Patents

Literature

220results about How to "Guaranteed delivery efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

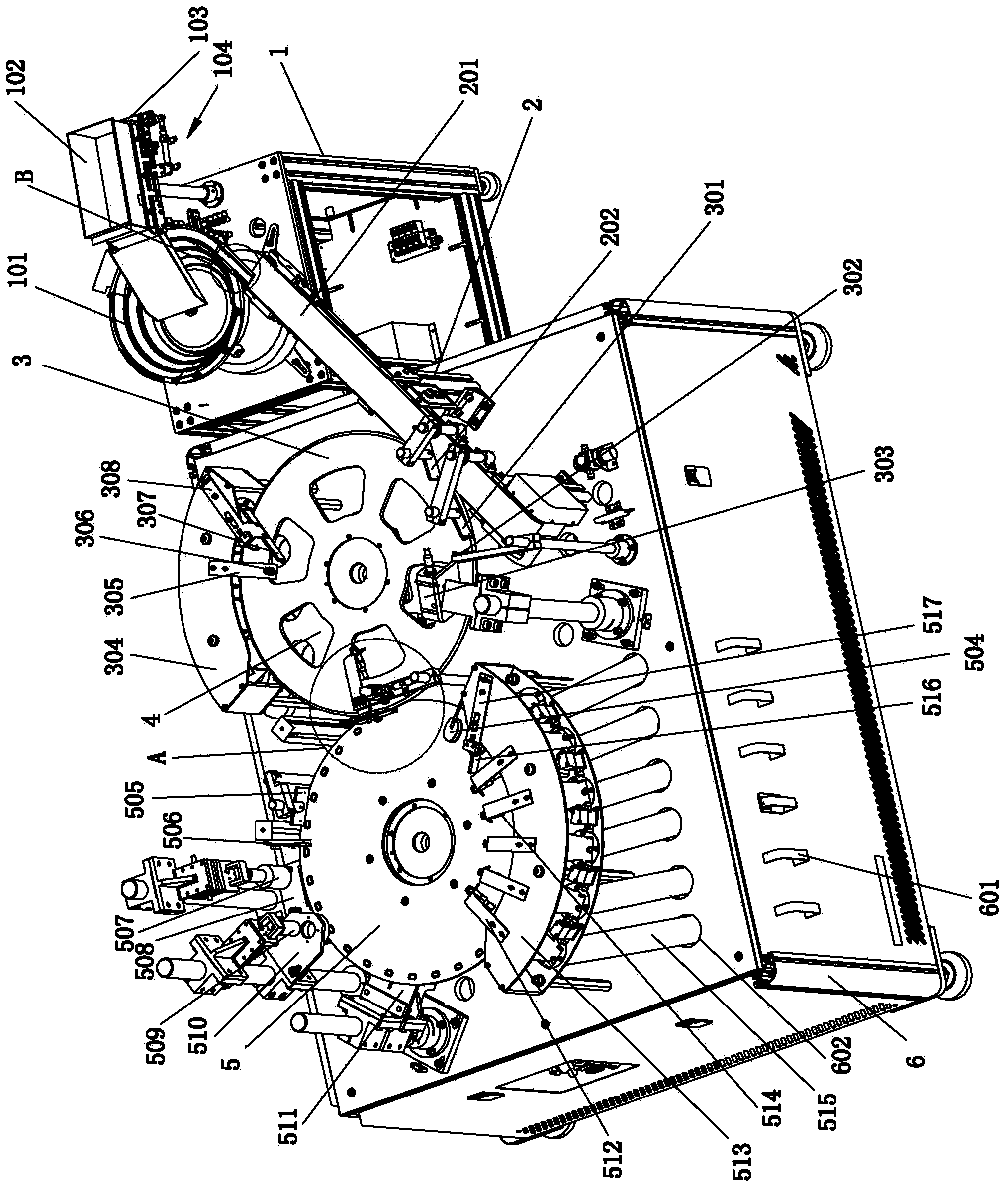

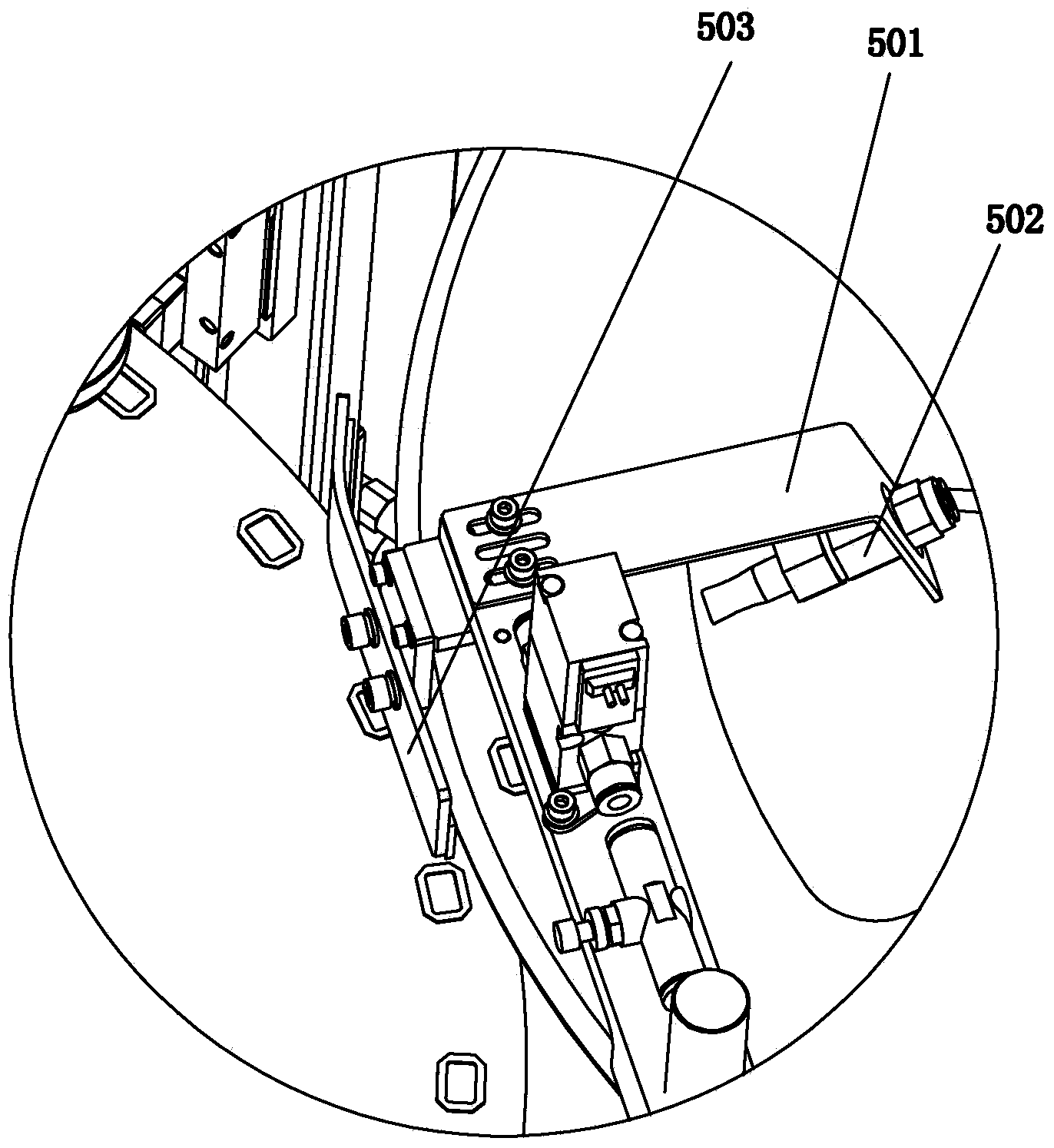

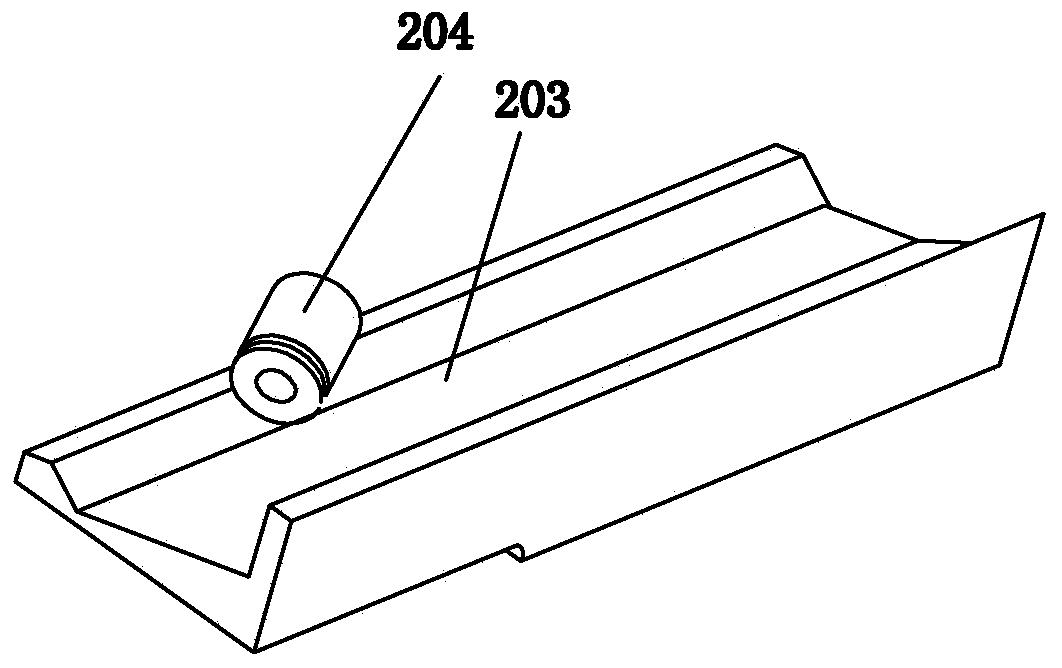

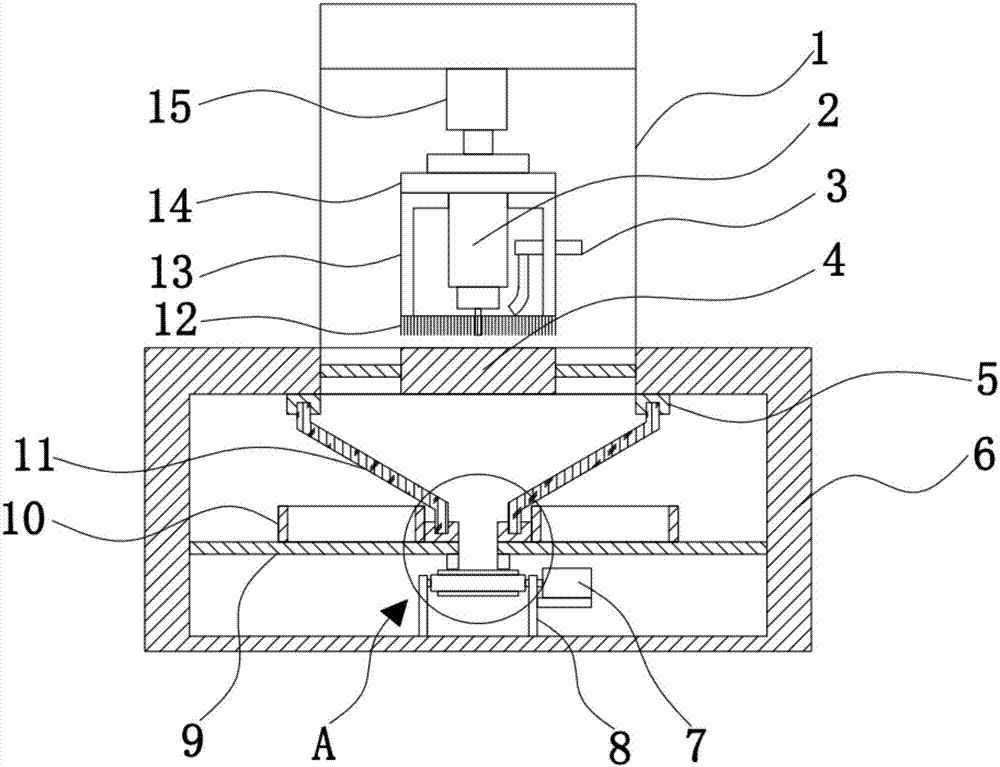

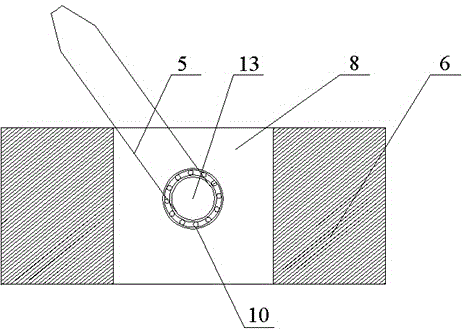

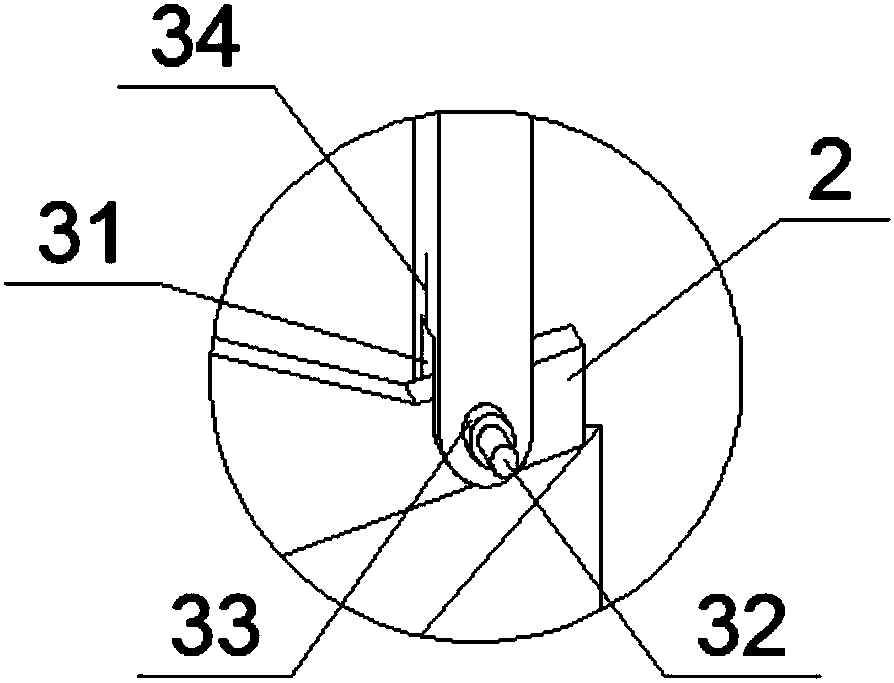

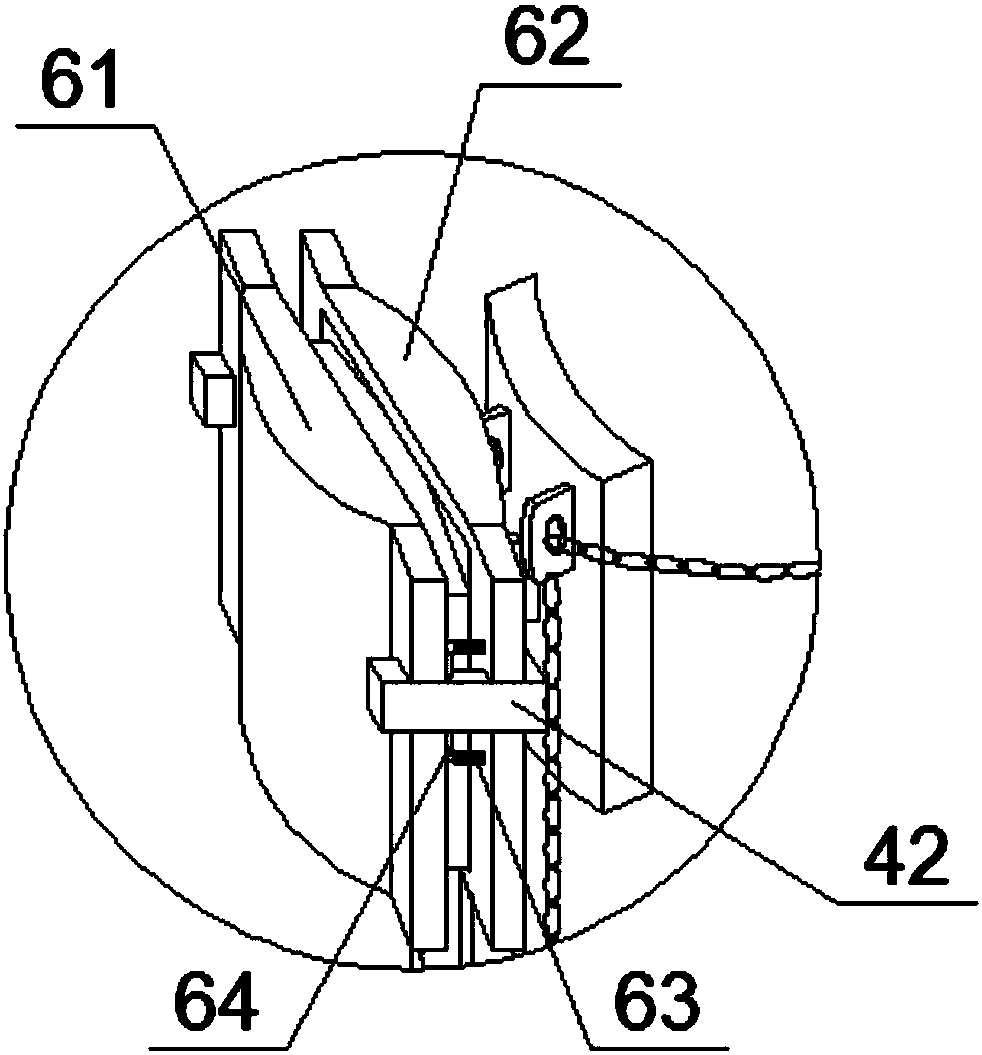

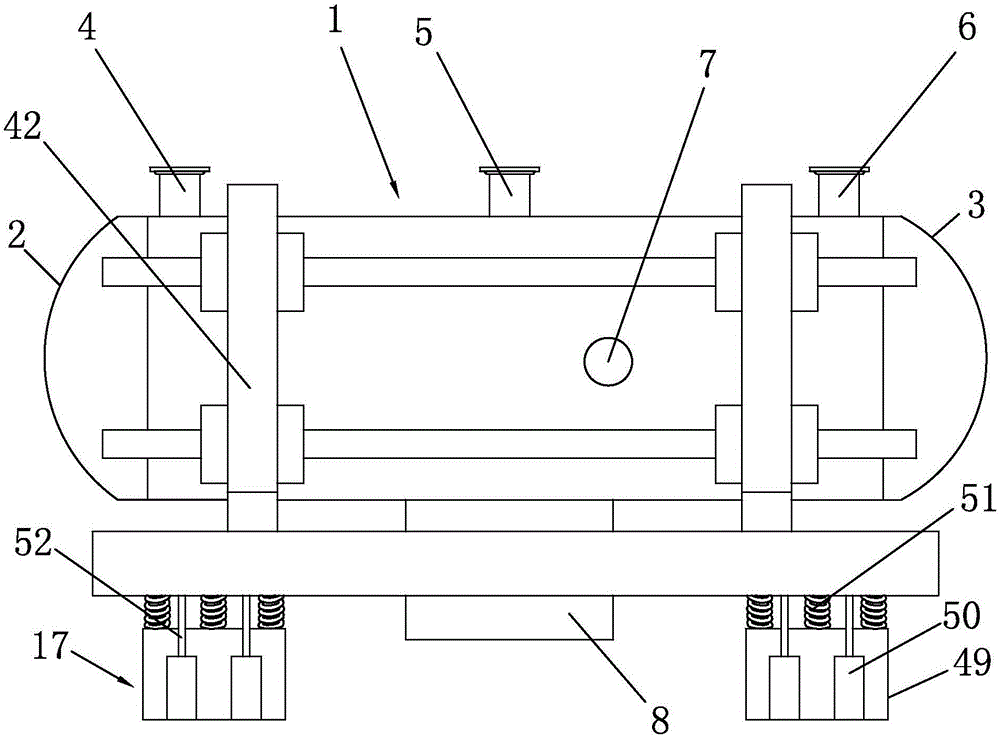

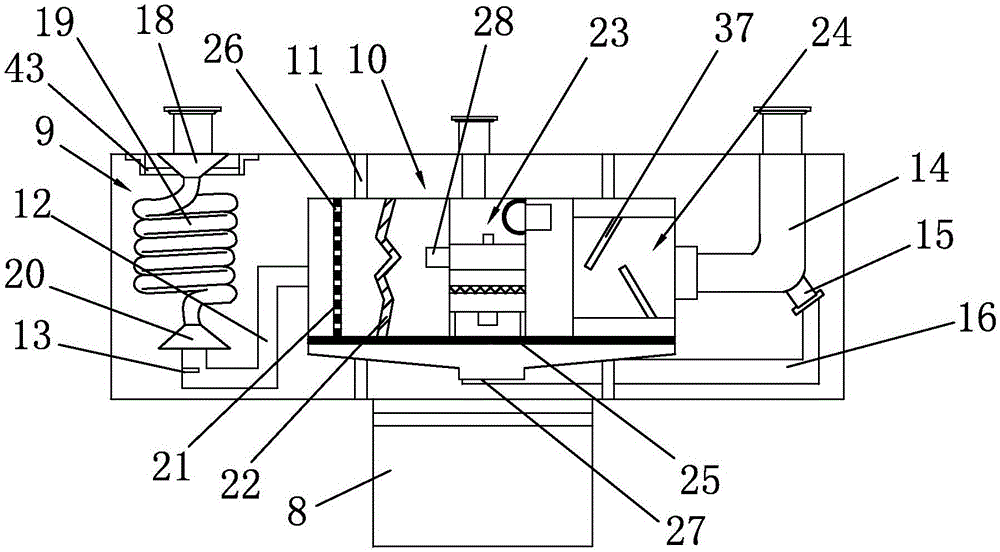

High-precision precise workpiece detecting-sorting machine

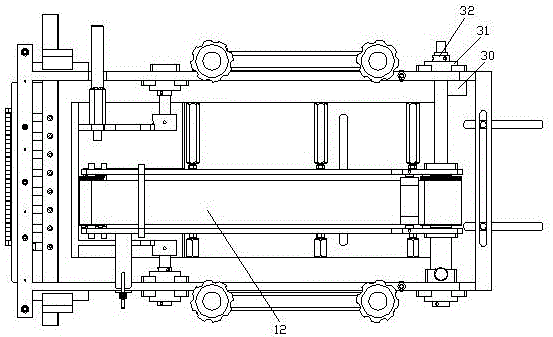

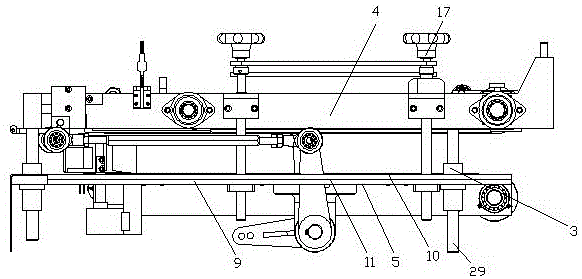

The invention discloses a high-precision precise workpiece detecting-sorting machine. The machine comprises a first stander and a second stander, wherein a loading mechanism is arranged on the first stander; a first metal rotating disc, a second transparent rotating disc, a first conveying mechanism and an electric control unit are arranged on the second stander, the first metal rotating disc and the second transparent rotating disc are respectively driven by power devices, and the first conveying mechanism is used for conveying a workpiece from the loading mechanism to the first rotating disc; a first sensor, a longitudinal surface size detection mechanism, a second conveying mechanism and a first receiving mechanism are circumferentially arranged on the first rotating disc, and the second conveying mechanism is used for conveying the workpiece on the first rotating disc to the second rotating disc; a second sensor, a transverse surface size detection mechanism, an appearance detection mechanism and a second receiving mechanism are circumferentially arranged on the second rotating disc; the electric control unit is used for coordinating and controlling the action of each component. According to the high-precision precise workpiece detecting-sorting machine, the mechanical production line automatic detection is realized, and the first rotating disc can be subjected to surface polishing in a later machining period, so that the longitudinal surface size detection precision is improved, and the detection and sorting efficiencies are further increased; meanwhile, as workpieces with different shapes can be detected, the universality is enhanced.

Owner:WEIFANG LOKOMO PRECISION IND

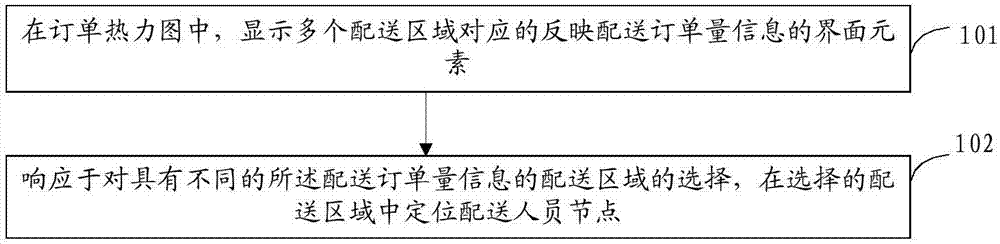

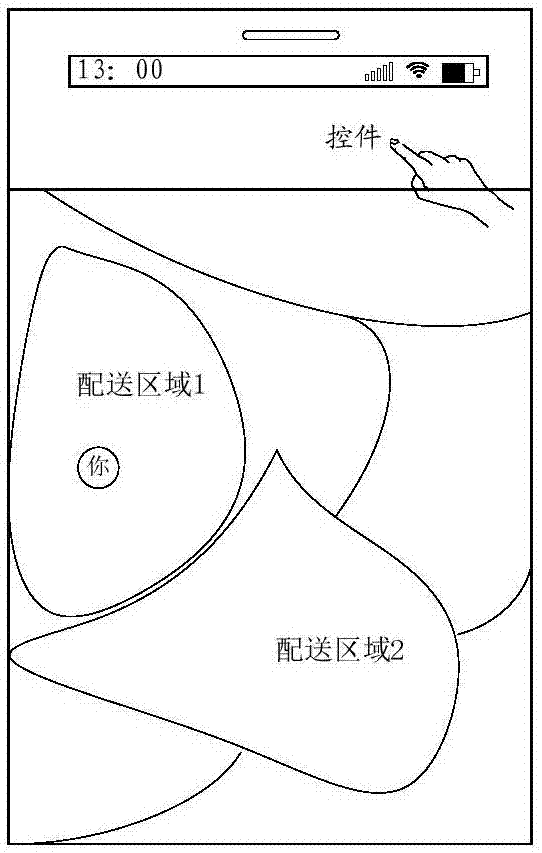

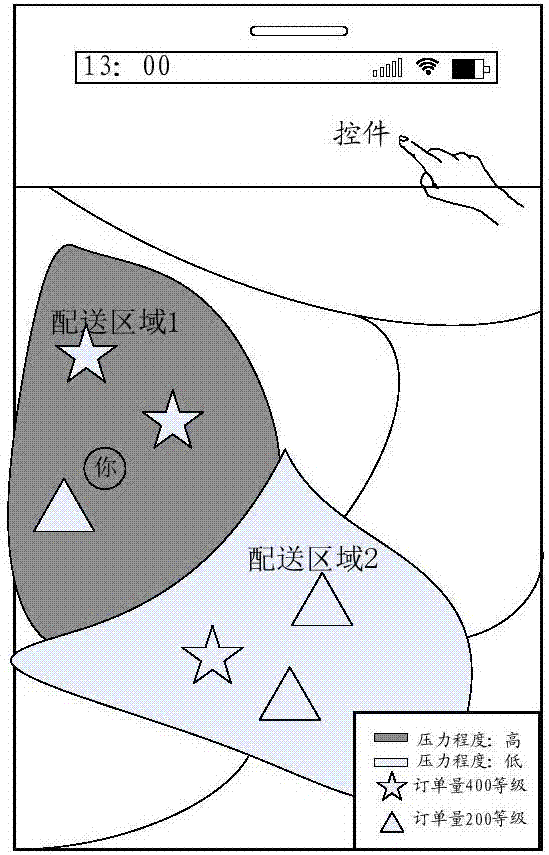

Interface display method, and delivery order distribution method and device

InactiveCN107093121AImprove distribution flexibilityUnderstand the order volumeBuying/selling/leasing transactionsResourcesDistribution methodOrder form

The embodiment of the invention provides an interface display method, and a delivery order distribution method and device. The interface display method comprises the steps: displaying interface elements which are corresponding to a plurality of delivery regions and reflect the information of a delivery order quantity in an order heat diagram; responding to the selection of delivery regions with the information of different delivery order quantities, and locating a delivery worker node in the selected delivery region. The interface elements which are corresponding to the plurality of delivery regions and reflect the information of the delivery order quantity are displayed in the order heat diagram in a client of the delivery worker, thereby enabling the delivery worker to be able to visually and completely know the condition of order quantities in a plurality of delivery regions based on the interface elements which reflect the information of the delivery order quantities corresponding to different delivery regions, enabling the delivery worker to actively make a decision to select the delivery region, and improving the delivery flexibility for the delivery worker.

