Powder coating with bonding metal effect

A metal effect, powder coating technology, applied in the field of coatings, can solve the problems of electrostatic spraying construction difficulties, particle size, chargeability, specific gravity and other problems, and achieve the effect of less free content, good floating effect, and stable color difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

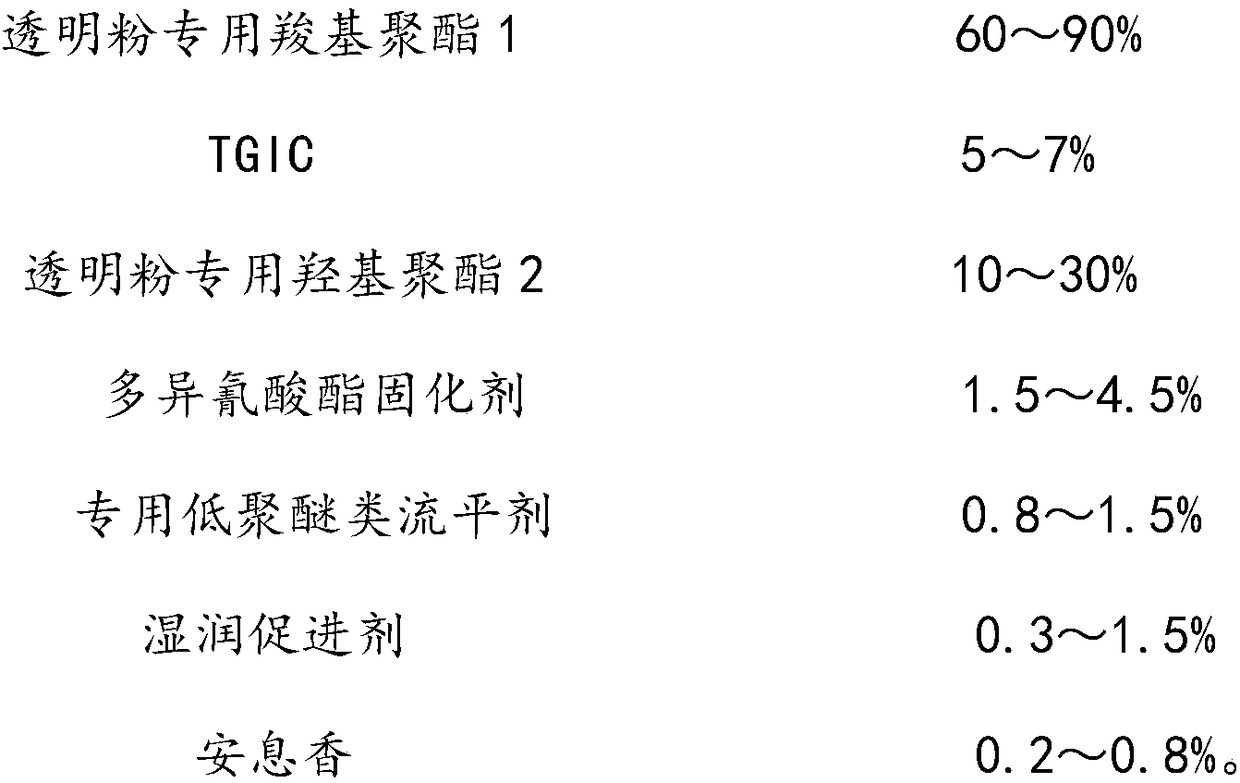

[0028] The composition of the transparent base powder is as follows:

[0029]

[0030]

[0031] Carboxyl polyester for transparent powder 1: SJ4213, product of Anhui Shenjian New Materials Co., Ltd.;

[0032] TGIC: product of Huangshan Huahui Technology Co., Ltd.;

[0033] Hydroxypolyester 2 for transparent powder: SJ1100, product of Anhui Shenjian New Material Co., Ltd.;

[0034] Polyisocyanate curing agent: VESTAGON BF 1530, product of German Evonic Company;

[0035] Special oligoethers leveling agent: 486CFL, the product of American Troy Company;

[0036] Wetting accelerator: 701B, product of Ningbo Nanhai Chemical Co., Ltd.;

[0037] Benzoin: a commercially available industrial grade product.

