Patents

Literature

33results about How to "Change flow characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

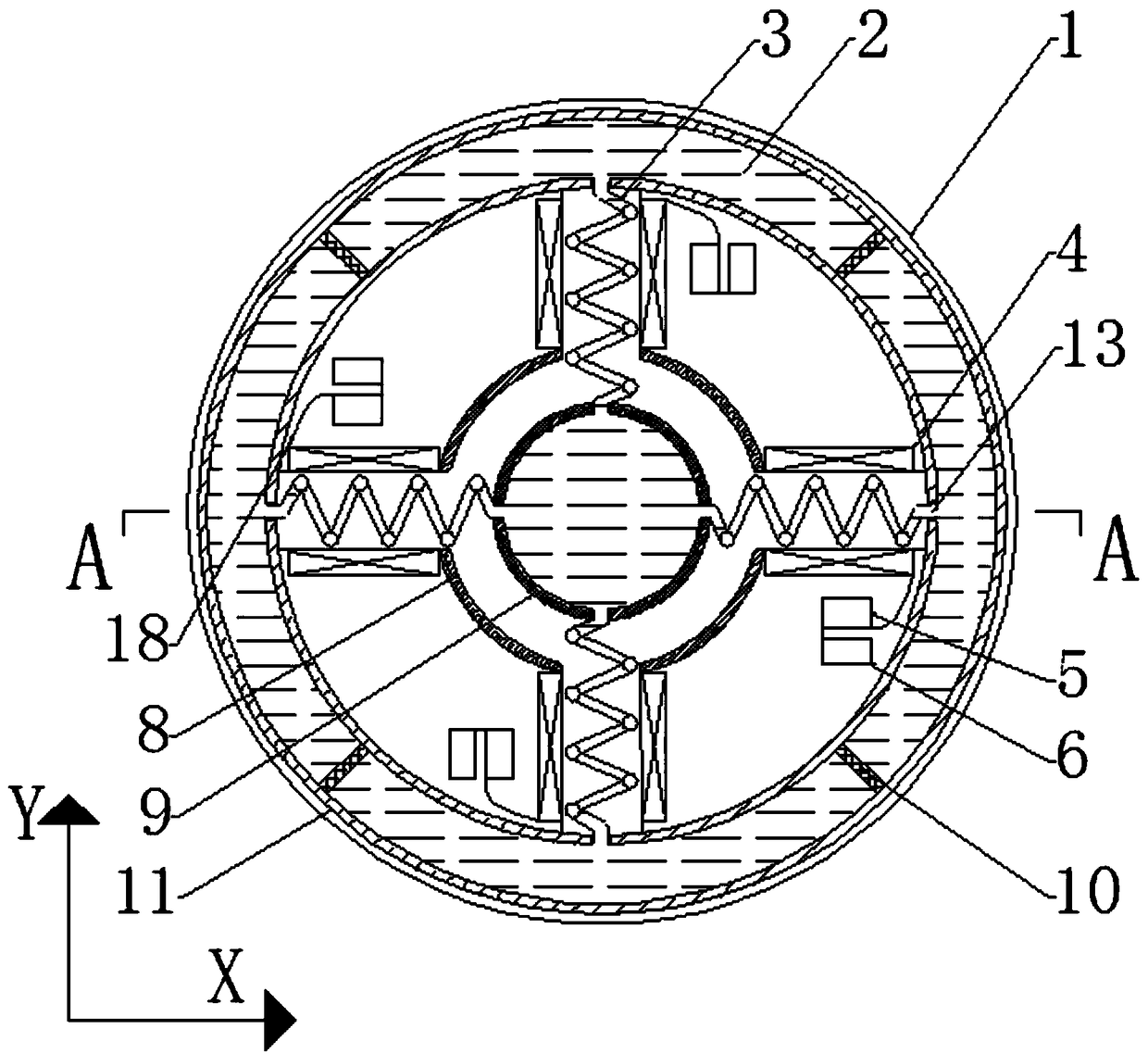

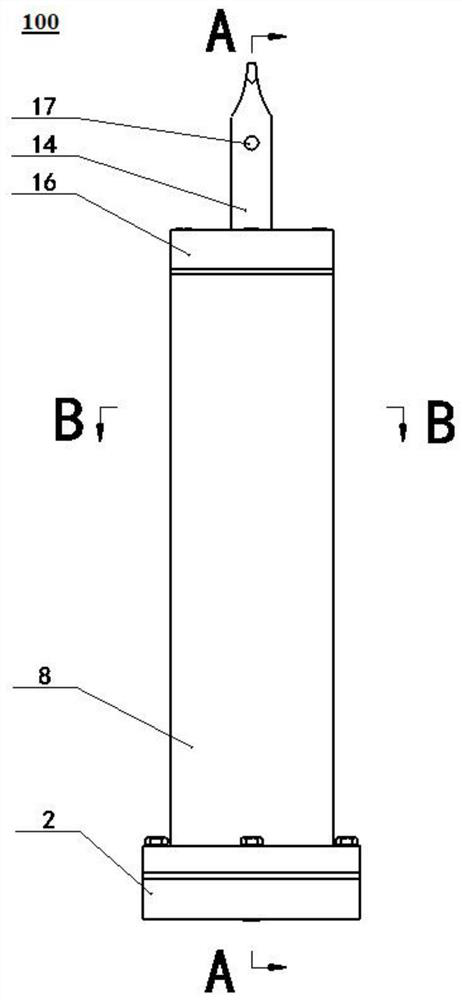

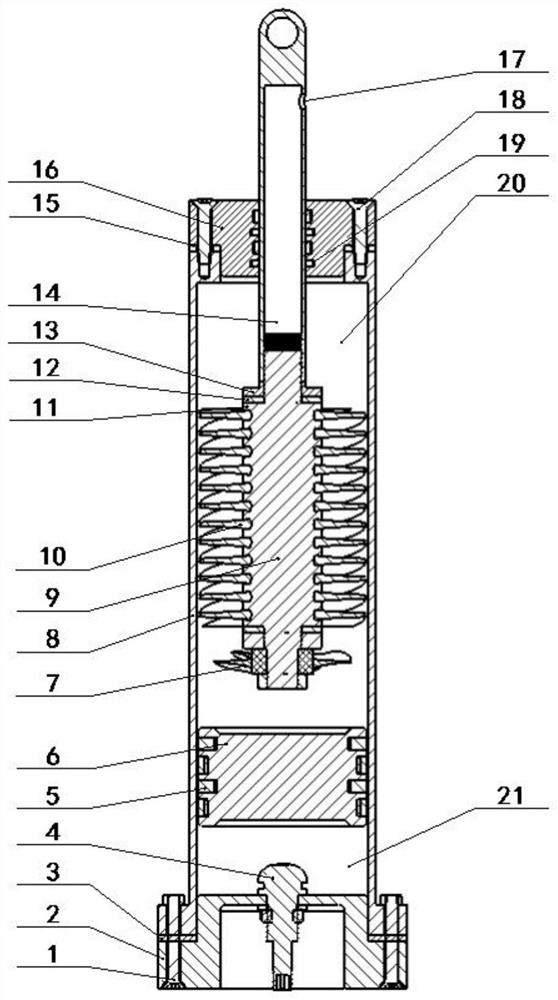

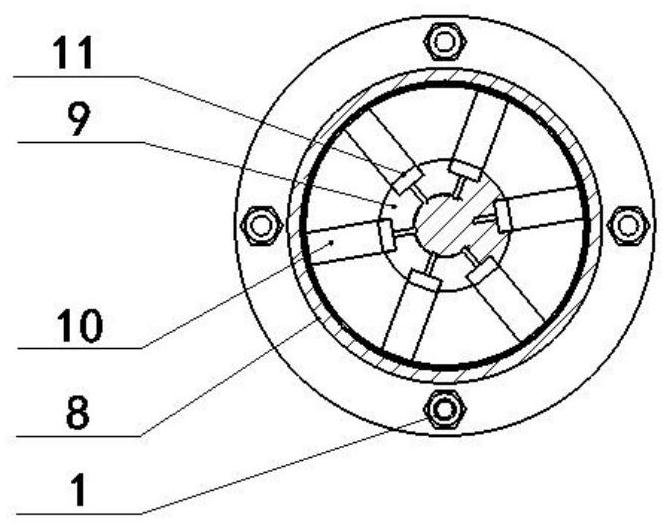

