Communication type no-handheld steel bar strapping machine and steel bar strapping automation equipment

A strapping machine and communication-type technology, which is applied in the field of steel bar binding, can solve the problems of easy to cause accidents, inapplicability, and easy to touch the steel bars on the other side, so as to achieve the effect of ensuring stability, great flexibility and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

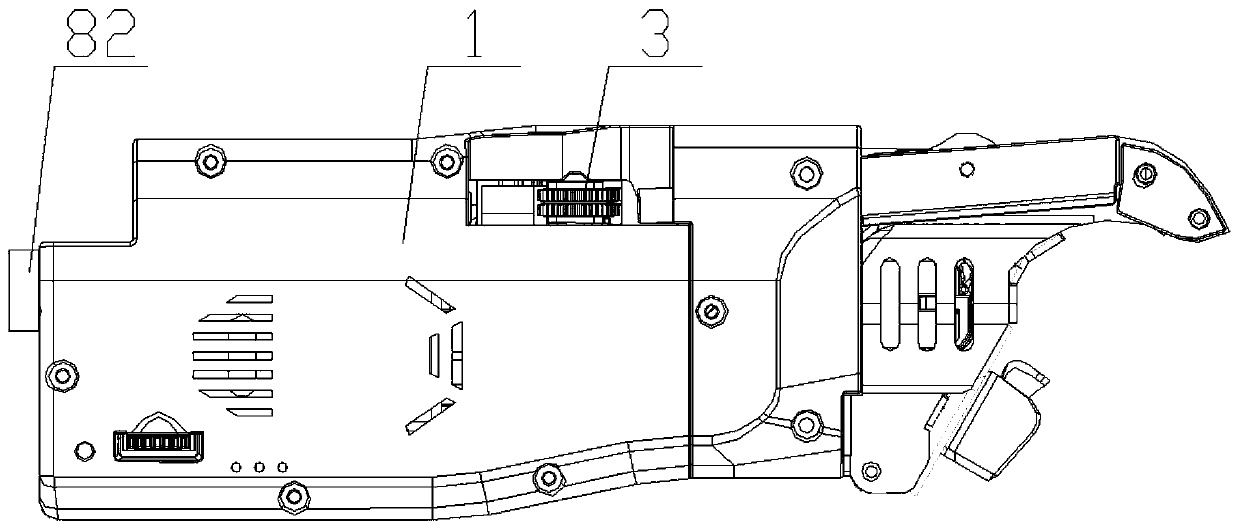

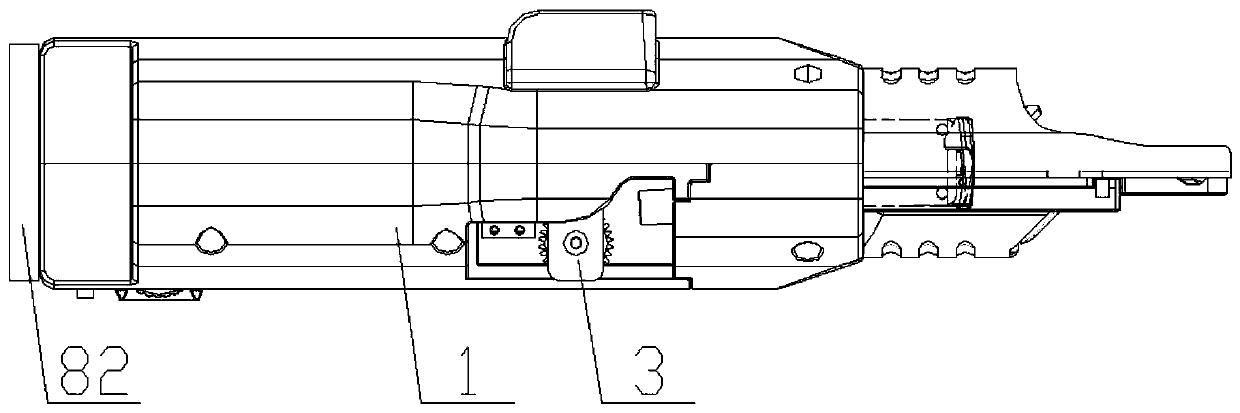

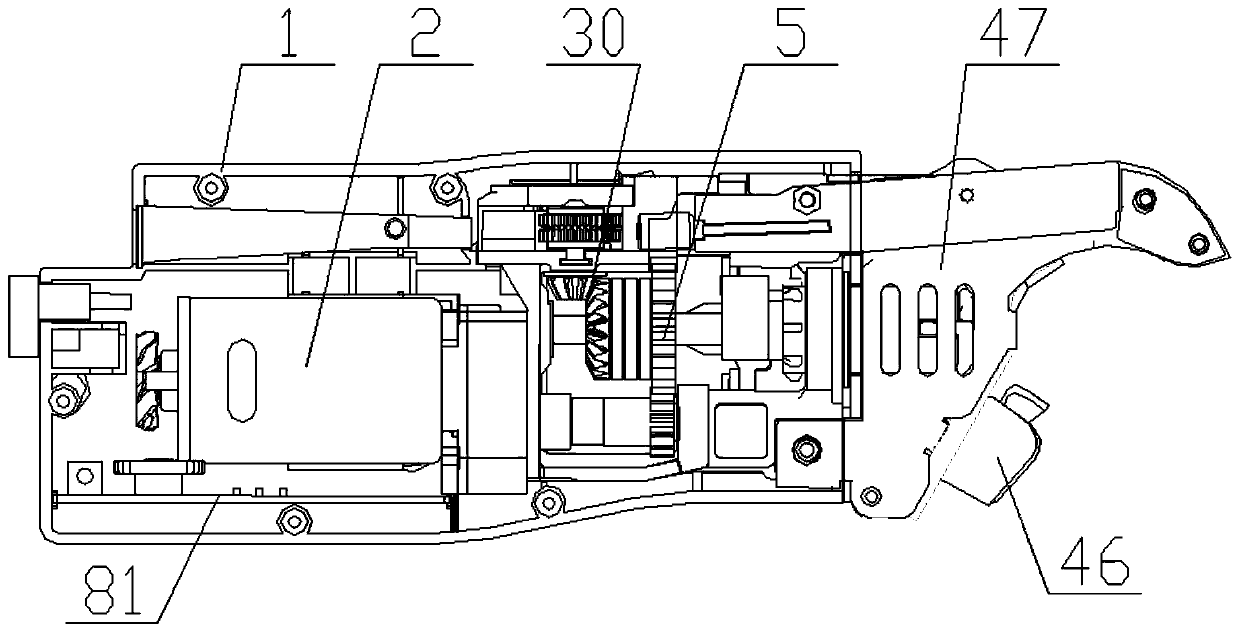

[0081] This embodiment discloses a communication-type non-handheld steel bar binding machine, which is small in size and suitable for automatic binding of various steel bar combinations. In addition, the non-handheld steel bar binding machine of this embodiment solves the problem The connection and fixation and communication problems of automation equipment make the steel bar binding machine and automation equipment better combined and synchronized.

[0082] In this example, if figure 1 , 2 And as shown in 3a to 3c, the communication-type non-handheld steel bar binding machine includes a casing 1, a main control unit 81, a motor 2, a wire feeding mechanism 3, a wire twisting mechanism 6 and a cutting mechanism 4, wherein:

[0083] The main control unit is connected to the motor for driving the rotation of the motor;

[0084] The motor 2 connects the wire feeding mechanism 3, the wire twisting mechanism 6 and the cutting structure 4 through the transmission system 5, and cont...

Embodiment 2

[0128] This embodiment discloses an automatic steel bar binding device, including a host computer, a robot arm, and the communication-type hands-free steel bar binding machine described in Embodiment 1.

