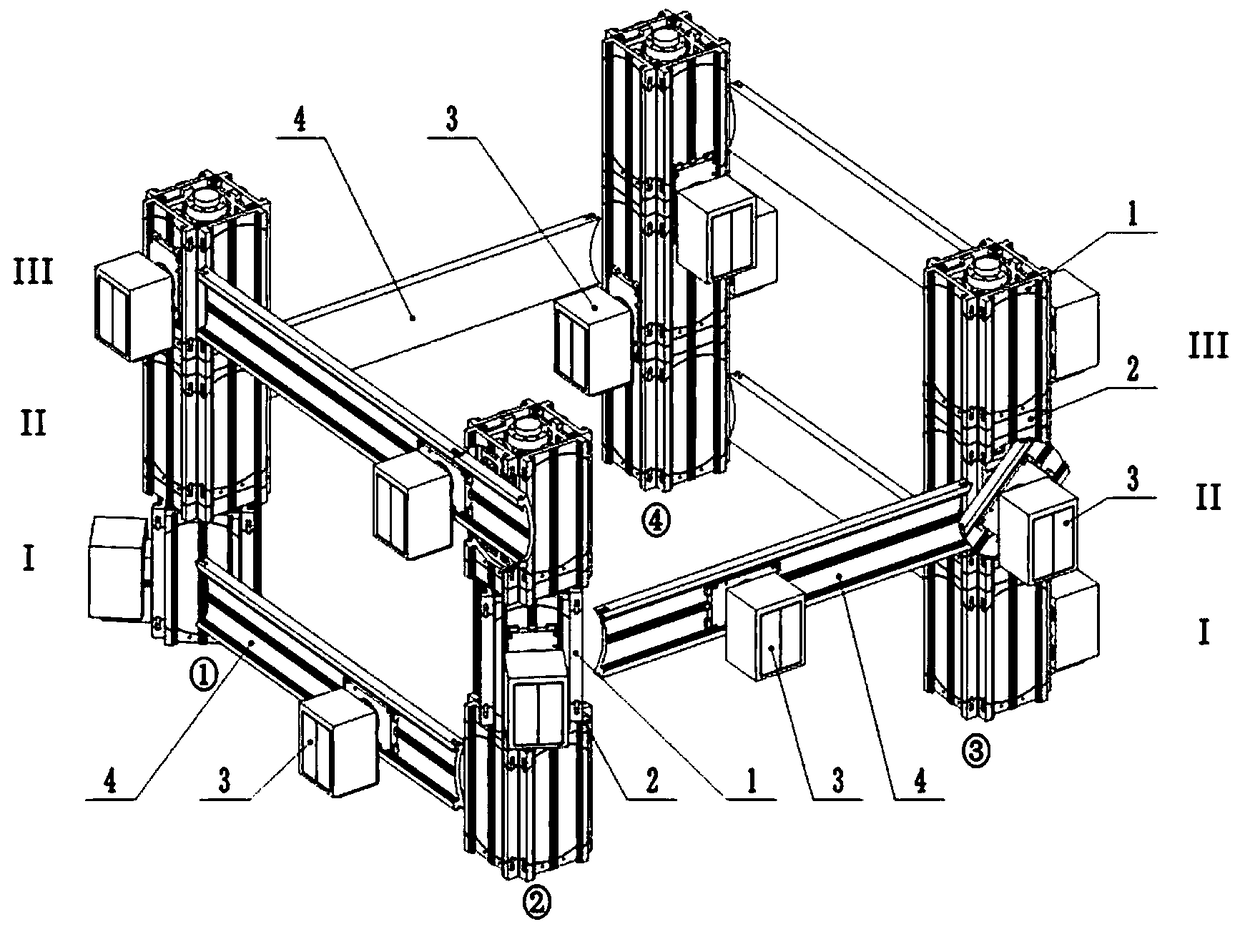

Multi-car three-dimensional circular elevator system and coordinated operation method

A three-dimensional circulation, elevator system technology, applied to elevators, transportation and packaging, elevators and other directions in buildings, can solve problems such as not seen, achieve good use effect, improve convenience, and ensure the effect of rail change action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

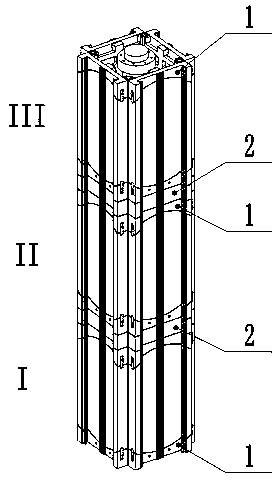

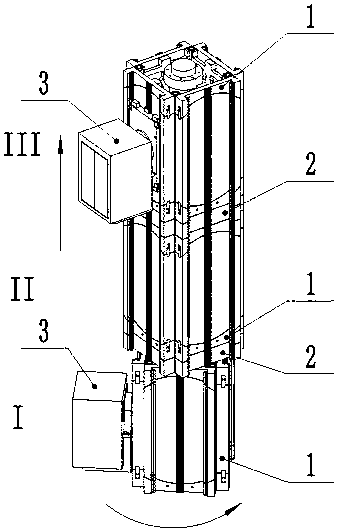

[0056] A multi-car three-dimensional circulation elevator cooperative operation method, such as Figure 26 As shown, the car runs from position {I①A} to position {III③B}, and its path is: move horizontally from position {I①A} to position {I②A} via track (1), and the small circulation rack at {I②} Component module 1 performs a small cycle of inverting the track by 90°, changing the track of the car to the position {I②B}, moving vertically along the {②B} plane to the position {II②B}, and horizontally moving to the position {II③B via the track (3) }, moving vertically along the {③B} plane to the position {III③B}, which can be simplified as {I①A}→orbit (1)→{I②A}→{I②B}→{II②B}→orbit (3)→{II③B} →{III③B}.

[0057] At the initial moment, the car component module 3 carrying the studied car (hereinafter referred to as the car component module 3) is located at the position {I①A}, the telescopic rod of the first positioning mechanism 306 is in the retracted state, and the telescopic rod of...

Embodiment 2

[0096] A multi-car three-dimensional circulation elevator cooperative operation method, such as Figure 27 As shown, the car runs from the position {II①B} to the position {I③A}, and its path is: the small cycle rack assembly module 1 located at {II①} performs a small cycle along the track by 90°, and the car moves from the position {II①B } to position {II①A}, move vertically down to position {I①A} along {①A} plane, move horizontally to position {I②A} via track (1), the small circulation rack at {I②} Component module 1 performs a small cycle inverter rail 90°, transforms the car from position {I②A} to position {I②B}, moves vertically along {②B} to position {II②B}, and passes through the track (3) Move horizontally to position {II③B}, move vertically down to position {I③B} along {③B} plane, the small circulation rack assembly module 1 located at {I③} performs a small circulation along 90°, and the car moves from Transform from position {I③B} to position {I③A}. Its path can be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com