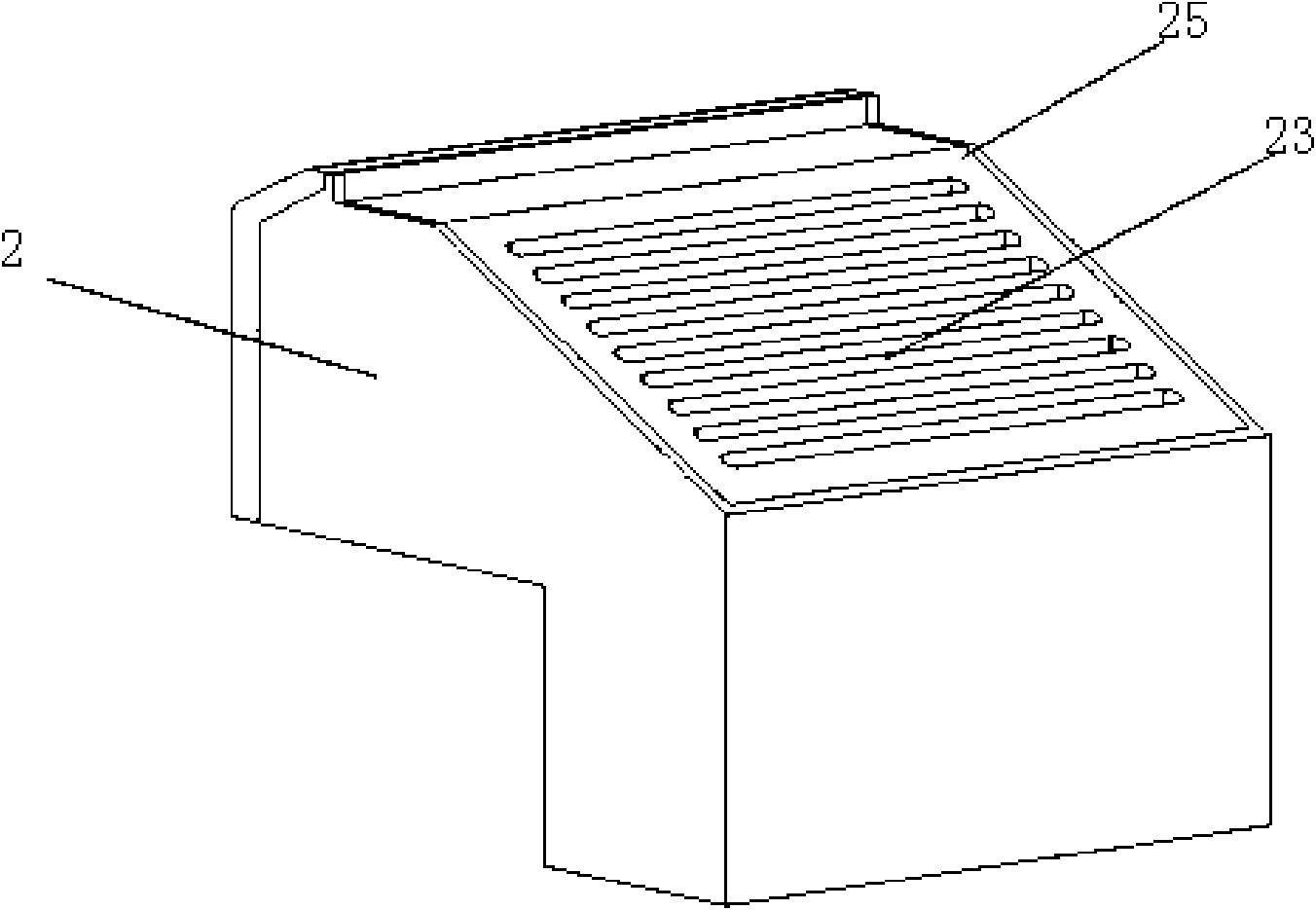

Magneto-rheological semi-active damper with adjustable stiffness

ActiveCN109235688AChange flow characteristicsGood vibration dampingProtective buildings/sheltersShock proofingSemi activeAdjustable stiffness

