Extrusion head and method for producing hollow bodies

A head and extruder technology, which is applied in applications, household appliances, household components, etc., can solve the problems of complicated and expensive wall thickness control system technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

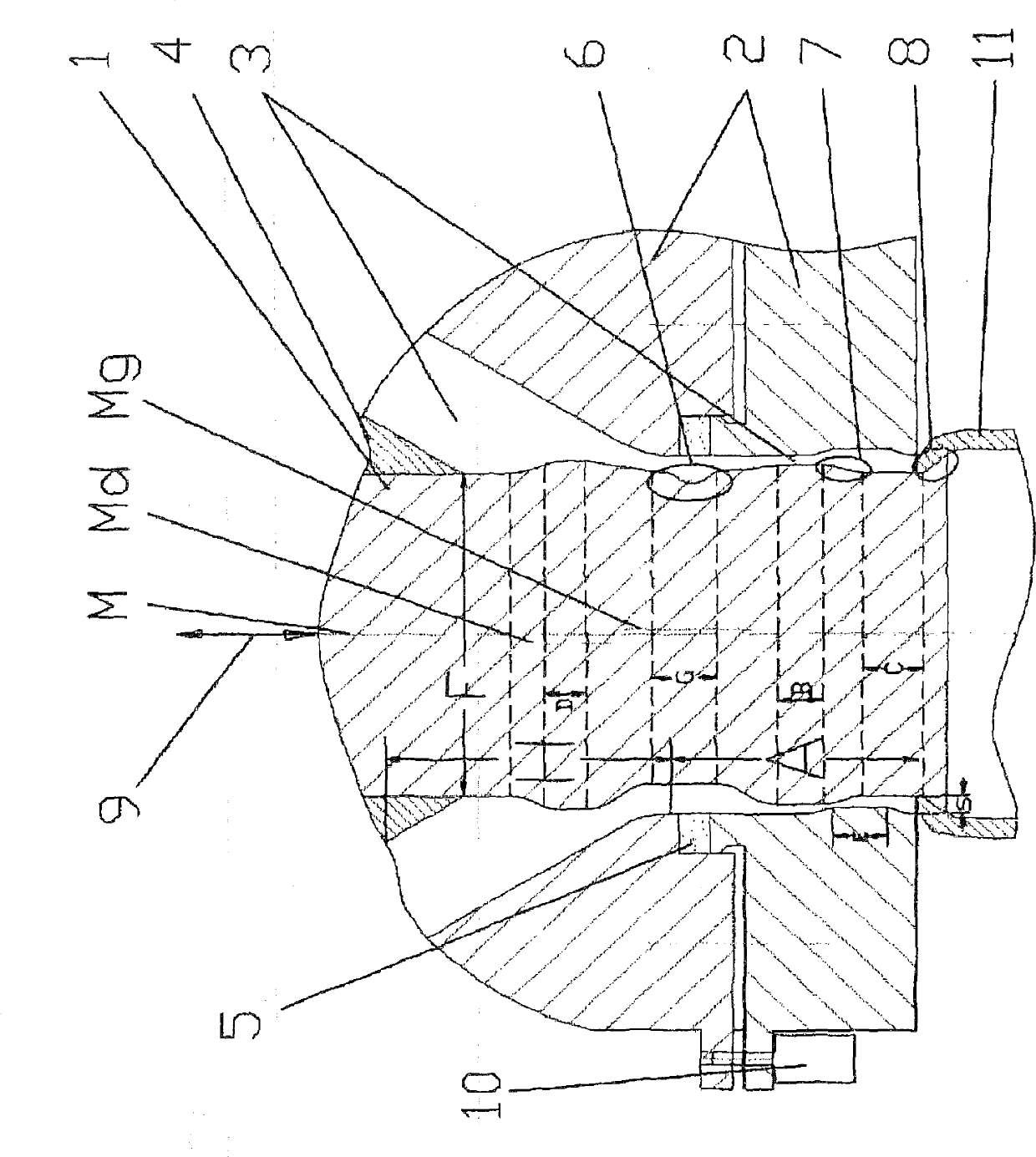

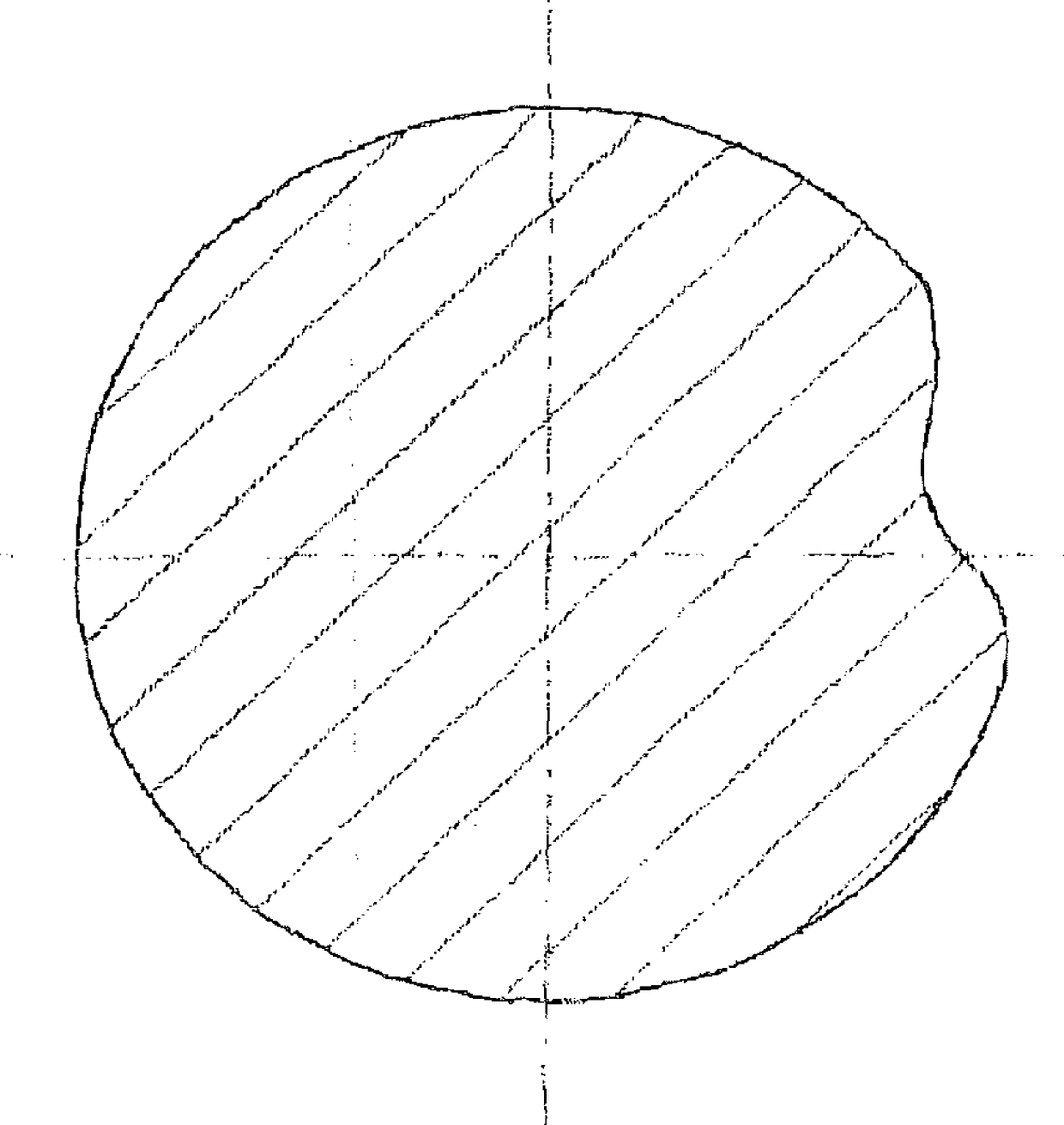

[0033] as in figure 1 As shown in , the extrusion head has a first head part, namely the blowing needle 1 , and a second head part, namely the nozzle 2 which defines the flow channel 3 . The head geometry or the shape of the annular flow channel 3 between the nozzle and the blowing needle can, as usual, be almost circular, with the blowing needle 1 positioned centrally in the nozzle 2 . The blowing needle 1 and the nozzle 2 thus have the same center line M. Of course, the nozzle 2 and / or the blowing needle 1 can also have any other geometric shape, for example a square, rectangular, oval geometry or also other point-symmetrical geometries.

[0034] Nozzle 2 is fixed with figure 1 The extruder connection is not shown, while the blowing needle 1 can move relative to the fixed nozzle 2 . In the outlet area A of the head, the blowing needle 1 and the nozzle 2 each have at least one head section which has a constant cross-section within the head section. The blowing needle 1 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com