Wide-line printer and ink supply system replacement method thereof

A replacement method and printer technology, applied in the direction of printing device, printing, etc., can solve the problems of difficult to clean sediment, ink waste, long ink delivery tube, etc., and achieve the effect of saving replacement time, reducing ink waste, and reducing ink waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

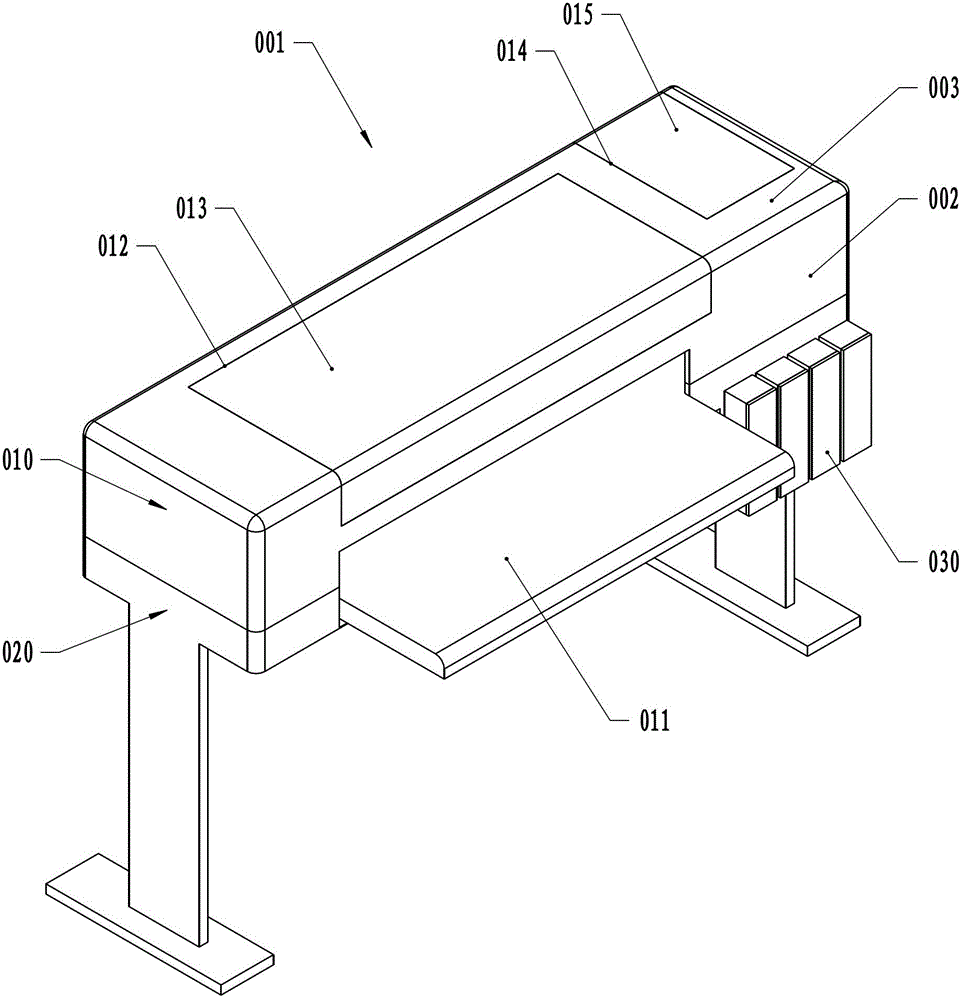

[0026] Such as figure 1 As shown, the casing of the wide-line printer 001 is formed by assembling an upper casing 010 and a lower casing 020 . Four sub-ink cartridges 030 are loaded into the wide-line printer 001 from the front wall 002 of the casing. The paper table 011 protrudes from the front wall 002. The top wall 003 of the housing is provided with a main window 012 and a maintenance window 014 , wherein the main window 012 is covered by a main cover 013 , and the maintenance window 014 is covered by a maintenance cover 015 .