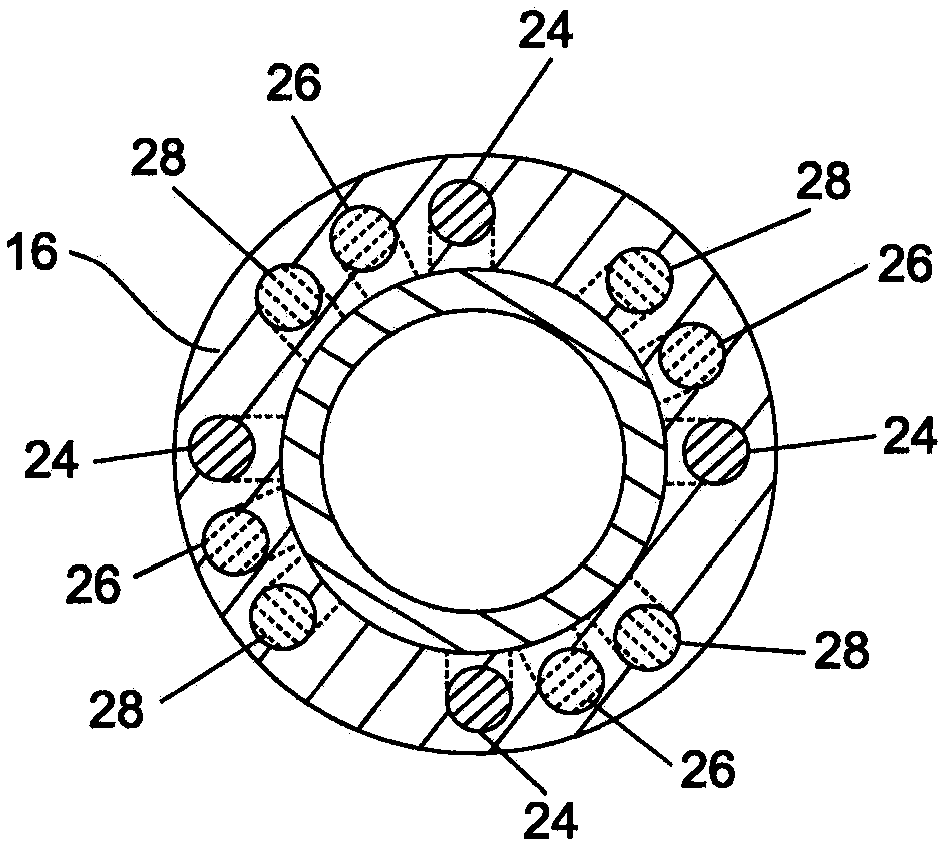

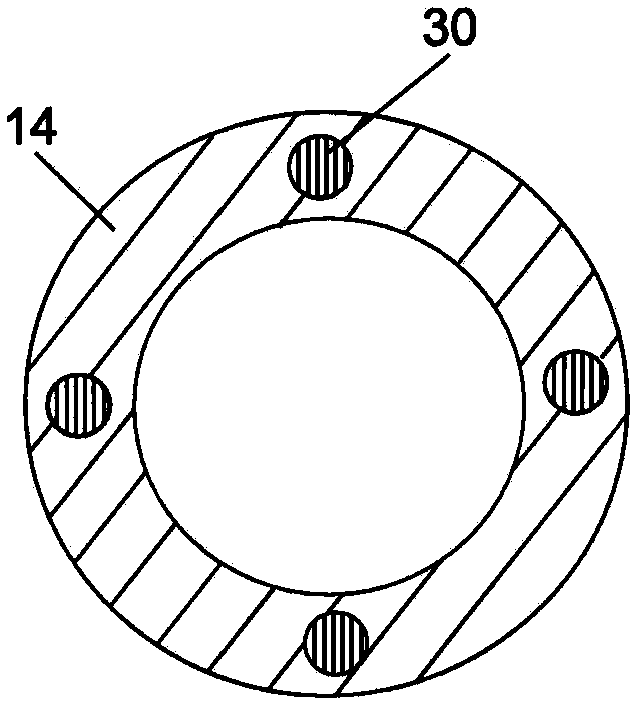

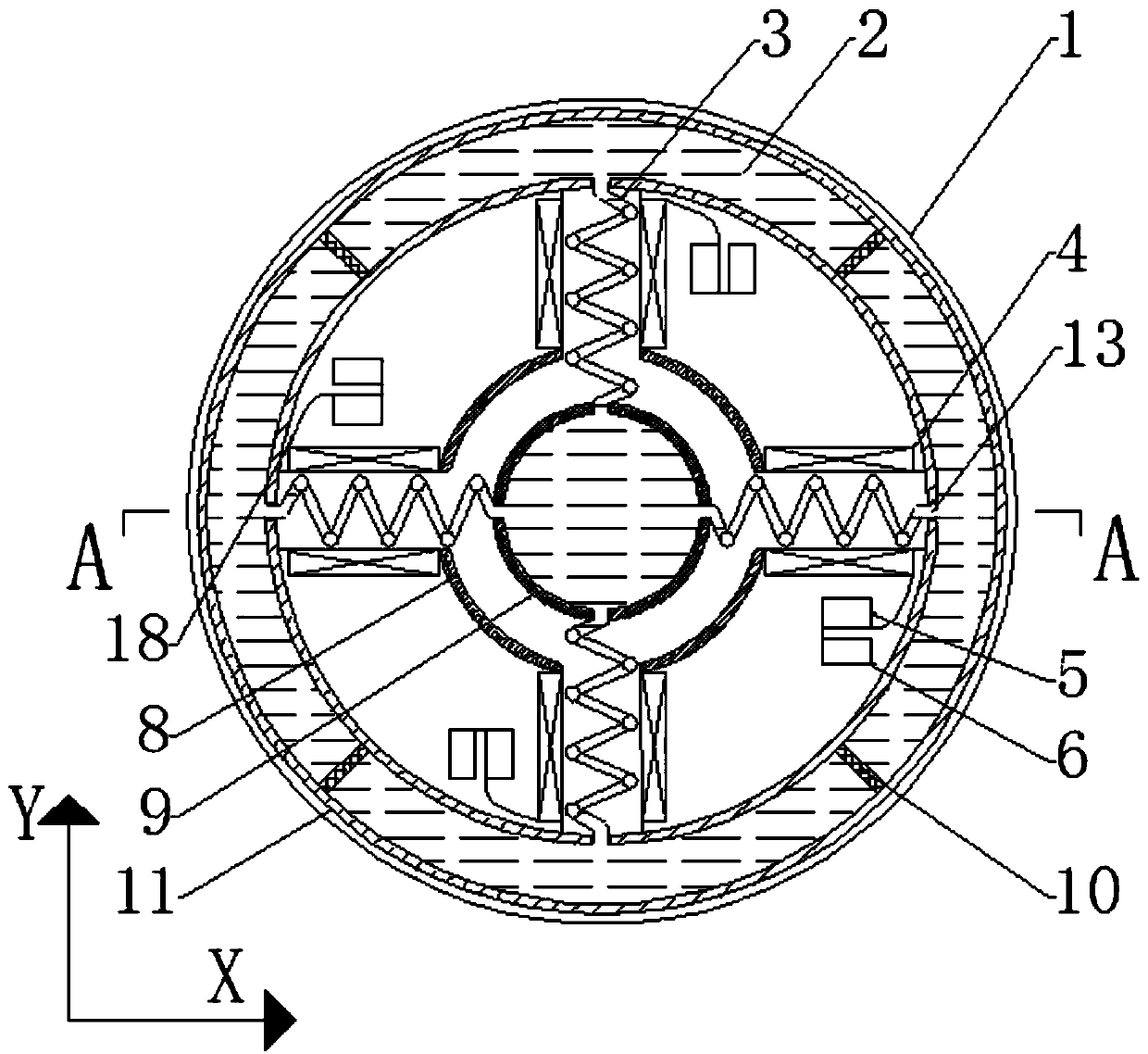

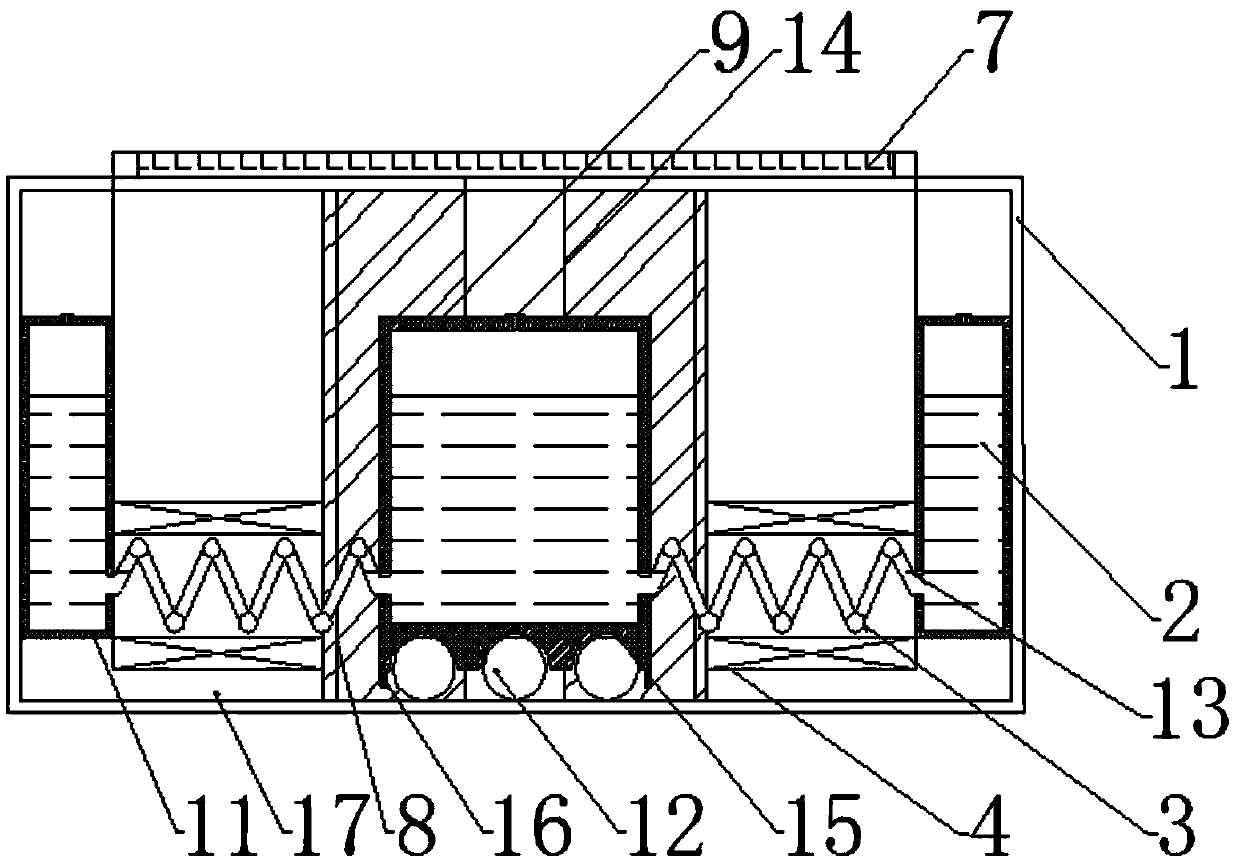

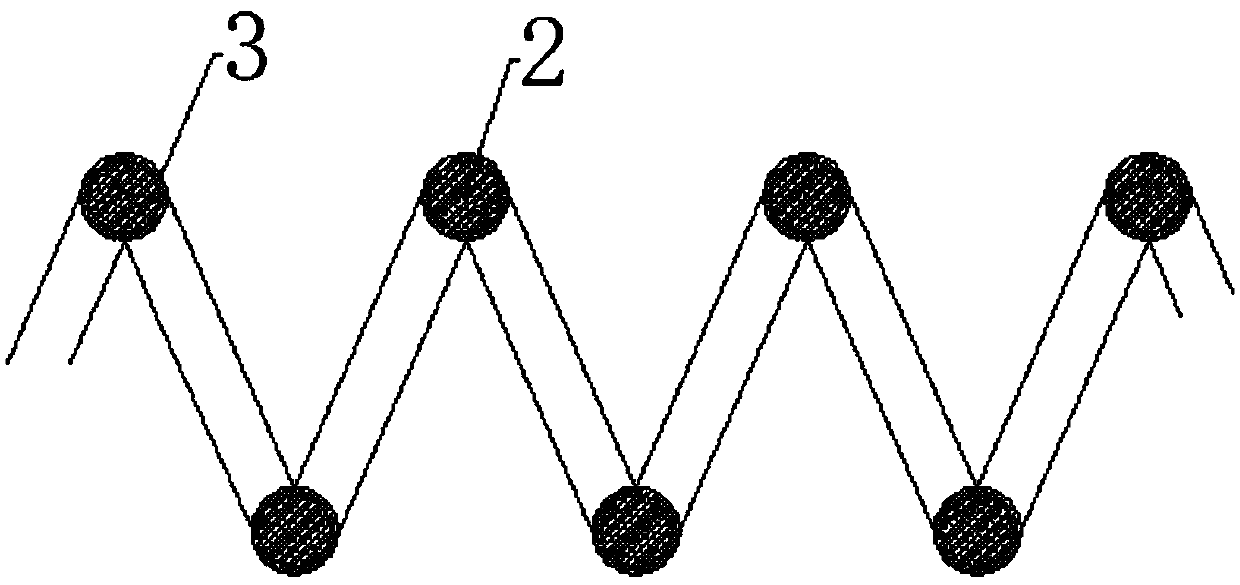

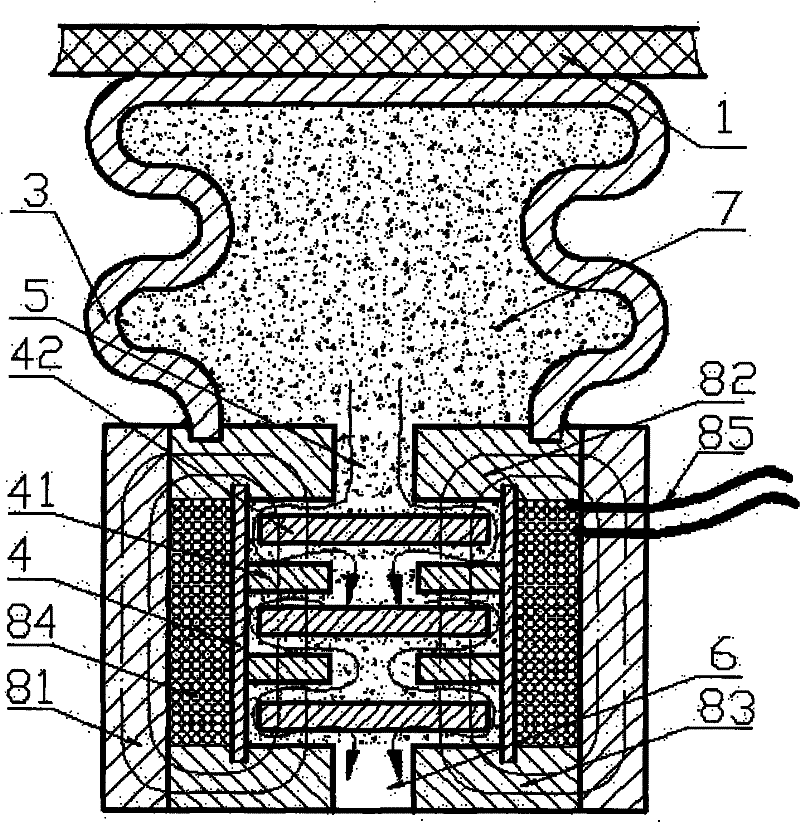

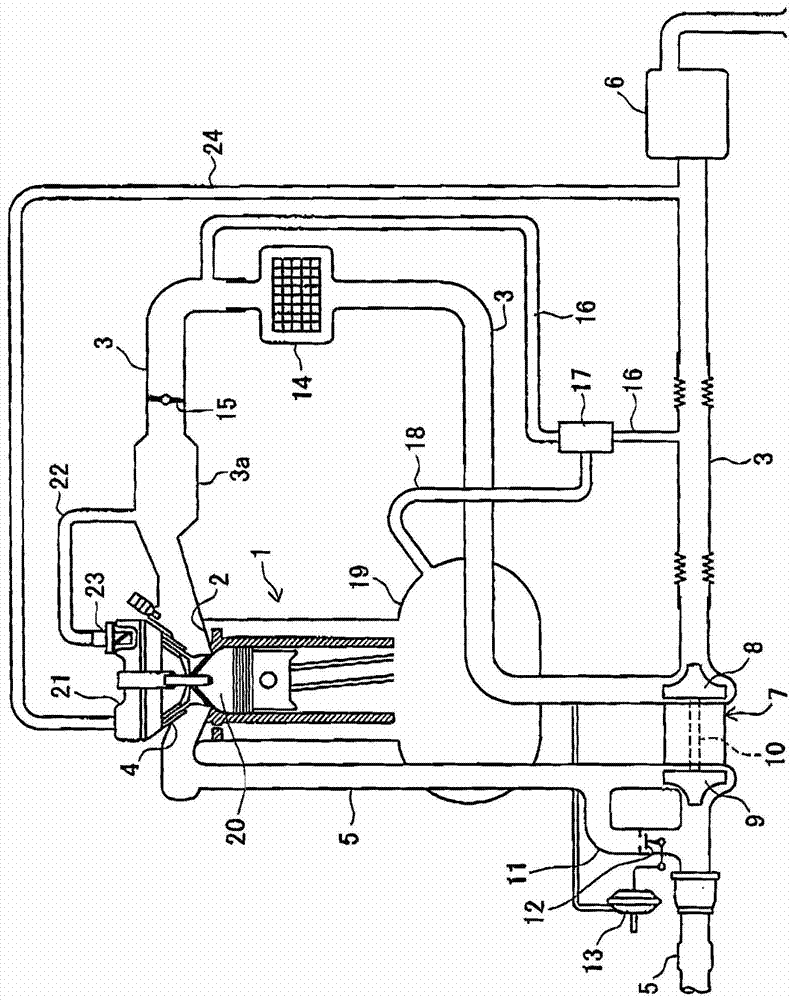

The invention discloses a magneto-rheological semi-active damper with adjustable stiffness. The damper comprises an outer annular cylinder fixed on the inner wall of a container and an inner cylinder;scrollable balls are arranged between the lower portion of the inner cylinder and a bottom plate of the device, and the inner cylinder and the outer annular cylinder are filled with a magneto-rheological liquid respectively; hollow spring pipes are connected between the cylinder walls of the inner cylinder and outer annular cylinder, the inner cylinder and the outer annular cylinder are communicated with each other through the hollow spring pipes, the magneto-rheological liquid can flow in the inner cylinder and the outer annular cylinder through the hollow spring pipes, the outer portions ofthe spring pipes are provided with magnet exciting coils, the magnet exciting coils, controllers and a solar panel arranged at the outer side of the upper portion of the container are connected in series to form a closed loop circuit, the controllers receive signals of acceleration sensors to control the current in the magnet exciting coils, thereby adjusting the stiffness of the hollow spring pipes and achieving the horizontal damping control; limiting plates are arranged between the outer annular cylinder and the inner cylinder to prevent the inner cylinder from being displaced too much; damping nets are arranged in the outer annular cylinder, and the torsion damping control is achieved through damping force.