Owner:BEIJING XIAODU INFORMATION TECH CO LTD

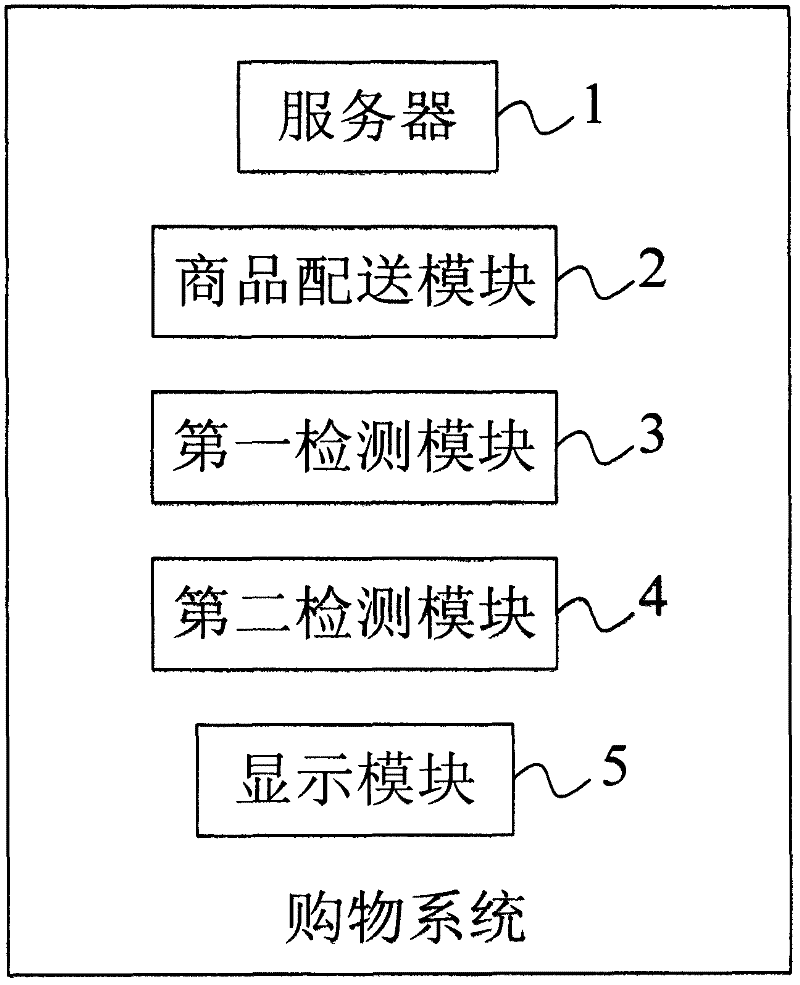

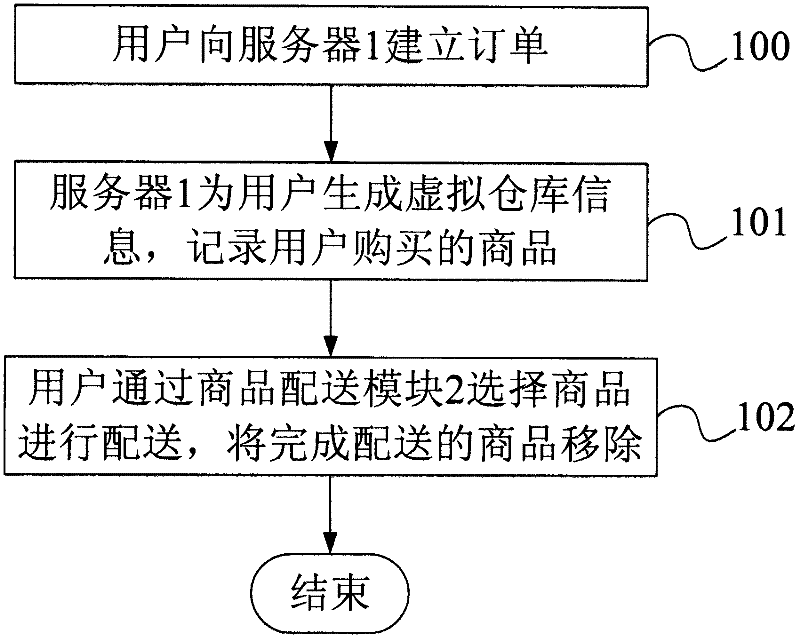

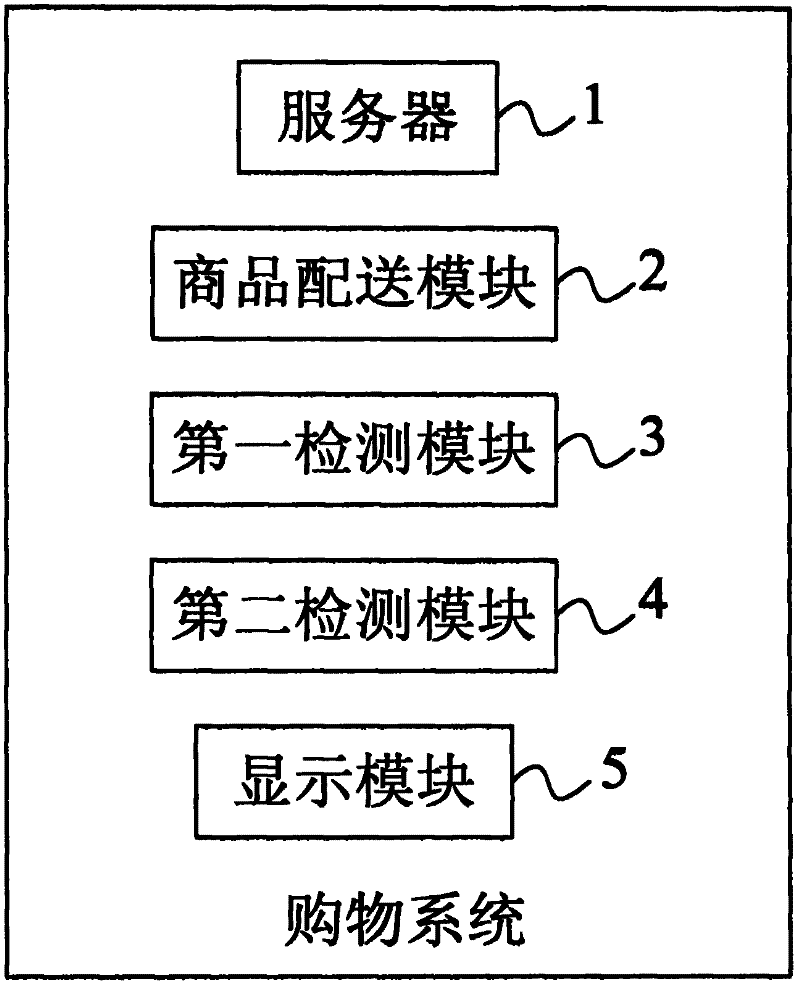

Shopping system and shopping method

ActiveCN102609868AGuaranteed delivery efficiencyPrevent long-term storage from not choosing deliveryBuying/selling/leasing transactionsOrder formComputer science

The invention discloses a shopping system and a shopping method. The shopping system comprises a server and a commodity delivery module, wherein the server is used for a user to construct at least a list of order forms for purchased commodities, and also used for generating virtual warehouse information characterizing a virtual warehouse for each user; the virtual warehouse information of each user is used for recording the commodities in all the order forms of the user; and the commodity delivery module is used for the user to select the commodities from the virtual warehouse information for delivery, and removing the commodities which are completely delivered from the virtual warehouse. According to the shopping system, the virtual warehouse information is generated for each user so as to record the commodities in all the order forms of the user; and the user can select the commodities in the same order form or in different order forms from the virtual warehouse information through the commodity delivery module, and select the delivery dates and delivery addresses, so that the shopping experiences of the user are improved, and the user can also conveniently select and process the delivery of the purchased commodities.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD

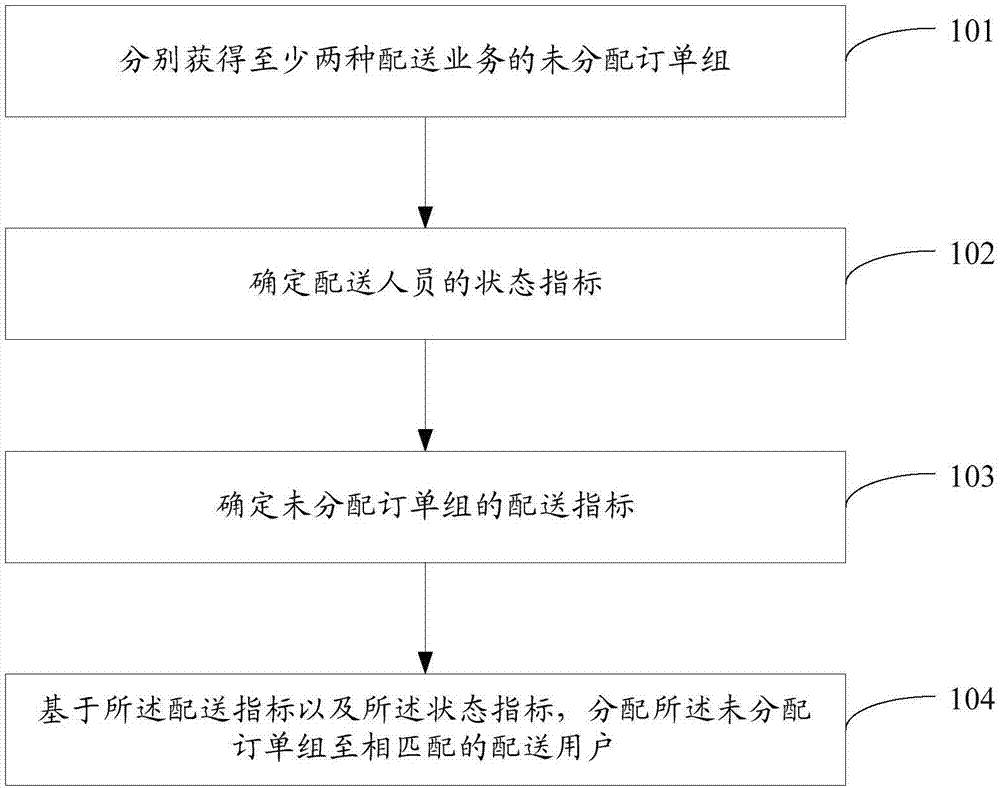

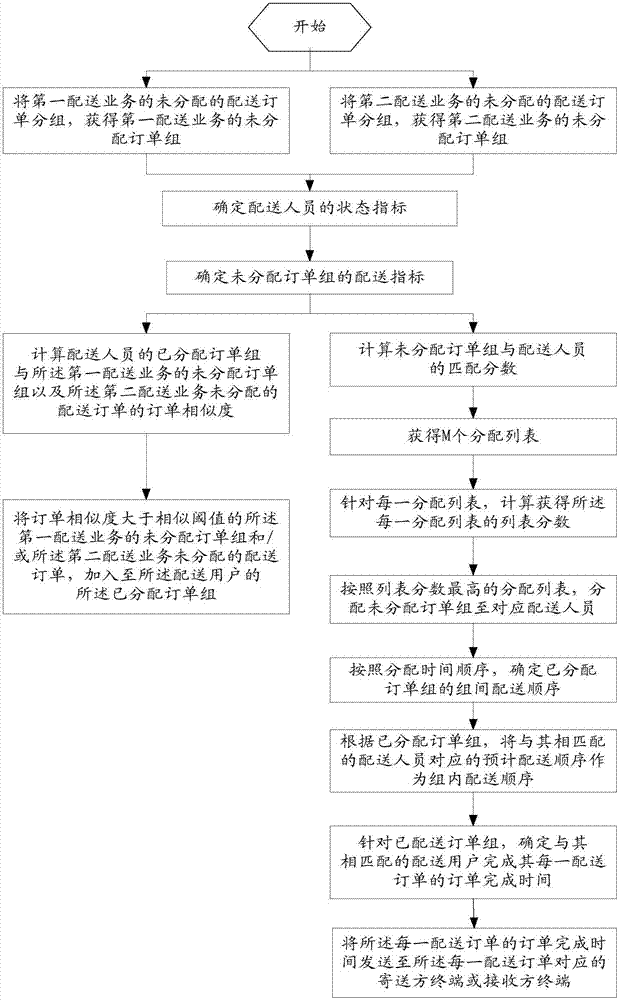

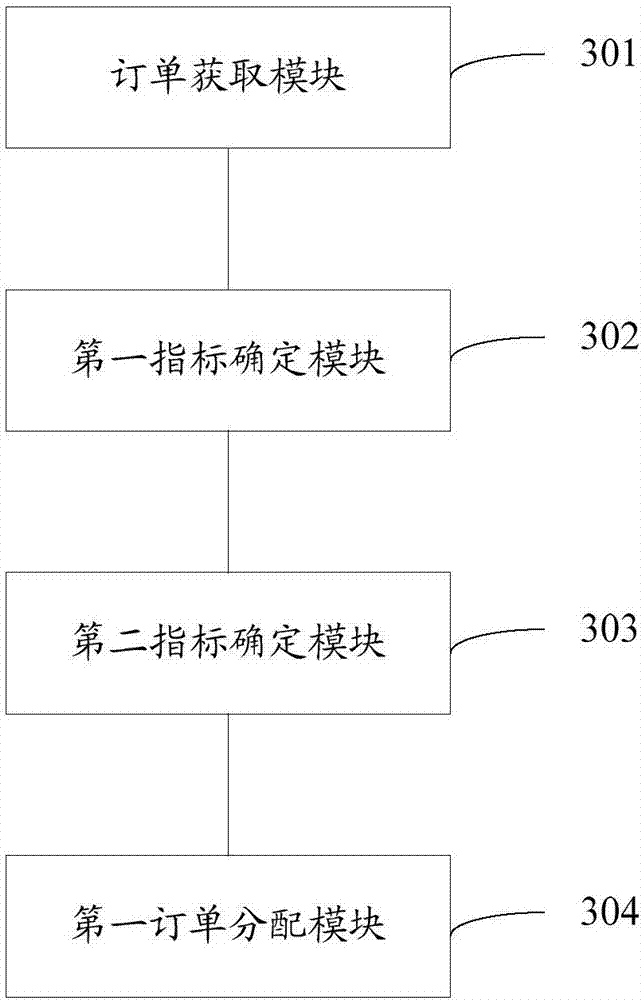

Data processing method, apparatus and device

ActiveCN107392405AAchieving Converged SchedulingRealize automatic delivery schedulingResourcesLogisticsComputer scienceUtilization rate

Embodiments of the invention provide a data processing method, apparatus and device. According to the technical scheme, undistributed order groups of at least two distribution businesses are obtained; state indexes of distribution personnel are determined; distribution indexes of the undistributed order groups are determined; and based on the distribution indexes and the state indexes, the undistributed order groups are distributed to the matched distribution personnel. Distribution orders of the at least two distribution businesses are subjected to fusion scheduling, so that the distribution cost is reduced, the distribution resources are saved, and the utilization rate of the distribution resources is increased.

Owner:BEIJING XIAODU INFORMATION TECH CO LTD +1

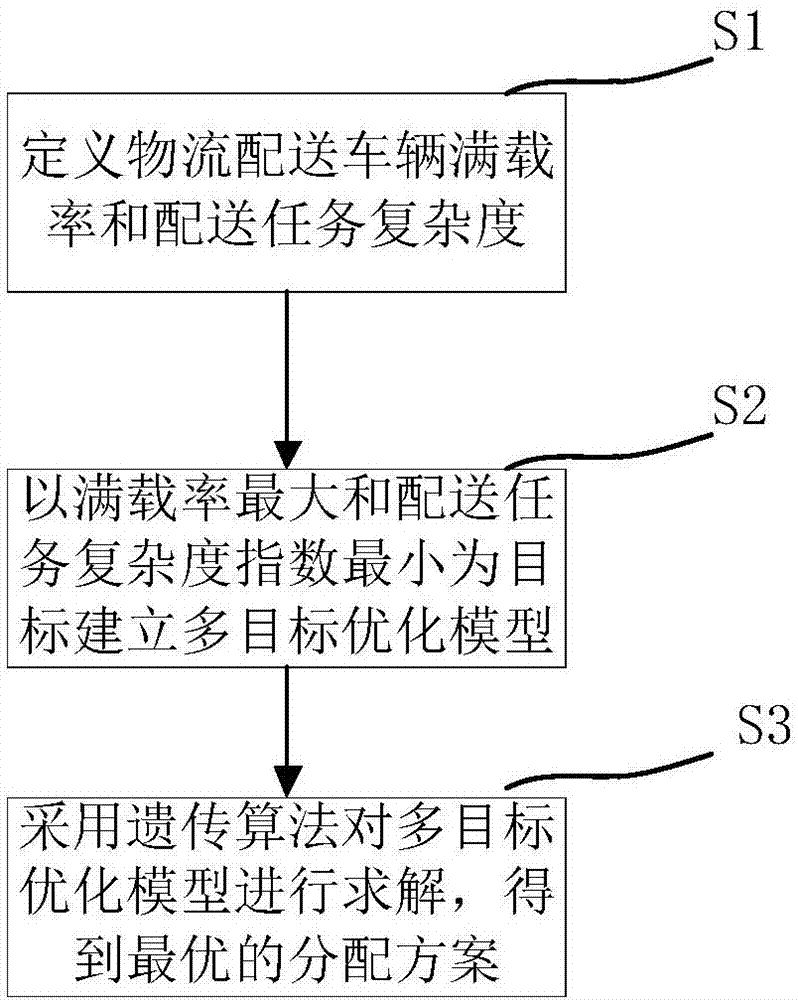

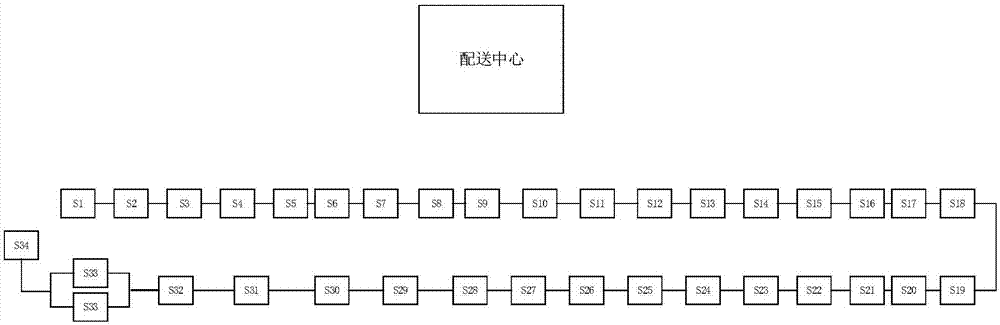

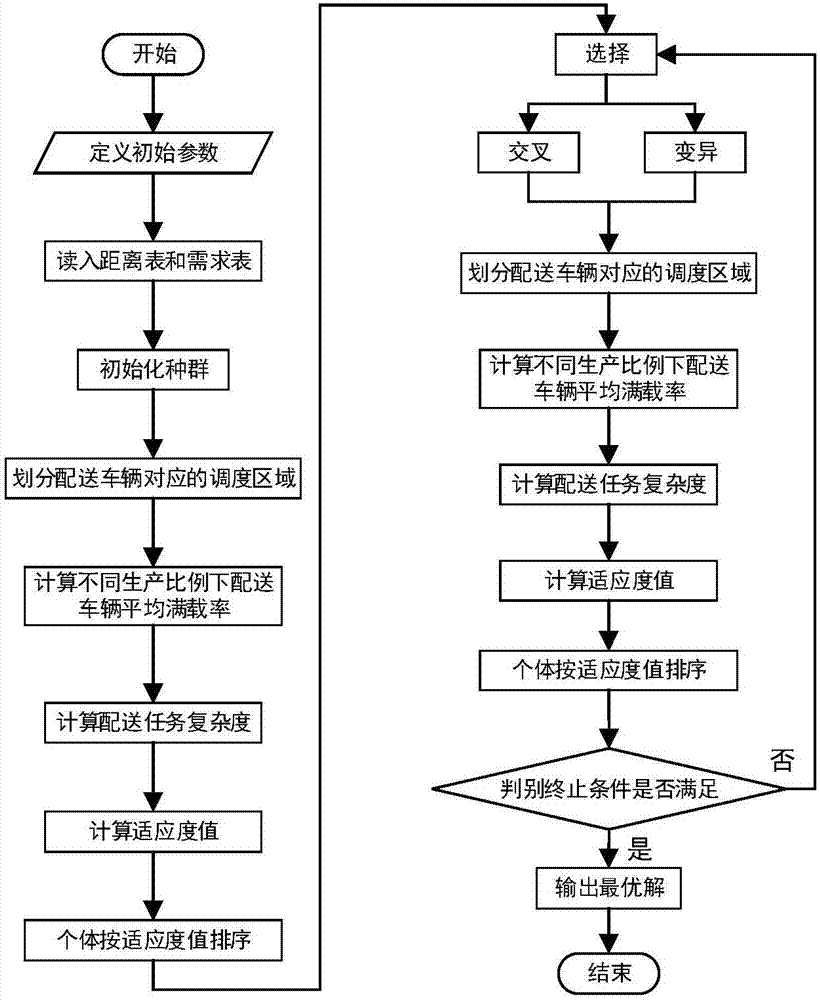

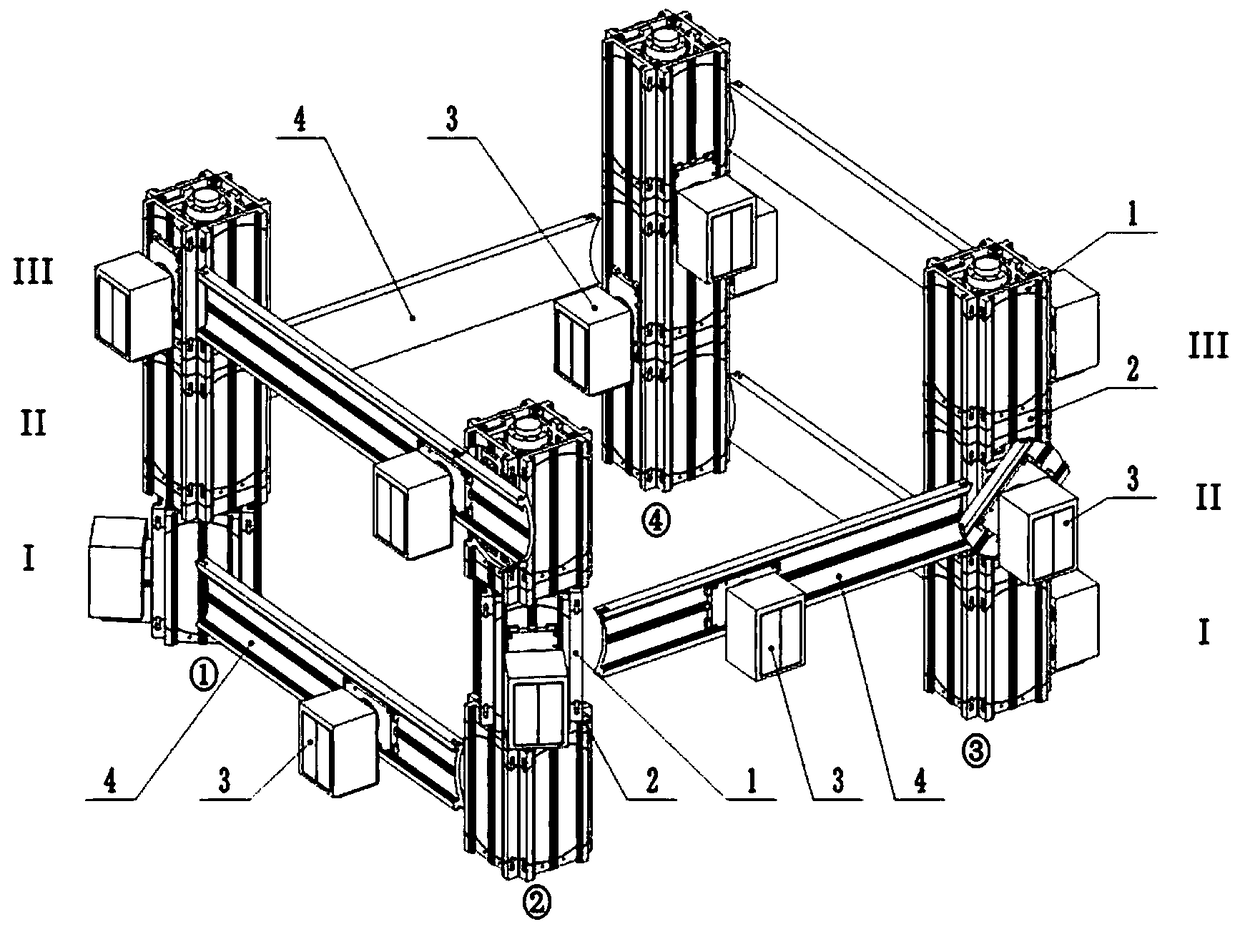

A logistics vehicle scheduling area optimization method for a mixed model assembly line with an uncertain demand

ActiveCN107578197AOptimal allocation planGuaranteed delivery efficiencyInternal combustion piston enginesGenetic modelsRobustificationDelivery vehicle

The invention relates to a logistics vehicle scheduling area optimization method for a mixed model assembly line with an uncertain demand, and is used to obtain a region division program of logisticsdistribution in a mixed model assembly line. The method comprises the following steps of: 1) defining the full load ratio of logistics distribution vehicles and the complexity of distribution tasks; 2) obtaining the constraint conditions of a multi-objective optimization model, and establishing a multi-objective optimization model with a goal of maximization of the average full load ratio of the logistics distribution vehicles and minimization of complexity indexes of the distribution tasks; and 3) using a genetic algorithm to solve the multi-objective optimization model to obtain an optimal allocation program. Compared with the methods in the prior art, the method in the invention has the advantages of ensuring the full load ratio of the delivery vehicles, reducing the complexity of the delivery tasks, avoiding the unstable state of the delivery vehicles caused by the accumulation of the demand uncertainty factors and improving the robustness of the logistics scheduling of the mixed model assembly line.

