Machine for automatically making milk powder

A milk powder, automatic technology, applied in beverage preparation devices, household appliances, feeding bottles, etc., can solve the problems of uneven discharge, blockage of the discharge pipe, affecting the feeding of infants, etc., and achieve the effect of ensuring efficiency and simple and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

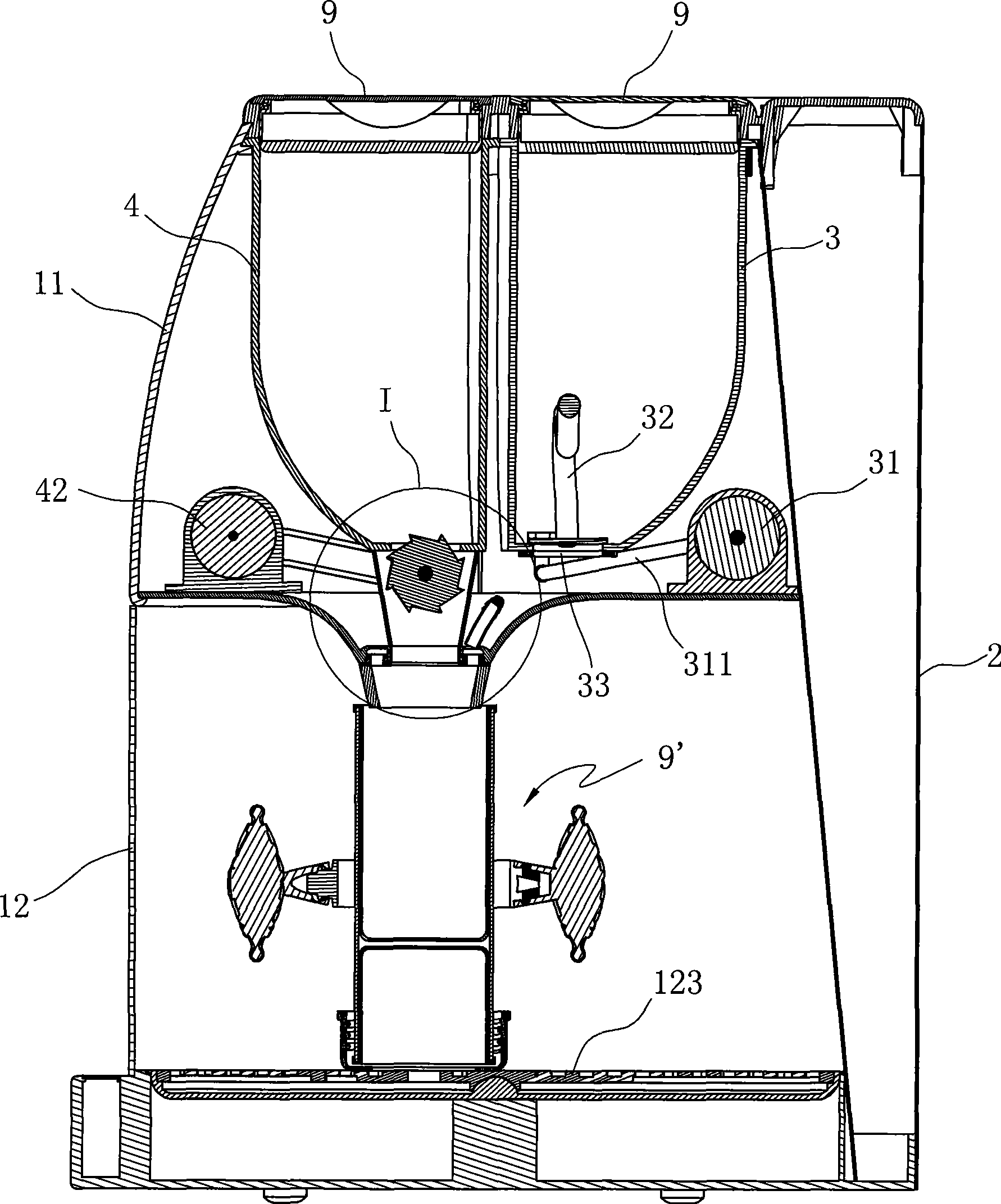

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