[0129] In this embodiment, the host computer is a control system of the robotic arm, or the host computer is connected to the control system of the robotic arm, and is used to control the movement of the robotic arm. In this embodiment, the upper computer can be directly a device in the mechanical arm as the control system, or it can be an external device of the mechanical arm. In the latter case, the upper computer is connected to the control system of the mechanical arm, and the control system of the mechanical arm Control the movement of the mechanical arm according to the signal received from the host computer.

[0130] The host computer is connected to the main control unit of the steel bar binding machine, and is used to send control instructions to the main control uni...

Embodiment 3

[0141] This embodiment discloses the steel bar binding method realized by the steel bar binding automation equipment shown in embodiment 2, including steps:

[0142] 1) The upper computer controls the movement of the mechanical arm, so that the steel bar binding machine on the mechanical arm moves to the steel bar binding node;

[0143] 2) When the steel bar binding machine reaches the position of the steel bar binding node, the upper computer sends a control command to the main control unit, and the main control unit controls the binding work of the steel bar binding machine according to the received control command. In this embodiment, after receiving the control command sent by the host computer, the main control unit controls the motor to work, so as to control the wire feeding mechanism, the cutting mechanism and the wire twisting mechanism to work respectively, so as to realize the functions of wire feeding, cutting and twisting. process, thereby realizing the reinforcem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com