Cleaning device for glass processing

A cleaning device and glass technology, applied in the direction of cleaning method using tools, cleaning method using liquid, cleaning flexible objects, etc., can solve the problems of inability to effectively transport glass, affecting cleaning and transportation, glass friction resistance, etc., and achieve a simple structure. , Easy to operate, to ensure the effect of cleaning strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

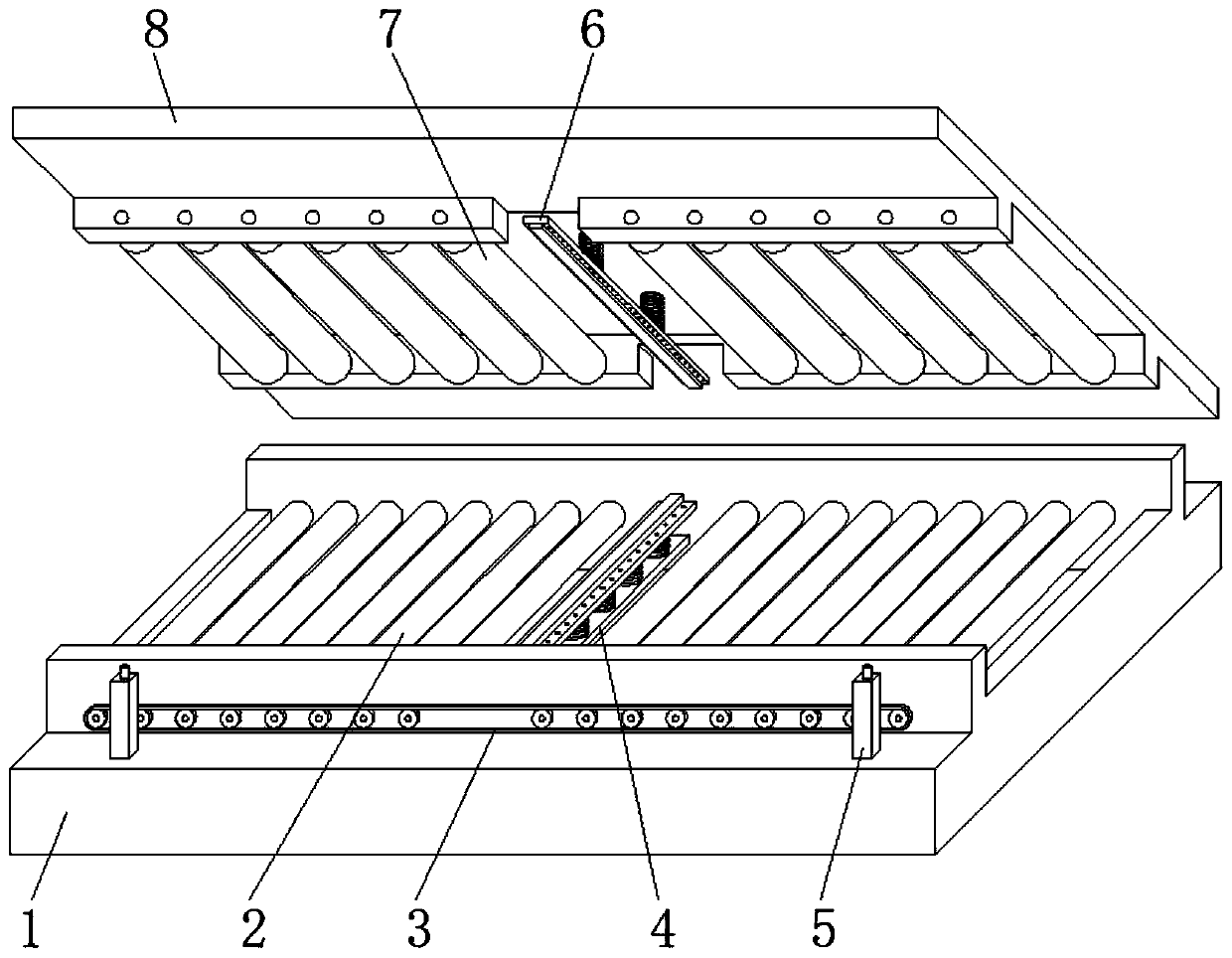

[0025] refer to Figure 1-2 , a cleaning device for glass processing, comprising a base 1, a hydraulic cylinder 5 is fixed on both sides of the top outer wall of the base 1 by screws, and a top plate 8 is fixed on the top of the piston rod of the hydraulic cylinder 5 by screws, and the inner wall of the top plate 8 is provided with Press roller installation hole, and the inwall of press roller installation hole is connected with press roller 7 by bearing, and the inwall of base 1 has delivery roller installation hole, and the inwall of delivery roller installation hole is connected with delivery roller 2 by bearing.

