Short net side low voltage dynamic reactive power compensation system in metallurgical industry

A compensation system and network system technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, transformer/inductor core, etc., can solve large reactive power consumption, three-phase imbalance, and low natural power factor and other issues to achieve the effect of increasing the active power output rate and improving the power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

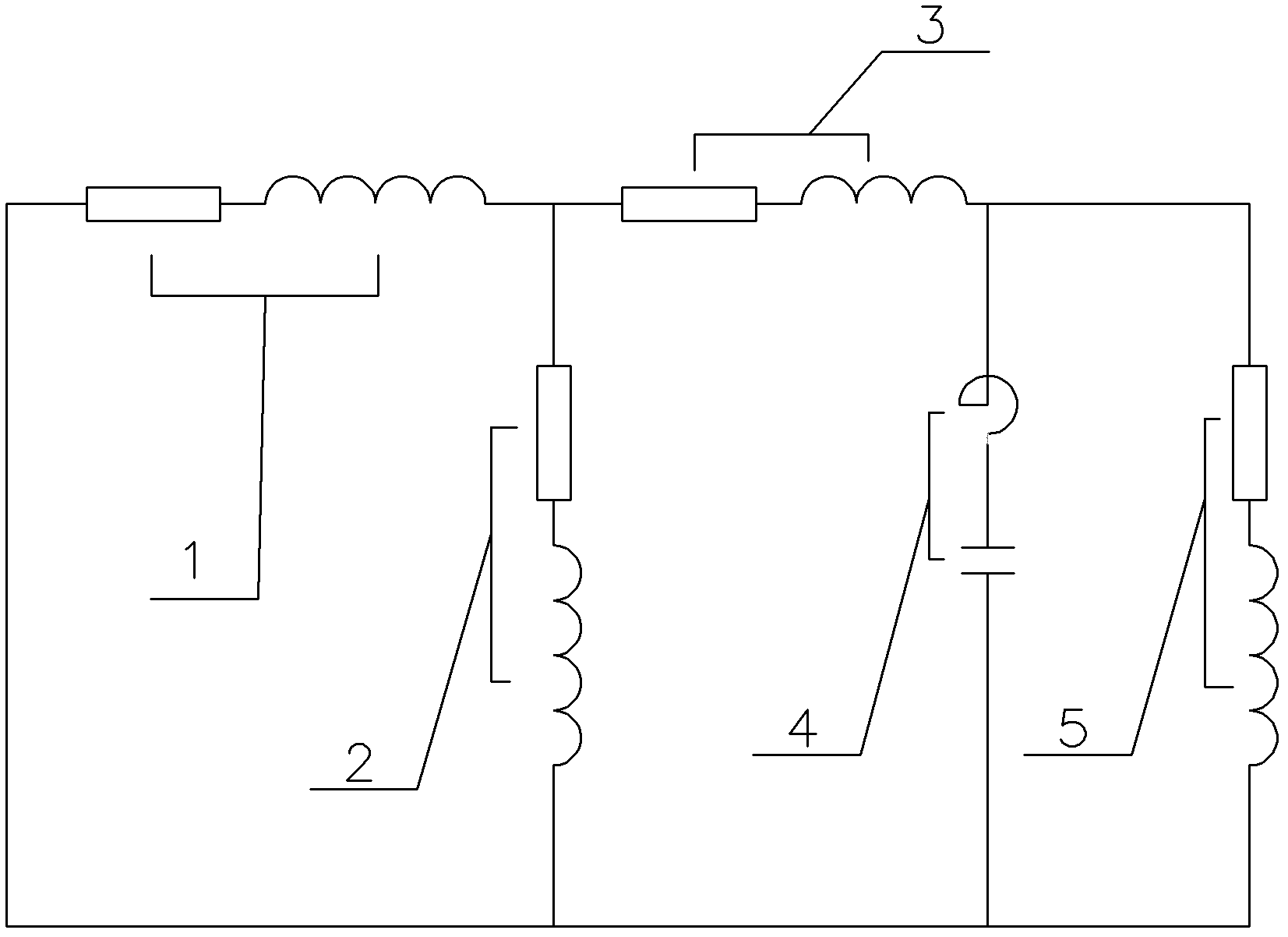

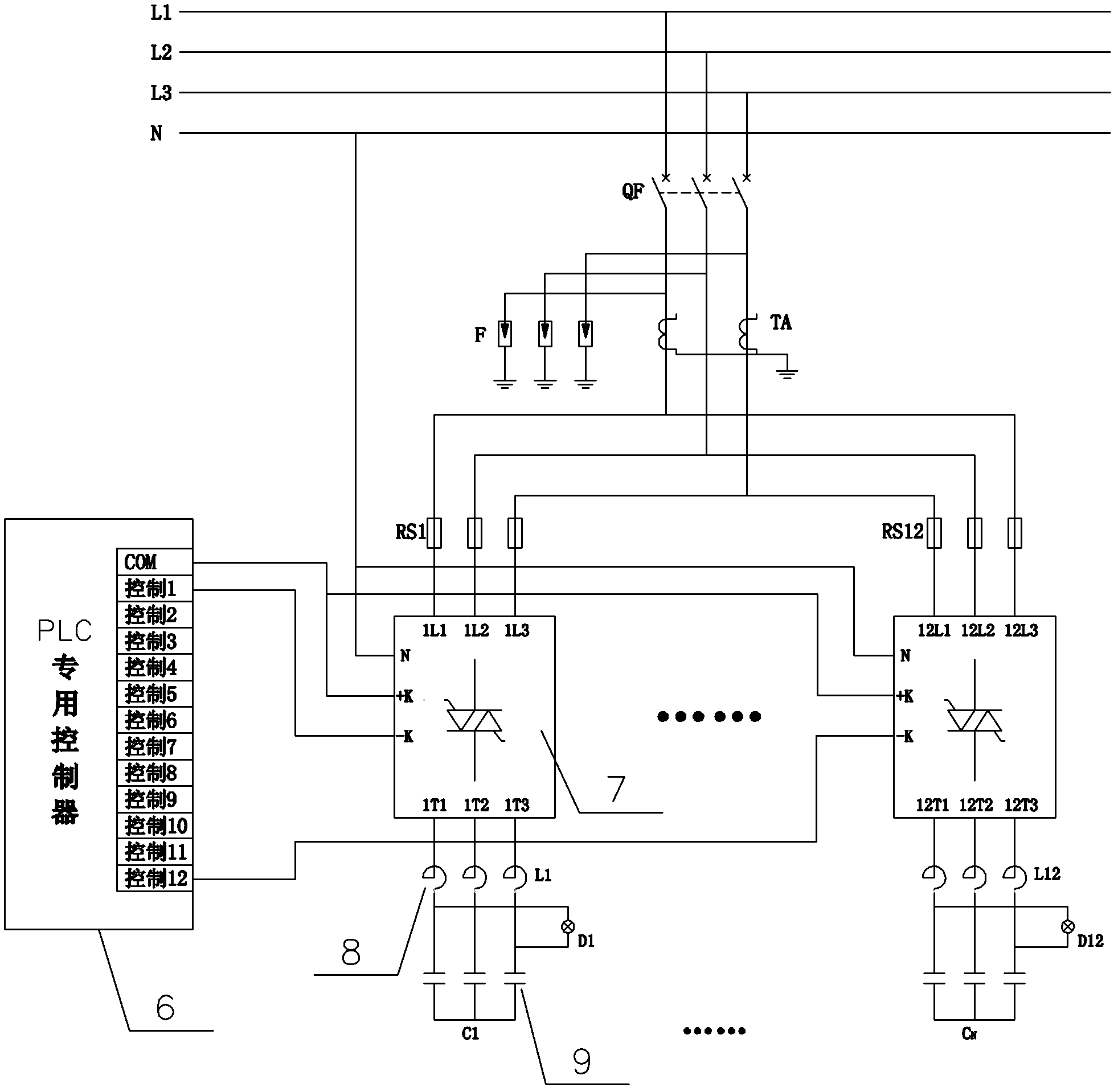