Owner:TONGJI UNIV

Numerically controlled beveling machine for mechanical manufacturing

ActiveCN107984290AAvoid affecting processing qualityAvoid accumulationMaintainance and safety accessoriesHydraulic cylinderEngineering

The invention discloses a numerically controlled beveling machine for mechanical manufacturing. The numerically controlled beveling machine for mechanical manufacturing comprises a machine table and afiltering hood, wherein a mounting back plate is fixed to the machine table, an electric sliding rail module is connected to the top end of the mounting back plate through a hydraulic cylinder, a machining spindle is fixed to the electric sliding rail module, and a machining platform is fixed to the machine table through a fixing rod; the upper end of the filtering hood is clamped to an upper clamping ring, the lower end of the filtering hood is clamped to a lower clamping ring, and the lower clamping ring is fixed to the machine table through a supporting plate; the machine table is furtherfixedly provided with a bracket; a guide roller is rotationally connected to the bracket and connected with the output end of a motor; a conveying belt is arranged on the guide roller; and a recoverybin is arranged below one end of the conveying belt. The numerically controlled beveling machine for mechanical manufacturing can clean up impurities on the surfaces of workpieces in the machining process, thereby ensuring the machining quality of the workpieces; and by means of the filtering hood, cutting fluid mixed with scrap iron, iron wires and other impurities can be filtered, solid and liquid can be separated and recovered separately, resources are saved, and the impurity removal efficiency is high.

Owner:泰州市银利标准件制造有限公司

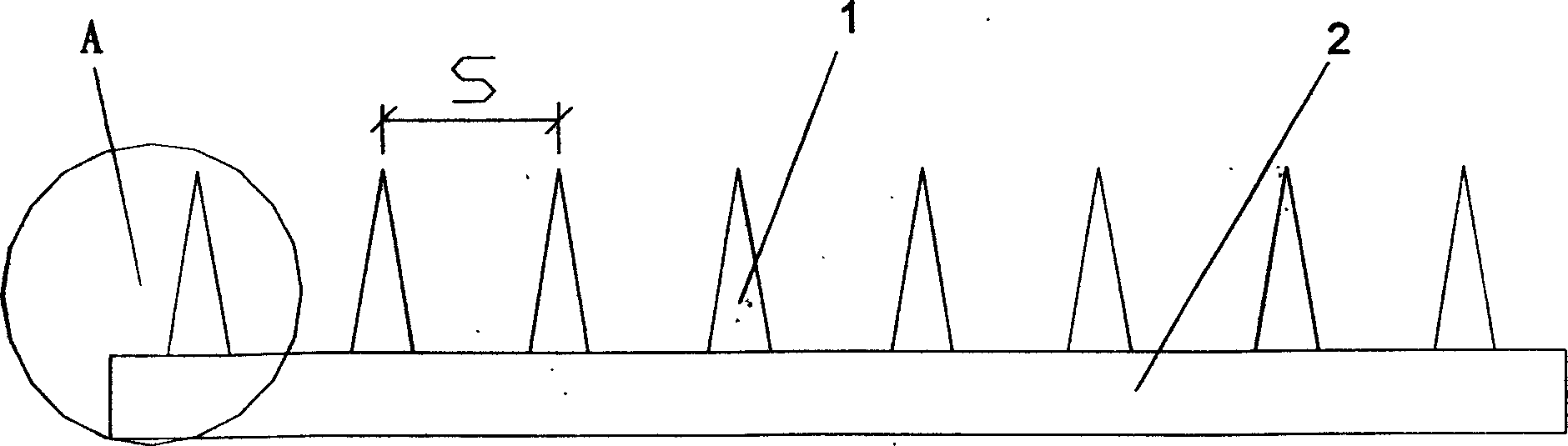

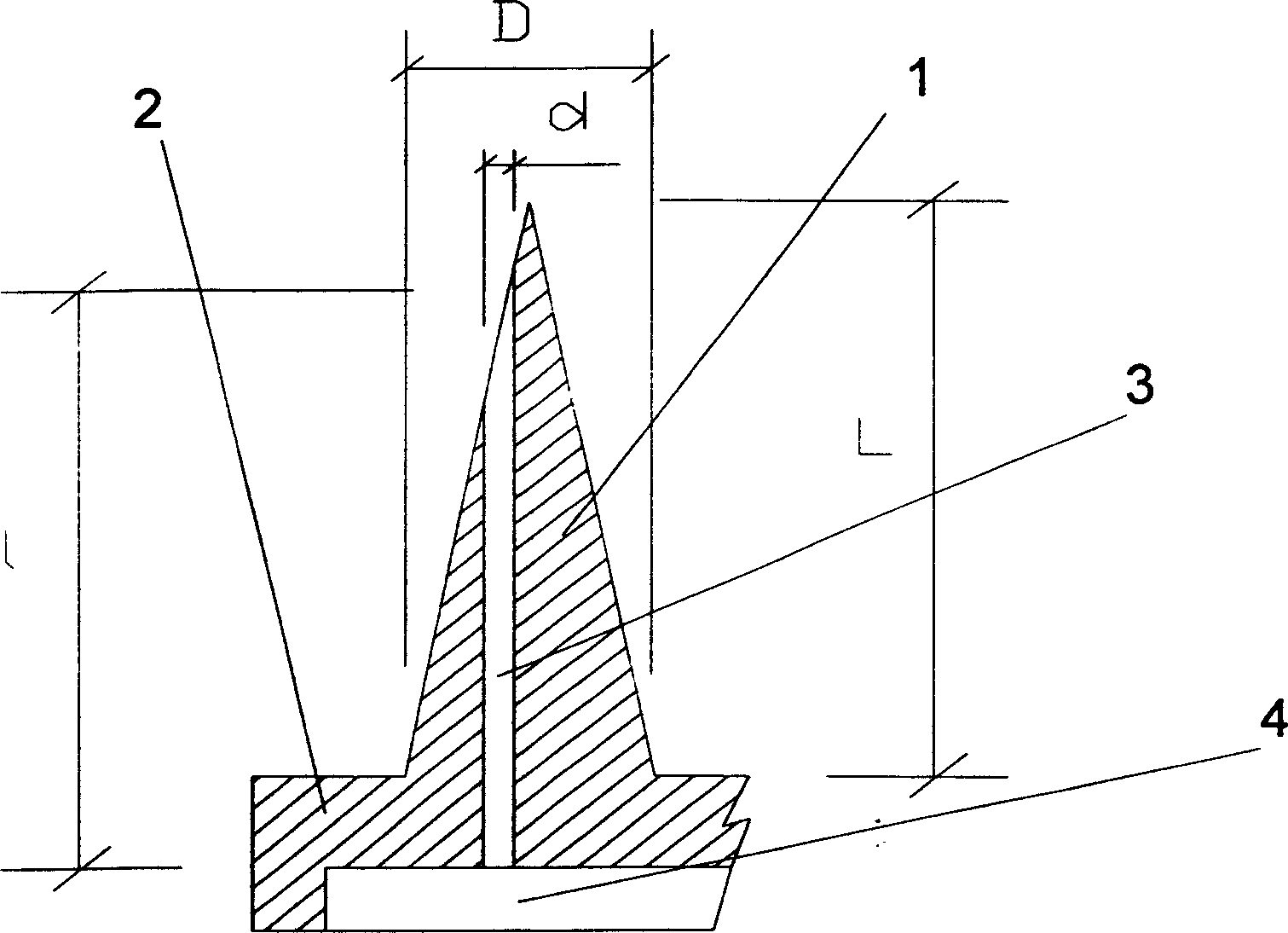

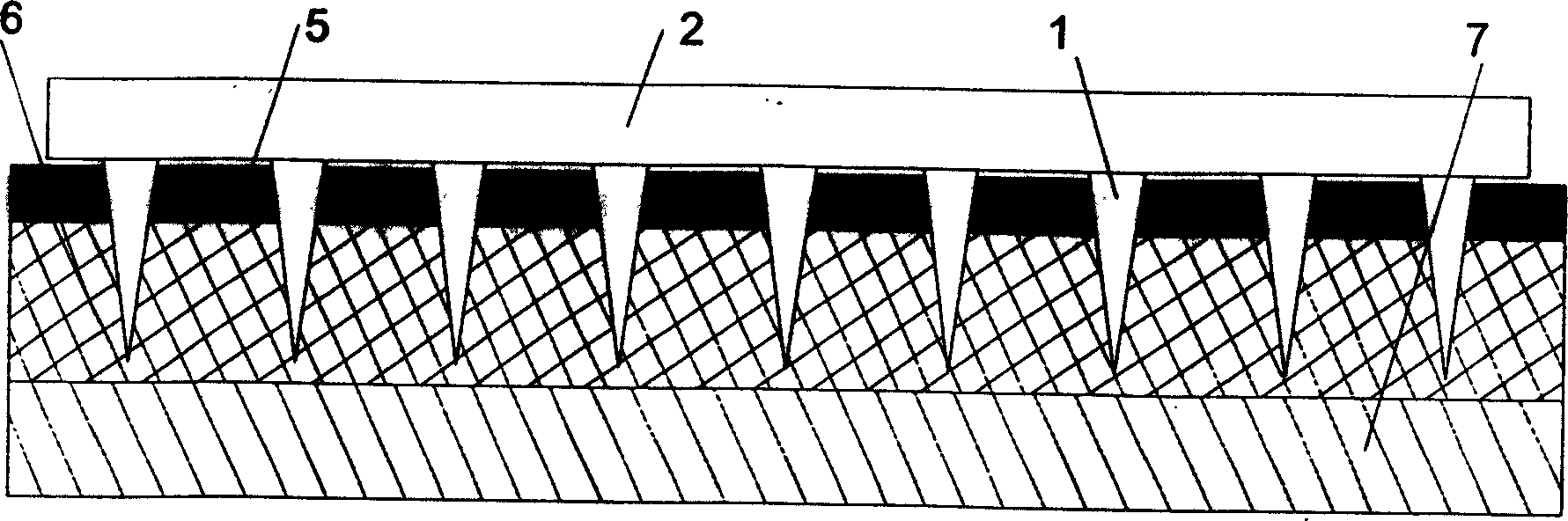

Fine stitch array for medicine controlled releasing

InactiveCN1541724AGuaranteed validityGuaranteed delivery efficiencyMedical applicatorsControl releaseSyringe needle

The mini needle array for controlling release of medicine includes one base board with slot in the bottom and one array of homogeneously distributed conic hollow mini needles, each of which is provided with eccentric hole in the tip and communicated with the slot in the base board. The mini needle array is manufactured via DIRE technological process to etch silicon. It is used for injection and has great hole depth / width ratio, sharp needle tip, moderate length, less destruction to skin, high medicine conveying efficiency, no pain produced and low infection probability.

Owner:ZHEJIANG UNIV

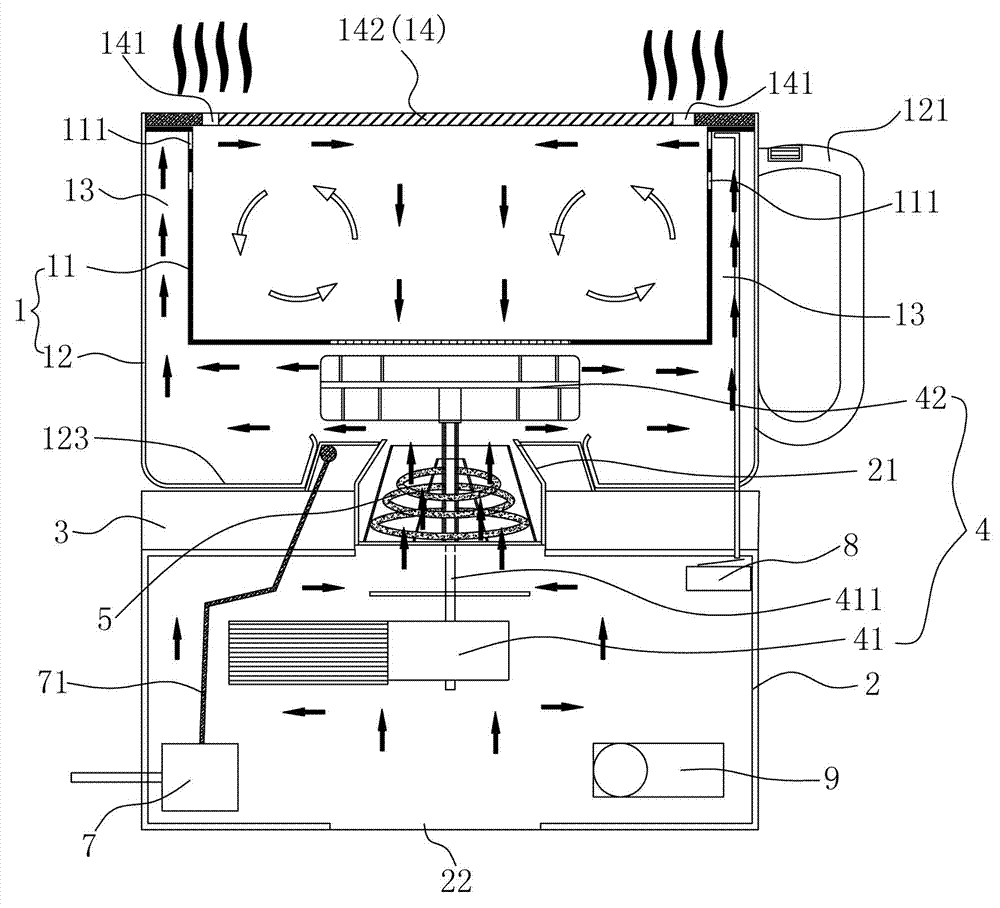

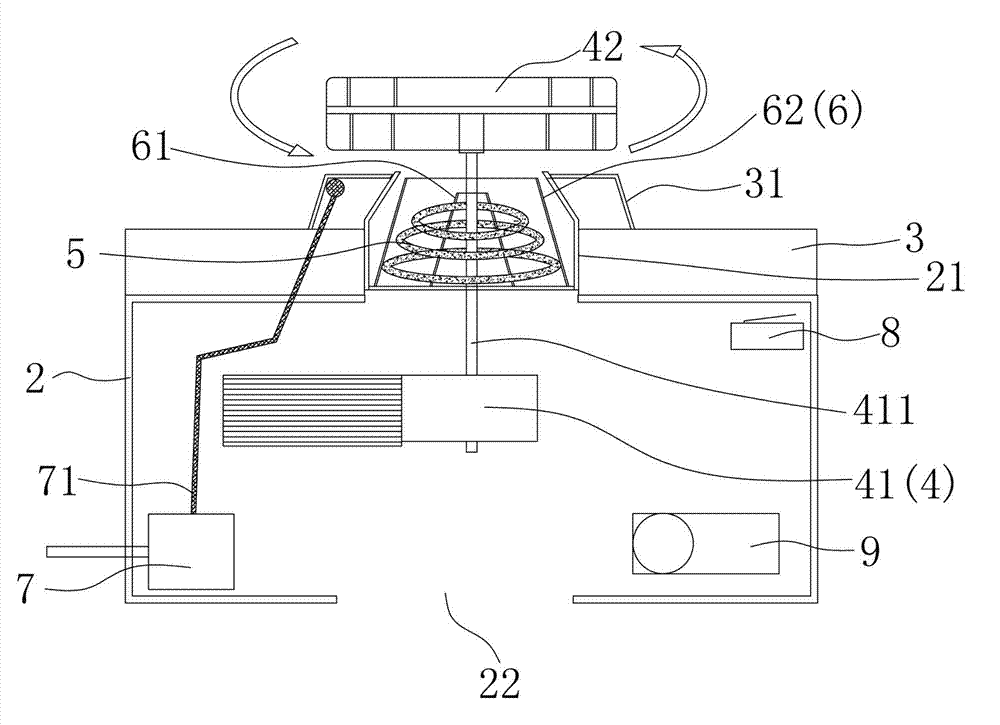

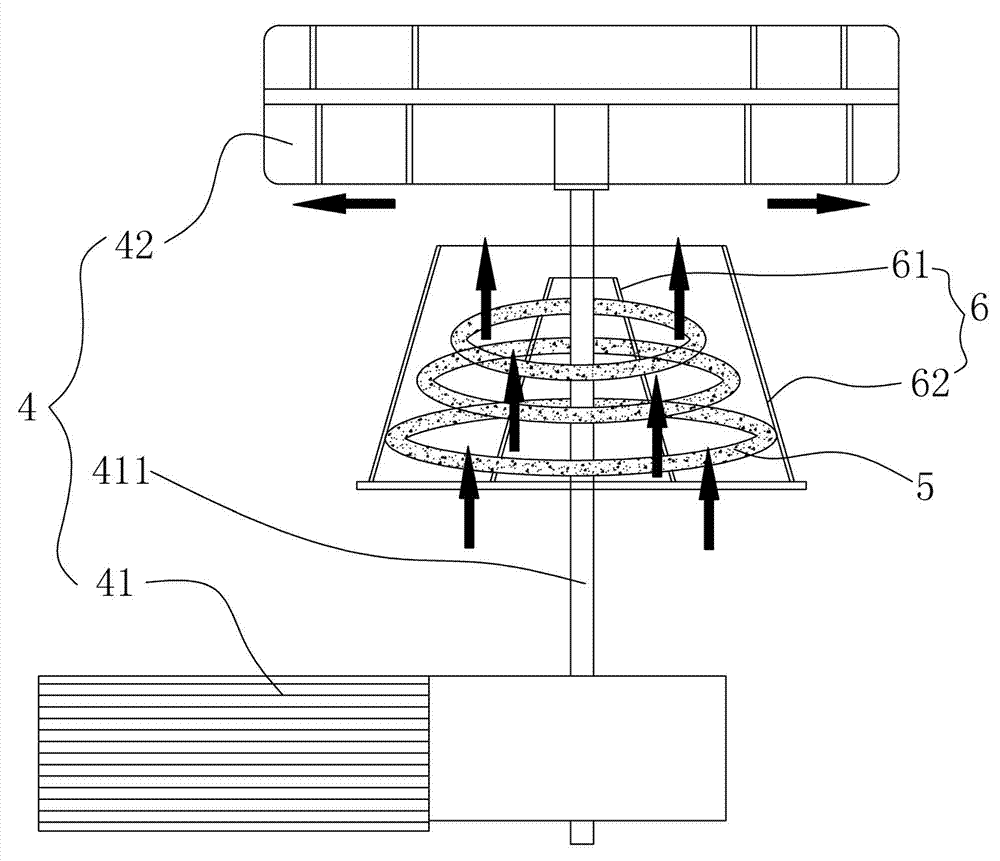

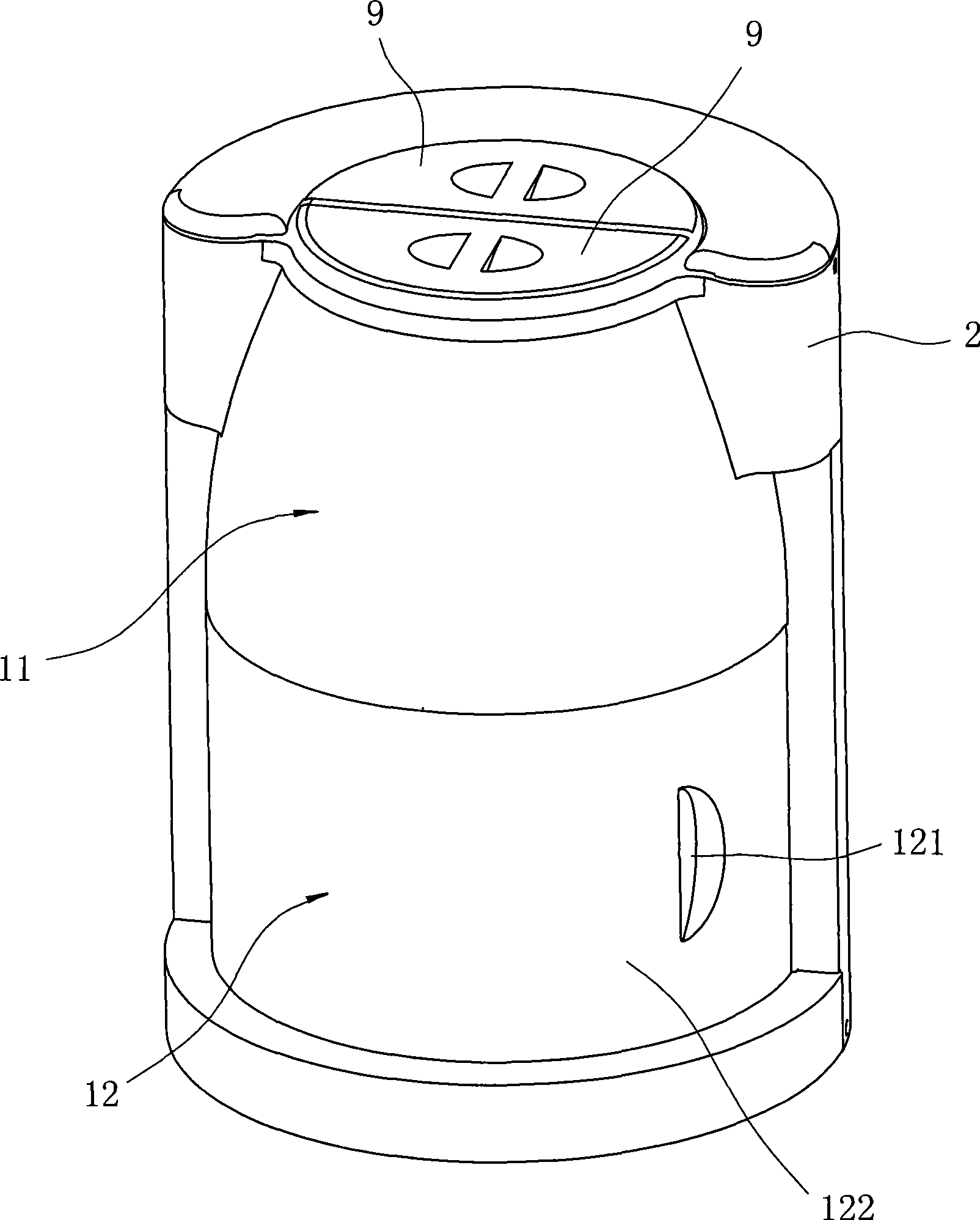

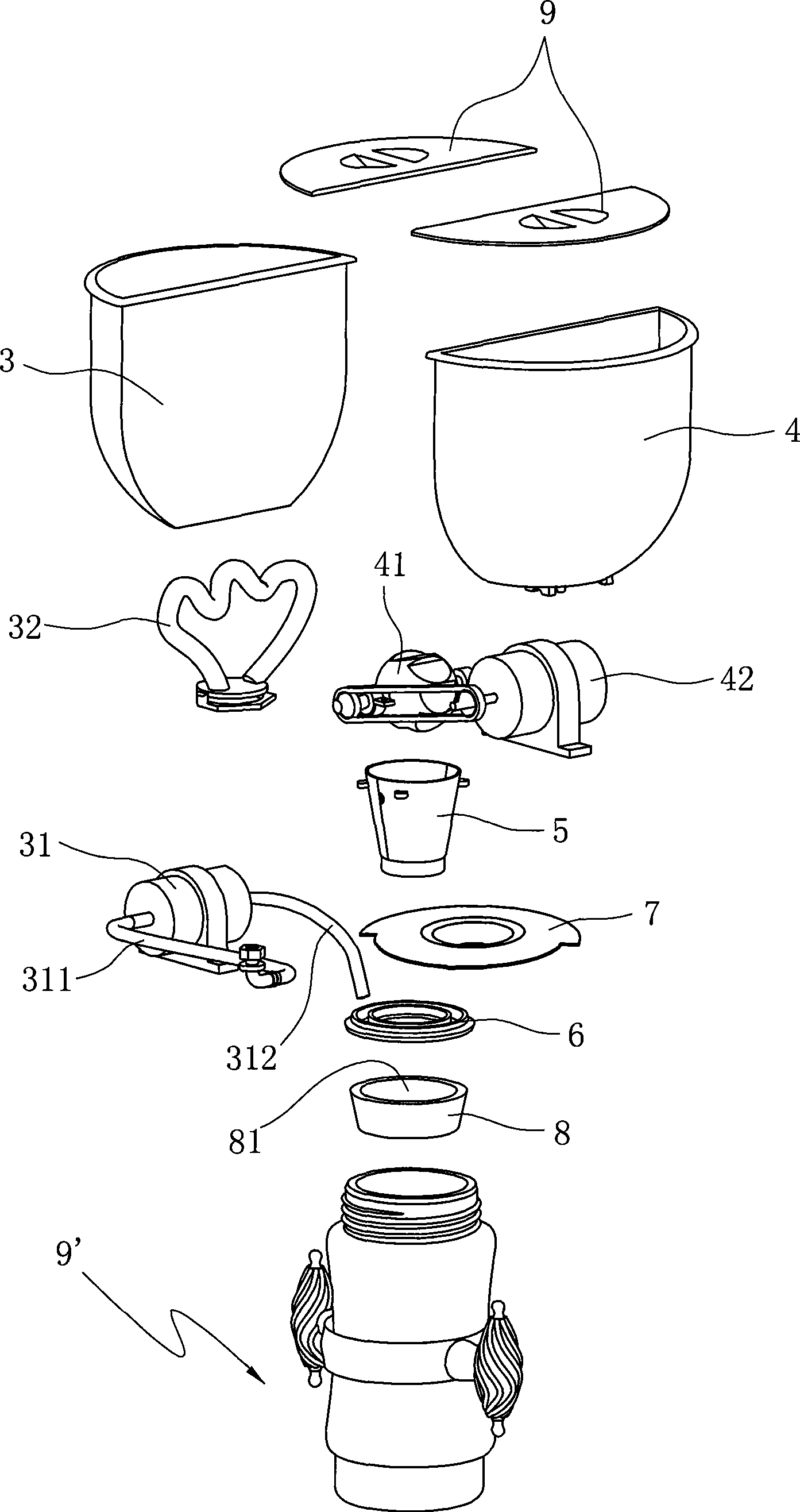

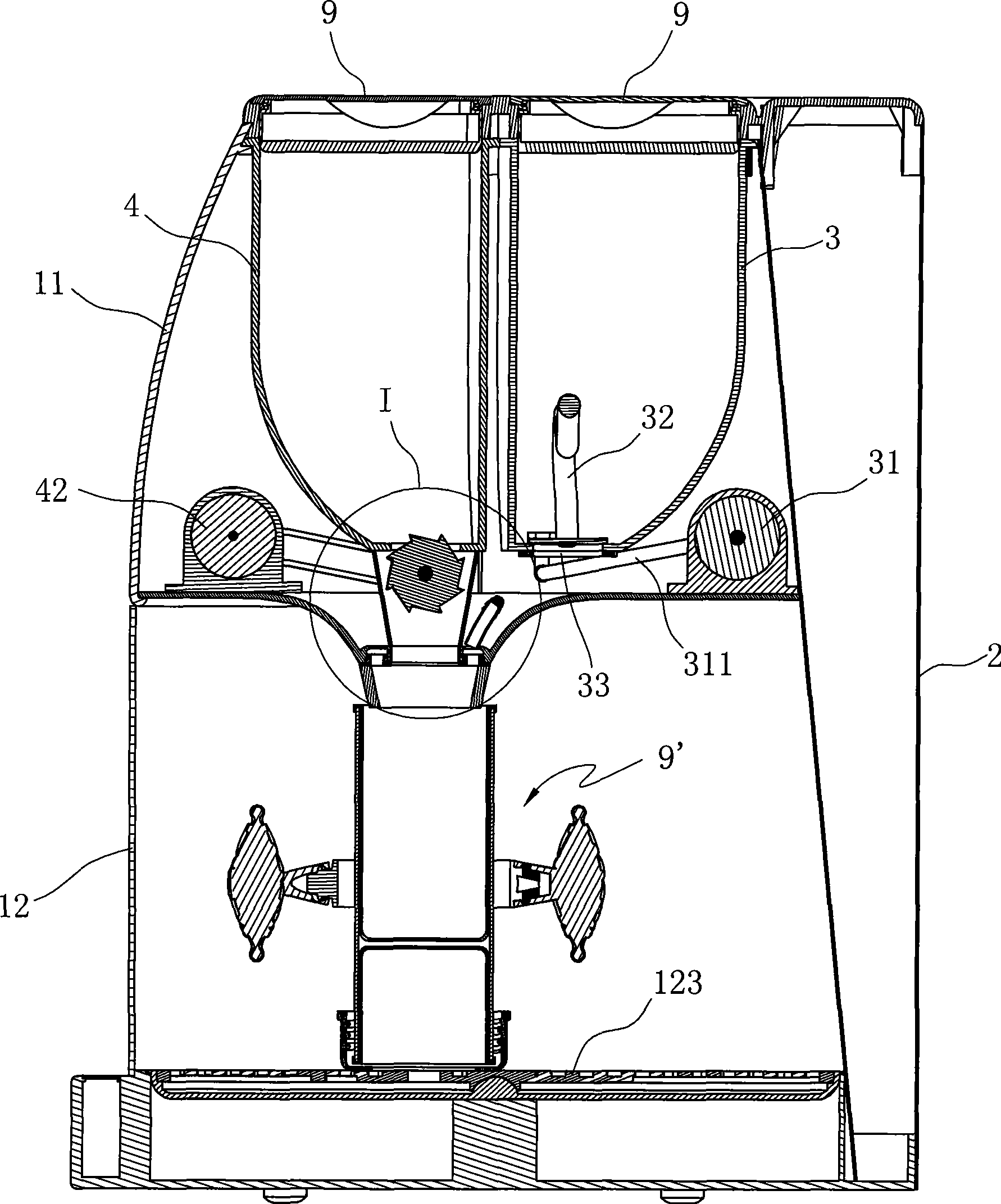

A new-type airfryer

InactiveCN104770418AIncrease cooking speedGuaranteed frying effectBaking ovenRoasters/grillsTemperature controlAdditive ingredient

The present invention discloses a new-type airfryer, and comprises a fryer body and an engine base. The underside of the fryer body is arranged with a connecting hole, the engine base is connected with the connecting hole through a guiding cover, a conveying device is arranged at a connecting end of the engine base and the guiding cover, the conveying device is used to convey heated air into the fryer body and to heat the fryer body, an air conveying end of the conveying device is arranged with a heat generating part, the heat generating part is electrically connected with the conveying device, a heat insulating guide structure is arranged on the heat generating part, the heat insulating guide structure is used to form a guide channel to guide and convey air to the heat generating part and to protect the heat generating device, the heat generating part is connected with a temperature control device, and the temperature control device is used to control heat generating pipes to generate heat when the airfryer is working. The airfryer ensures hot-air supply in the fryer body, effectively improves cooking speed of ingredients and avoids hot air outleakage. The airfryer ensures that moisture contents of the ingredients cannot be taken away entirely due to quick hot-air flow, which can ensure the frying effect of the ingredients and improve the efficiency and quality of the fried food.

