Arrangement equipment for packaging with supporting and sending device

A conveying device and equipment technology, which is applied in the field of packing and sorting equipment, can solve the problems of loud equipment operation, uneven up and down, and uneven stacking, and achieve the effects of good coordination, equipment simplification, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

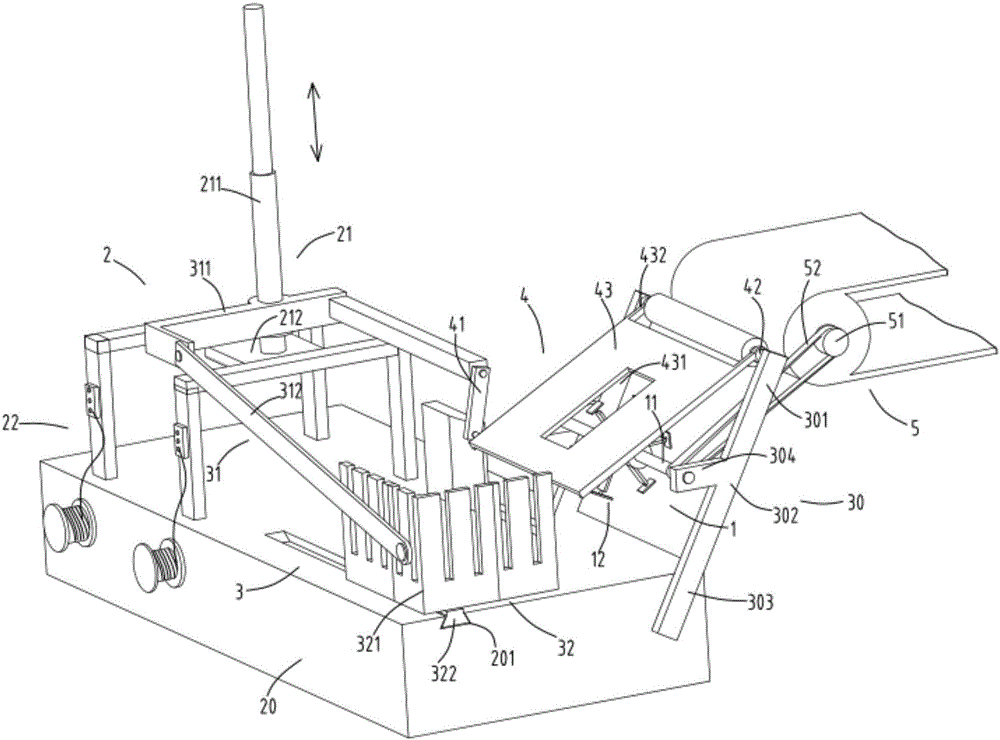

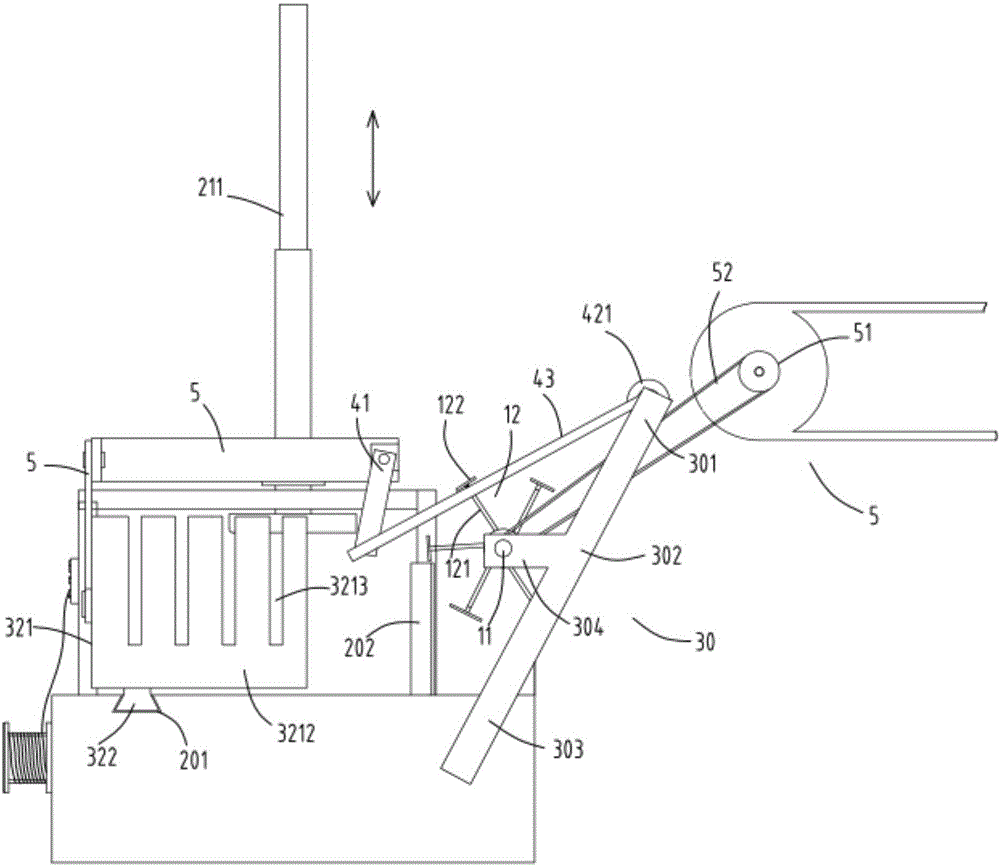

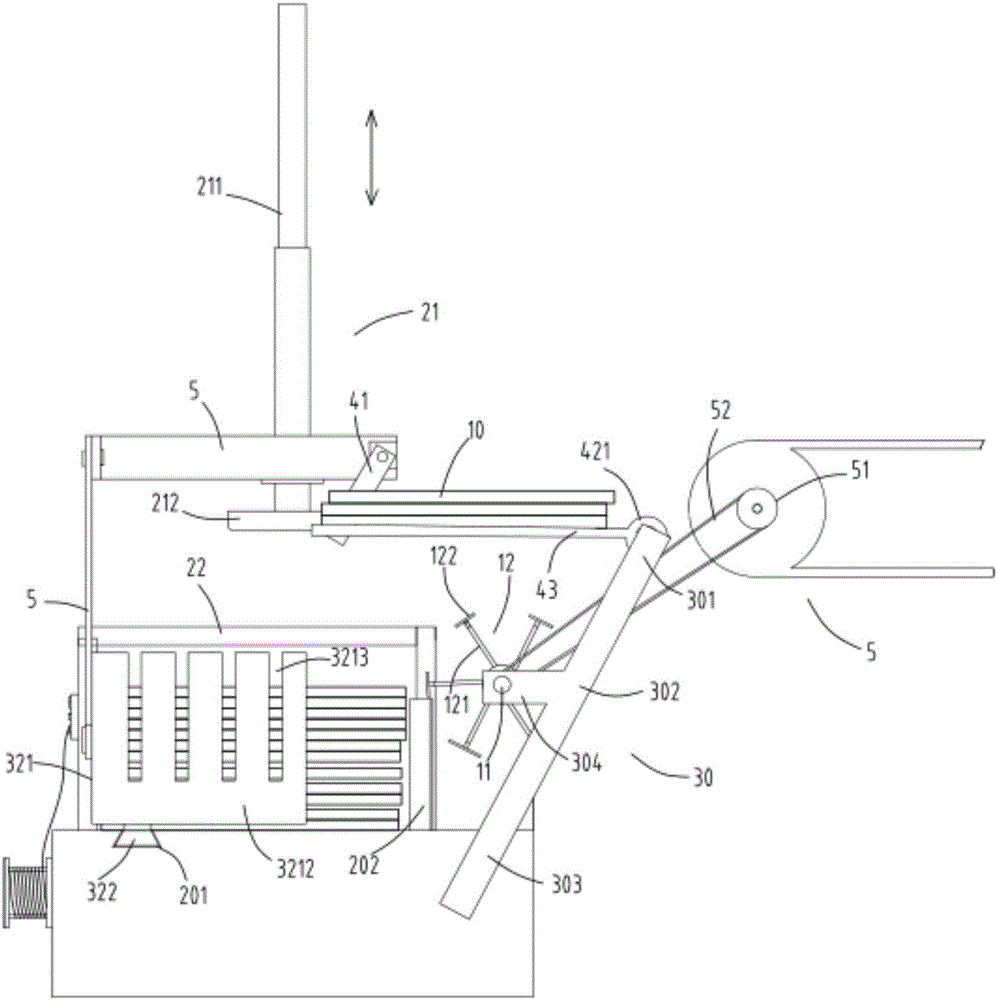

[0038] figure 1 is a schematic diagram of a finishing equipment for packing with a carrier device, figure 2 It is a schematic diagram of the front view when the baffle plate of the packaging finishing equipment with the palletizing device is connected to the position of stacking cartons, image 3 It is a schematic diagram of the front view when the baffle of the packaging finishing equipment with the supporting device drives the carton to move to the pressing device, Figure 4 It is a schematic diagram of part of the structure of the sorting equipment for packaging with a pallet delivery device, Figure 5 is a schematic illustration of cartons stacked on a carrier plate as they slide down an incline without a pallet, Figure 6 It is a schematic diagram of the cartons stacked on the carrier plate when the pallet is used and slides down, Figure 7 It is a schematic diagram of the structure of the supporting device. Such as figure 1 , figure 2 , image 3 , Figure 4 , ...

Embodiment 2

[0055] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that the middle position of the support plate 122 of the support unit 12 is rotatably arranged at the end of the support rod 121 through the rotating part 123, more specifically, the support plate 122 can rotate around the rotating part 123 on the support rod 121 along the direction of carton 10 transmission. Compared with the support plate 122 in the first embodiment, in this embodiment, when the support rod 121 drives the support plate 122 to rotate to contact the carton 10 , the support plate 122 can automatically adjust the angle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com