Laced farci food forming device

A technology for food forming and lace stuffing, applied in food science, baking, dough processing, etc., can solve the problems of incomplete shape processing of stuffed food, poor forming effect, etc., and achieve good forming effect and improve aesthetics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

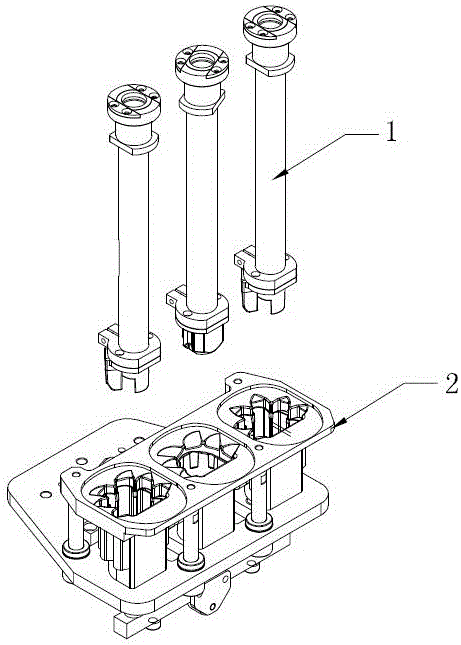

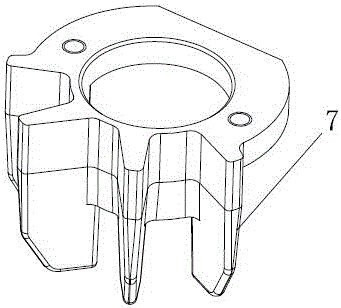

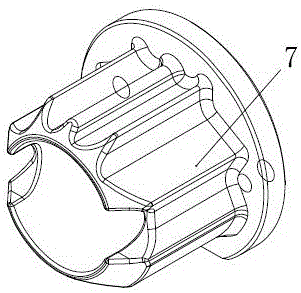

[0046] A kind of lacy stuffed food molding device comprises filling pipe 1 and is positioned at the forming die 2 below filling pipe 1, and described forming die 2 comprises skin-joint plate 3 and is positioned at the mold cup 4 below skin-joint plate 3, and described joint The leather plate 3 is provided with a forming hole 5, the filling pipe 1 is located above the forming hole 5, the mold cup 4 is correspondingly arranged below the forming hole 5, and the outer edge of the forming hole 5 is provided with a plurality of sequentially distributed The corrugated through hole 6, the lower part of the filling pipe 1 is provided with a molding convex strip 7. The function of the forming convex strip 7 is to cooperate with the forming hole 5 to extrude the dough into a pattern when the stuffing head 11 pushes the dough downward. The dough is placed on the forming hole 5 of the skin connecting plate 3, the filling pipe 1 moves downward, and the dough is pushed downward, the forming ...

Embodiment 2

[0048] A kind of lacy stuffed food molding device comprises filling pipe 1 and is positioned at the forming die 2 below filling pipe 1, and described forming die 2 comprises skin-joint plate 3 and is positioned at the mold cup 4 below skin-joint plate 3, and described joint The leather plate 3 is provided with a forming hole 5, the filling pipe 1 is located above the forming hole 5, the mold cup 4 is correspondingly arranged below the forming hole 5, and the outer edge of the forming hole 5 is provided with a plurality of sequentially distributed The corrugated through hole 6, the lower part of the filling pipe 1 is provided with a molding convex strip 7. The function of the forming convex strip 7 is to cooperate with the forming hole 5 to extrude the dough into a pattern when the stuffing head 11 pushes the dough downward.

[0049] The forming ridges 7 are distributed along the length direction of the filling tube 1 . The positions of the forming protrusions 7 correspond to ...

Embodiment 3

[0055] A kind of lacy stuffed food molding device comprises filling pipe 1 and is positioned at the forming die 2 below filling pipe 1, and described forming die 2 comprises skin-joint plate 3 and is positioned at the mold cup 4 below skin-joint plate 3, and described joint The leather plate 3 is provided with a forming hole 5, the filling pipe 1 is located above the forming hole 5, the mold cup 4 is correspondingly arranged below the forming hole 5, and the outer edge of the forming hole 5 is provided with a plurality of sequentially distributed The corrugated through hole 6, the lower part of the filling pipe 1 is provided with a molding convex strip 7. The function of the forming convex strip 7 is to cooperate with the forming hole 5 to extrude the dough into a pattern when the stuffing head 11 pushes the dough downward.

[0056] The forming ridges 7 are distributed along the length direction of the filling tube 1 . The positions of the forming protrusions 7 correspond to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com