Owner:DONGGUAN GEMA ELECTRICAL APPLIANCE

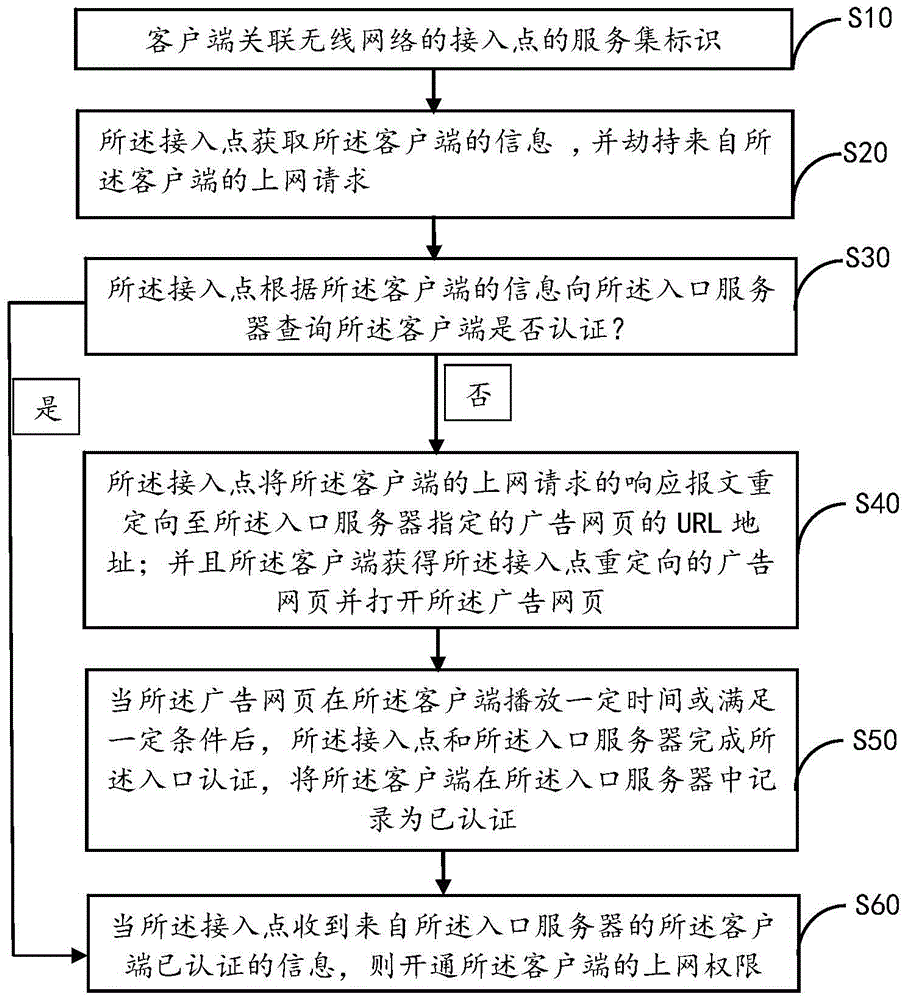

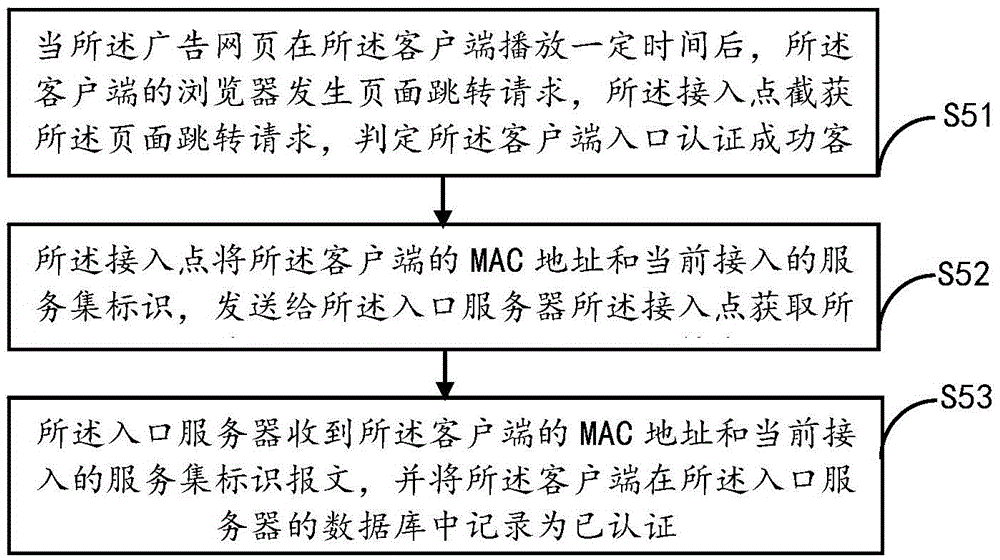

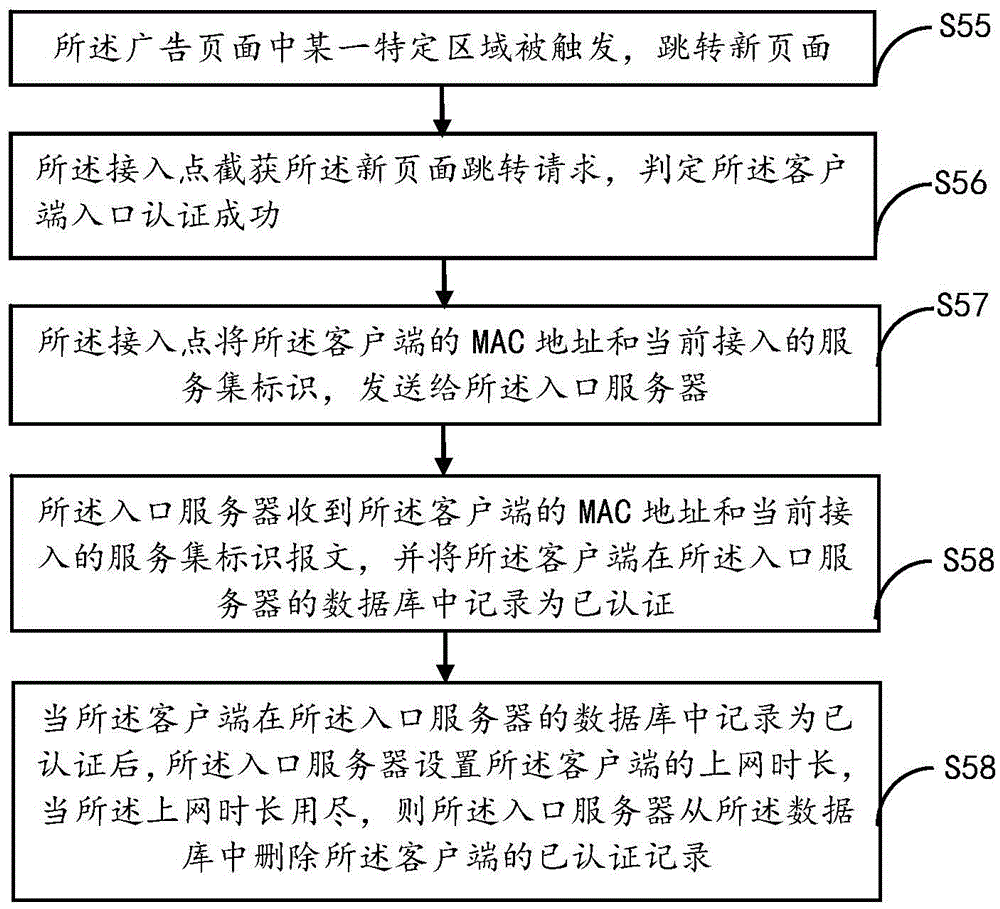

Wireless network authentication method and system

InactiveCN105657710ASimplify the certification processGuaranteed delivery efficiencyAdvertisementsNetwork topologiesWeb authenticationInternet privacy

The invention provides a wireless network authentication method and system. The wireless network authentication method comprises the following steps that a client side is associated with a service set identifier of an access point of a wireless network; the access point acquires information of the client side and hijacks a first Internet surfing request from the client side; the access point inquires an access server about whether the client side is authenticated or not according to the information of the client side, and if the client side is not authenticated, the responding message of the Internet surfing request of the client side is redirected from the access point to the URL address of a specified advertisement page of the access server; the advertisement page is opened on the client side, and after the advertisement page is played for a certain time on the client side or certain conditions are met, the access point and the access server complete access authentication, and the client side is recorded to be authenticated in the access server; if the client side is authenticated, the Internet surfing authority of the client side is opened up.

Owner:PHICOMM (SHANGHAI) CO LTD

Multi-car three-dimensional circular elevator system and coordinated operation method

ActiveCN108313855AEasy to moveGuaranteed delivery efficiencyElevatorsBuilding liftsElevator systemEngineering

The invention belongs to the field of linear motor direct driven elevators, and in particular relates to a multi-car three-dimensional circular elevator system and a coordinated operation method. Thesystem totally comprises five positioning mechanisms and two rotating devices, wherein the five positioning mechanisms are separately a first positioning mechanism which fixes a car to a driving rack,a second positioning mechanism which fixes a car to a small circular rack, a third positioning mechanism which fixes the small circular rack along a horizontal rotating direction, a fourth positioning mechanism which fixes a rotating rack along a vertical track direction and a fifth positioning mechanism which fixes the rotating rack along a horizontal track direction; and the two rotating devices are separately a first rotating device for small circular track transfer and a second rotating device for horizontal track transfer. The five positioning mechanisms and the two rotating devices as well as a linear motor of an elevator are coordinated in action and position accurately, so that the cars can move in the three-dimensional directions, and the track transfer movement of the elevator is reasonable and passengers are safe. The multi-car three-dimensional circular elevator system and the coordinated operation method provided by the invention are put forward for the first time at home.

Owner:HENAN POLYTECHNIC UNIV +1

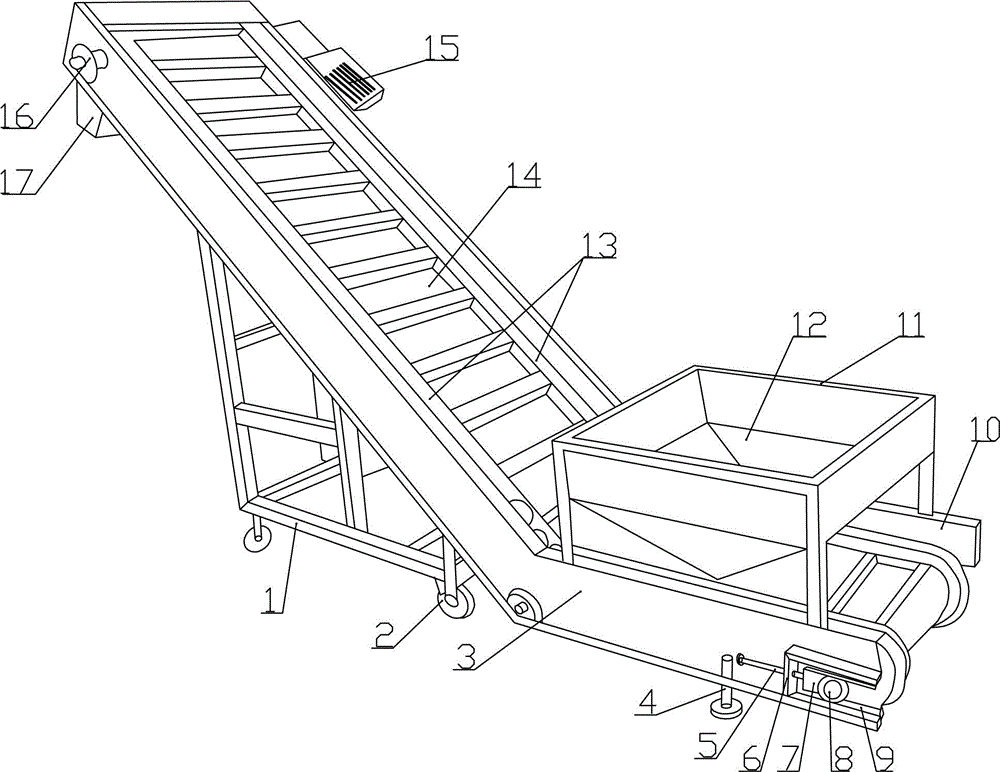

Building mortar conveyer

InactiveCN104986545AGuaranteed delivery efficiencyEasy to cleanCleaningArchitectural engineeringStructural engineering

The invention discloses a building mortar conveyer. The building mortar conveyor comprises a conveyer belt, and a cleaner is disposed under the conveyer belt. A crank of the cleaner is connected with a rocker, a rocker is connected with a scraper plate, the scraper plate is connected with a sliding block, the sliding block is movably connected with a support, a shaft is disposed in a cavity of the sliding block, the shaft is connected with the scraper plate, and outer sides of the left side wall and the right side wall are provided with bumps. The support comprises columns, bottoms of the columns are provided with a top board, a square chamber is disposed on the top board, inner sides of the left side wall and the right side wall of the square chamber are provided with guide rails matching with the bumps, a collecting chamber is disposed under the top board, side plates of the collecting chamber are connected with the top board of the support, and the collecting chamber is a taper chamber which is connected with a conveyer pipe. Material adhered on the conveyer belt of the conveyer can be cleaned up, the cleaning effect is good, and the scraped material can be collected without waste. The building mortar conveyer is low in labour cost and high in efficiency.