Owner:SHANDONG UNIV

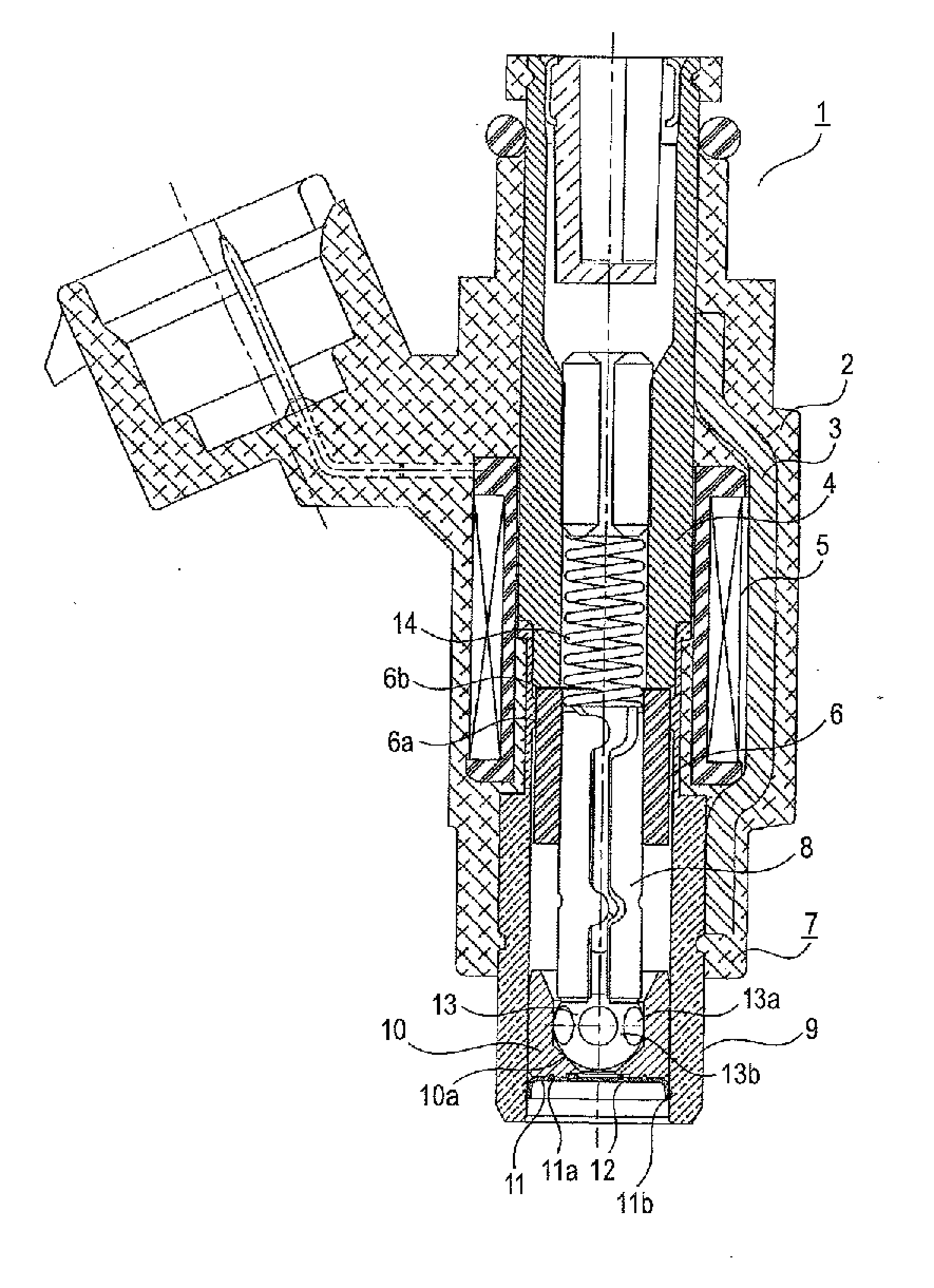

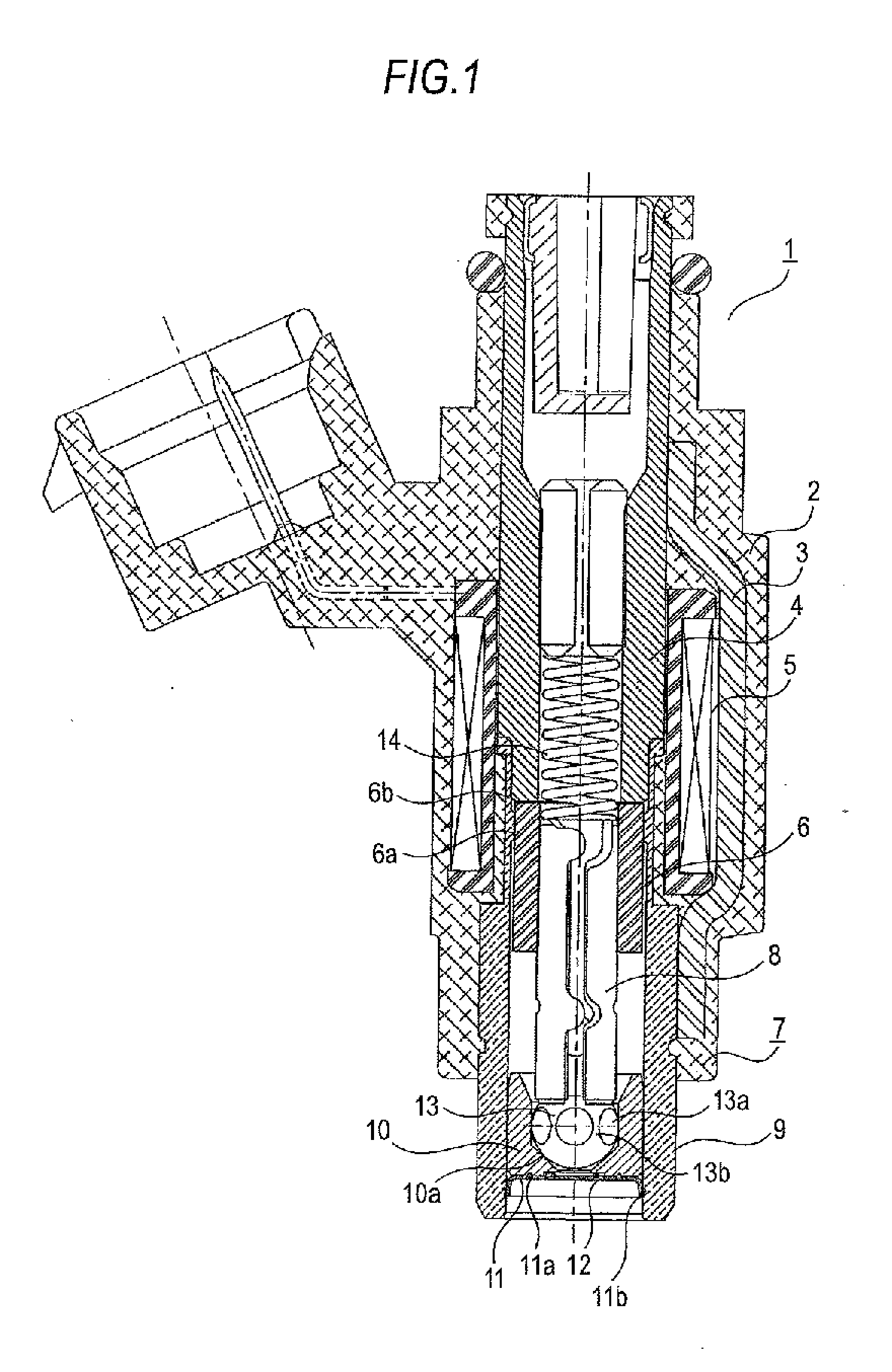

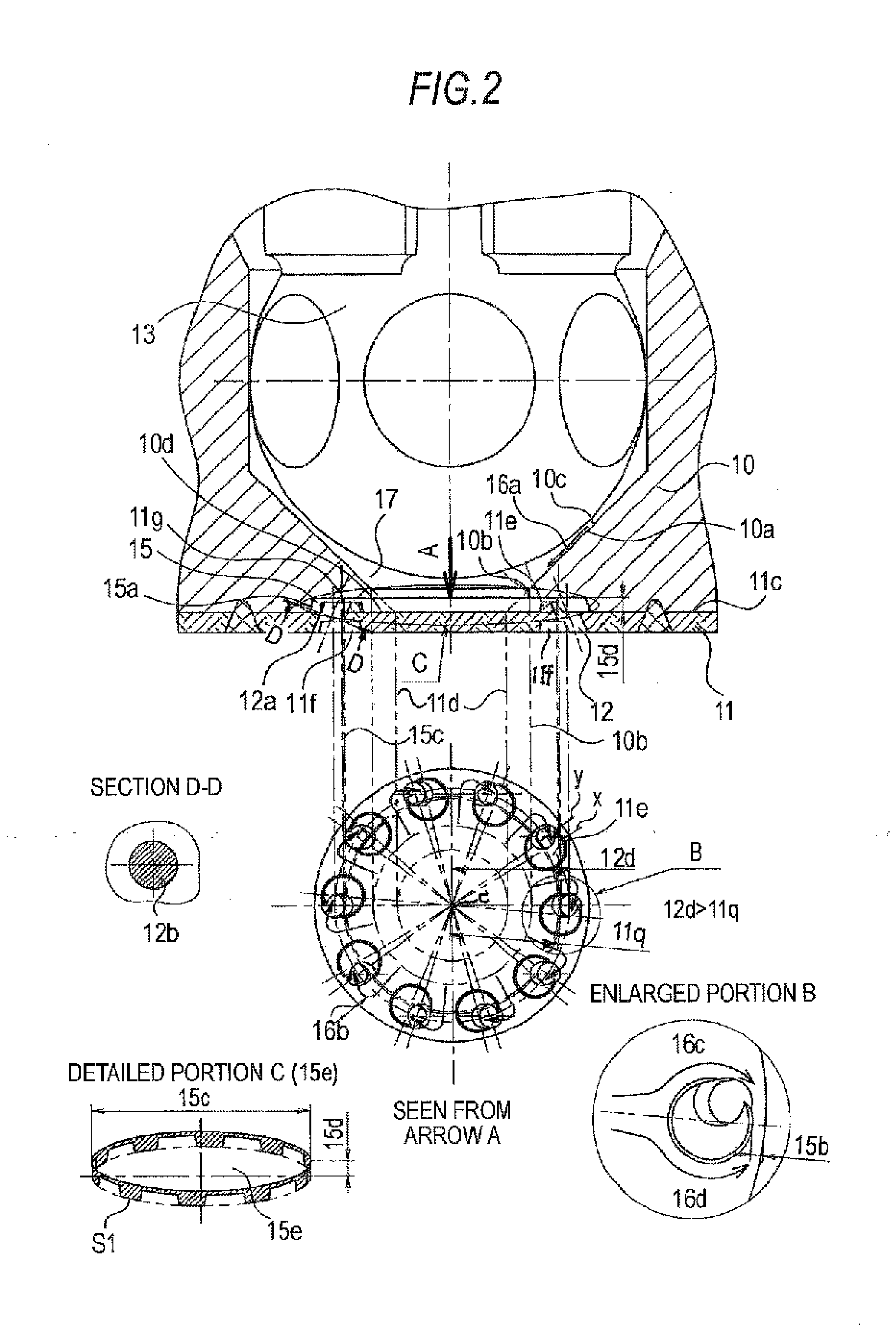

Fuel injection valve

InactiveUS20110253812A1Avoid cloggingChange flow characteristicsFuel injection apparatusMachines/enginesEngineeringFuel injection

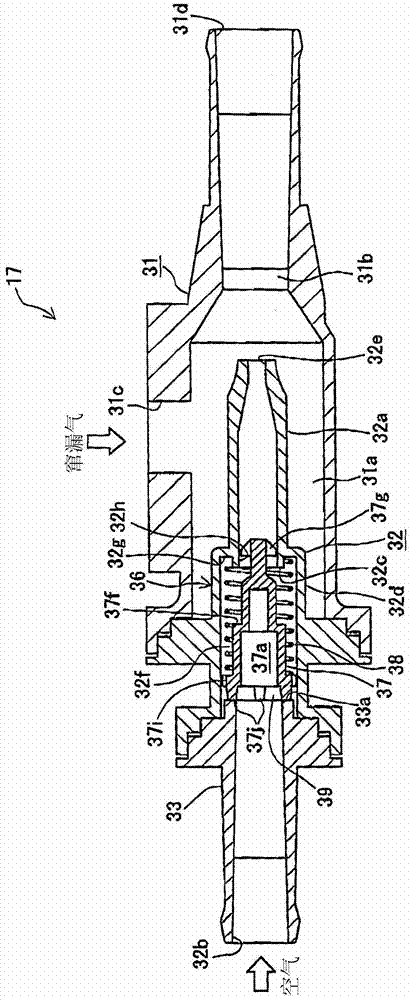

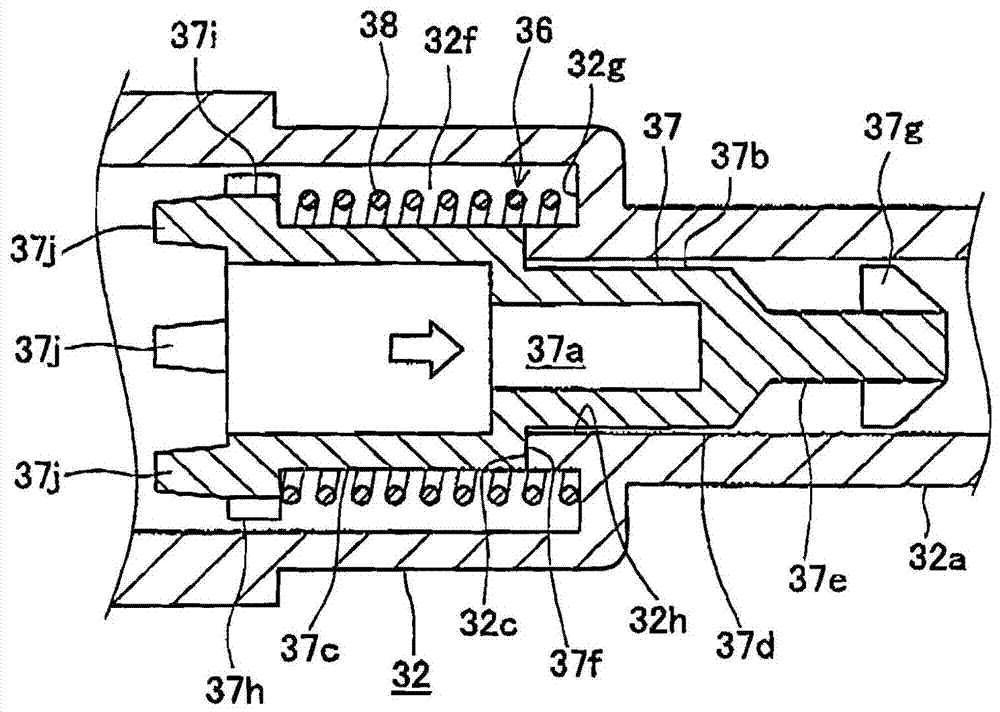

A plate convex is formed on the upstream side of the injection hole plate and a plate concave is formed on the downstream side of the injection hole plate so as to form a pair together, a minimum of one set of the plate convexes and the plate concaves are formed, and the injection holes are arranged so that the radial centerline which connects the centerline of the plate convex from the axial center of the fuel injection valve does not overlap the center of the injection hole on an upstream flat surface of the injection hole plate, and the plate convex is arranged so as to straddle the injection hole on the upstream flat surface of the injection hole plate, and the top surface of the plate convex.

