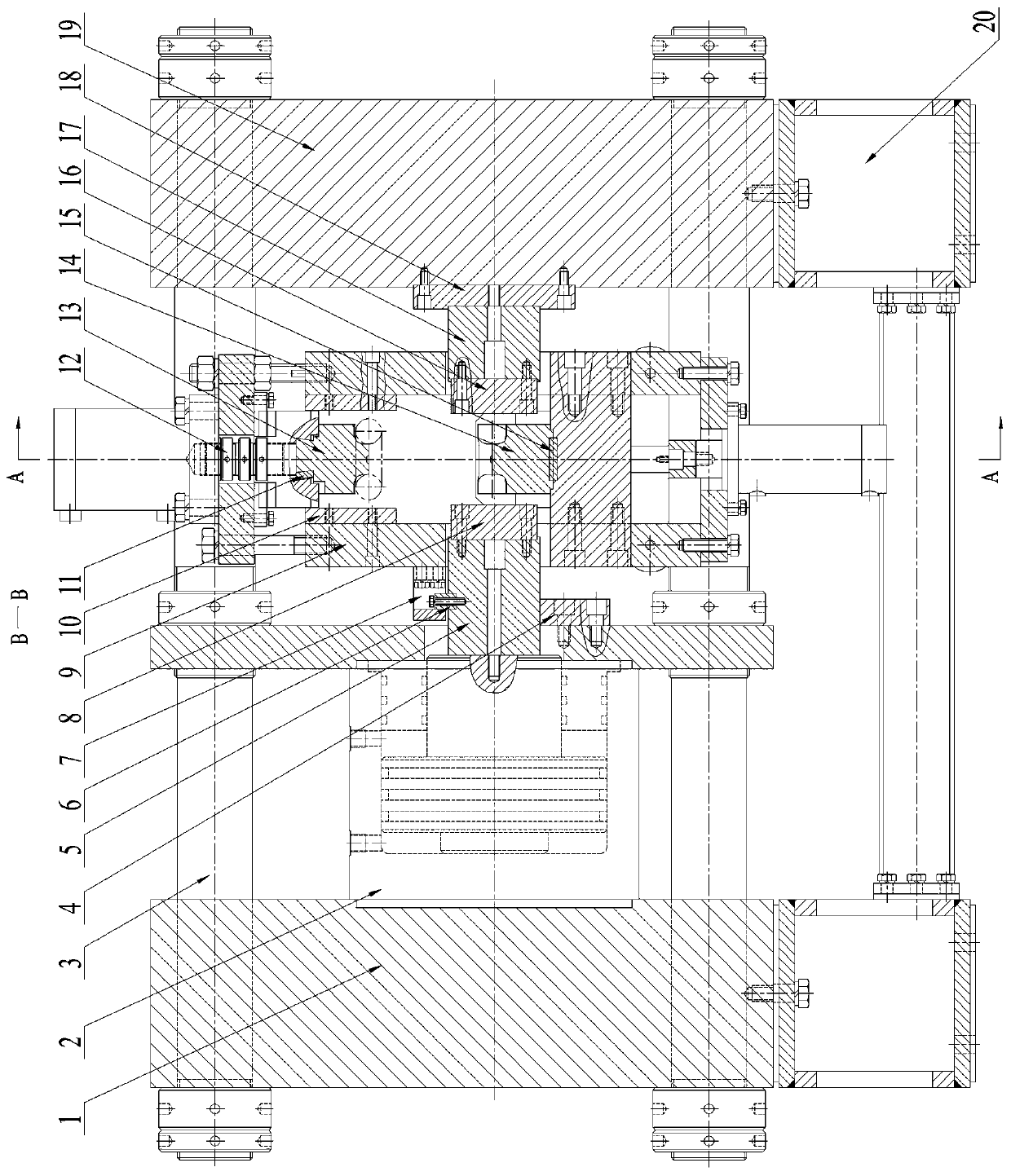

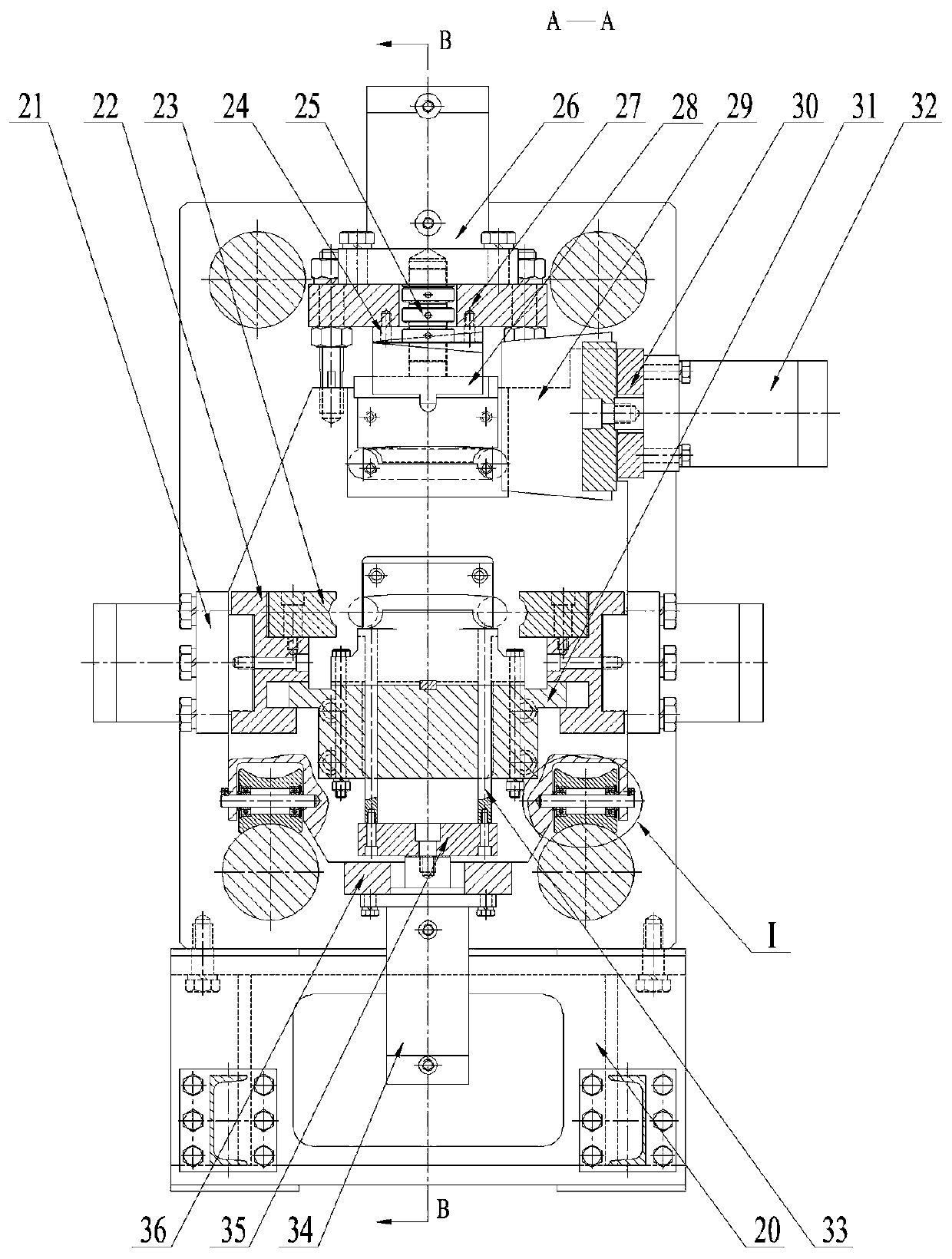

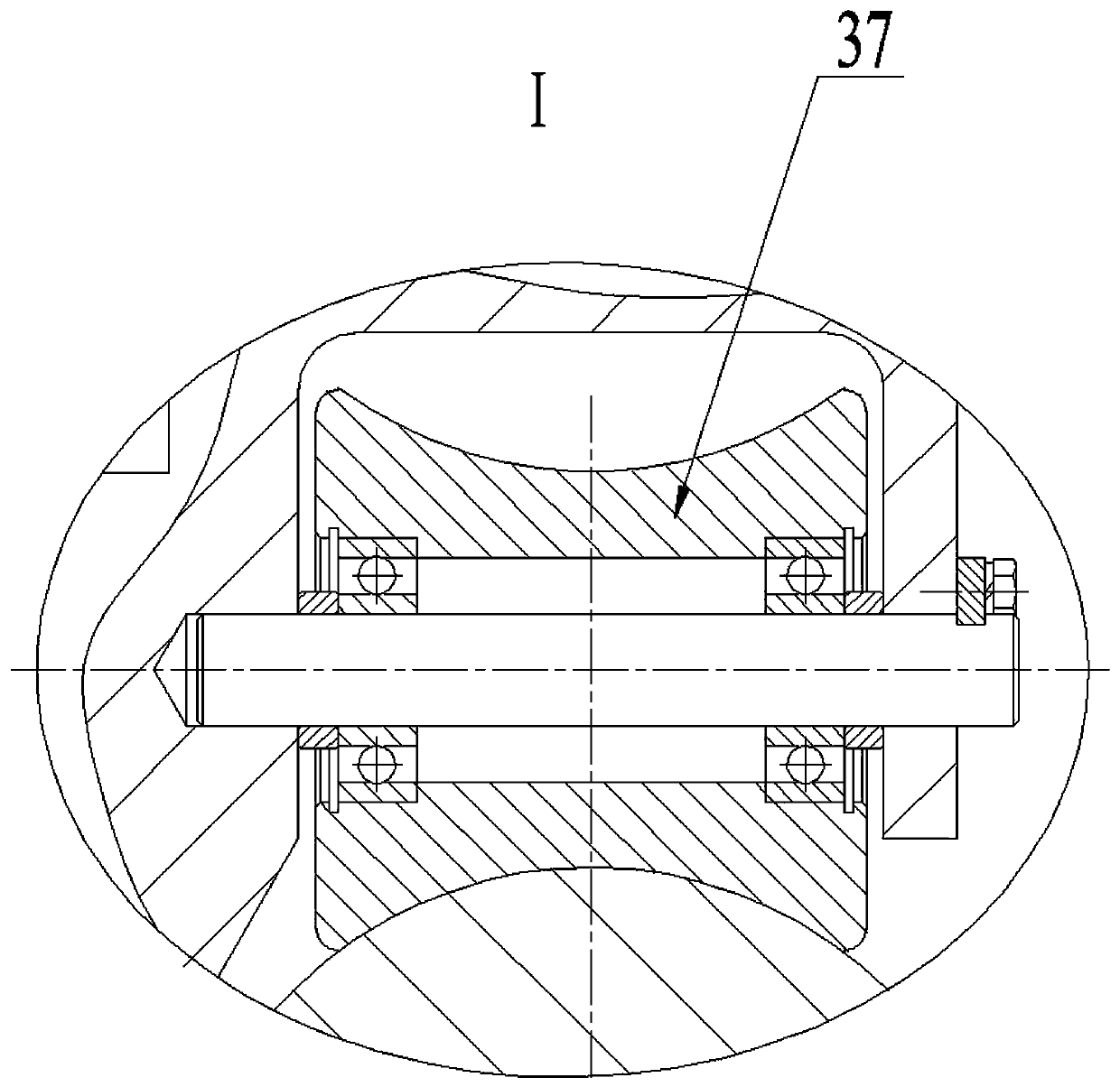

[0032] From Figure 1 ~ Figure 4 It can be seen that the technical solution of the present invention includes a frame, a movable frame, a forming mechanism, a reset mechanism, and a ring-removing mechanism;

[0033] The frame is composed of a machine base 20, a left side plate 1, a right side plate 19, and tie rods 3; the left side plate 1 and the right side plate 19 are connected into one body by four tie rods 3 arranged vertically and horizontally. Structure, the fixing method of the left side plate 1, the right side plate 19 and the tie rod 3 is as follows: the corners of the left side plate 1 and the right side plate 19 are provided with corresponding through holes, and the two ends of the four tie rods pass through the left and right side plates through the through hole, and tighten the position through the tie rod nut 39 and the tie rod lock nut 38 located on the outside of the left and right side plates. The left and right side plates and the upper and lower pull rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com