Owner:WENZHOU UNIVERSITY

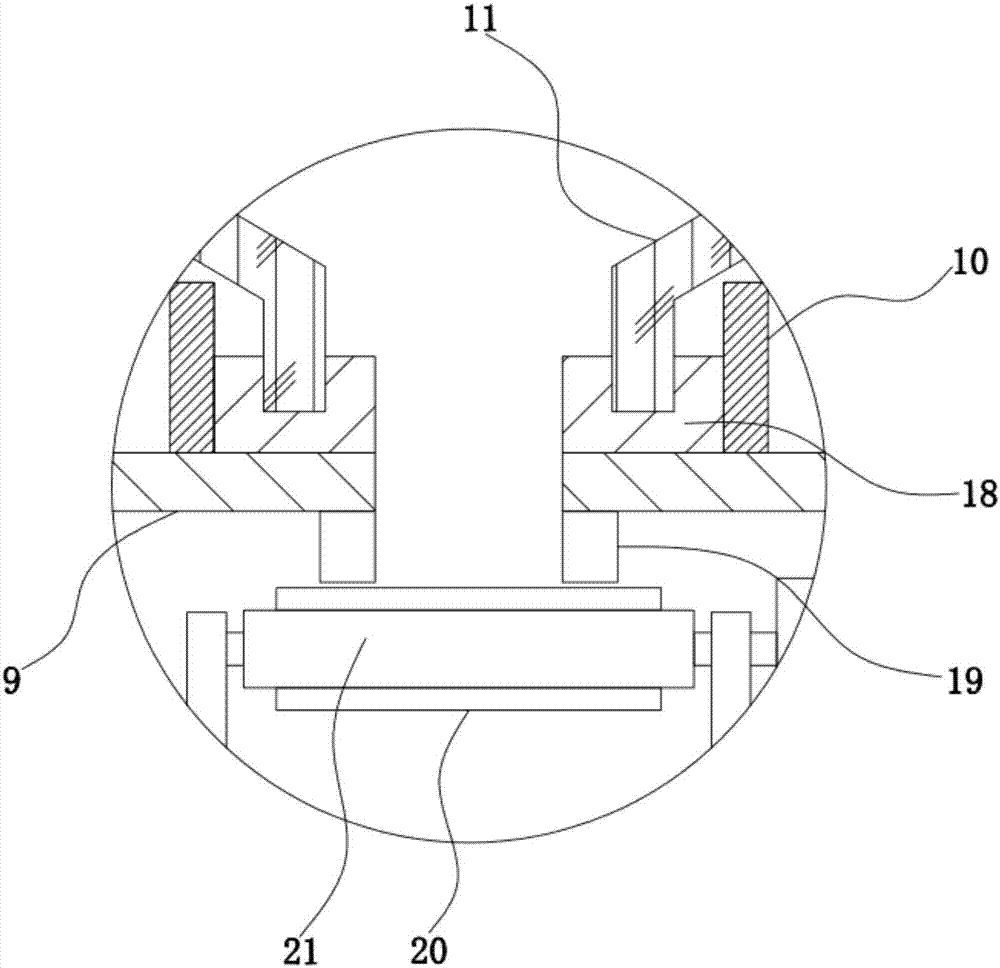

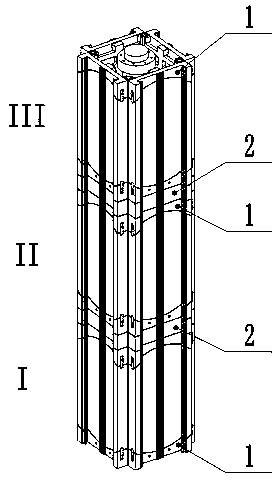

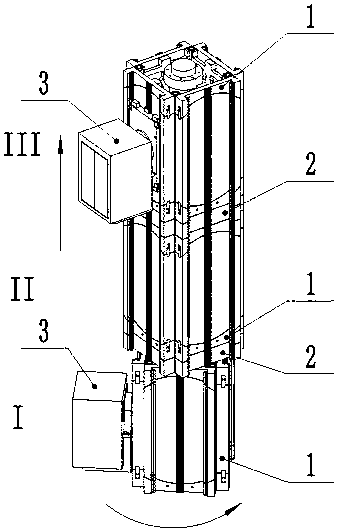

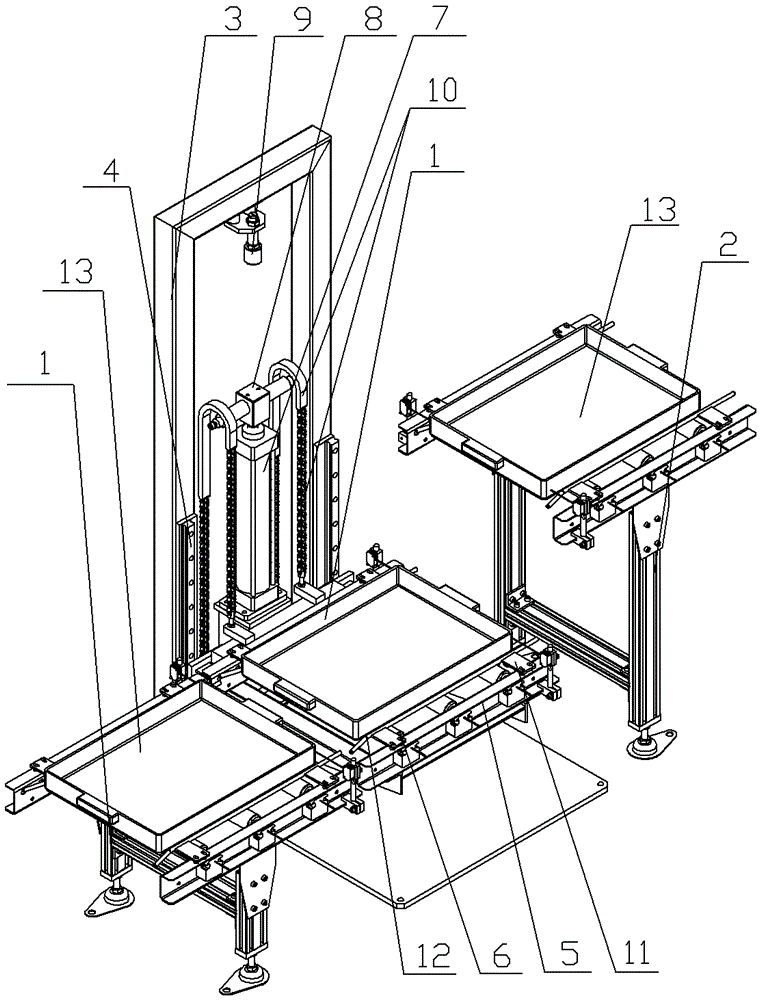

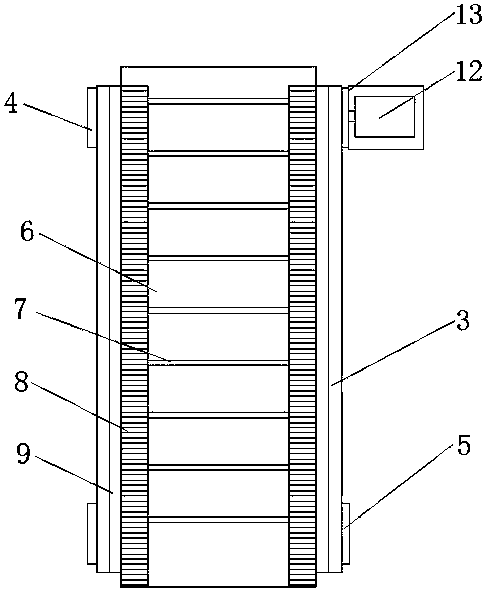

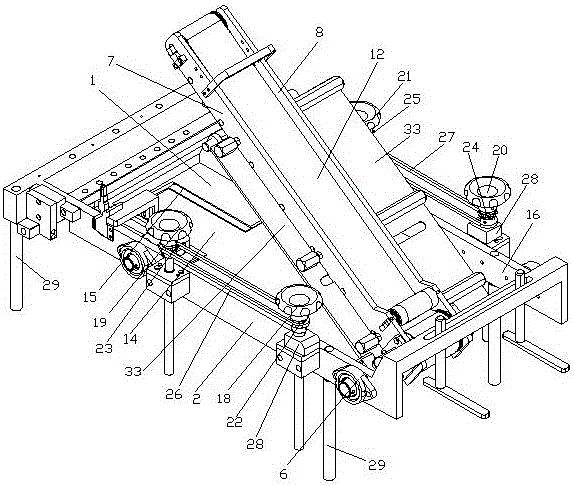

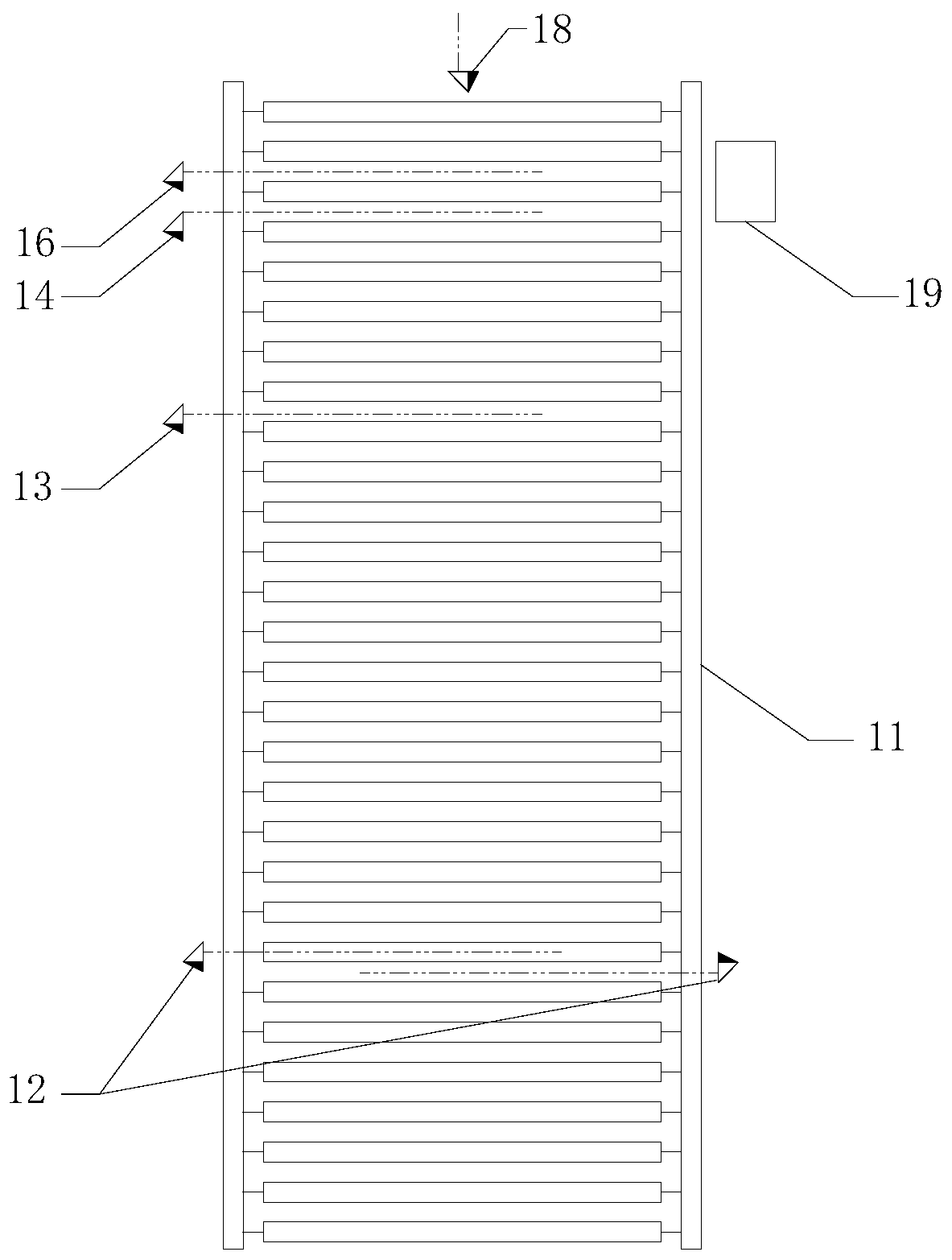

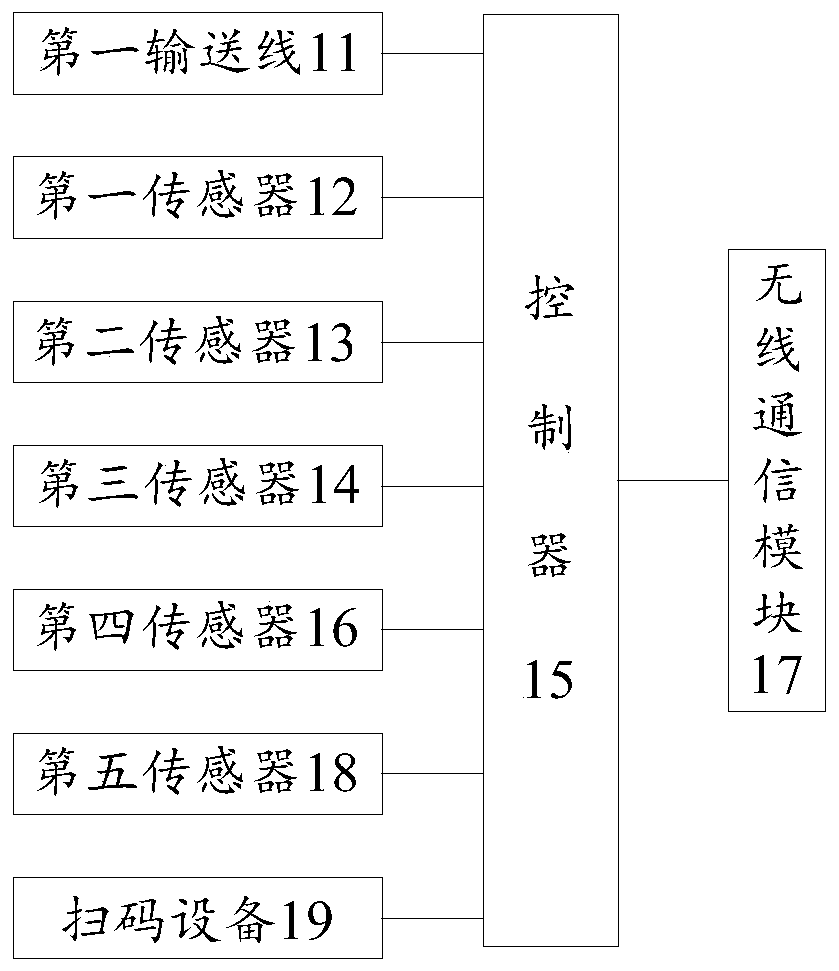

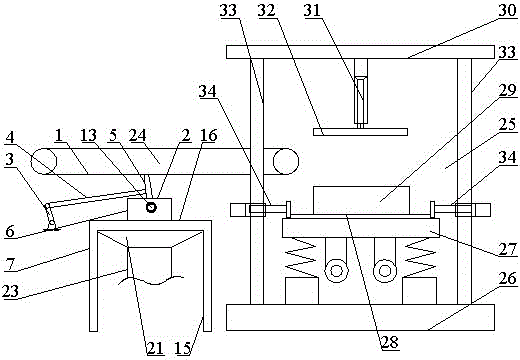

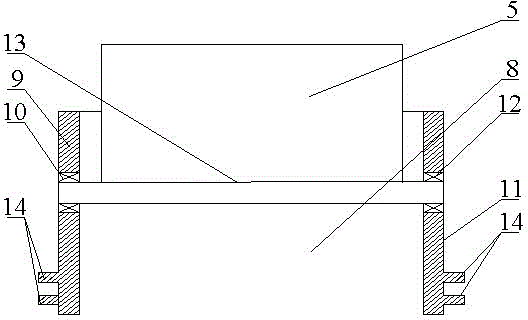

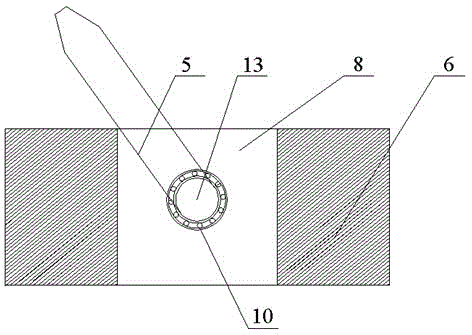

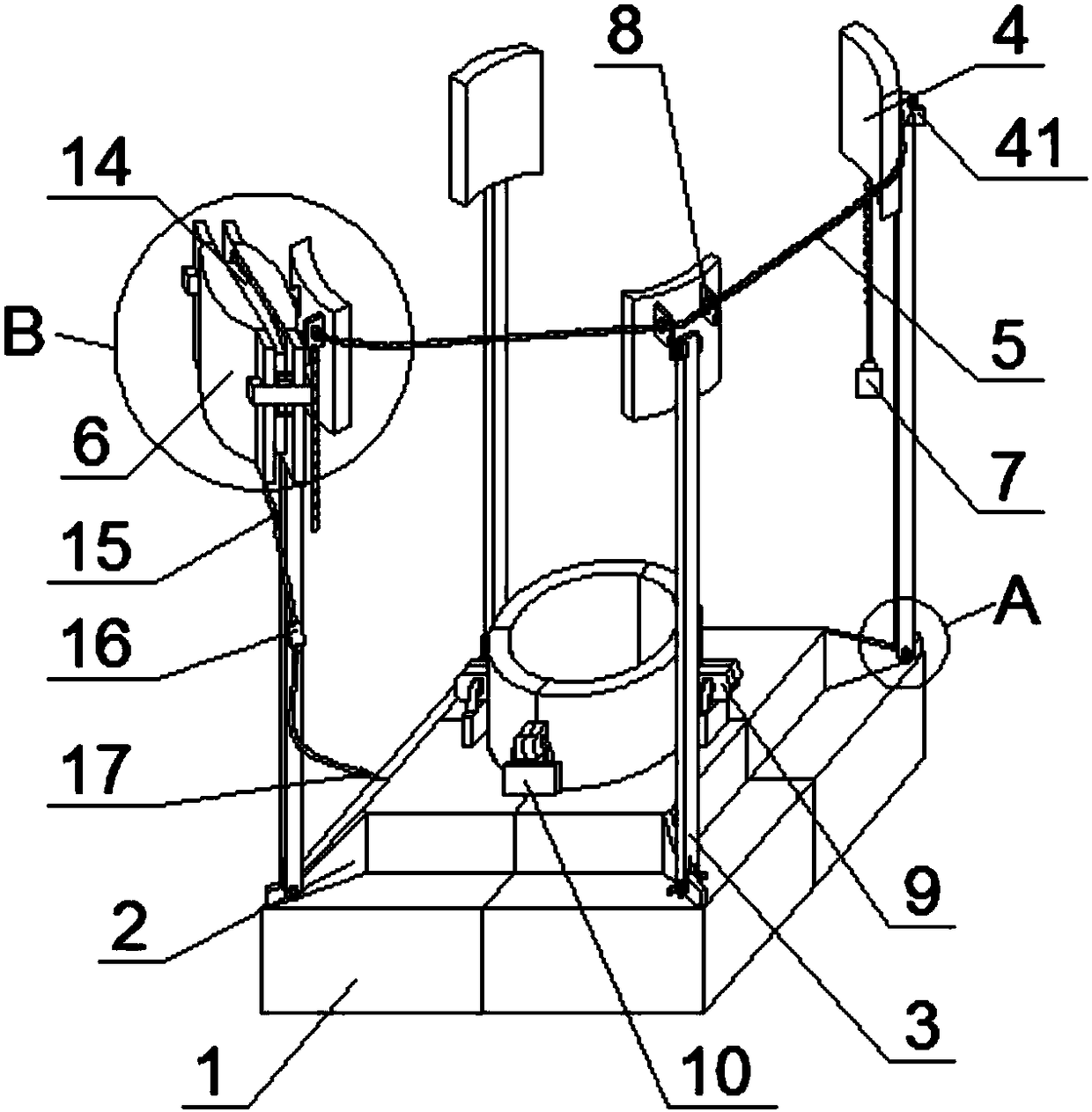

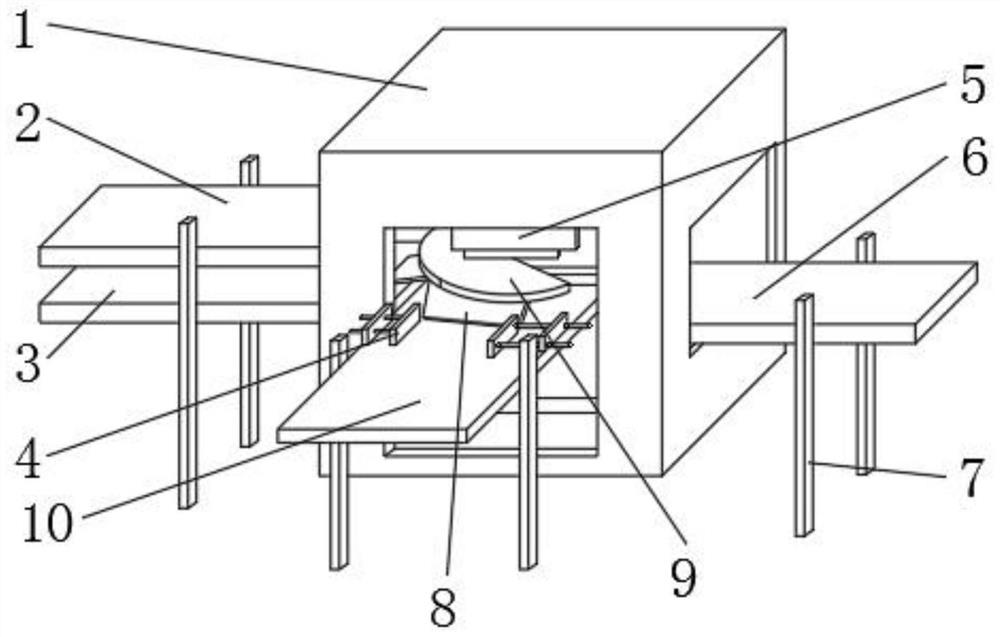

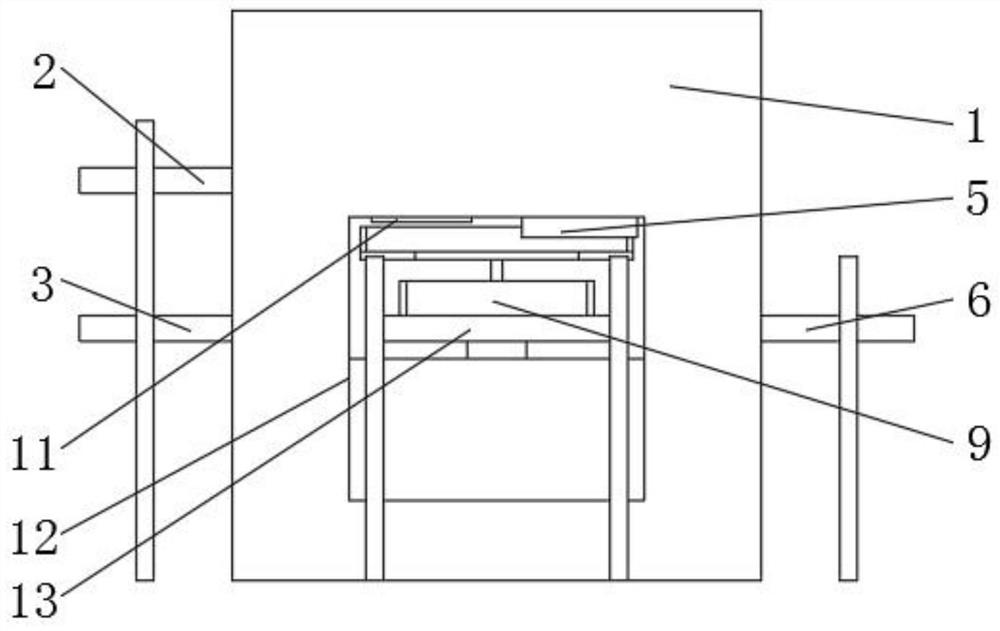

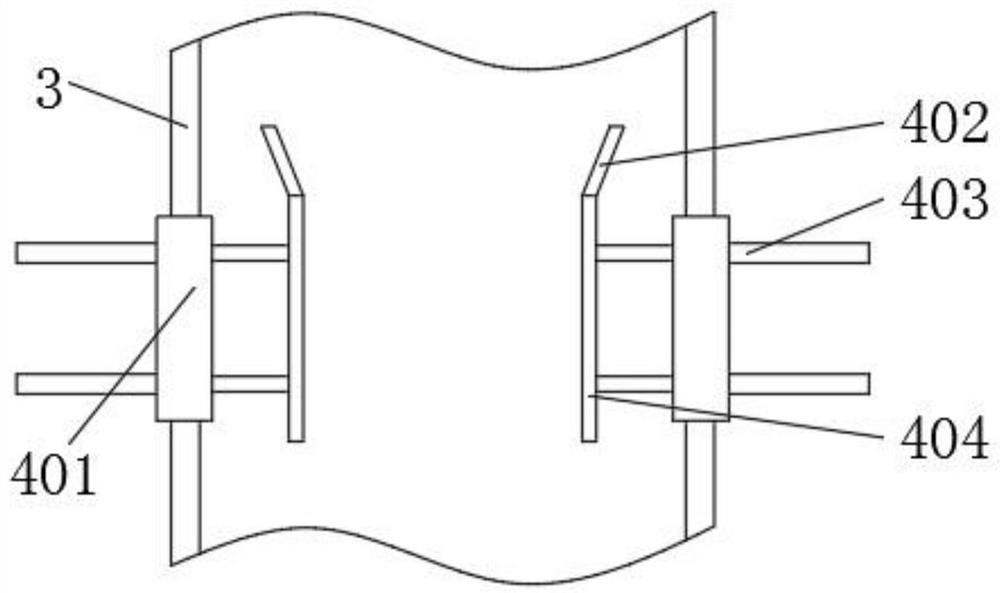

Tray lifting and conveying mechanism

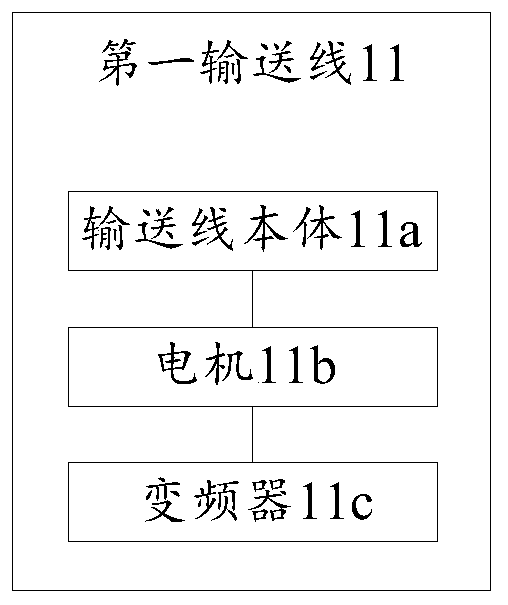

InactiveCN106516686AImplement auto-boostGuaranteed delivery efficiencyConveyor partsSprocketEngineering

The invention relates to the technical field of tray conveying equipment, in particular to a tray lifting and conveying mechanism. By adoption of the tray lifting and conveying mechanism, automatic lifting of trays can be achieved conveniently, and the conveying efficiency is guaranteed. The tray lifting and conveying mechanism comprises a first conveying line and a second conveying line, and the second conveying line is higher than the first conveying line. The tray lifting and conveying mechanism is characterized in that a lifting mechanism is arranged between the first conveying line and the second conveying line and comprises an inverted-U-shaped support, and linear guide rails are mounted on two vertical rods of the inverted-U-shaped support correspondingly; a lifting roller frame is mounted on the linear guide rails through sliding blocks, a plurality of conveying rollers are mounted on the lifting roller frame, and limiting stop rods are mounted on the two sides of each conveying roller; a longitudinal driving cylinder is mounted between the two vertical rods of the inverted-U-shaped support, and a piston rod of the longitudinal driving cylinder is connected with a supporting block; supporting chain wheels are mounted at the two ends of the supporting block correspondingly, and a supporting chain is arranged on the supporting chain wheels; and one end of the supporting chain is fixedly connected with the lifting roller frame, and the other end of the supporting chain is fixedly connected to a bottom fixing base of the inverted-U-shaped support.

Owner:WUXI MINGZHU TURBOCHARGER MFG

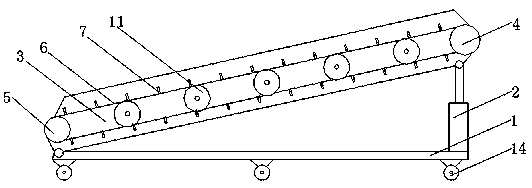

Conveyor for mining industry

The invention relates to a conveyor for the mining industry. The conveyor comprises a supporting frame, the right end of the top of the supporting frame is provided with a vertical air cylinder, the top of the air cylinder is rotatably connected with a conveying frame, and the left side of the bottom of the conveying frame is rotatably connected with the left side of the top of the supporting frame. The right side of the top of the conveying frame is provided with a driving wheel, the left side of the bottom of the conveying frame is provided with a driven wheel, and the outer sides of the driving wheel and the driven wheel are rotatably provided with a conveyer belt in a sleeved manner. The inner side of the conveyer belt is connected with a fixing strip, and the fixing strip is slidablyconnected with the conveying frame through a sliding chute. The outer side of the conveying frame is vertically connected with baffles distributed uniformly, the two sides of the baffles are providedwith hair brushes, the hair brushes are connected to the two sides of the top of the conveying frame, and one sides of the hair brushes are provided with vertical protection plates. The conveyor for the mining industry is simple in structure and stable and reliable, and through the arrangement of the air cylinder, the conveyer can be applied to multiple conveying heights; and through the arrangement of the fixing strip and the sliding chute, deviation of the conveyer belt in the conveying process is avoided, and conveying efficiency is guaranteed.

Owner:平湖市飞天人图文设计有限公司

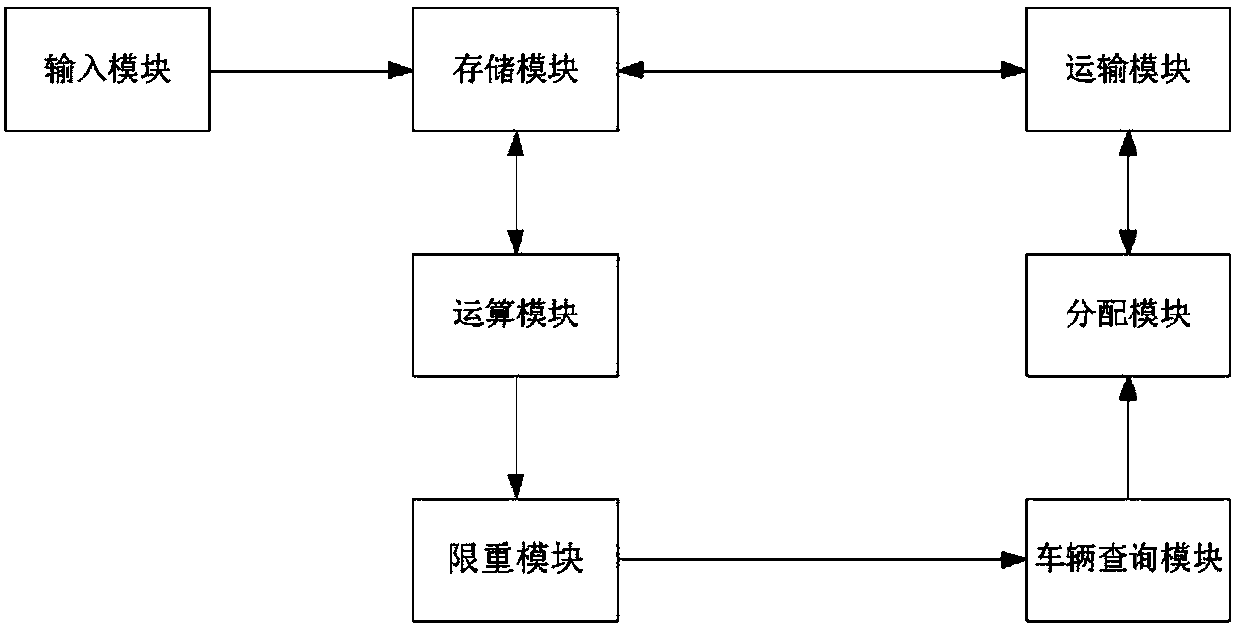

Intelligent vehicle dispatching system

InactiveCN108038625ATake advantage ofReduce experienceResourcesLogisticsDriver/operatorLogistics management

The invention relates to the technical field of logistics dispatching, in particular to an intelligent vehicle dispatching system. The intelligent vehicle dispatching system comprises a storage moduleused for storing vehicle information, transport routes and road condition information, and an input module used for dispatching personnel to input order information, wherein the vehicle information further comprises hometown places of vehicle drivers and frequent driving place information. The intelligent vehicle dispatching system further comprises a calculation module used for matching the corresponding transport routes according to the input order information and storing the transport routes in a route planning module, a weight limiting module for performing output to a vehicle query module according to the matching, the vehicle query module for matching information of vehicles with corresponding weights in the storage module according to maximum weight limiting information, an allocation module for generating allocation information, a transport module for generating to-be-allocated information according to the allocation module and storing the to-be-allocated information in the storage module, a combination module for performing combination to obtain dispatching information and sending the dispatching information to a dispatching module, and the dispatching module for sendingthe dispatching information to the corresponding vehicles according to the received dispatching information.

Owner:重庆博欧科技有限公司

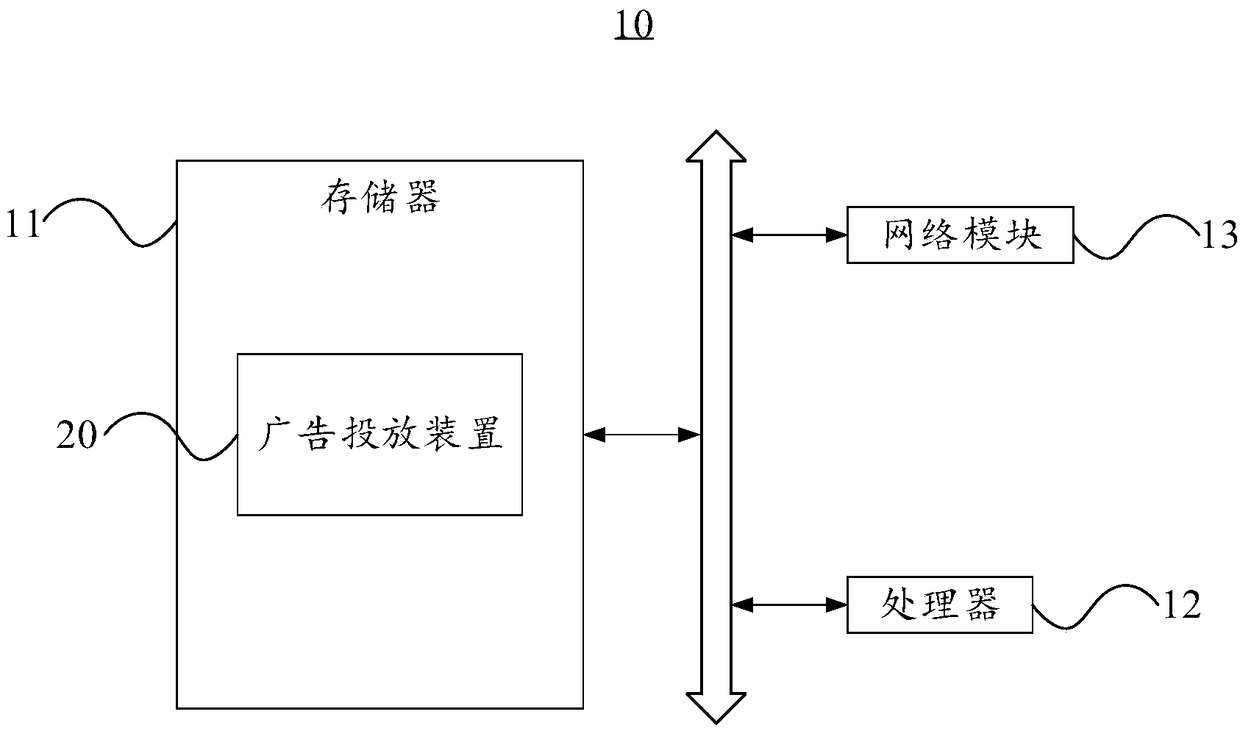

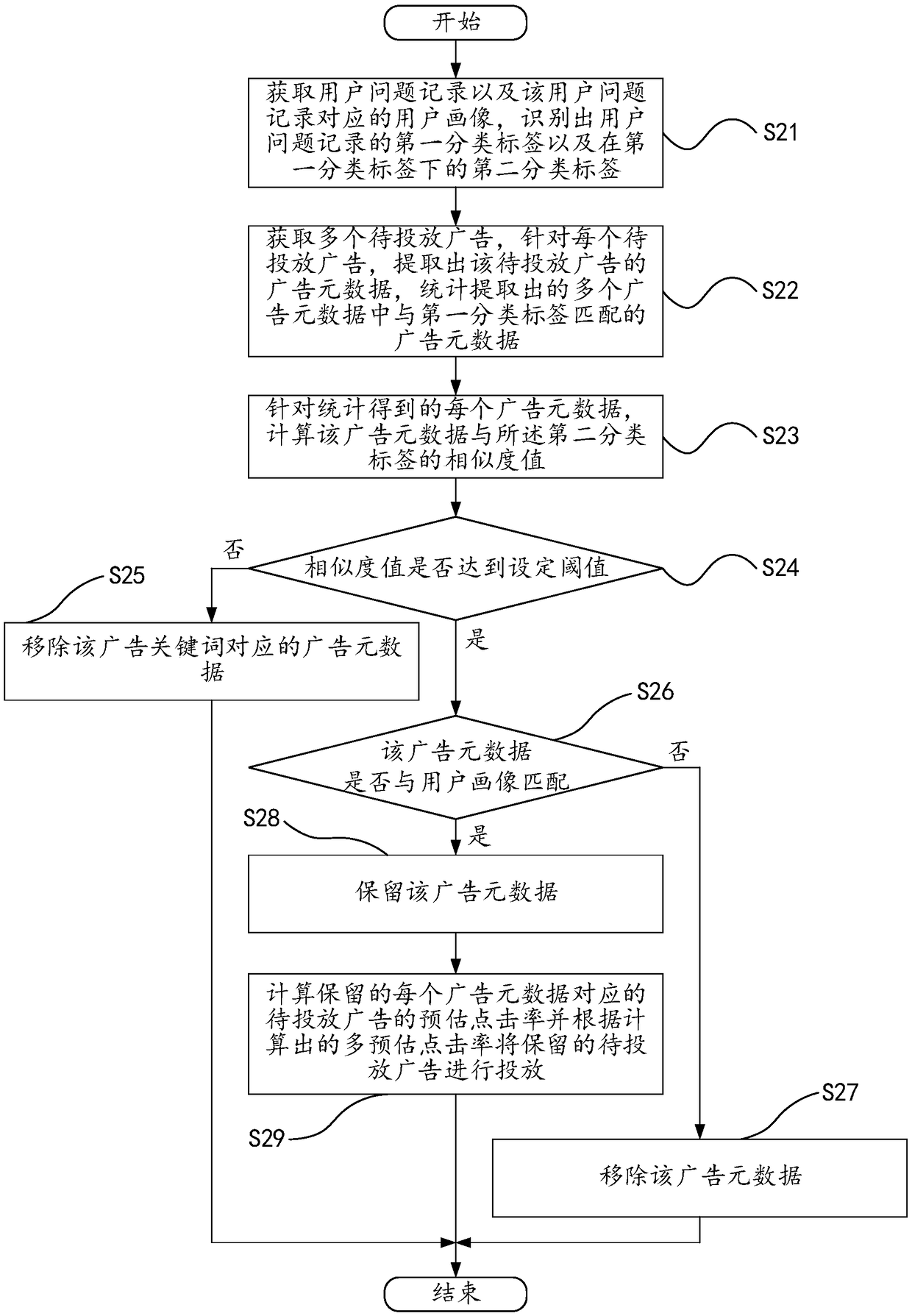

Advertisement putting method and device

InactiveCN109493146AImprove accuracyIncrease the chances of clicking on your adMarketingClick-through rate