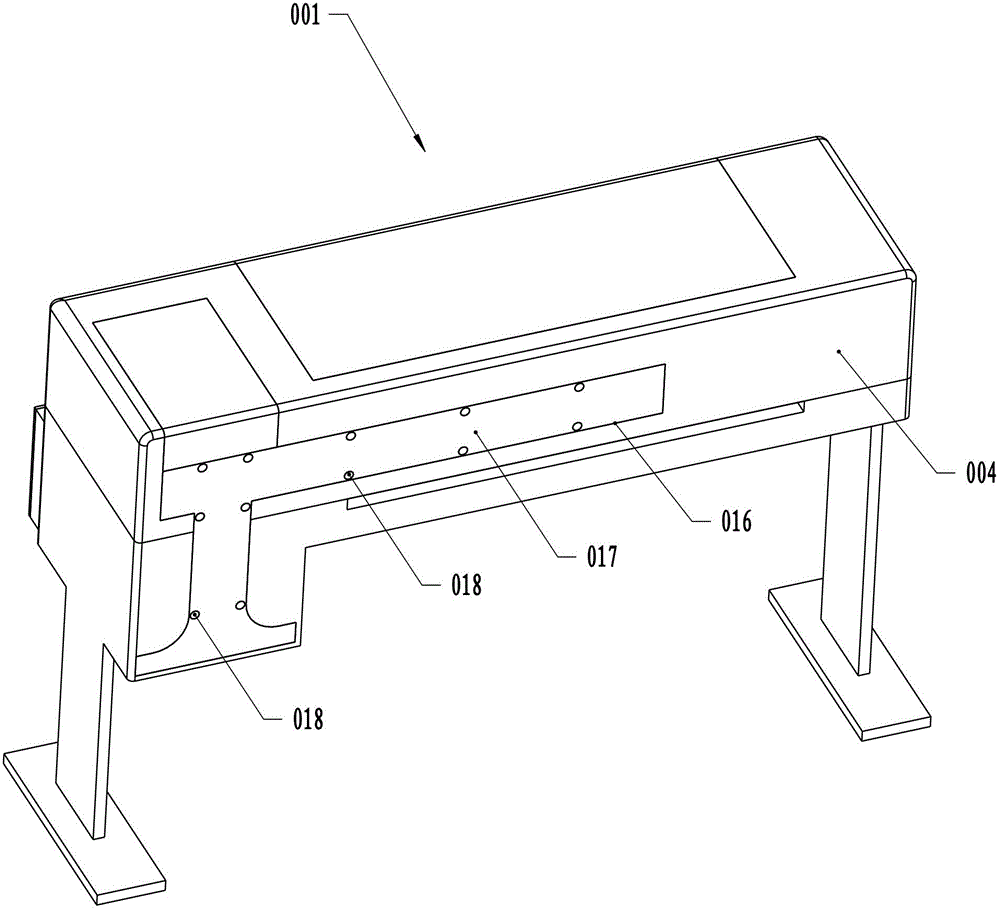

[0027] Such as figure 2 As shown, the rear wall 004 of the casing of the wide-line printer 001 is provided with an opening 016, and the opening 016 is covered by a baffle 017, and the baffle 017 is fixed on the rear wall 004 by a plurality of screws 018.

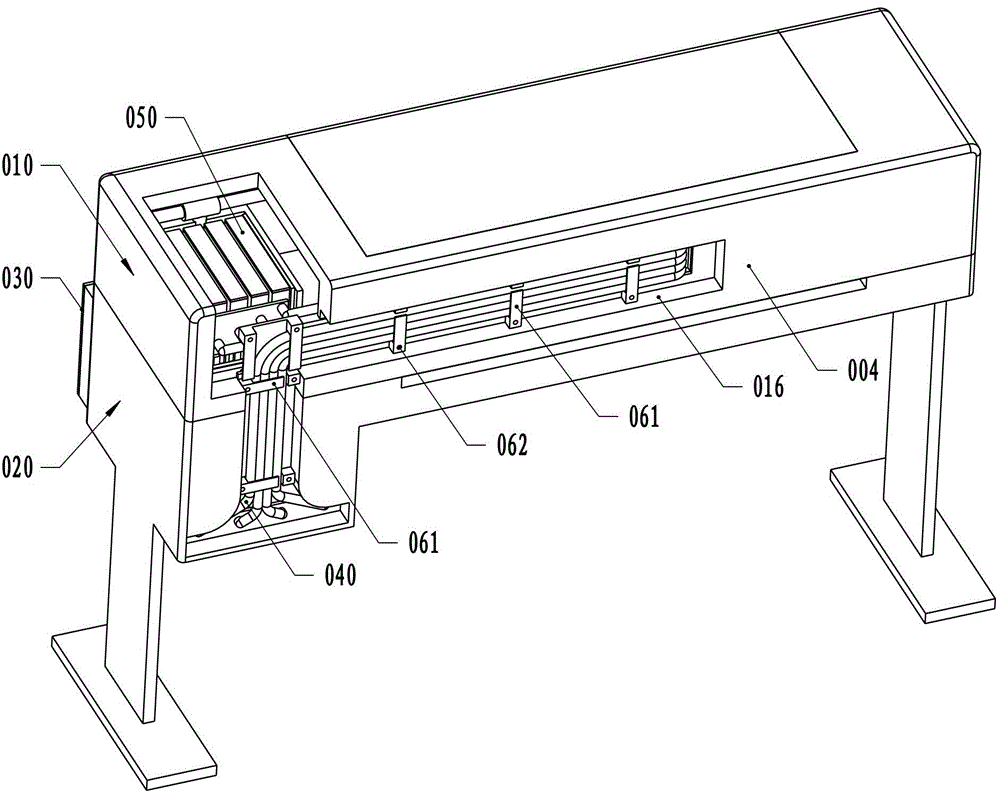

[0028] Such as image 3 As shown, the four ink delivery pipes 040 communicate with the four sub-ink tanks 030 and the four main ink tanks 050 corresponding to the colors respectively. The i...

no. 2 example

[0031] Such as Figure 5 As shown, the difference between the second embodiment and the first embodiment lies in the clamping method of the ink delivery tube 040 . Fix the fixed section of the ink delivery tube 040 on the baffle 017 through the fixing bracket 270 and the shorter screw 271, and then use the longer screw 272 to fix the baffle 017 to the corresponding part of the housing 210 of the wide-line printer 201 on the screw hole. Preferably, the size of the opening 216 meets the loading and unloading requirements of the main ink tank 050, and the ink delivery tube 040 and the main ink tank 050 can be taken out from the opening 216 together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com