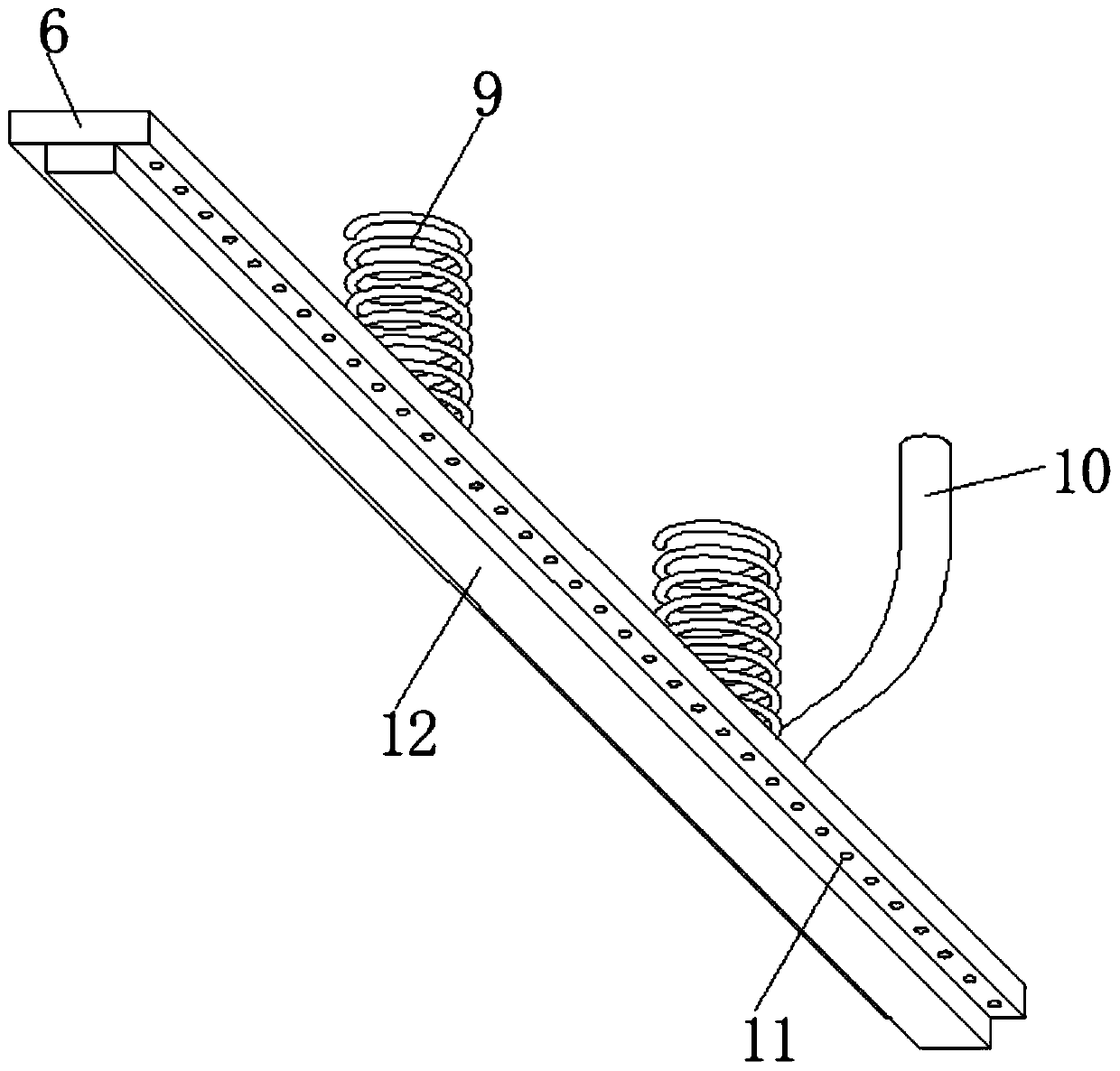

[0026] In the present invention, the middle part of the inner wall of the base 1 is welded with a supporting plate 4, and the top outer wall of the supporting plate 4 and the top inner wall of the top plate 8 are welded with a buffer spring 9, and one end of the buffer spring 9 is welded with a water spray pipe 6.

[0027] In the present invention, water spray ho...

Embodiment 2

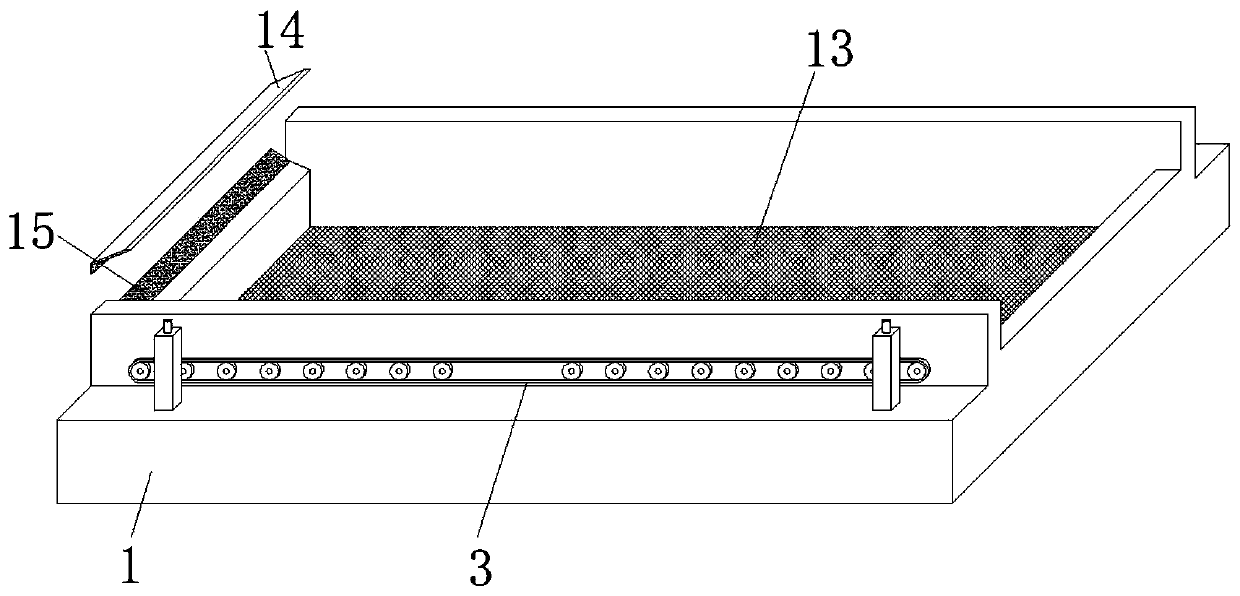

[0033] refer to image 3 , a glass cleaning device, one side of the top outer wall of the base 1 and one side of the top inner wall of the top plate 8 are welded with shrapnel 14, and the outer walls of the opposite sides of the two shrapnel 14 are pasted with absorbent cotton 15, the glass from both sides When passing out between two shrapnels 14, absorbent cotton 15 wipes the moisture on the glass surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com