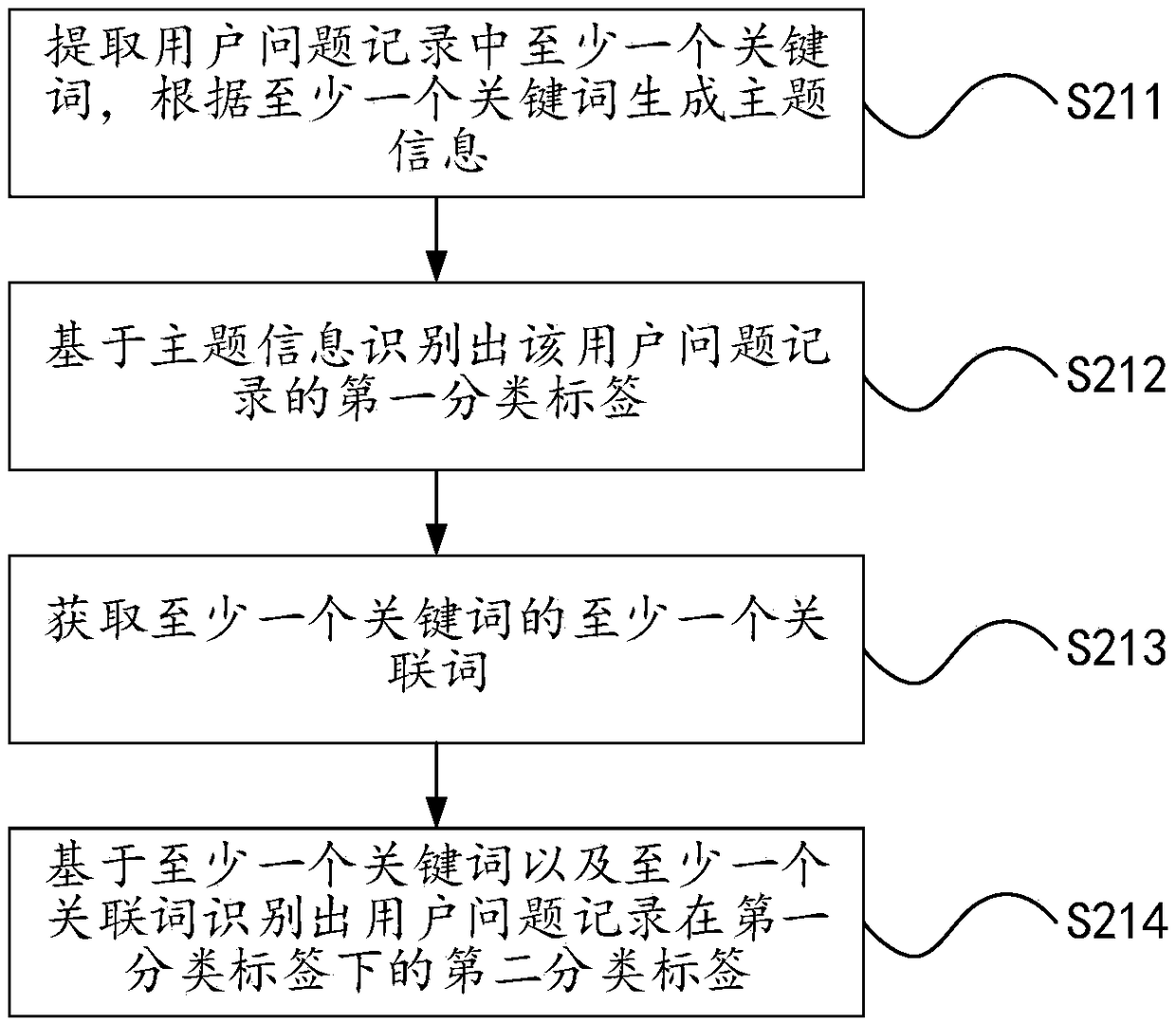

The embodiment of the invention relates to the technical field of advertisement processing, in particular to an advertisement putting method and device. The method comprises the steps of obtaining a user problem record and a corresponding user portrait; the user problem is identified for the second time; the method comprises the steps of obtaining a plurality of to-be-put advertisements, carryingout matching screening on the to-be-put advertisements based on a secondary recognition result and a user portrait, finally calculating the estimated click rate of each to-be-put advertisement obtained through screening, and realizing ordered putting of the to-be-put advertisements according to the magnitude order of the estimated click rates, so that the accuracy and efficiency of advertisement putting can be improved.

Owner:深圳爱问科技股份有限公司

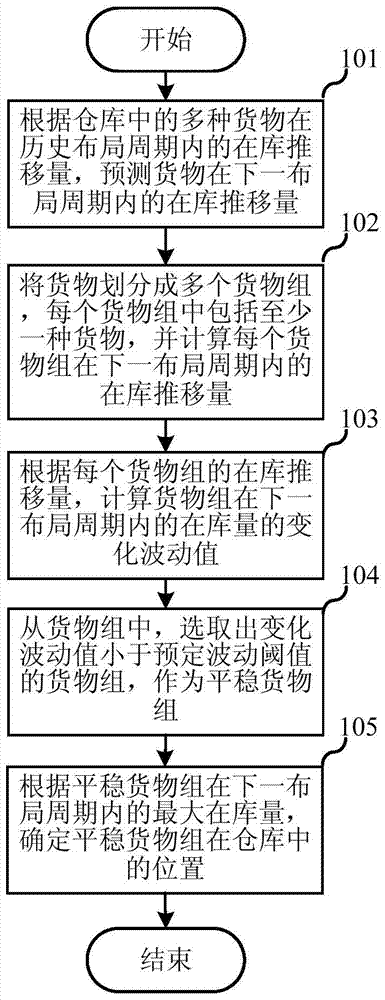

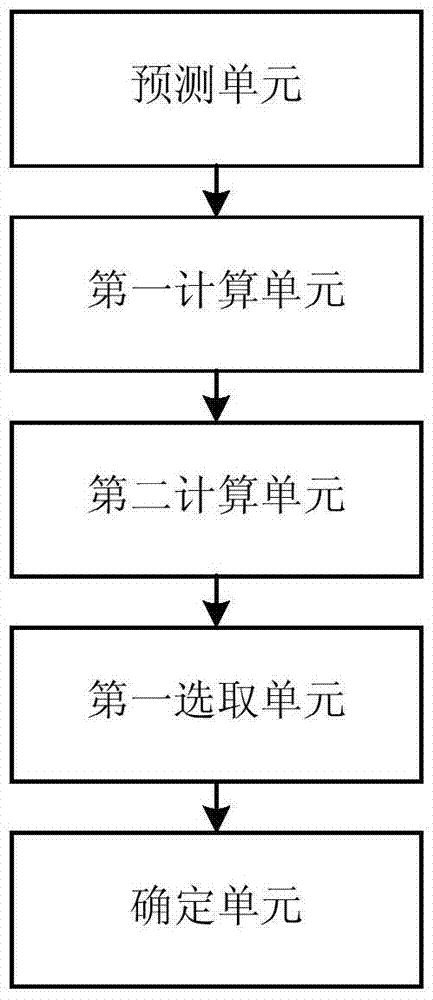

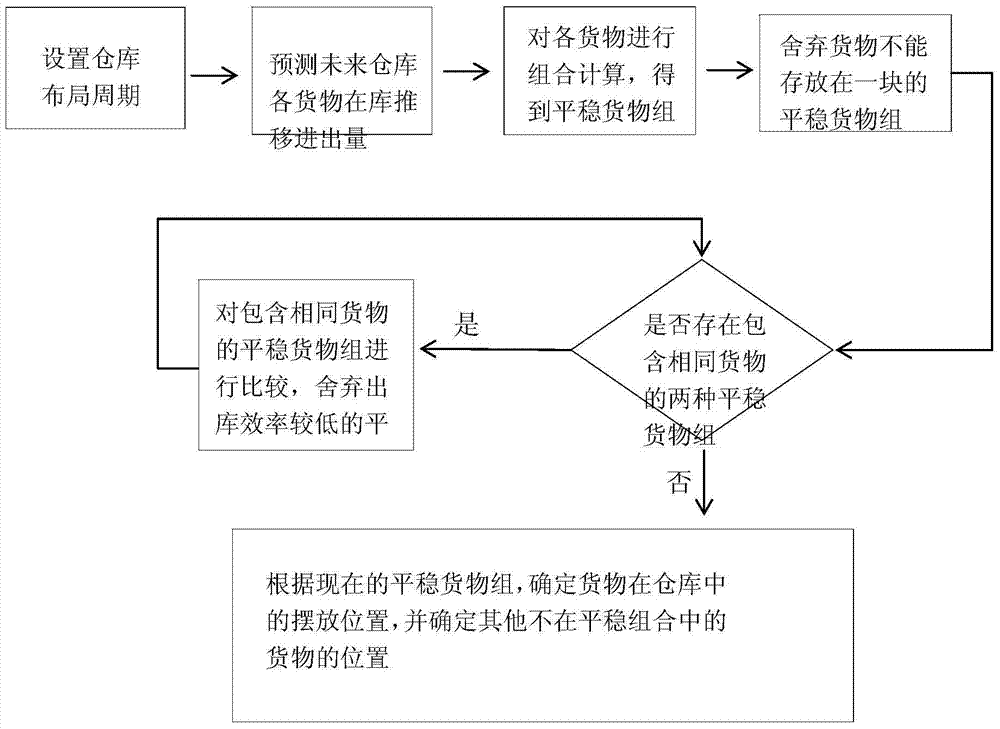

Warehouse layout optimization method and device

ActiveCN107016515AImprove space utilization efficiencyImprove work efficiencyLogisticsLogistics managementComputer science

The invention, which relates to the field of warehouse logistics, discloses a warehouse layout optimization method and device. The optimization method comprises: according to in-stock pass amounts of various commodities in a warehouse within a historical layout cycle, in-stock pass amounts of the commodities within a next layout cycle are predicted; the commodities are classified into a plurality of commodity groups and each commodity group includes at least one kind of commodities, and an in-stock pass amount of each commodity group within a next layout cycle is calculated; according to the in-stock pass amount of each commodity group, a changing fluctuation value of an in-stock amount of each commodity group within a next layout cycle is calculated; a commodity group with the changing fluctuation value lower than a predetermined fluctuation threshold is selected from the commodity group and is used as a steady commodity group; and according to a maximum in-stock amount of the steady commodity group within a next layout cycle, the location of the steady commodity group in the warehouse is determined. Therefore, the space utilization rate of the warehouse and the in-out working efficiency of commodities in a warehouse can be improved; and the warehousing cost can be saved.

Owner:HITACHI LTD

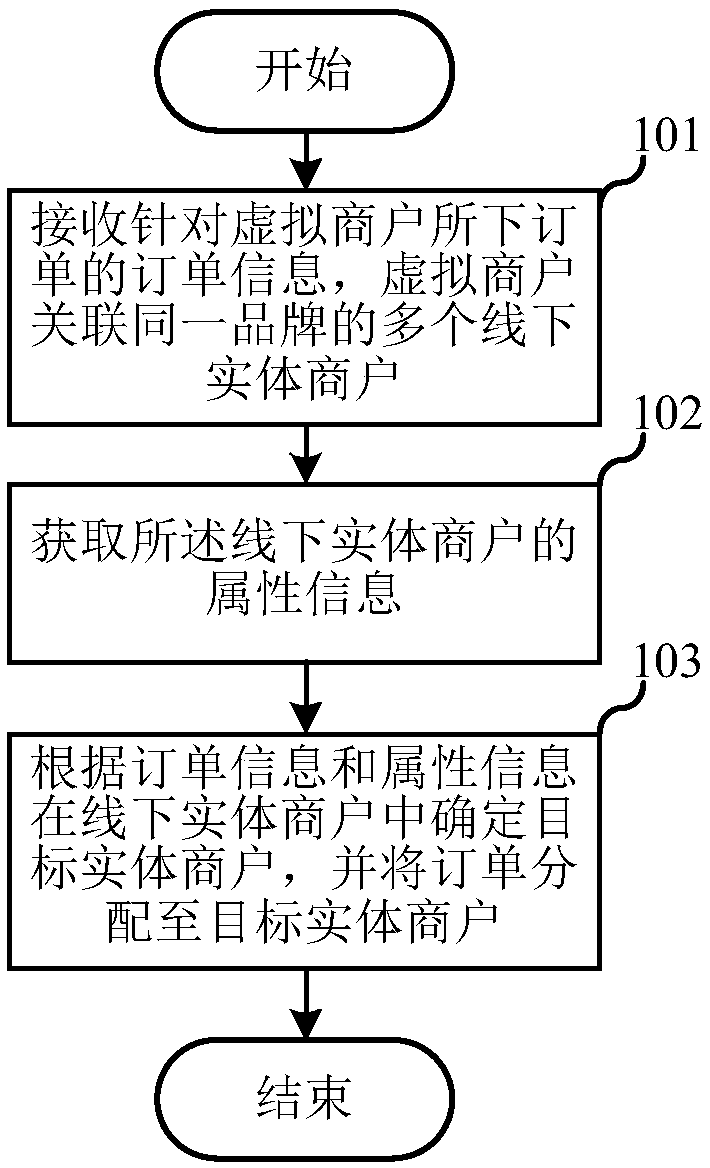

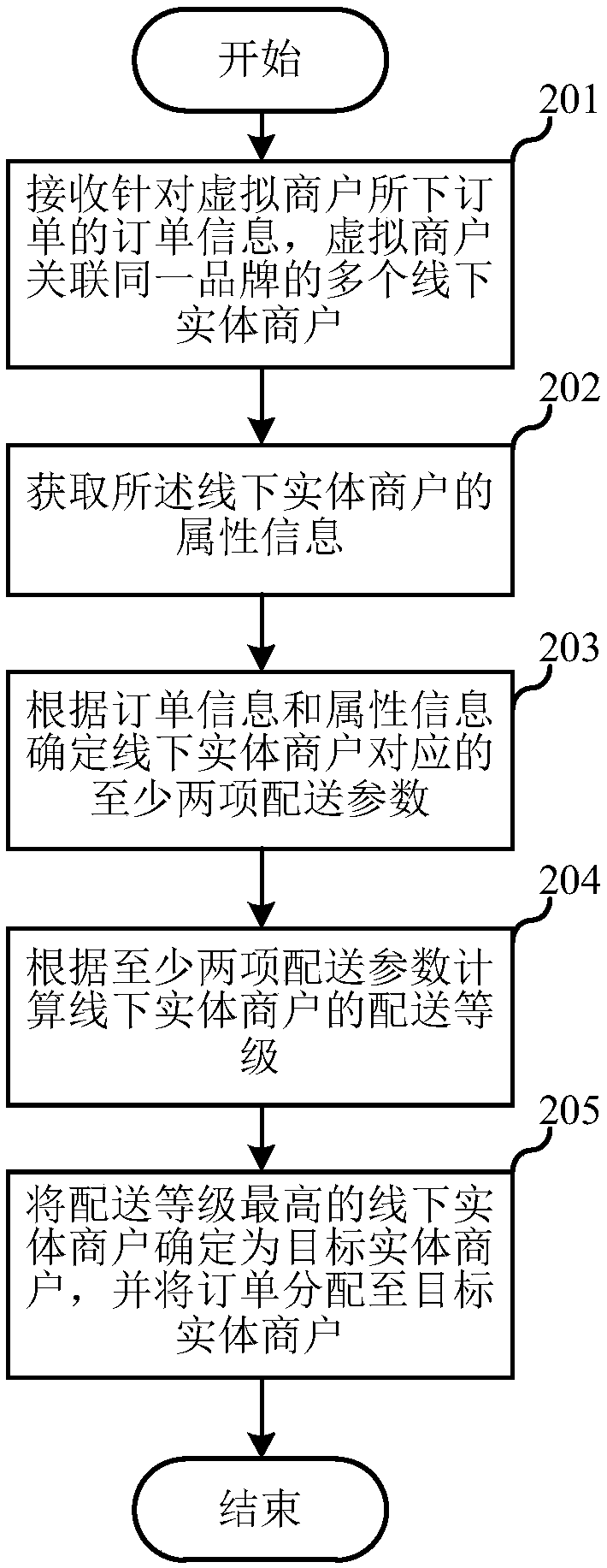

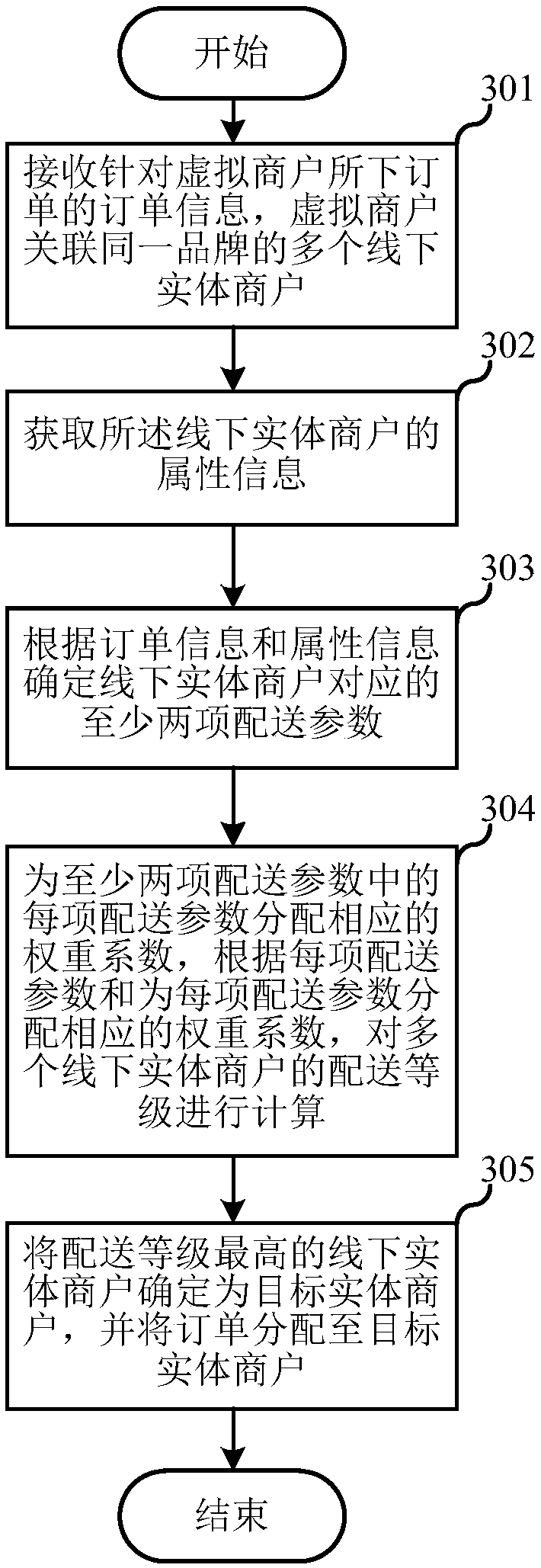

Order allocation method and apparatus, electronic device, and storage medium

InactiveCN109360042AReduce selection pressureImprove display qualityBuying/selling/leasing transactionsLogisticsDistribution methodComputer science

The embodiment of the invention relates to the field of communication technology, and discloses an order distribution method and apparatus, an electronic device and a storage medium. The method includes receiving order information for orders placed by virtual merchants, wherein the virtual merchants are associated with a plurality of offline entity merchants of the same brand; obtaining attributeinformation of offline entity merchants; determining a target offline entity merchant from that offline entity merchants according to the order information and the attribute information, and allocating an order to the target offline entity merchant. The invention integrally packages a plurality of offline entity merchants of the same brand as one virtual merchant for online display, only one virtual merchant of the brand is displayed online, The user only needs to select the virtual merchant to place an order, and the background comprehensively considers multiple distribution factors of eachphysical merchant offline, and distributes the orders received by the virtual merchant to one of the physical stores offline for distribution, thereby greatly reducing the selection pressure of consumers, and making the display of the platform more clear and intuitive at the same time.

Owner:RAJAX NETWORK &TECHNOLOGY (SHANGHAI) CO LTD

Package pressing conveying structure applicable to packaging machine

ActiveCN105775259AReduce power sourceReduce energy consumptionPaper article packagingEngineeringEnergy consumption

The invention discloses a package pressing conveying structure applicable to a packaging machine and belongs to the technical field of packaging machines. The package pressing conveying structure applicable to the packaging machine comprises a package pressing plate and is characterized in that the package pressing conveying structure further comprises a lifting portal frame and a conveying mechanism driven by a power source; the conveying mechanism is of a one-segment type structure and comprises an upper conveying part and a lower conveying part; the package pressing plate is arranged on the lifting portal frame; one end of the upper conveying part is hinged to the lifting portal frame through a hinging shaft; the upper conveying part makes contact with the package pressing plate; and the upper conveying part is located on the package pressing plate. According to the package pressing conveying structure applicable to the packaging machine, the package pressing plate and the conveying mechanism are separated; during package pressing, the conveying mechanism cannot make downward-pressing swing action along with the package pressing plate, only when the conveying mechanism detects that materials come, can the conveying mechanism rotate, and therefore energy consumption is lower, and the conveying efficiency is higher; and the upper conveying part makes contact with the package pressing plate so that the materials pressed by the package pressing plate can be square, regular and attractive, the lower conveying part is used in cooperation so that material packages conveyed in a package pressing manner can be more orderly and compacted, and therefore the subsequent packaging efficiency can be improved.

Owner:上海松川峰冠包装自动化有限公司

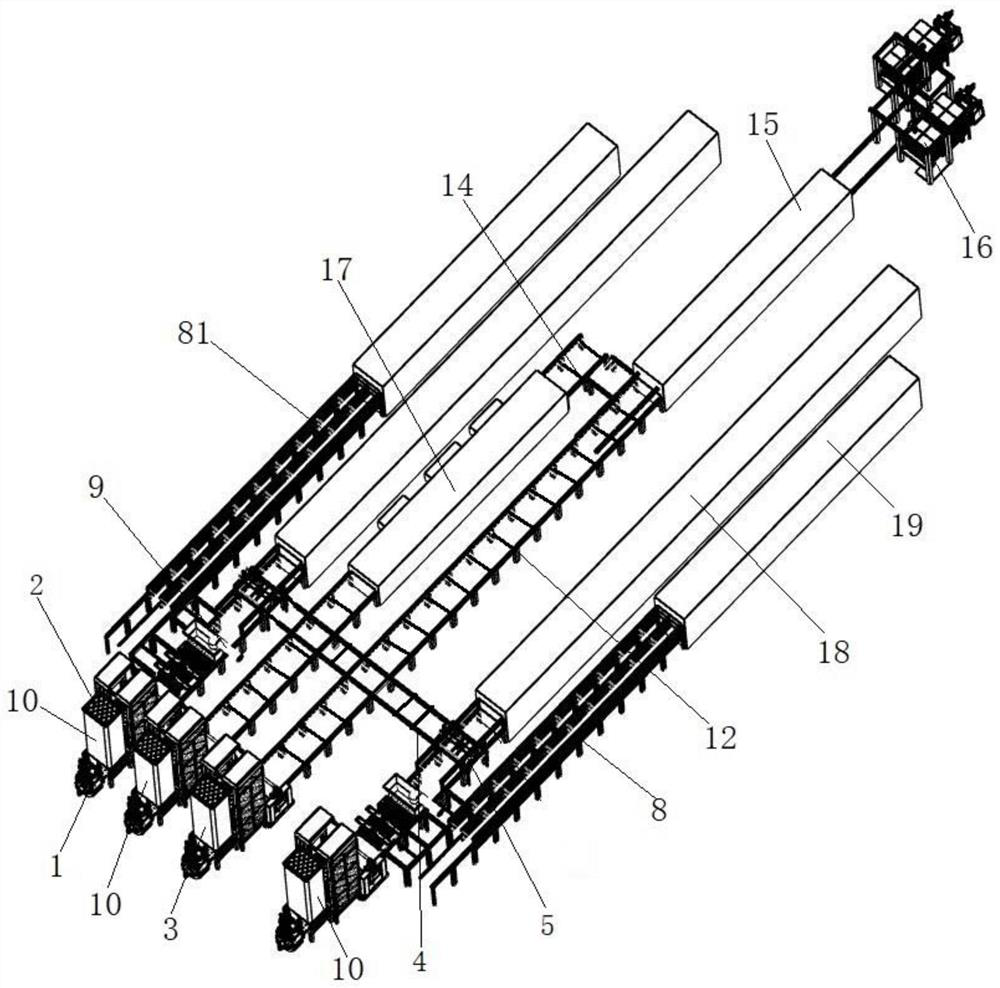

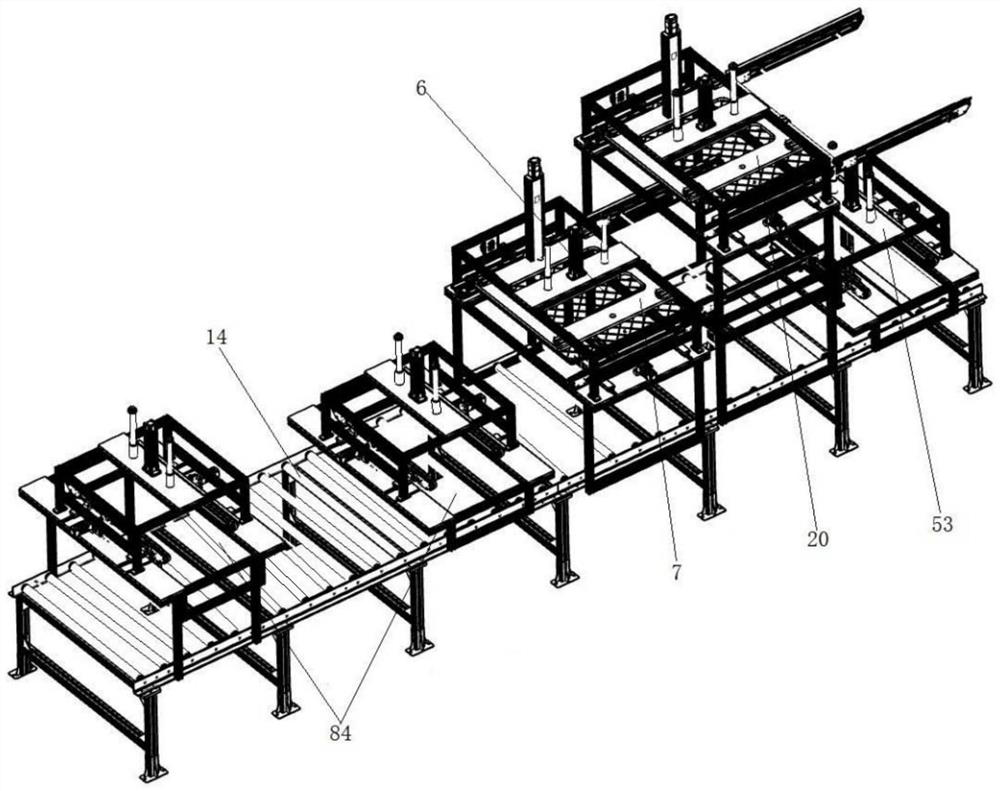

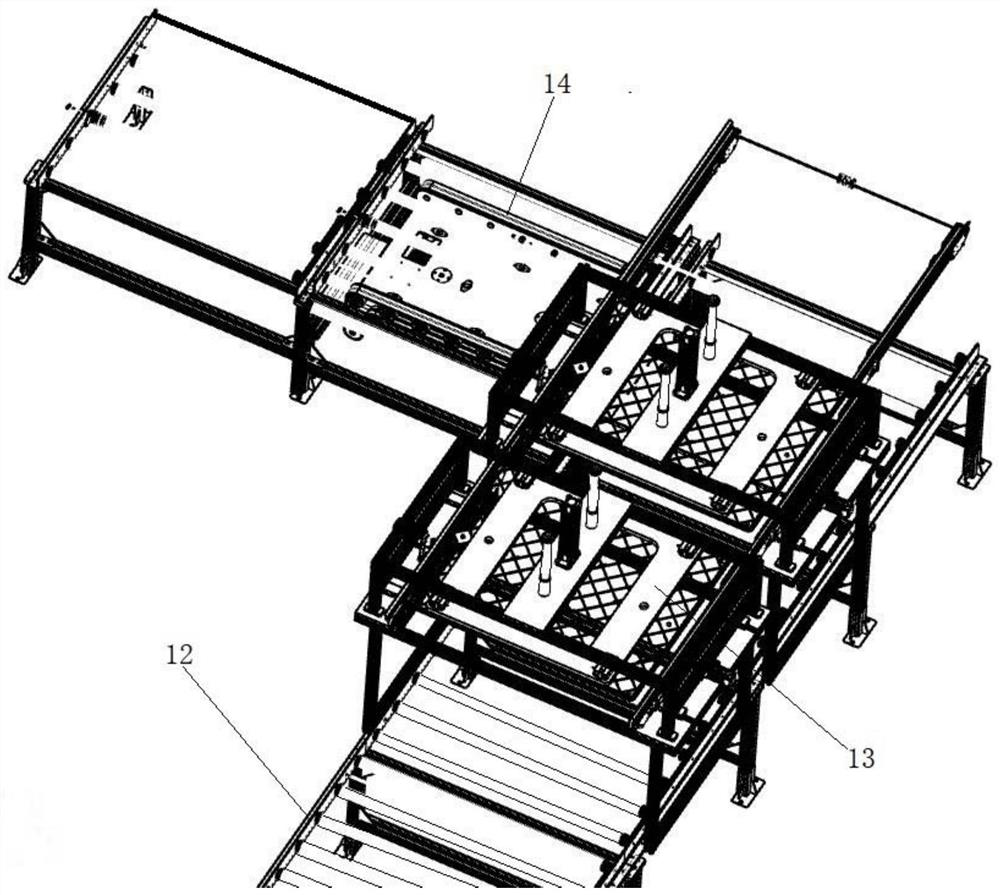

Conveying equipment and conveying method

InactiveCN109911553AImprove stabilityImprove accuracyControl devices for conveyorsRoller-waysEngineeringMechanical engineering

