Omnidirectional wheel system and vacuum leak detection robot

An omnidirectional wheel and walking wheel technology, applied in the field of robots, can solve the problems of lack of compact and efficient walking mechanism, difficulty in walking of the leak detection robot, and limited volume of the leak detection robot, so as to achieve good leak detection effect, and realize automation and visualization. , the effect of high degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

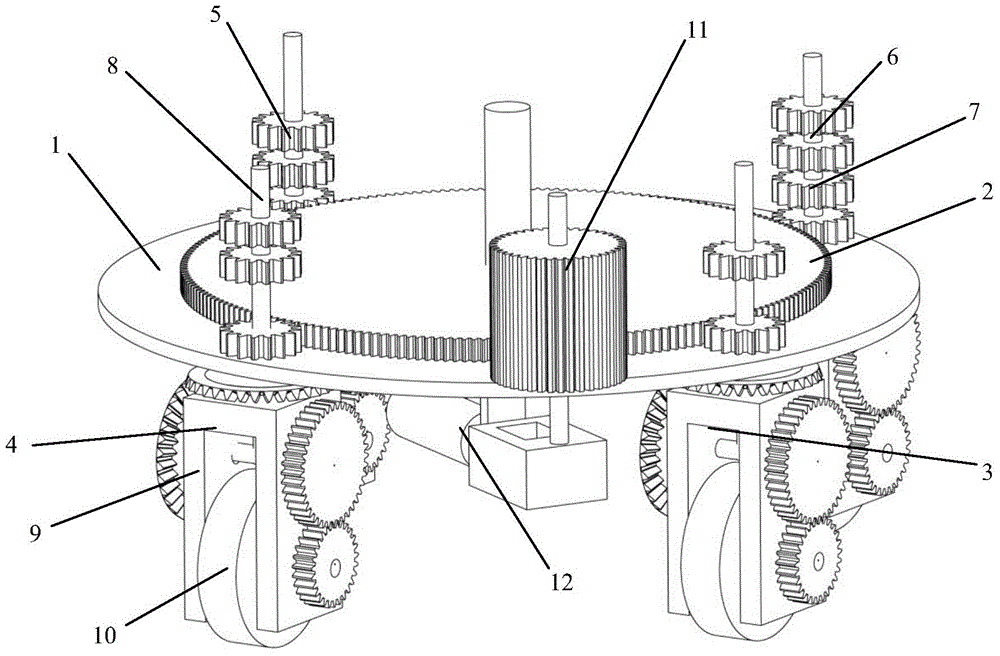

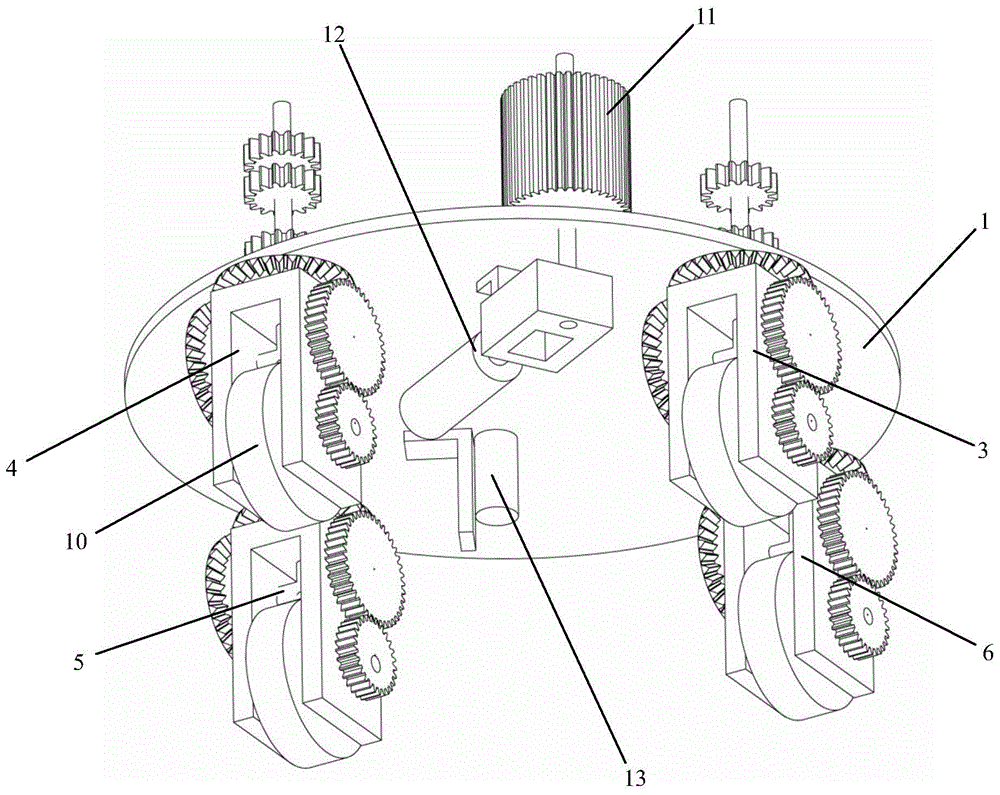

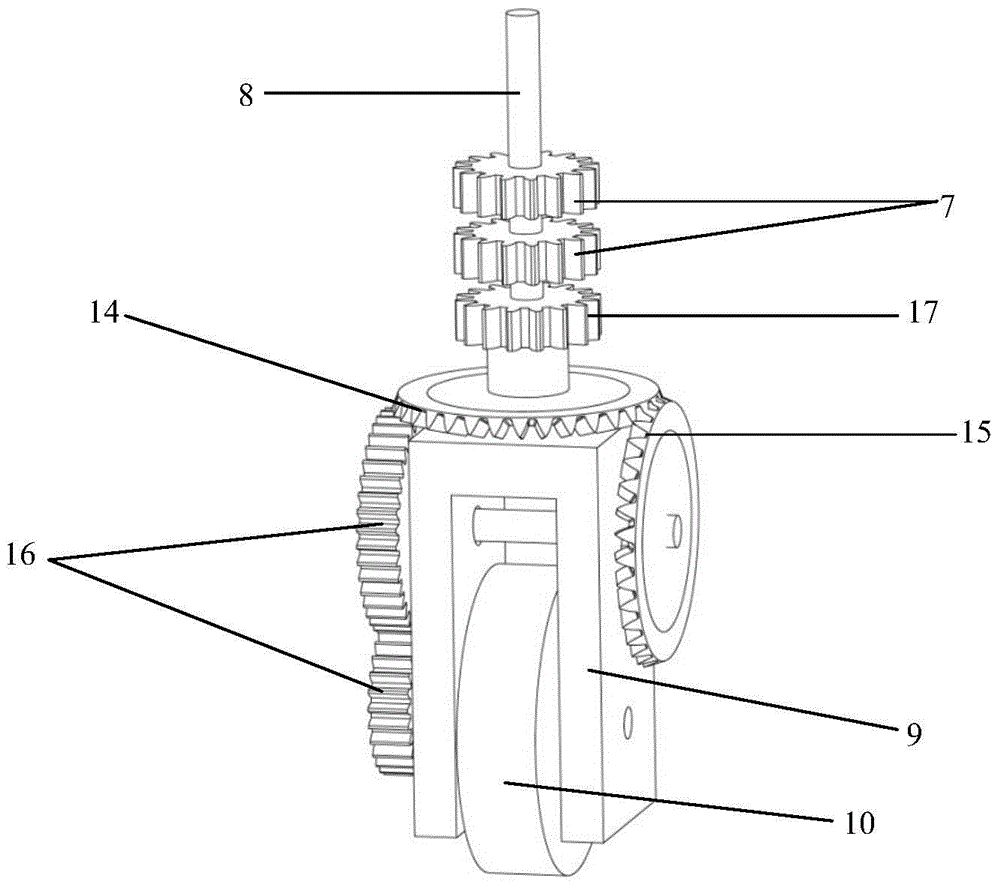

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail: as Figure 1 ~ Figure 3 As shown, an embodiment of the omnidirectional wheel train of the present invention includes a chassis 1, a power gear 2 that can rotate and move up and down in different height gears is arranged in the center of the chassis 1, and a vertical upward gear is arranged below the power gear 2. The electric push rod 13, the main body of the electric push rod 13 is arranged on the bottom of the chassis 1, and its elongated end passes through the through hole of the chassis 1, and the shaft of the power gear 2 is connected with the elongated end of the electric push rod 13 through a bearing; On the chassis 1, a driving gear 11 is provided with a bearing. The thickness of the driving gear 11 is consistent with the length of the electric push rod 13, and can be meshed with the power gear 2. The driving gear 11 is driven by the motor 12. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com