[0038] The preparation process of the bonding metallic effect powder coating comprises the following steps:

[0039] S1, preparation of transparent base powder

[0040] After distributing the ingredients of the transparent base powder, put them into a high-speed mixer ...

Embodiment 2

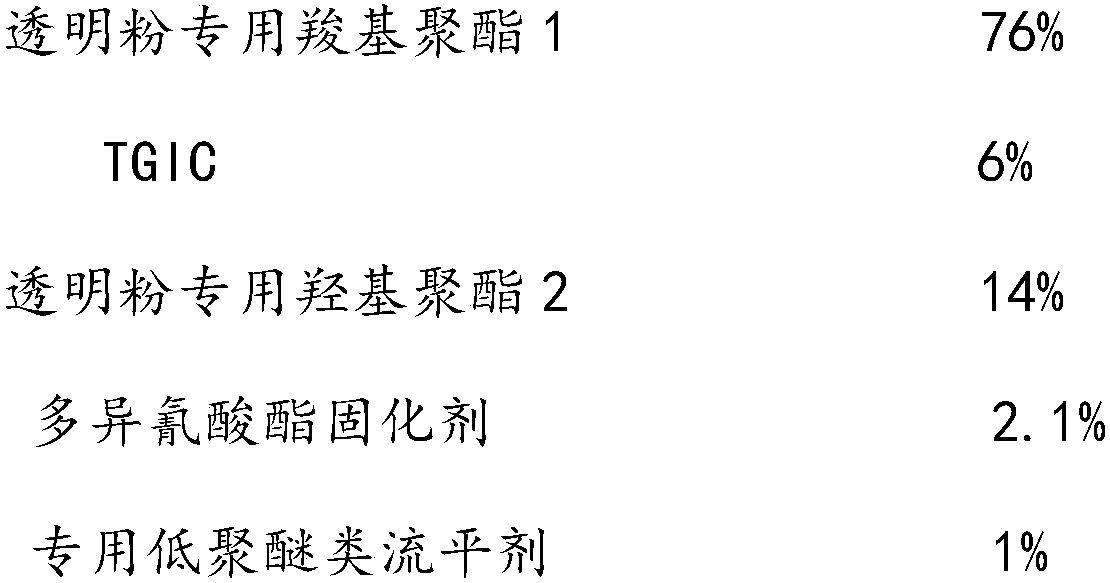

[0049] The composition of the transparent base powder is as follows:

[0050]

[0051]

[0052]Carboxyl polyester for transparent powder 1: SJ4213, product of Anhui Shenjian New Materials Co., Ltd.;

[0053] TGIC: product of Huangshan Huahui Technology Co., Ltd.;

[0054] Hydroxypolyester 2 for transparent powder: SJ1100, product of Anhui Shenjian New Material Co., Ltd.;

[0055] Polyisocyanate curing agent: VESTAGON BF 1530, product of German Evonic Company;

[0056] Special oligoethers leveling agent: 486CFL, the product of American Troy Company;

[0057] Wetting accelerator: 701B, product of Ningbo Nanhai Chemical Co., Ltd.;

[0058] Benzoin: a commercially available industrial grade product.

[0059] The preparation process of the bonding metallic effect powder coating comprises the following steps:

[0060] S1, preparation of transparent base powder

[0061] After distributing the various components of the transparent base powder, put them into a high-speed ...

Embodiment 3

[0067] The composition of the transparent base powder is as follows:

[0068]

[0069] Carboxyl polyester for transparent powder 1: SJ4213, product of Anhui Shenjian New Materials Co., Ltd.;

[0070] TGIC: product of Huangshan Huahui Technology Co., Ltd.;

[0071] Hydroxypolyester 2 for transparent powder: SJ1100, product of Anhui Shenjian New Material Co., Ltd.;

[0072] Polyisocyanate curing agent: VESTAGON BF 1530, product of German Evonic Company;

[0073] Special oligoethers leveling agent: 486CFL, the product of American Troy Company;

[0074] Wetting accelerator: 701B, product of Ningbo Nanhai Chemical Co., Ltd.;

[0075] Benzoin: a commercially available industrial grade product.

[0076] The preparation process of the bonding metallic effect powder coating comprises the following steps:

[0077] S1, preparation of transparent base powder

[0078] After distributing the various components of the transparent base powder, put them into a high-speed mixer and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com