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

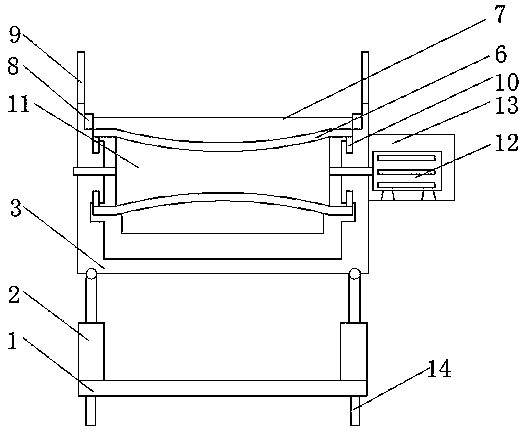

Five-age silkworm egg breeding system and breeding method thereof

PendingCN113558015AReduce deliveryGuaranteed delivery efficiencyConveyorsStacking articlesFisheryZoology

The invention relates to a five-age silkworm egg breeding system and a breeding method thereof. The breeding system comprises a silkworm frame detaching and chopping device for detaching and chopping four-age silkworm frames conveyed by an AGV dispatching system, first carrier roller conveying lines for conveying five-age silkworm frames are arranged on the two sides perpendicular to the conveying direction of the silkworm frame detaching and chopping device, the silkworm frame detaching and chopping device is connected with a splitting device which splits four-age trough plates in the four-age silkworm frames one by one and conveys the trough plates to corresponding the five-age silkworm frames, stacking devices which place the five-age trough plates in the five-age silkworm frames are distributed above the first carrier roller conveying lines, and the first carrier roller conveying lines are connected with a cocoon frame feeding device which covers the five-age silkworm frames and baits with cocoon frames. The breeding system is provided with the two first carrier roller conveying lines for conveying the five-age silkworm frames, the conveying amount of five-age silkworm eggs is increased, the two four-age trough plates in the four-age silkworm frames are split one by one through the splitting device, and the conveying efficiency of the five-age silkworm eggs is guaranteed.

Owner:WUHU HUIYING AUTOMATIC EQUIP CO LTD

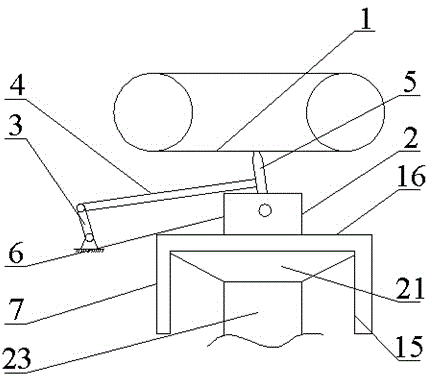

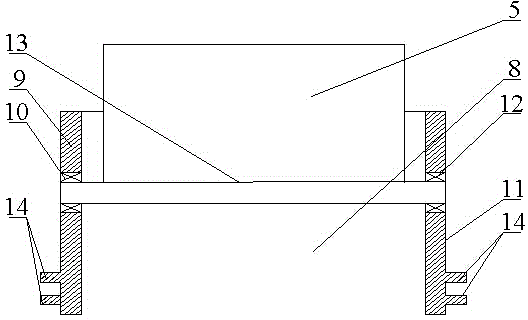

Block machine for construction

ActiveCN104891137AGuaranteed delivery efficiencyEasy to cleanCleaningFeeding arrangmentsMolding machineCrank

The invention discloses a block machine for construction. The block machine for construction comprises a feeding device connected with a rack. A jolt ramming device is installed on a bottom board of the rack. A die is placed on a carrying board of the jolt ramming device. A first oil cylinder on a beam of the rack is connected with a pressing head. A second oil cylinder on an upright of the rack corresponds to the carrying board in position. A sweeping device is arranged below a conveyor belt of the feeding device. A crank of the sweeping device is connected with a rocker. The rocker is connected with a scraper. The scraper is connected with a sliding block. The sliding block is movably connected with a support. A shaft is arranged in a cavity of the sliding block and connected with the scraper. Protrusions are arranged on the outer side of the cavity. A top board is arranged at the top of the upright of the support. Guide rails are arranged on the inner side of a square cavity of the top board. A collection cavity of the top board is connected with the support and is conic. The collection cavity is connected with a conveying pipe. Mortar adhering to the conveyor belt of the block machine can be well removed, the removed mortar can be collected, waste is avoided, labor cost is low, and efficiency is high.

Owner:河北技科新型建材制造有限公司

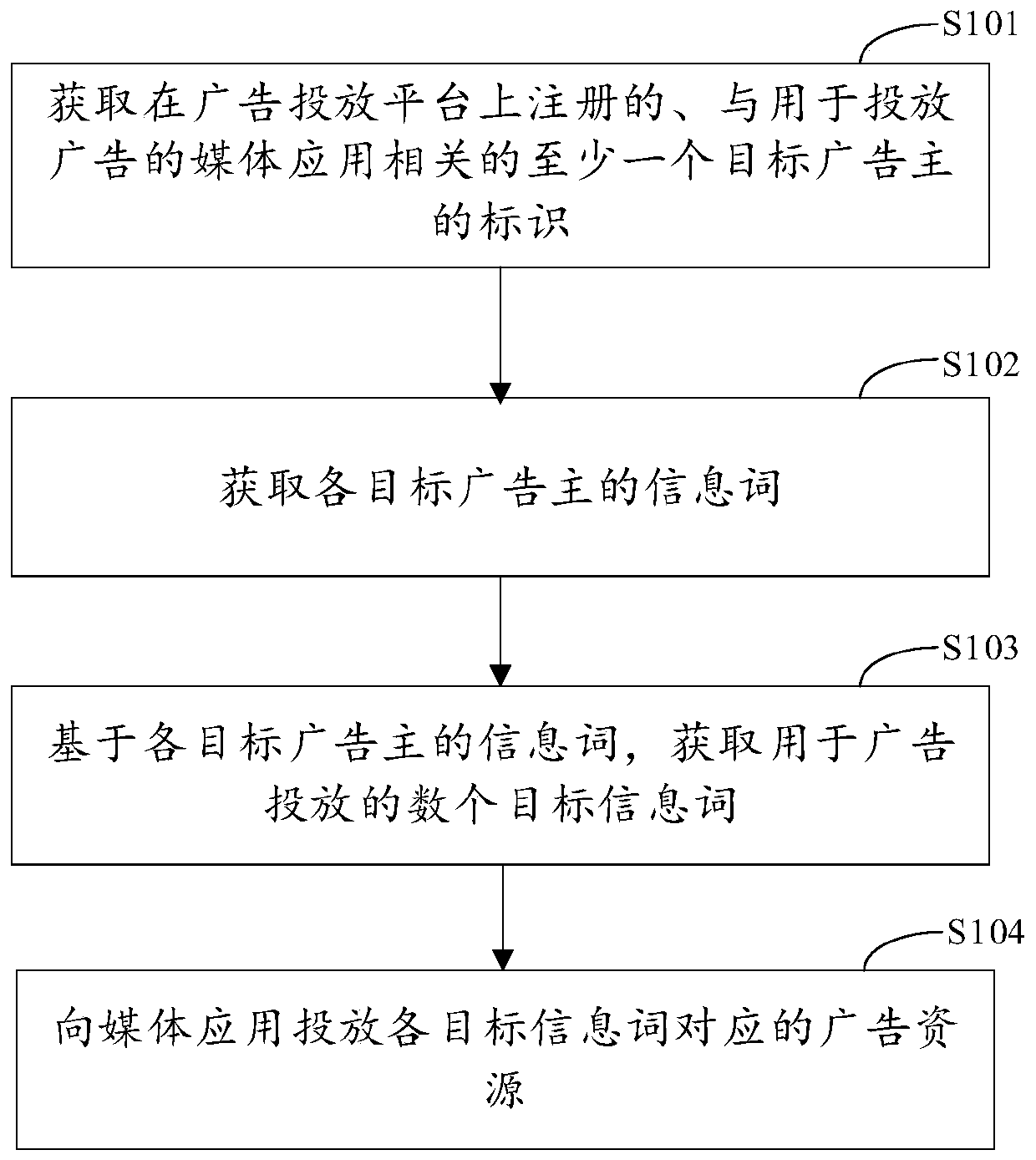

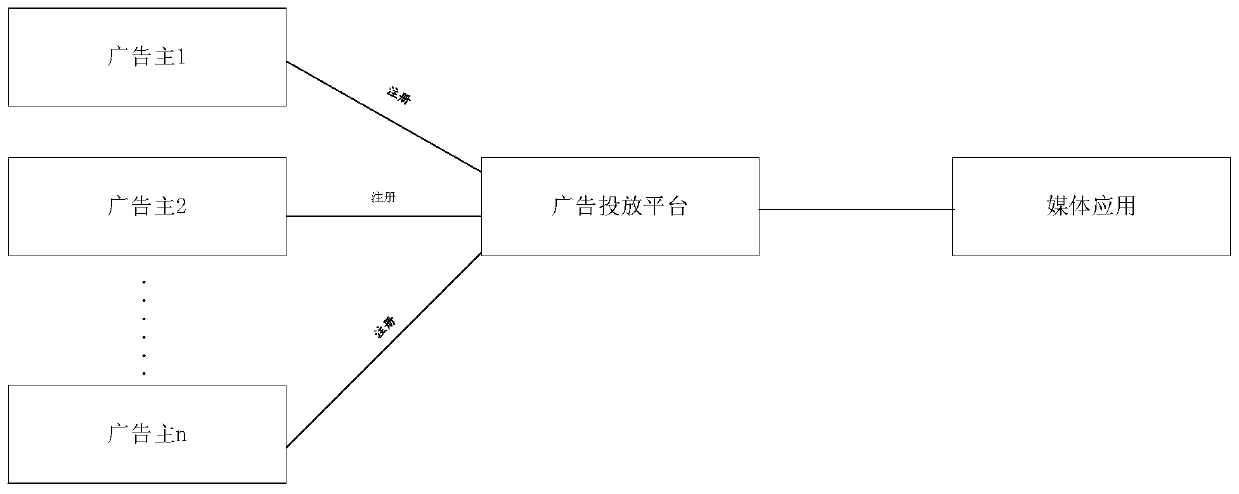

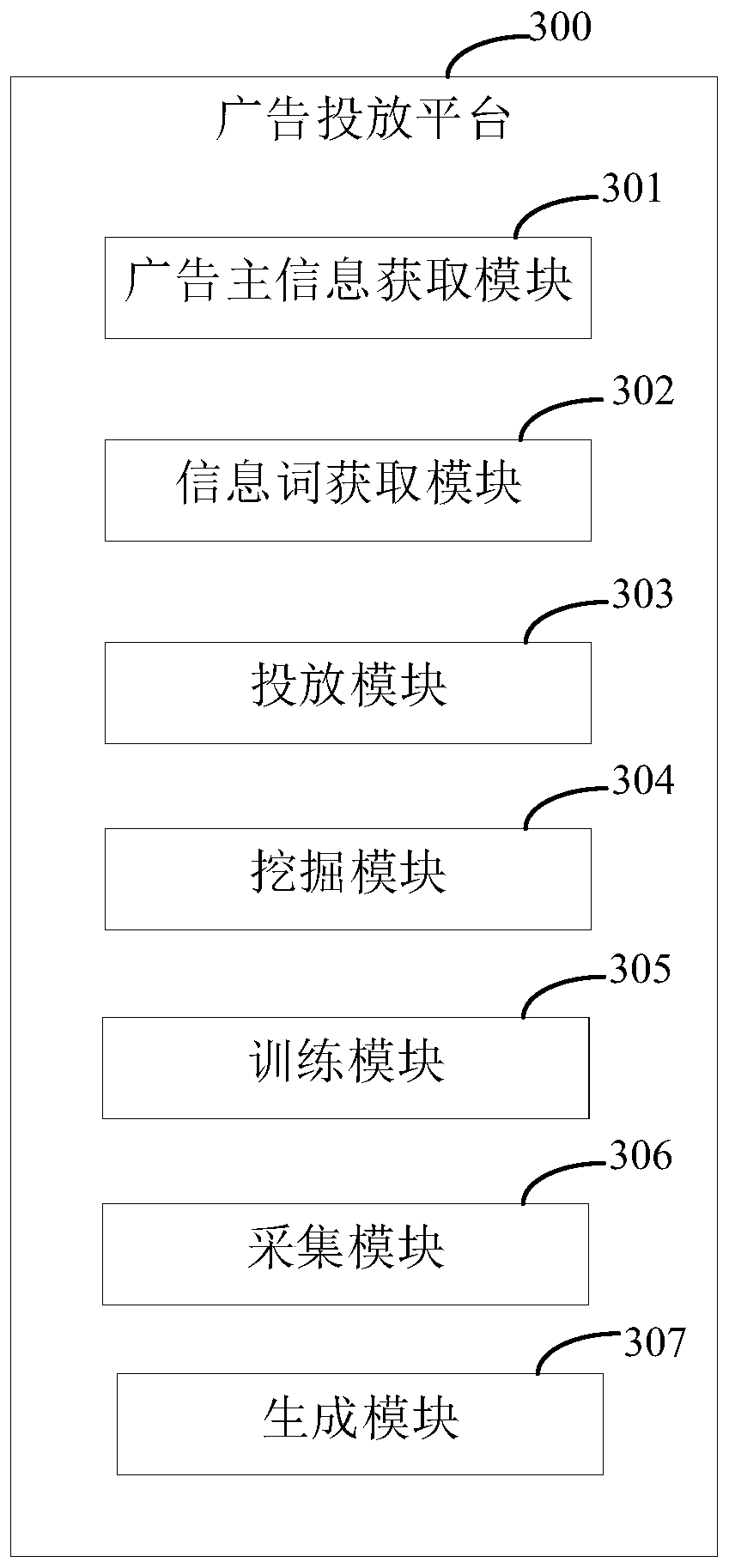

Advertisement putting method, advertisement putting platform, electronic equipment and storage medium

ActiveCN111177545ARealize targeted deliveryGuaranteed delivery efficiencyDigital data information retrievalAdvertisementsMediaFLOEngineering

The invention discloses an advertisement putting method, an advertisement putting platform, electronic equipment and a storage medium, and relates to the technical field of information pushing. The method comprises the following steps: acquiring an identifier of at least one target advertiser registered on an advertisement putting platform and related to a media application used for putting an advertisement; acquiring an information word of each target advertiser; acquiring a plurality of target information words used for advertisement putting based on the information words of all the target advertisers; and delivering advertisement resources corresponding to the target information words to the media application. The defects in the prior art can be overcome, the technical scheme that the advertisement delivery platform can directionally deliver the advertisement when the interest data of the user of the media application cannot be obtained is provided, and the method and the platform can be applied to alliance advertisement delivery scenes. The advertisement resources interested by the user of the media application can be directionally put to the media application, and the advertisement putting efficiency is ensured.