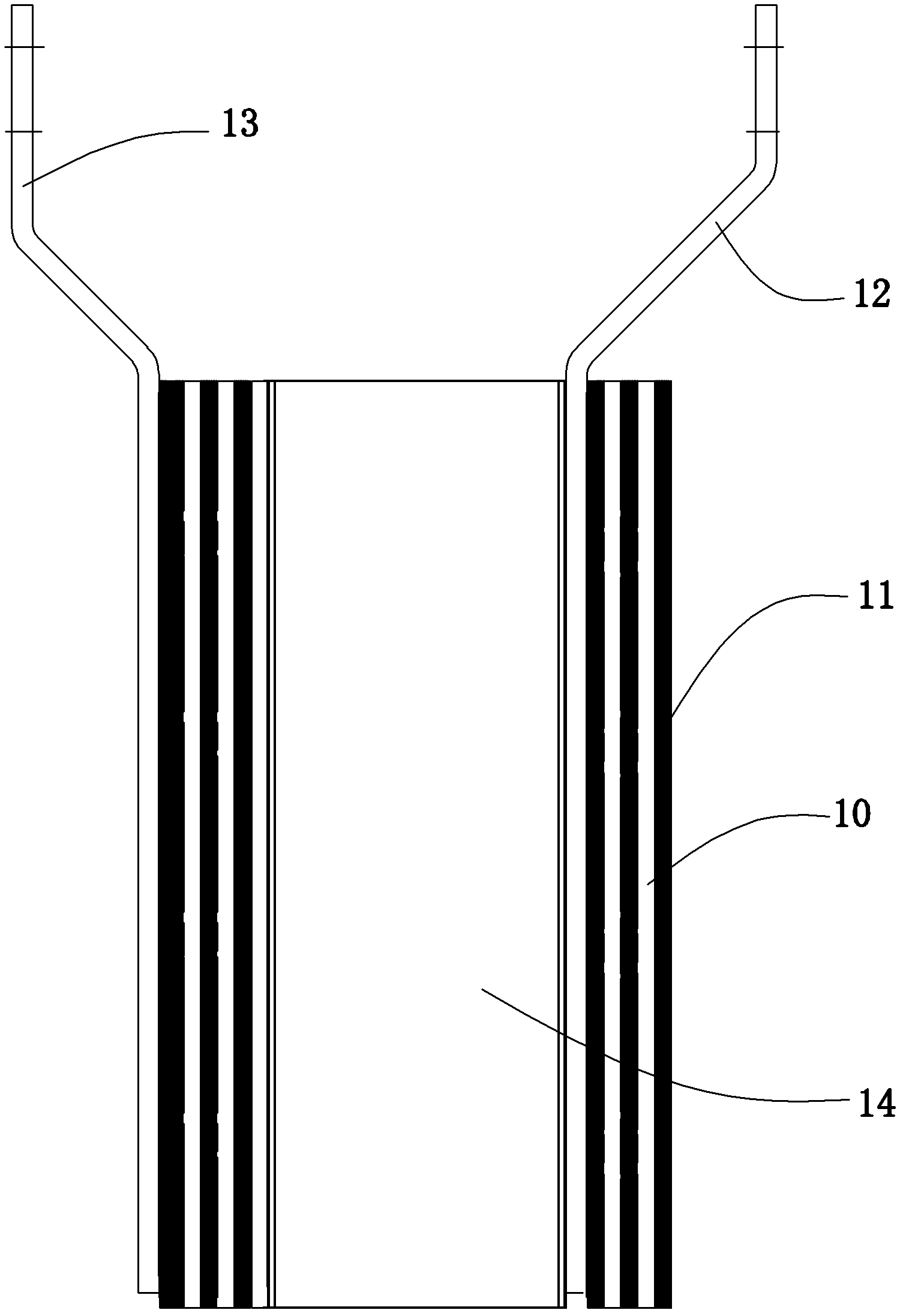

[0026] Embodiment: A low-voltage dynamic reactive power compensation system on the short-network side of the metallurgical industry, including a high-voltage power supply network system, a short-network system connected in series with the high-voltage power supply network system, and metallurgical equipment connected in series with the short-network system. The metallurgical equipment is connected in parallel with low-voltage dynamic compensation The device, the short network system and the metallurgical equipment are connected in parallel with the furnace transformation system, and the high voltage side of the furnace transformation system is connected to the high voltage power supply network system. impedance within the system (see attached figure 1 ) Including high-voltage power supply network system impedance 1, short network system impedance 3, furnace transformer system impedance 2, low-voltage dynamic compensation device impedance 4, and metallurgical equipment impedance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com