Owner:MITSUBISHI ELECTRIC CORP

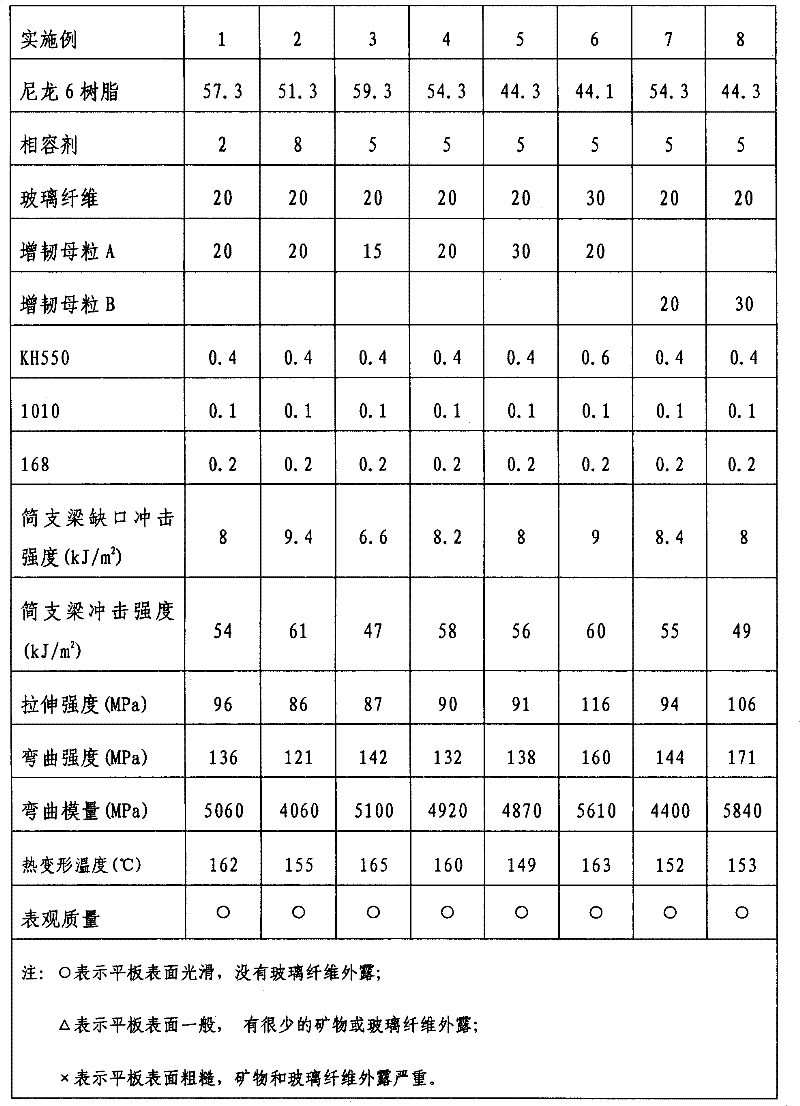

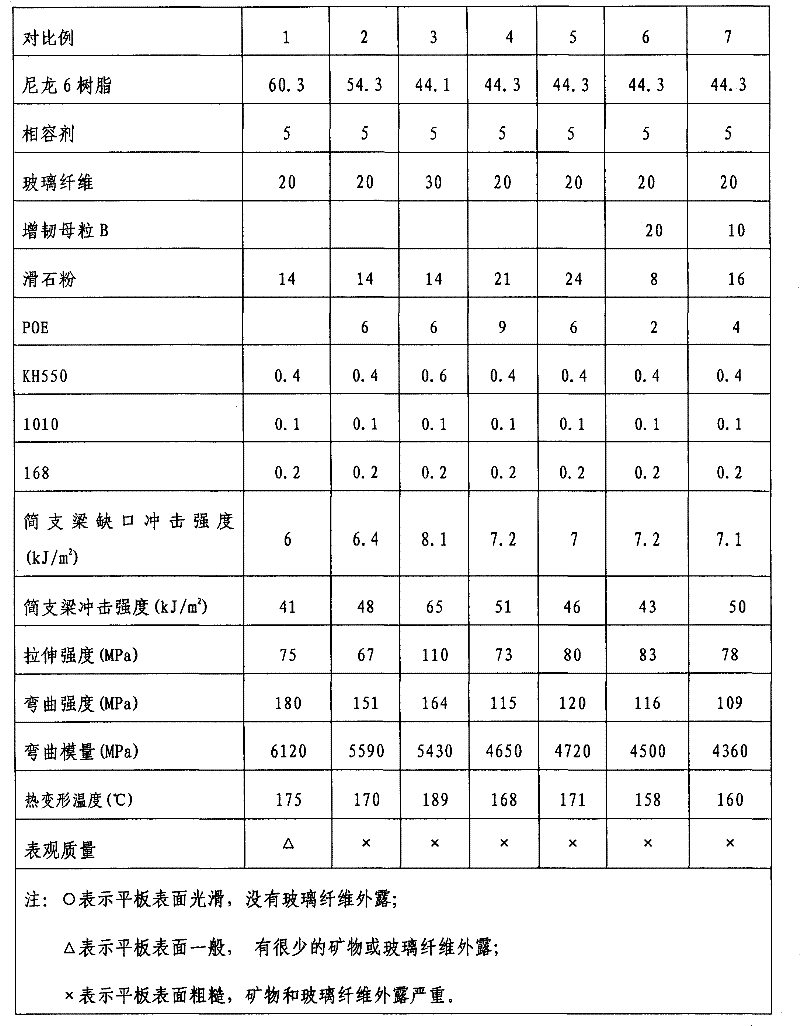

High glazing and high liquidity glass fiber-reinforced nylon 6 composite material and preparation method thereof

The invention discloses a glass-fiber reinforced nylon 6 composite material with high gloss and high fluidity and a preparation method of the glass-fiber reinforced nylon 6 composite material. The glass-fiber reinforced nylon 6 composite material comprises the following components by weight: nylon 6 resin 40 to 88 percent, compatilizer 1 to 20 percent, glass fiber 10 to 50 percent, master batches with high gloss 0.5 to 5 percent, the other additives 0.5 to 4 percent. The master batches with high gloss are made into granulates with organic fatty acid ester, ethylene copolymer and nylon copolymer by being extruded by twin screw. The specific steps of the method are as follow: all the materials except the glass fiber are weighed to be mixed in a mixer for 3 to 5 minutes, and then the mixed material is put into a twin screw extruder with the glass fiber being added from a first exhaust port. The temperatures from a material feeding port to an extrusion die head respectively are: 160 to 180 DEG C, 190 to 220 DEG C, 210 to 240 DEG C, 220 to 250 DEG C and 210 to 240 DEG C, the engine speed is 20 to 50 Hz. Then the material is made into sample with a plastic injection modeling machine. The composite material has the advantages of fine gloss on the surface, good performance and easy process.

