A logistics vehicle scheduling area optimization method for a mixed model assembly line with an uncertain demand

A logistics vehicle and area optimization technology, applied in logistics, data processing applications, resources, etc., can solve problems such as weak real-time control capabilities, unstable production conditions, and changes in delivery dates that affect market demand, and achieve the effect of improving computing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

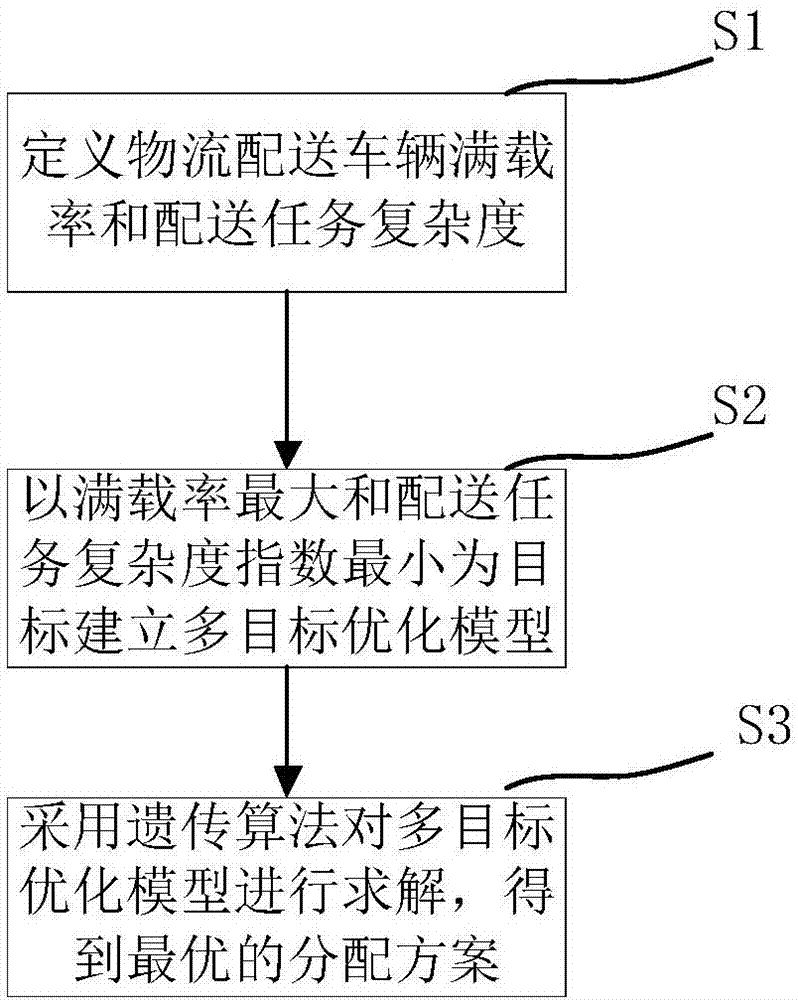

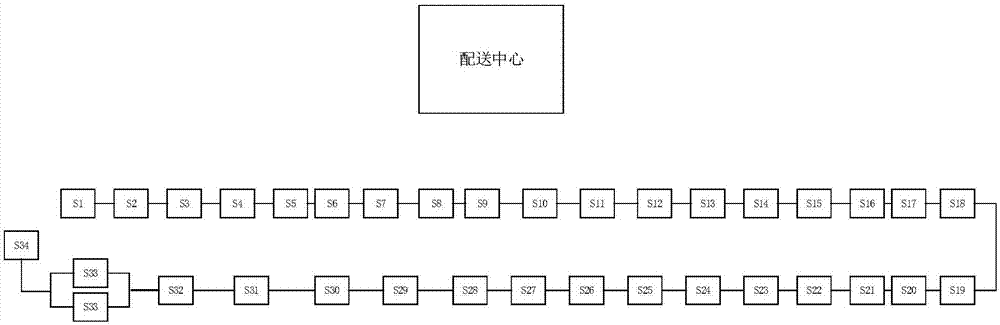

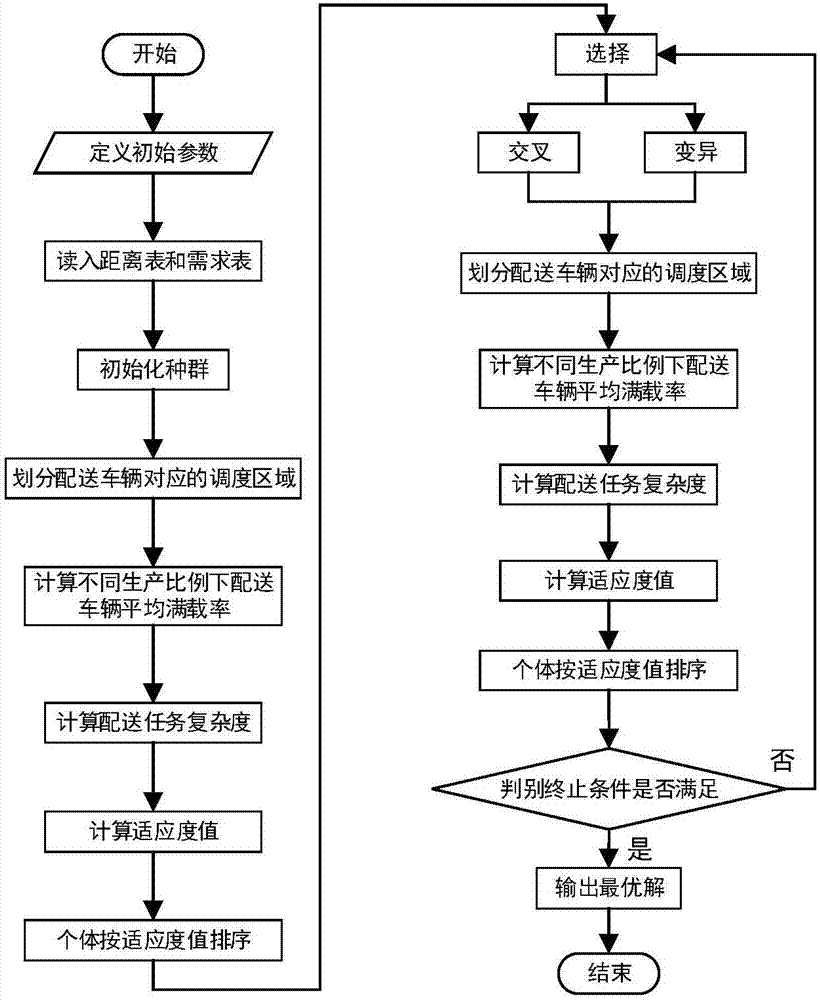

[0056] The basic idea of the present invention is to consider the full load rate in the logistics distribution vehicle scheduling process of the mixed-flow assembly line as the optimization index of the distribution efficiency, introduce the information entropy theory at the same time, define the complexity measurement of the distribution task complexity, design an intelligent algorithm, and satisfy the constraint conditions Under the premise of , the maximum full load rate and the minimum distribution task complexity are pursued through appropriate scheduling area division.

[0057] (1) Demand uncertainty analysis of mixed flow assembly line

[0058] Traditional production scheduling is carried out under the precondition of complete information. The research object has the characteristics of determinism and staticity. However, in actual work, the acquisition of information is not timely or complete. For example, temporary order insertion and delivery date changes will aff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com