Owner:BAIDU INT TECH (SHENZHEN) CO LTD

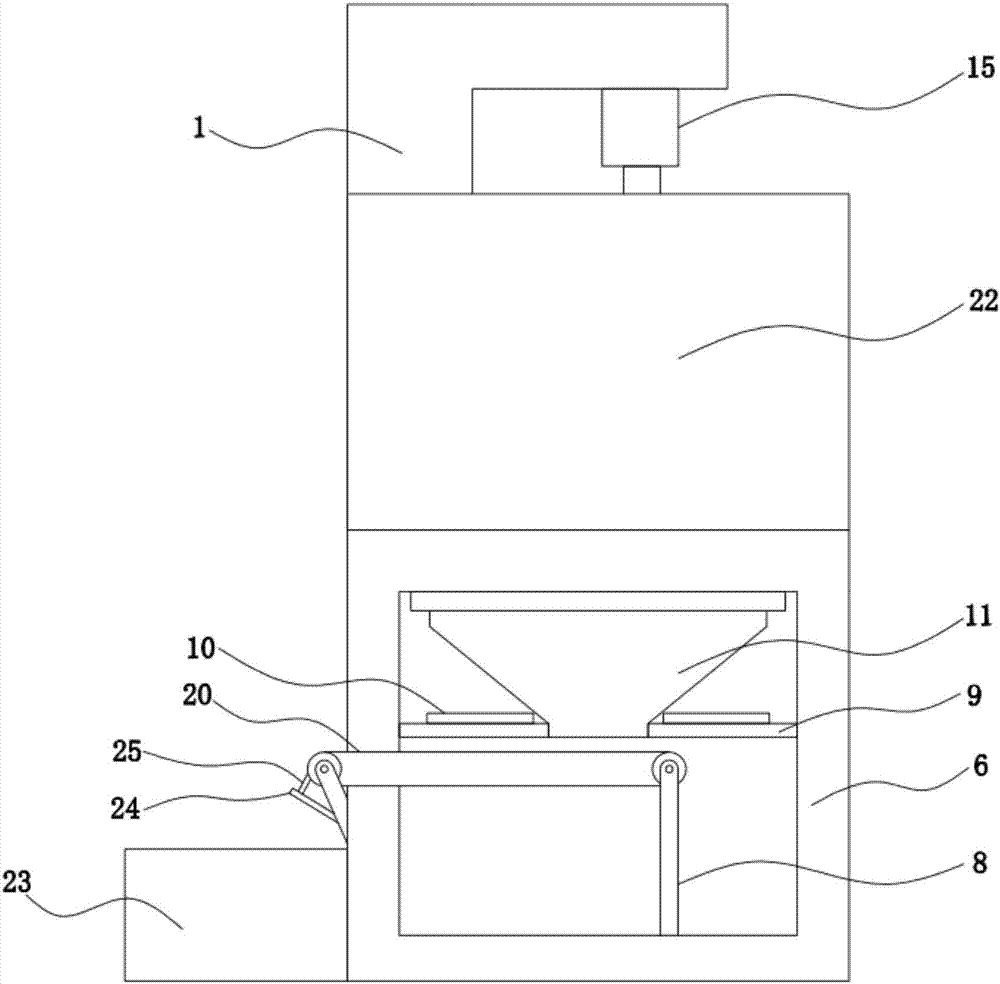

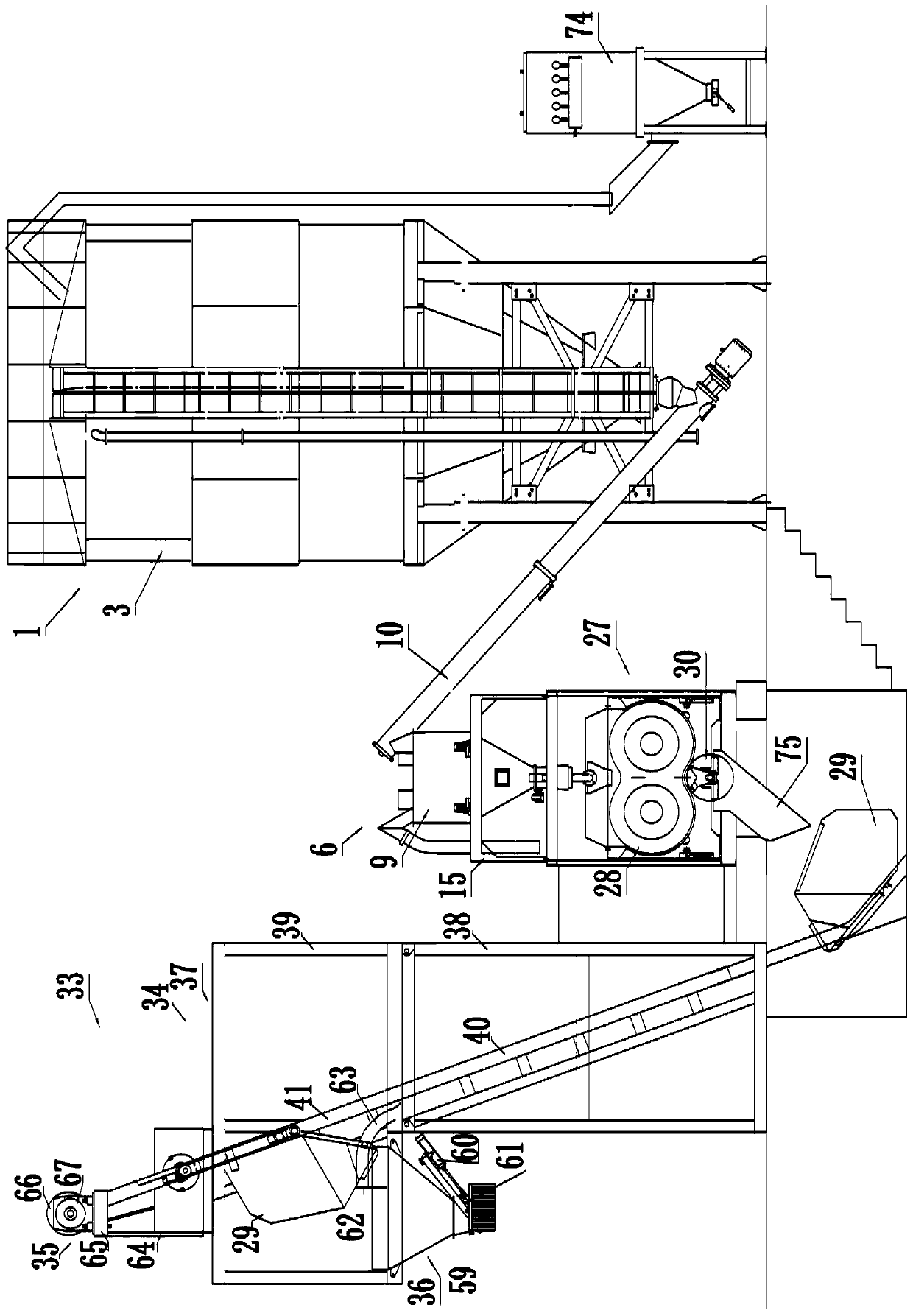

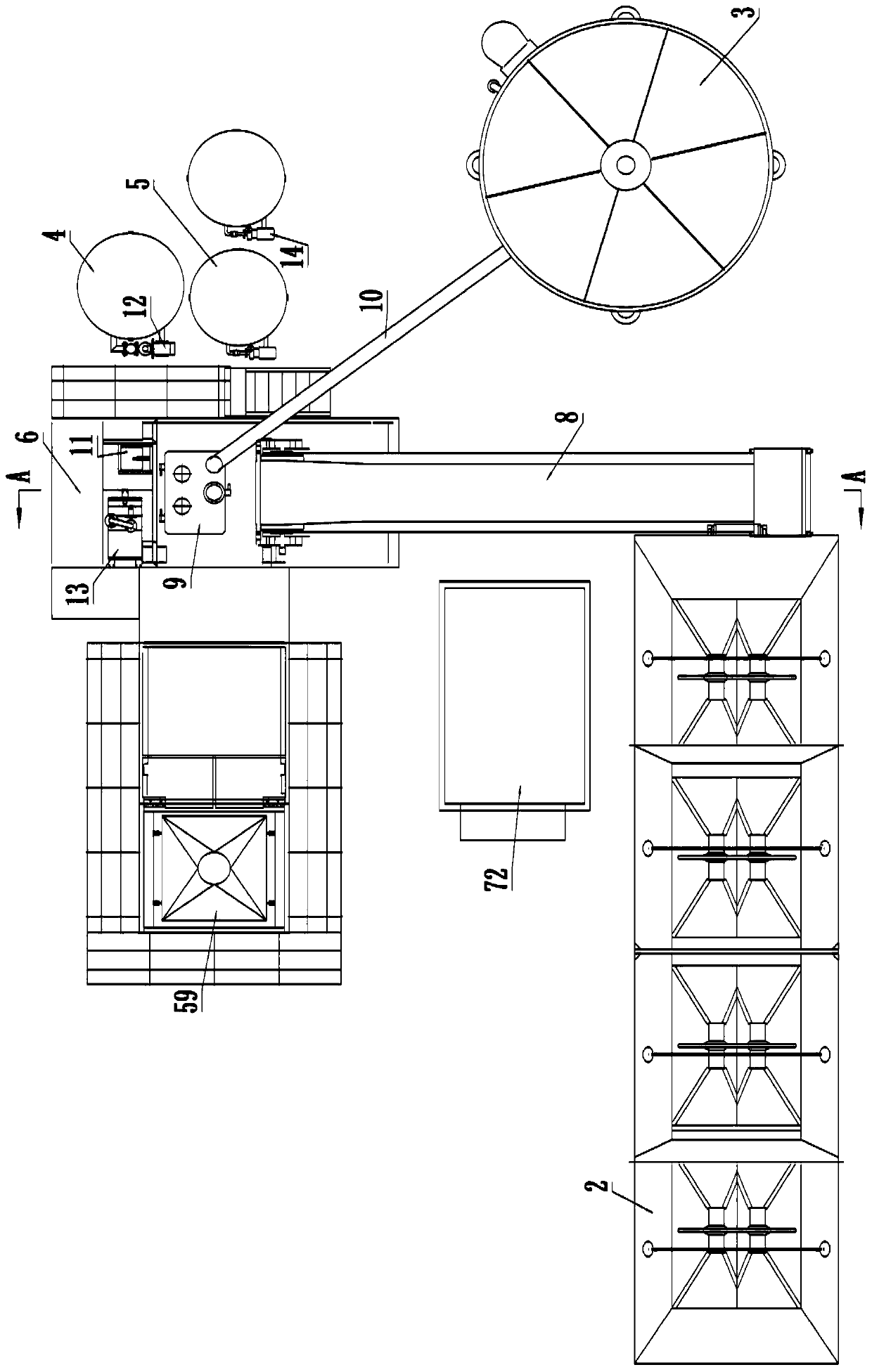

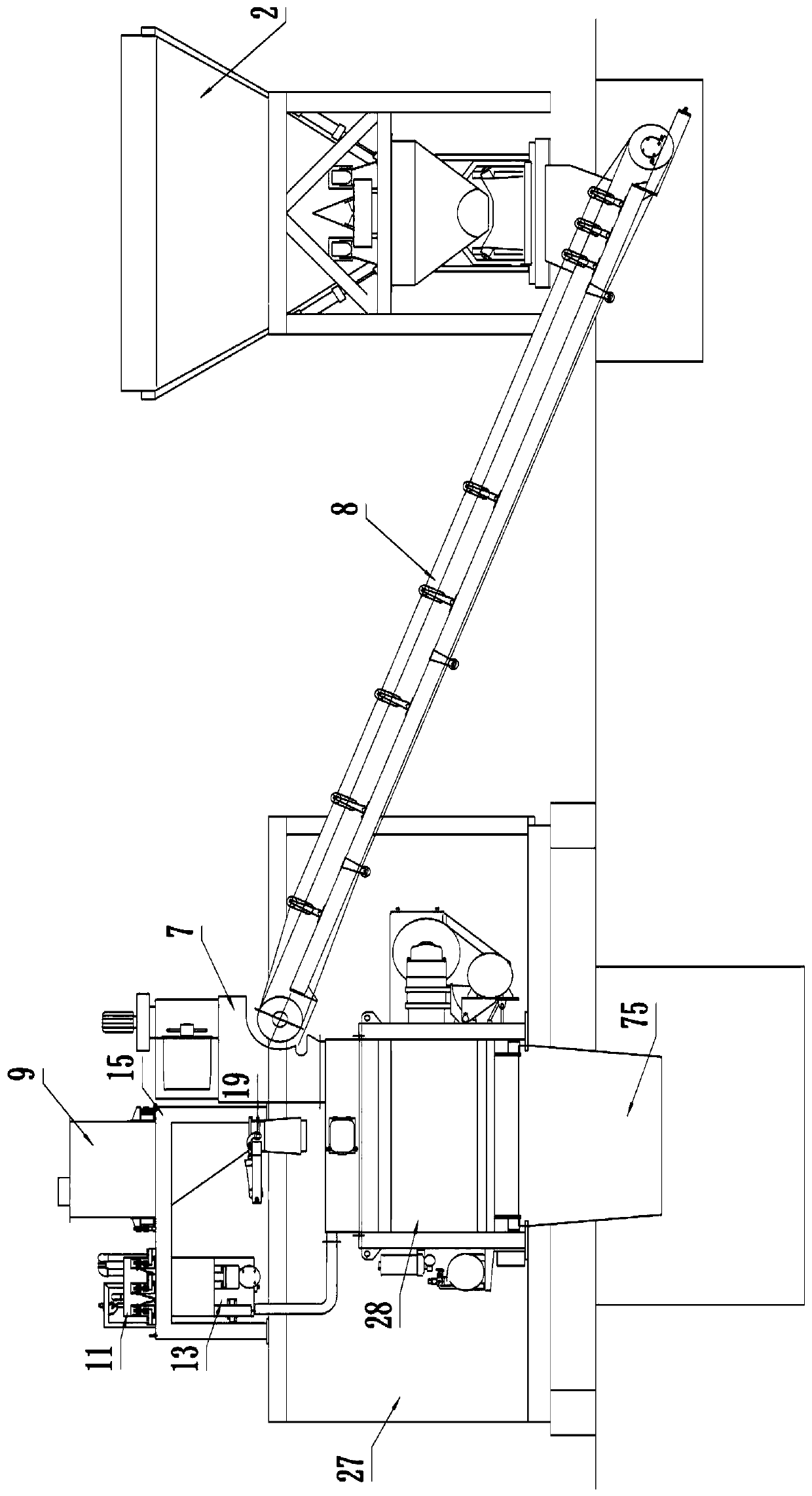

Compact modular concrete stirring equipment

InactiveCN110653945ALower the altitudeSolve environmental pollutionDischarging apparatusMixing operation control apparatusCold areaStructural engineering

The invention provides compact modular concrete stirring equipment. The compact modular concrete stirring equipment comprises a storage material module, a material weighing and batching module, a stirring main machine module and a concrete lifting and discharging device, and due to the concrete lifting and discharging device can raise the concrete to a high position, so that the stirring main machine module can be lowered to the ground for installation, so that the height of a stirring station is greatly reduced. The stirring main machine is lowered to the ground for installation through the deformation design, then the concrete is lifted and discharged through a concrete lifting discharging trolley, the height of the main body is further reduced; the structure of a powder material storagebin adopts a large-diameter vertical cylindrical bin structure, so that the height of the powder material storage bin is reduced, the height of the whole stirring station is greatly reduced, If the construction site has a factory building, the equipment can be arranged in the factory building, the factory building heating can solve the stirring of concrete in winter in the severe cold area, a dust removal device is arranged on the factory building, namely, and the dust removal device can effectively solve the problem of environmental pollution caused by flying dust.

Owner:中国人民解放军火箭军士官学校

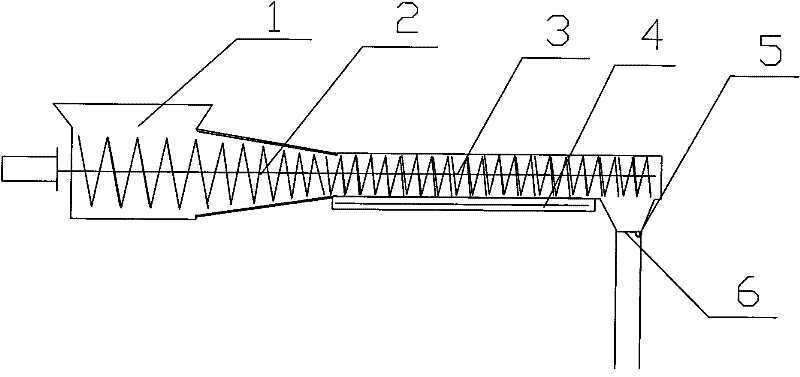

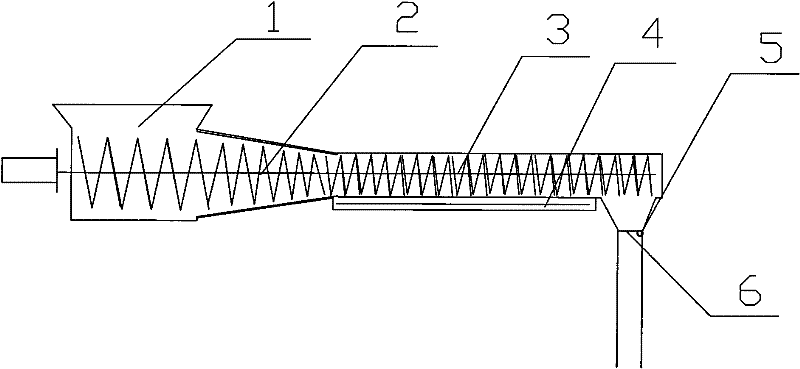

Spiral medicine addition device

InactiveCN102241322APrevent re-cakingSmooth entryPackagingConveyor partsEngineeringMechanical engineering

The invention provides a spiral medicine addition device capable of smoothly conveying moisturized medicine powder such as moisturized dry powder and the like. The spiral medicine addition device comprises a feeding hole, a conveying section and a discharge hole, wherein a conveying screw rod is arranged in the conveying section; an opening which has a gradually decreased cone shape is formed at the connection position between the conveying section and the feeding hole; and a heating device is arranged on the conveying section. In the conveying process, the medicine addition device can pulverize caked materials and can heat the materials to make the materials loosened; and after the conveying process is finished, the materials cannot be moisturized by external moisture, so that medicines can be smoothly and efficiently added.

Owner:JIANGSU QINGYI ENVIRONMENTAL PROTECTION EQUIPCO

Multifunctional protection device for trees

ActiveCN108551965AImprove stabilityReduce decomposition rateCultivating equipmentsHorticulture methodsNutrientAnti theft

The invention discloses a multifunctional protection device for trees. The device comprises a base, and the base is formed by splicing at least two base bodies; each base body comprises an upper fixation layer plate, a middle transition layer plate and a lower support layer plate, a reinforcing plate is fixed between the outer walls of each middle transition plate and the corresponding lower support layer plate, support rods are installed on the reinforcing plates, and wood protection plates are hinged to the upper ends of the support rods; each wood protection plate is fixedly provided with at least one second lock lug, the second lock lugs of every two adjacent wood protection plates are connected through a lock chain, each lock chain is provided with a hanging lock, and a nutrient conveying device is installed on one or more wood protection plates. According to the multifunctional protection device, sufficient support can be provided for the middles, lower portions and roots of thetrees so that the trees can bear external force; moreover, the device has a certain anti-theft function, and the trees can be prevented from being transplanted, pulled up or cut off; meanwhile, nutrition bags are convenient to hang, a layer of protection is provided for the nutrition bags, and therefore the smooth implementation of the nutrient conveying work is ensured.

Owner:绍兴市米莉农业科技有限公司

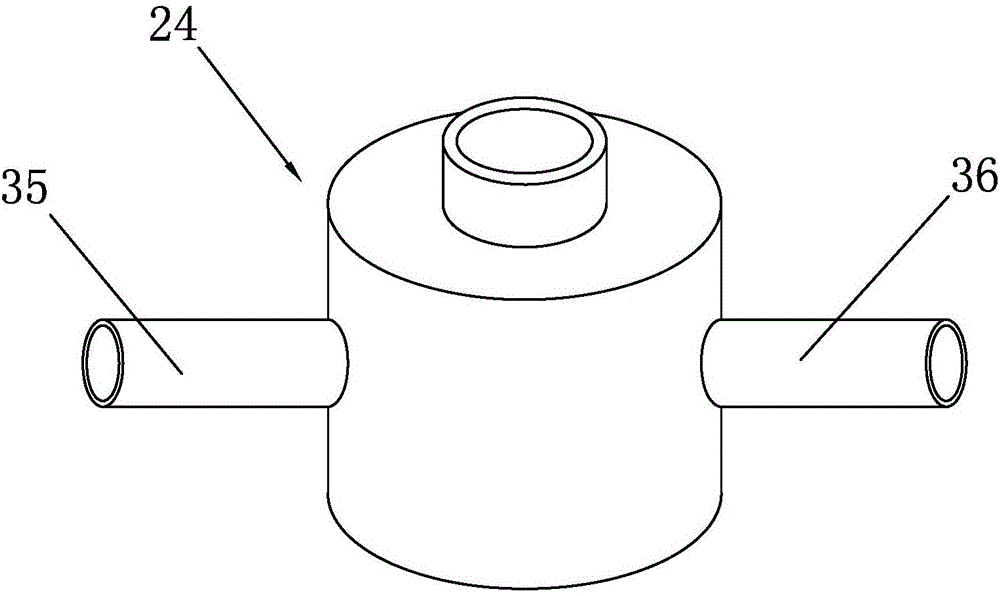

Horizontal type liquid storage device and installation method thereof

The invention discloses a horizontal type liquid storage device and an installation method thereof. The horizontal type liquid storage device comprises a liquid storage device barrel and an installation fixing rack, wherein an air inlet, an oil return hole and an air outlet are formed above the liquid storage device barrel; the liquid storage device barrel is internally provided with a buffer tube and a treating barrel, and the treating barrel is connected with the buffer tube by an air inlet pipe; an outlet of the treating barrel is connected with the air outlet by an air outlet pipe; the installation method comprises the following steps: (1) preparatory work; (2) installation of parts in the liquid storage device barrel; (3) installation between the liquid storage device barrel and a left seal cover as well as a right seal cover; (4) installation between the liquid storage device barrel and the installation fixing rack; (5) connection and fixation between the liquid storage device and a compressor. The horizontal type liquid storage device is simple in structure and high in practicality; by improving an internal structure of the horizontal type liquid storage device, the work stability of a whole refrigerating system is improved; furthermore, by the design of the installation fixing rack, the horizontal type liquid storage device is more conveniently installed and fixed, and the structural design of the horizontal type liquid storage device is more reasonable.

Owner:新昌县行峰制冷配件厂

Machine for automatically making milk powder

InactiveCN101480315AStable deliveryGuaranteed ratioBeverage vesselsFeeding-bottlesWater storageEngineering

The invention relates to an automatic powdered milk mixing machine which comprises a shell, a water storage container, a pump and a powdered milk container, wherein the pump comprises a water inlet pipe and a water outlet pipe, and the water inlet pipe is connected with a water outlet of the water storage container; and the bottom of the powdered milk container is provided with a powdered milk outlet which is provided with a powdered milk discharging device. The automatic powdered milk mixing machine is characterized in that the powdered milk discharging device comprises a motor and a ball body which can uni-directionally rotate, the ball body can be rotatably connected to the powdered milk outlet, a rotating shaft of the ball body is connected with the output shaft of the motor, moreover, the ball is circumferentially provided with ratchet teeth which outwards extend along the rotating direction of the ball body and are used for containing and conveying powdered milk. Compared with the prior art, the invention improves the powdered milk discharging device and changes the traditional screw discharging device into the ball body device which can be directly arranged on the powdered milk outlet of the powdered milk container and can uni-directionally rotate; the ball body is circumferentially provided with the ratchet teeth which can contain the powdered milk and realize the powdered milk transportation, the powdered milk can not be deposited or blocked on the ball body, and the powdered milk is more smoothly conveyed.

Owner:俞安烊

Traditional Chinese medicine material hoister with transportation quantity convenient to control

InactiveCN106516582ANo changeTo achieve the purpose of quantitative deliveryConveyorsLoading/unloadingDrive shaftEngineering

The invention relates to a traditional Chinese medicine material hoister with the transportation quantity convenient to control. Sliding wheels are mounted at the bottom end of a rack. A left protection plate and a right protection plate are obliquely mounted on the rack. The horizontal section of the left protection plate and the horizontal section of the right protection plate are mounted on threaded adjustable supporting legs. A discharging support is mounted on the top face of the horizontal section of the left protection plate and the top face of the horizontal section of the right protection plate and provided with a discharging funnel. A hopper is mounted under the discharging funnel and arranged between two conveying belts. The conveying belts are connected with a driving shaft and a driven shaft at the same time. The driving shaft is connected with a motor, and the motor is fixedly mounted on the side face of the right protection plate. According to the hoister, automatic feeding can be achieved, traditional Chinese medicine materials are conveyed to a higher position from a lower position, and therefore manual operation is saved; and when granular traditional Chinese medicines are transported, the transportation quantity of every time can be controlled, and it is guaranteed that the transportation quantities of all times are approximately identical.

Owner:HUBEI KUNYAN PHARMA

Logistics good sorting device

PendingCN111715536AAvoid scratchingFast and efficient sortingSortingStructural engineeringMechanical engineering

The invention discloses a logistics good sorting device. The device includes a sorting tank body, a sorting chamber is arranged in the sorting tank body, a first conveyer belt, a second conveyer belt,a third conveyer belt, a fourth conveyer belt, and a fifth conveyer belt are arranged on four sides of the sorting tank body, an alignment device is arranged on the second conveyer belt, a handling structure is arranged above one end of the first conveyer belt at a top end of the sorting chamber, and a pushing structure is arranged on the middle of the top end of the sorting chamber. According tothe logistics good sorting device, a storage device is arranged, goods on conveyer belts are pushed through a fixing stop plate so that the goods are located on the middle of the conveyer belts, thestatement of occurrence of scratching between logistics and a conveyer belt fixing rack can be prevented, the device is comparative convenient, coordination between the pushing structure and a rotation device can make sorting more quick and efficient, the statements that the goods directly drop to the rotation device and are damaged are prevented, the conveyer efficiency is guaranteed, and the device is practical.

Owner:长兴正力物流设备有限公司

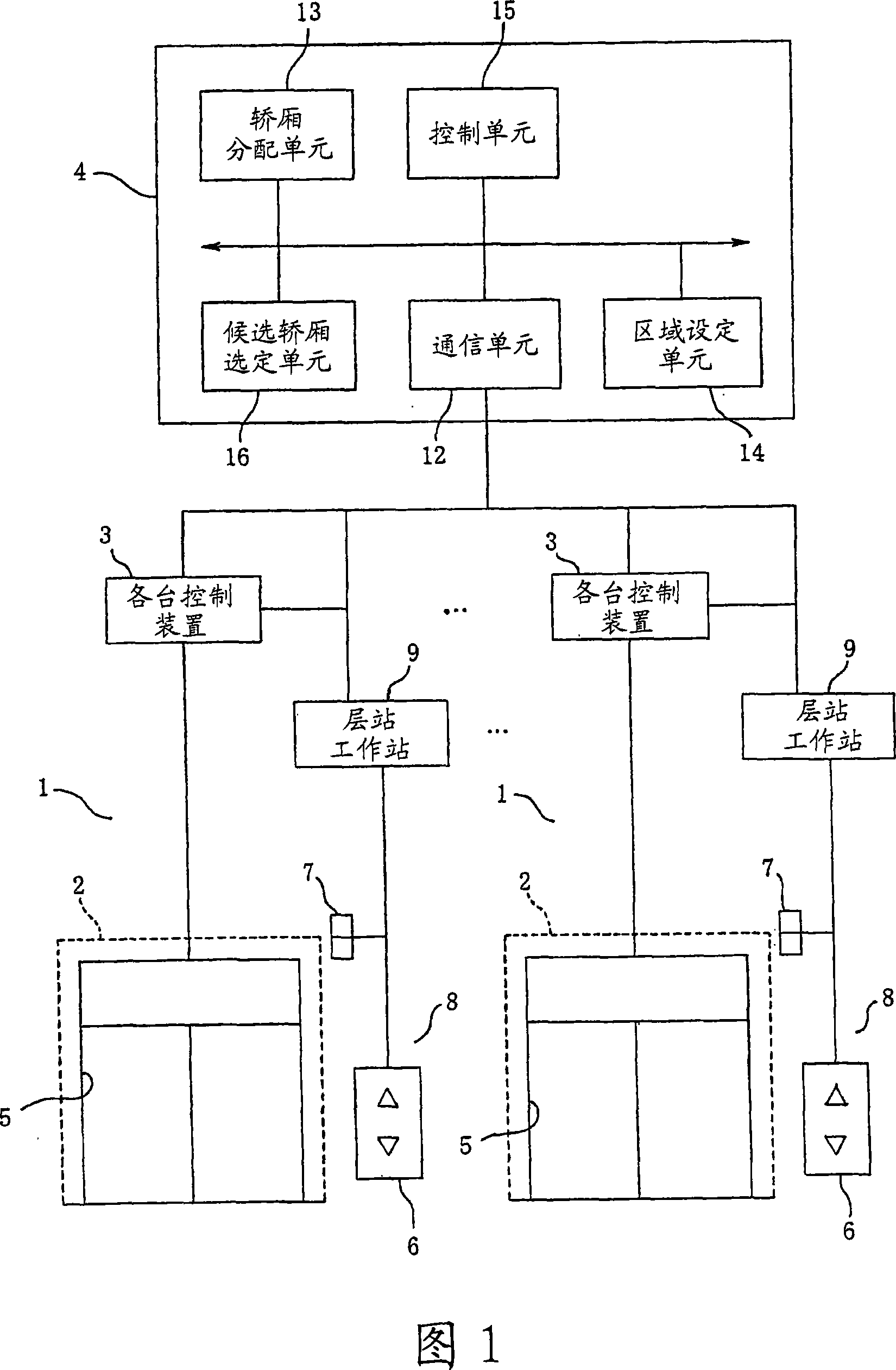

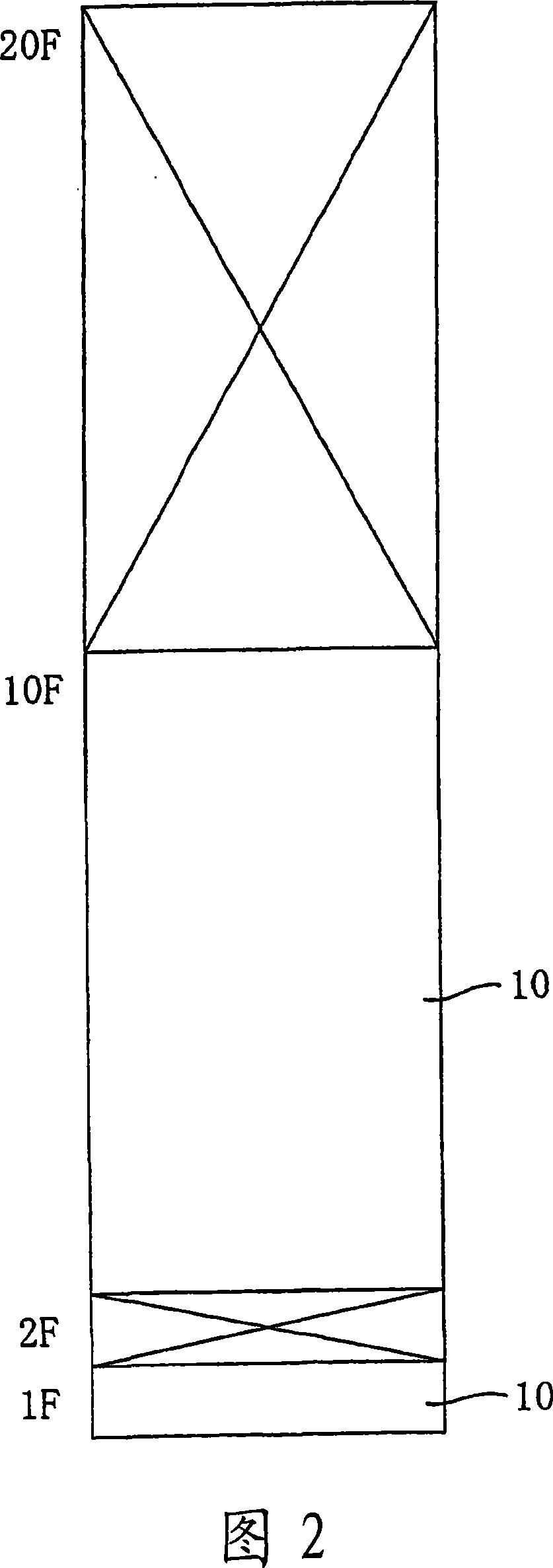

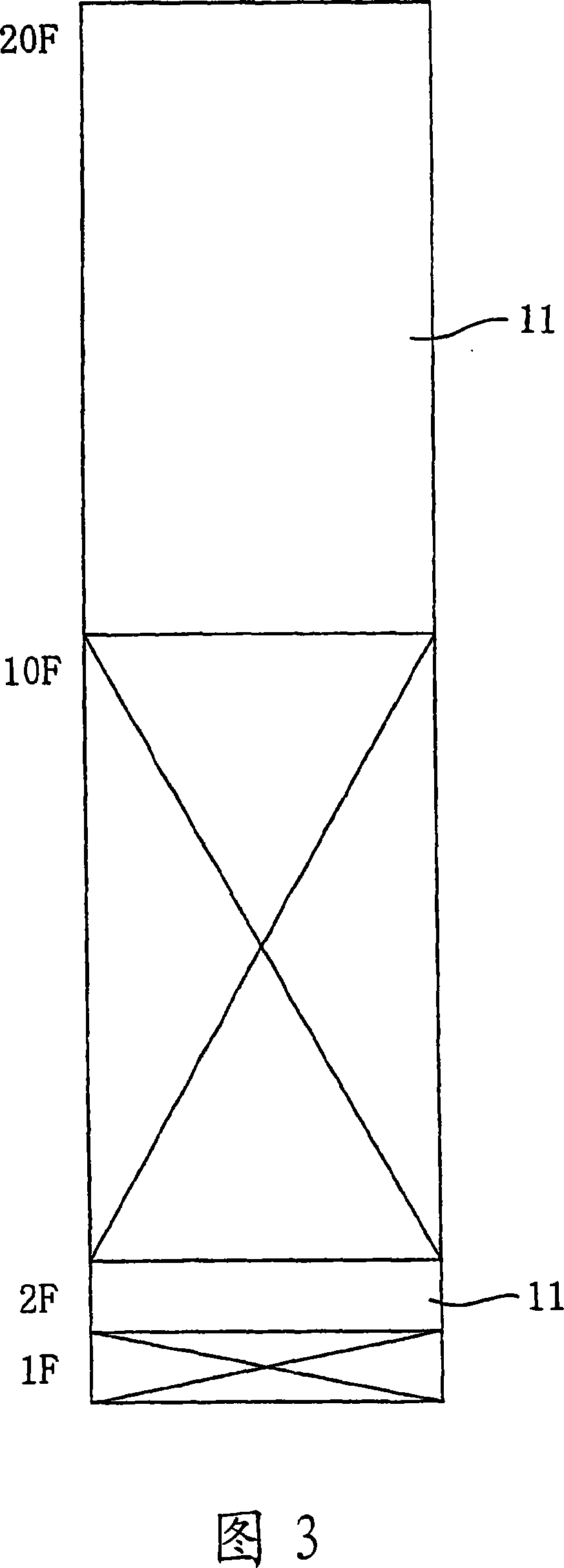

Elevator group management controller

A method of balancing a user's input to an interactive computer program with the program's output is obtained by continually measuring the difference between the user's input and the program's output and adjusting one or more parameters of the program's output so that the difference from the user's performance is progressively reduced. The adjustment may be obtained dynamically through negative feedback dampening of the measured difference (delta) between user input and program output, and / or by selection of predetermined apposite values for program output corresponding to the measurement of user input. The adjustment results in dynamic generation and / or selection of premodeled segments of interactive output in closer balance with user input. The adjustment method can be applied to video games, educational games, productivity programs, training programs, biofeedback programs, entertainment programs, and other interactive programs. In video games, the adjustment method results in balancing user performance with game difficulty for a more engaging game experience. It can also enable embedded advertising to be triggered when the user is in an optimum state of engagement. The adjustment method may be performed by projecting future trends of user performance, selecting predetermined or dynamically determined levels of value, modifying user control of input devices, or even modifying the program's challenges to user capability over time.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com