Package pressing conveying structure applicable to packaging machine

A packaging machine and conveying mechanism technology, applied in packaging, paper product packaging, transportation and packaging, etc., can solve the problems of low packing conveying efficiency, long conveying stroke and high maintenance cost, achieve high packing conveying efficiency and improve packaging. Efficiency and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

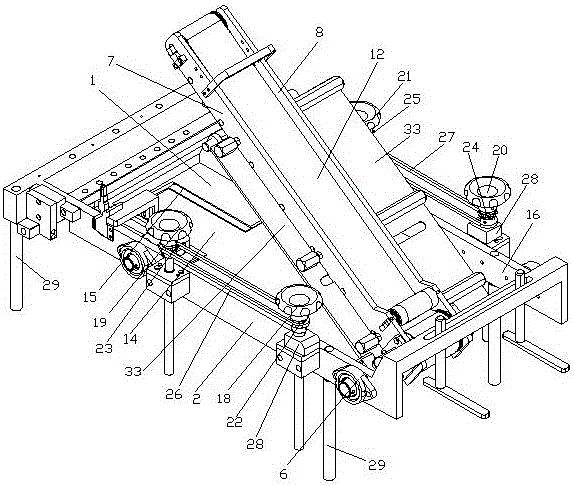

[0047] The compressed bag conveying structure suitable for packaging machines includes a pressed bag plate 1, a lifting gantry 2 and a conveying mechanism 3 driven by a power source. The conveying mechanism 3 is a one-piece structure, including an upper conveying part 4 and a lower conveying Part 5, the pressing plate 1 is arranged on the lifting gantry 2, one end of the upper conveying part 4 is hinged on the lifting gantry 2 through the hinge shaft 6, and the upper conveying part 4 is in contact with the pressing plate 1 , the upper conveying part 4 is located above the pressing plate 1 .

[0048] This embodiment is the most basic implementation. The conveying mechanism is a one-piece structure, including an upper conveying part and a lower conveying part. The pressing plate is arranged on the lifting gantry, and one end of the upper conveying part is hinged on the lifting gantry through a hinge shaft. , the upper conveying part is in contact with the pressing plate, and the...

Embodiment 2

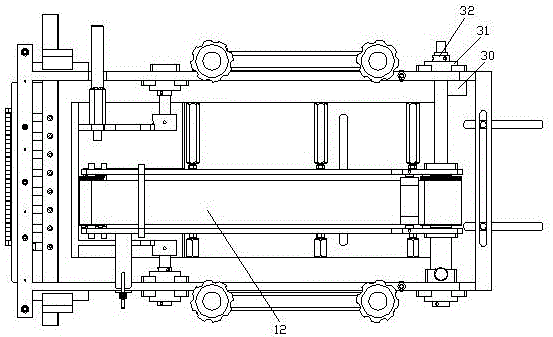

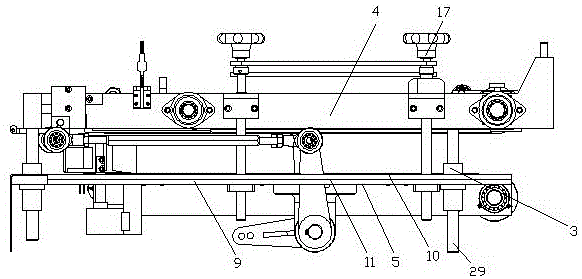

[0050] The compressed bag conveying structure suitable for packaging machines includes a pressed bag plate 1, a lifting gantry 2 and a conveying mechanism 3 driven by a power source. The conveying mechanism 3 is a one-piece structure, including an upper conveying part 4 and a lower conveying Part 5, the pressing plate 1 is arranged on the lifting gantry 2, one end of the upper conveying part 4 is hinged on the lifting gantry 2 through the hinge shaft 6, and the upper conveying part 4 is in contact with the pressing plate 1 , the upper conveying part 4 is located above the pressing plate 1 .

[0051] The upper conveying part 4 comprises a first supporting frame 7 and a second supporting frame 8, and the lower conveying part 5 comprises a third supporting frame 9, a fourth supporting frame 10 and a support frame arranged on the third supporting frame 9 and the fourth supporting frame 10. The support plate 11 is located between the third support frame 9 and the fourth support fra...

Embodiment 3

[0054] The compressed bag conveying structure suitable for packaging machines includes a pressed bag plate 1, a lifting gantry 2 and a conveying mechanism 3 driven by a power source. The conveying mechanism 3 is a one-piece structure, including an upper conveying part 4 and a lower conveying Part 5, the pressing plate 1 is arranged on the lifting gantry 2, one end of the upper conveying part 4 is hinged on the lifting gantry 2 through the hinge shaft 6, and the upper conveying part 4 is in contact with the pressing plate 1 , the upper conveying part 4 is located above the pressing plate 1 .

[0055] The upper conveying part 4 includes a first support frame 7 and a second support frame 8 .

[0056] The upper conveying part 4 also includes an upper synchronous belt 12, and the upper synchronous belt 12 is arranged between the first supporting frame 7 and the second supporting frame 8, and the lower conveying part 5 includes a third supporting frame 9, a fourth supporting frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com