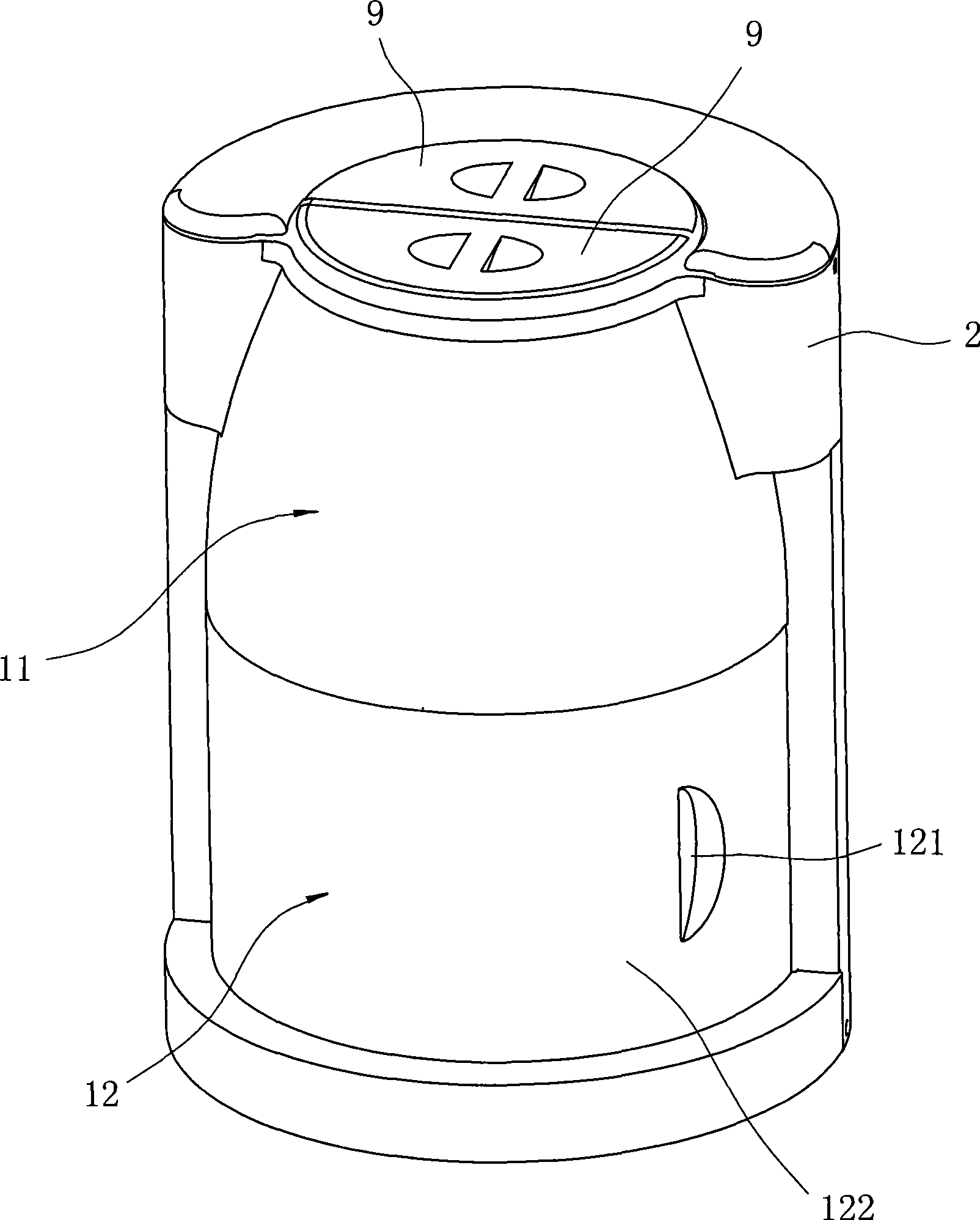

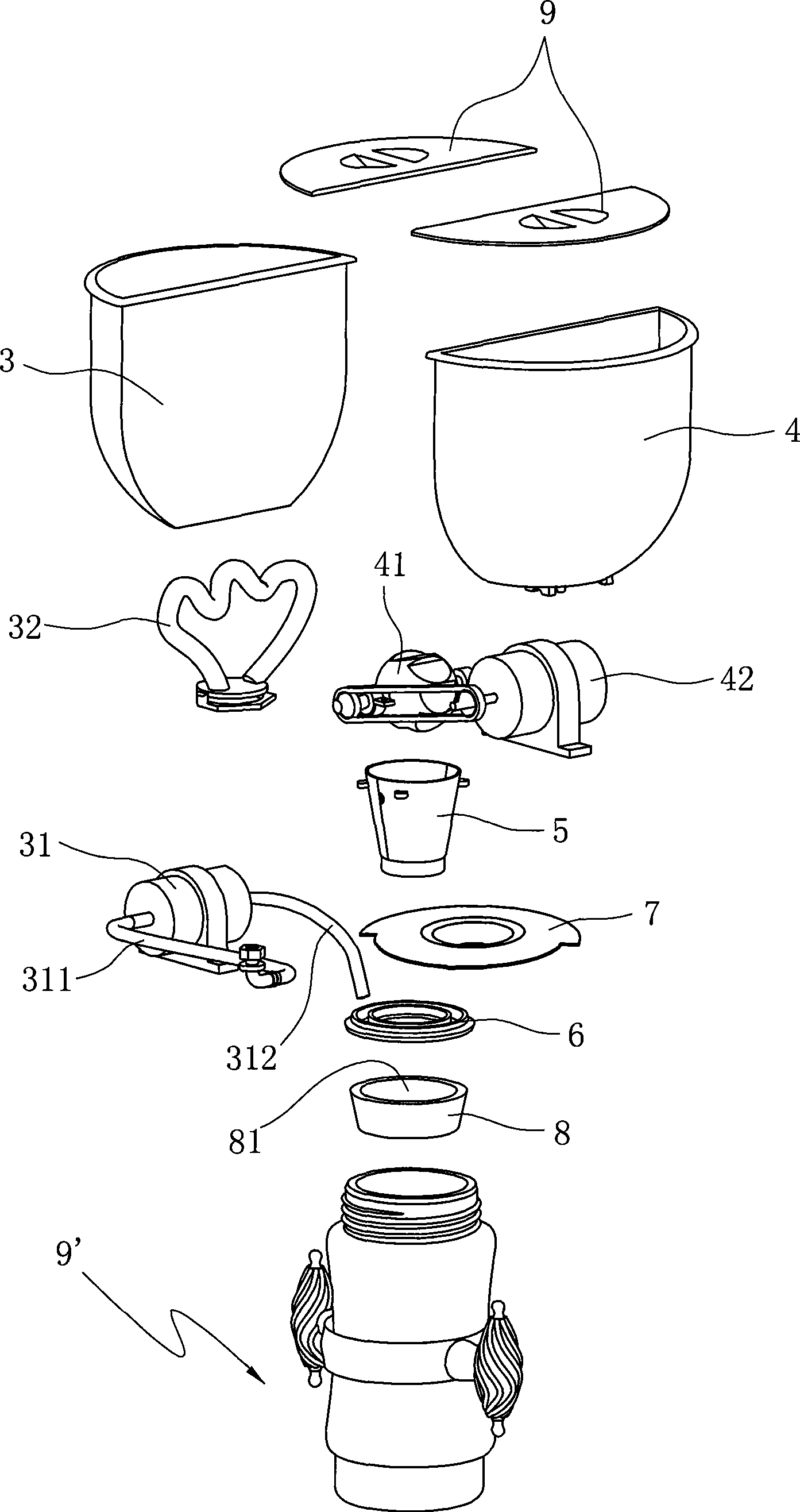

[0030] Such as Figure 1 to Figure 7 Shown, be a preferred embodiment of the present invention, this automatic milk powder machine includes

[0031] The shell, the shell is divided into upper and lower parts that are independent and closed, including an upper shell 11 and a lower shell 12. The upper shell 11 is laminated on the lower shell and then clamped and fixed in a support seat 2. , so that the upper casing 11, the lower casing 12 and the support seat 2 are fixedly connected as one, wherein the lower casing 12 is also provided with a swing door 122 with a handle 121 that can be opened or closed, and the feeding bottle 9' can be closed and accommodated. In the lower casing 12, a feeding bottle rack 123 for placing feeding bottles 9' is also provided at the bottom of the lower casing 12;

[0032] A barrel-shaped water storage container 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com