Lightweight active support structure of suspended circular-section flow passage

A support structure and circular section technology, applied in the field of additive manufacturing, can solve the problems of damage to the powder coating structure, failure of the manufacturing process, uneven powder coating, etc., and achieve the effects of increasing stability, shortening the manufacturing cycle, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The foregoing and other technical contents, features and effects of the present invention will be further described below in conjunction with the accompanying drawings.

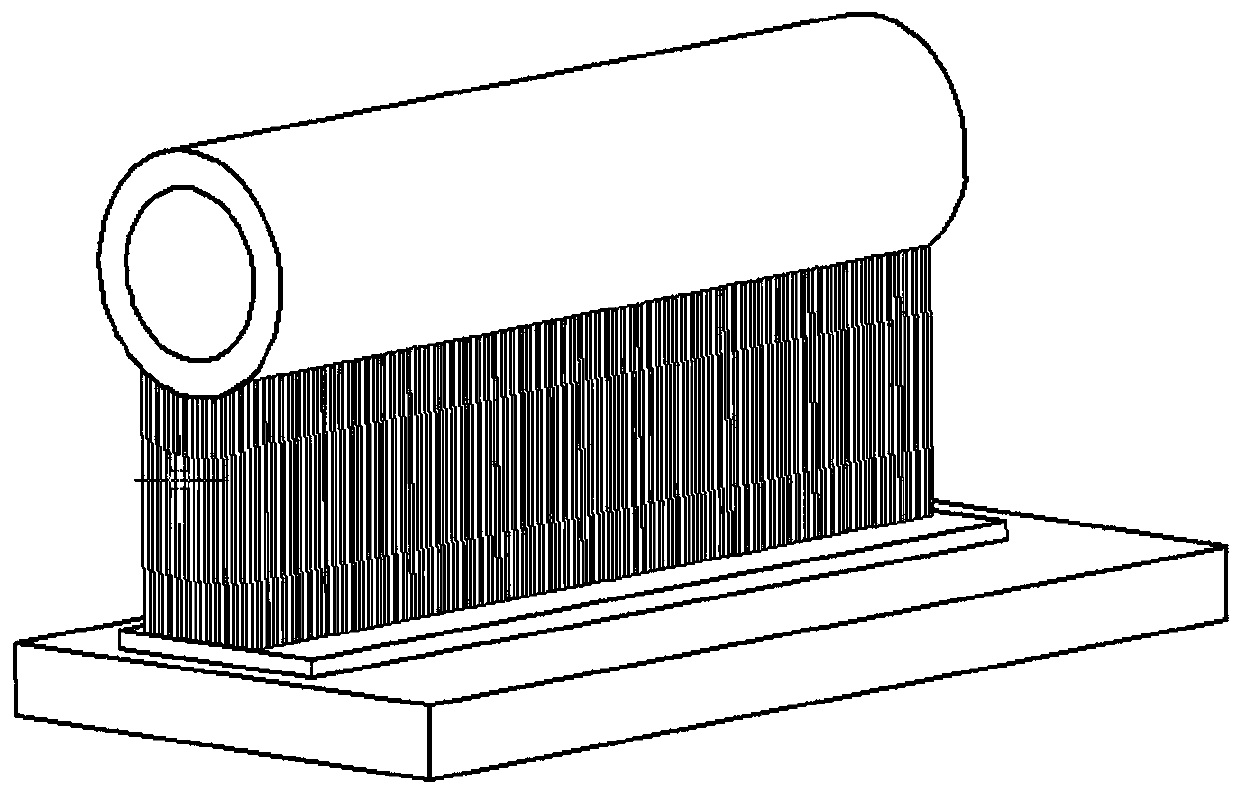

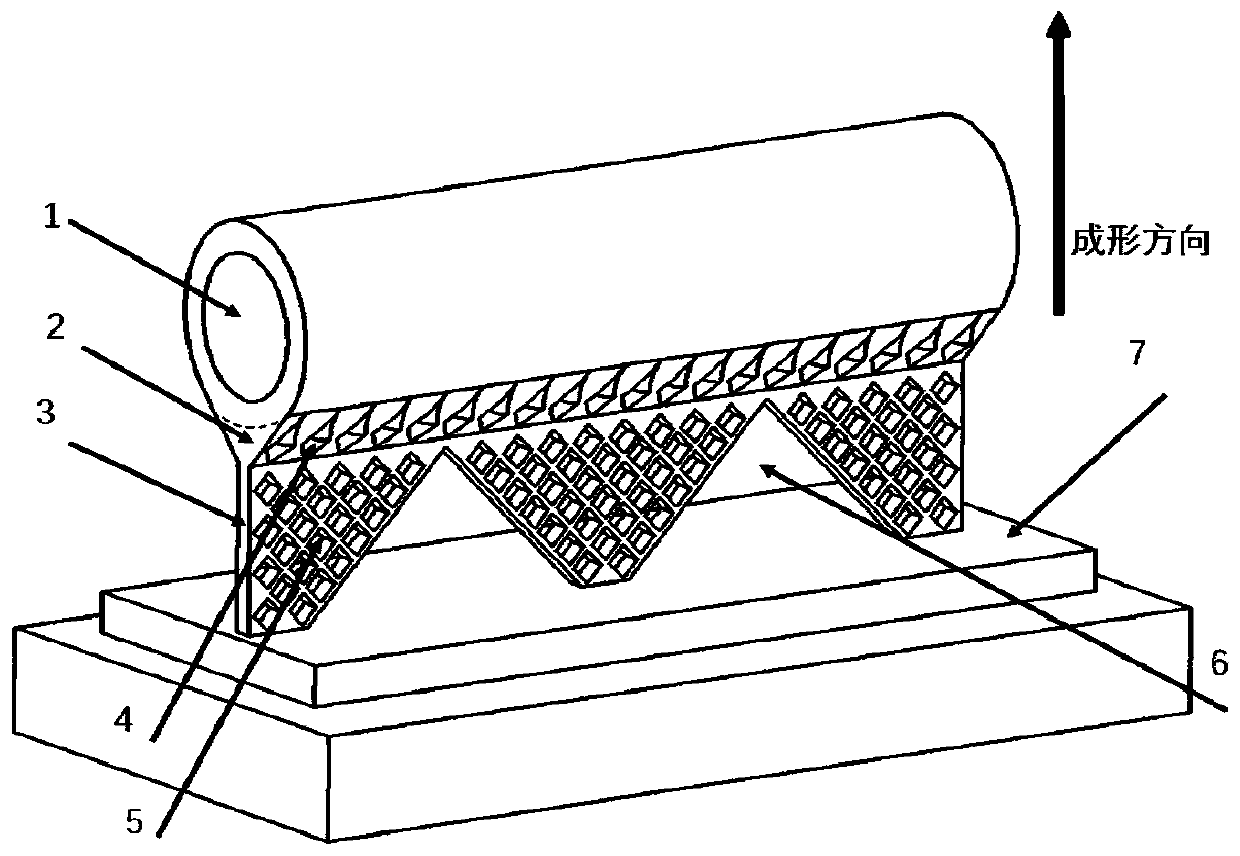

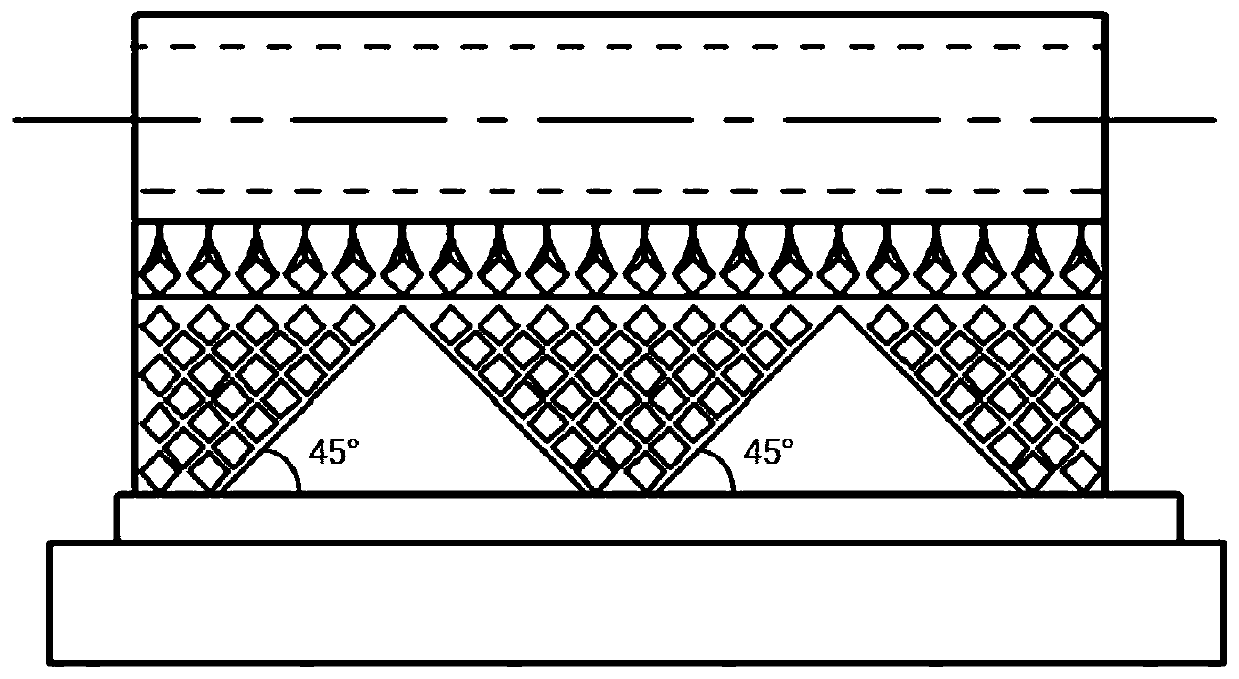

[0021] figure 1 Shown is the support structure generated by the preprocessing software in the SLM additive manufacturing process. The dangerous surface during the construction process, that is, the tangent angle of the semi-circular arc under the circular cross-section runner is less than 45°, which is all uniformly added. 状Support. The automatically generated block support is composed of uniform and dense linear supports inside. The linear support inside the block support is usually long and thin. When the temperature gradient is too large, it is prone to thermal warpage, which damages the powder spreading system and causes uneven powder spreading, which makes the manufacturing process fail. At the same time, the block support has a large volume, which increases the use of raw materials in the manufactur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com