Anode carbon block for clamped anode conductive device

A technology of anode carbon block and conductive device, which is applied in the field of anode carbon block, can solve the problems of high cost, high contact resistance, uneven current density distribution of anode carbon block, etc., so as to reduce contact voltage drop, reduce assembly cost, and simplify assembly. The effect of process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

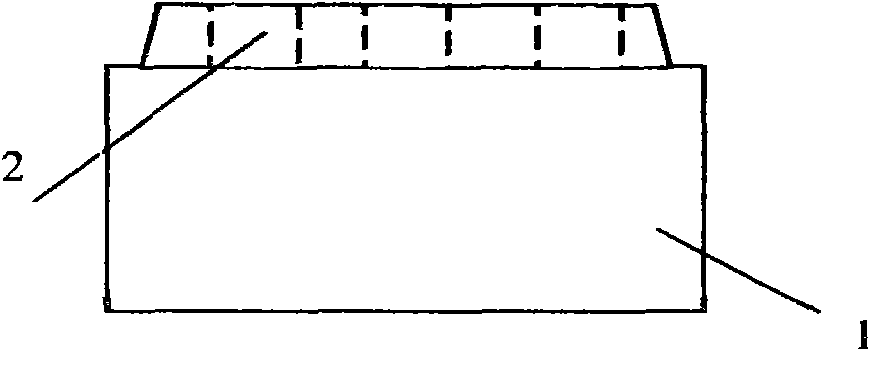

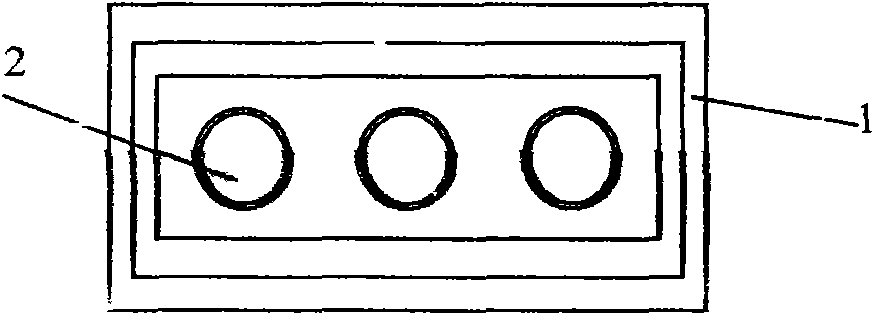

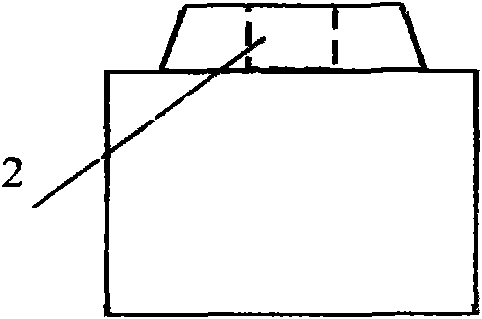

[0026] Embodiment one: the anode carbon block (1) for aluminum electrolytic cell clamping type anode conduction device of the present invention, such as image 3 Figure 4 As shown, the upper part of the carbon block (1) has a convex clamping platform (3) connected with the anode conductive fixture, and there is no such thing as the general-purpose anode carbon block (1), on the top of the carbon block (1). Set the cast carbon bowl (2) with phosphorus iron ring as figure 1 , figure 2 , image 3 As shown, the two sides of the convex clamping table (3) of the anode carbon block (1) for the clamping type anode conductive device are constructed with convex retaining walls (4 ). Two conductive side splints forming an anode conductive fixture between the convex retaining walls (4) on both sides and the convex clamping table (3) can be inserted and can be electrically connected to the lower clamping table (3). Recessed slots (5), such as Figure 4 , Figure 5 , Figure 6 Sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com