Owner:CHONGQNG PRET NEW MATERIAL +2

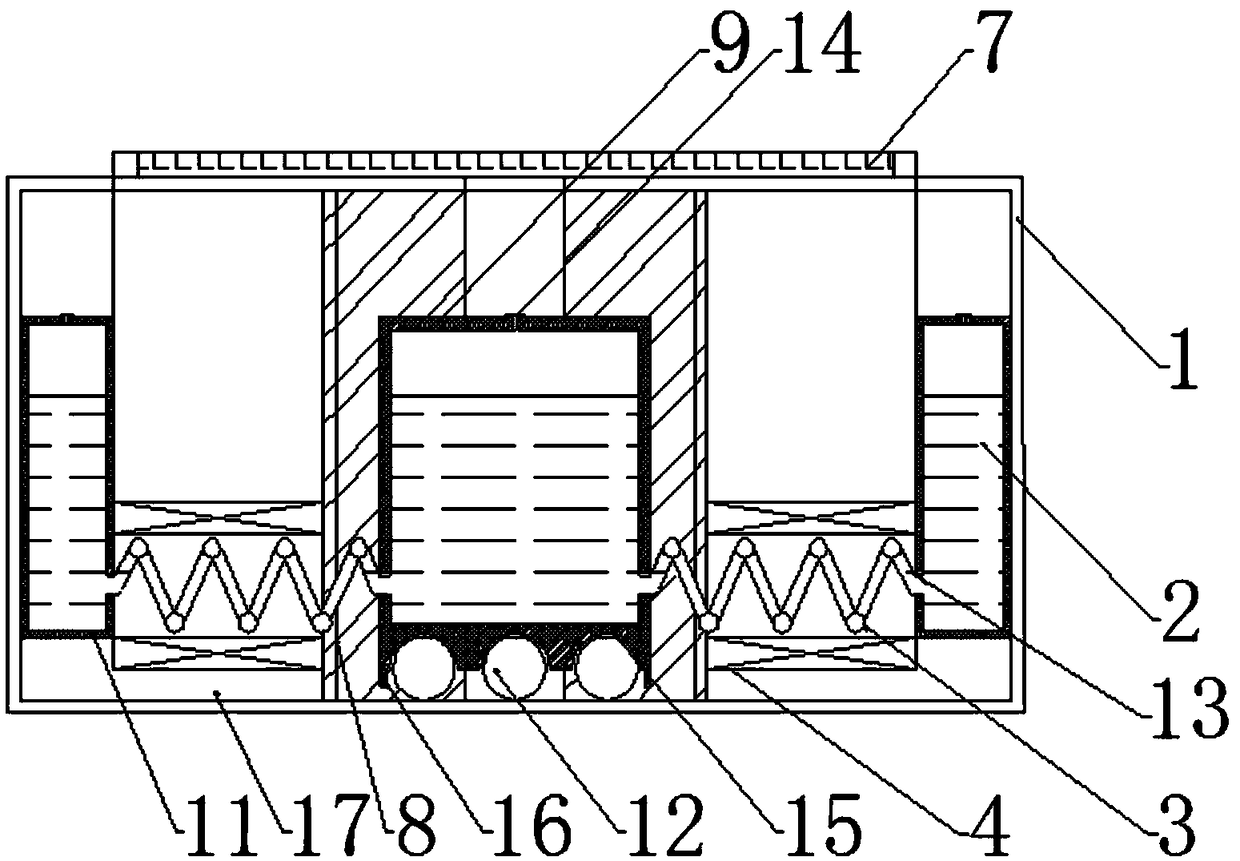

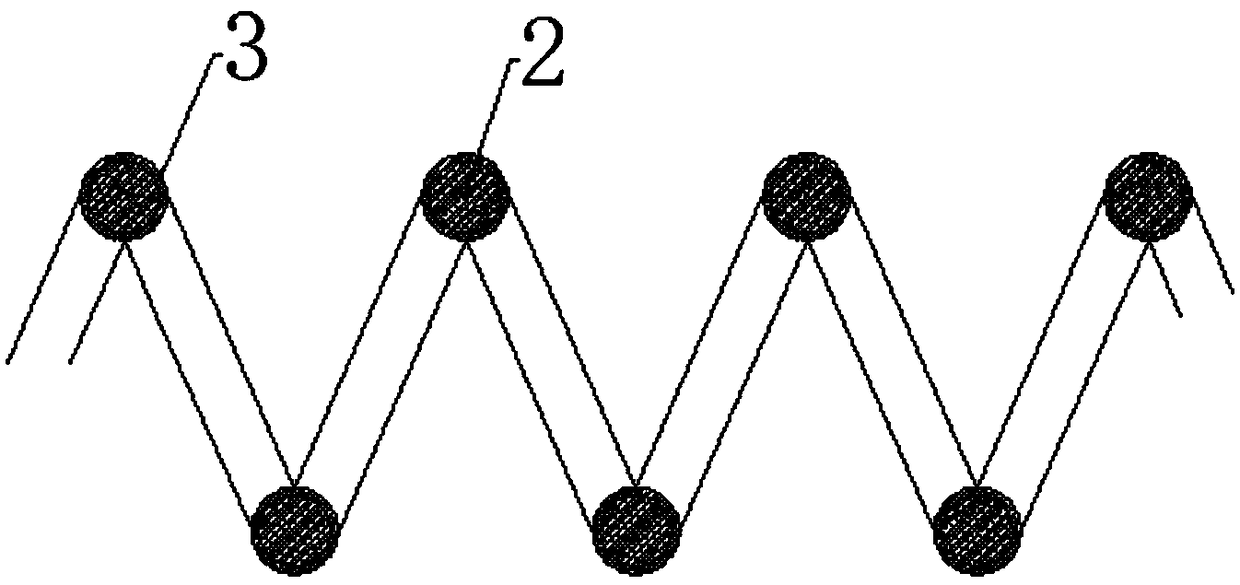

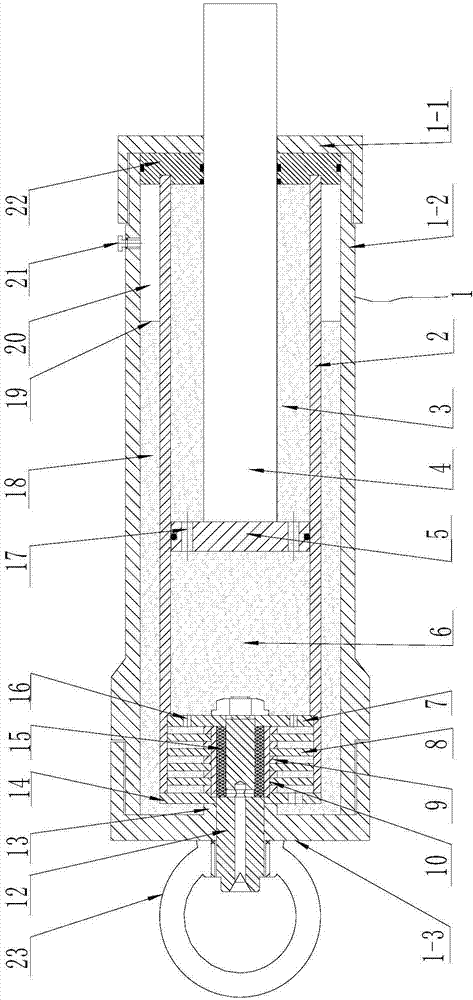

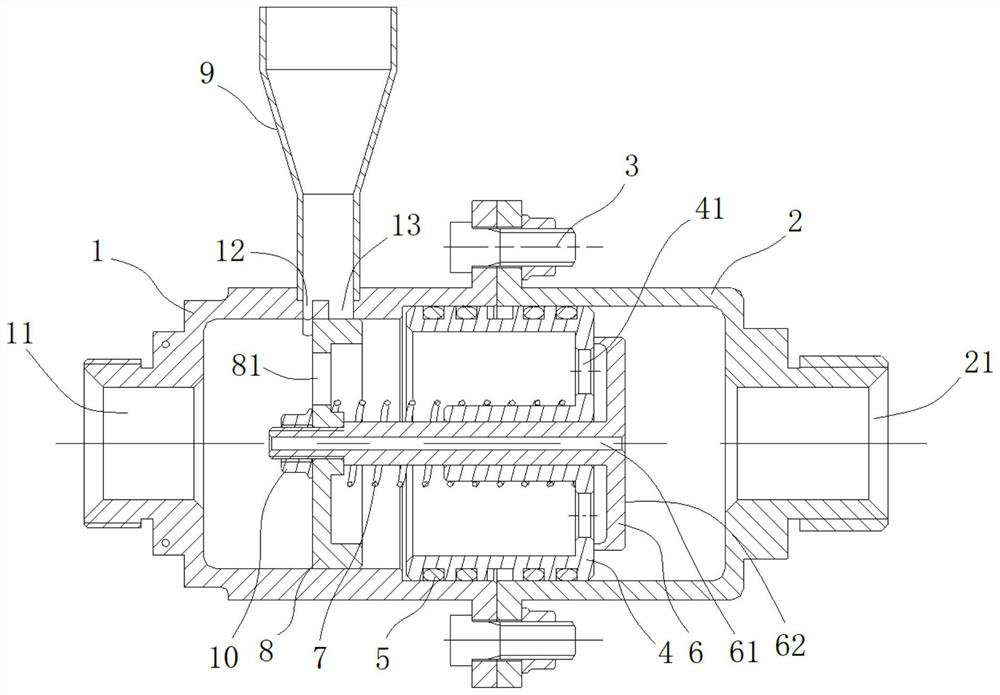

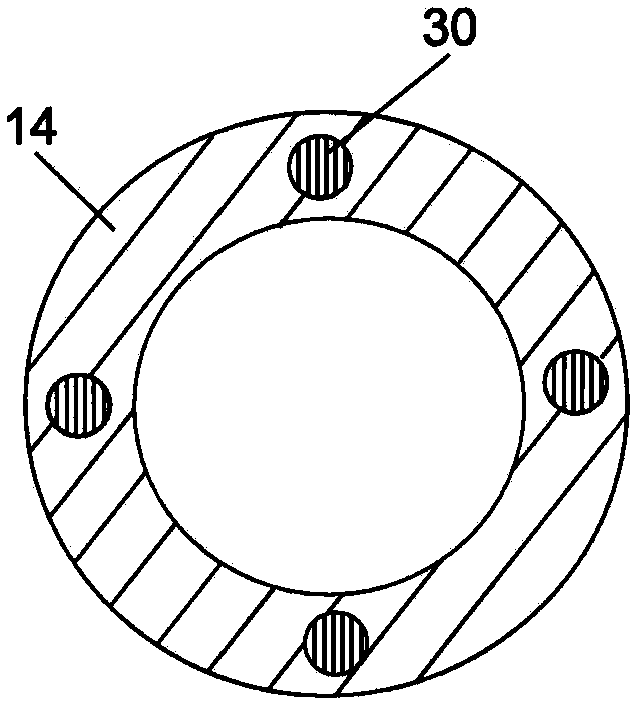

Magnetorheological buffer

InactiveCN107131244AControl flow characteristicsChange flow characteristicsSpringsNon-rotating vibration suppressionExcitation currentMagnetorheological fluid

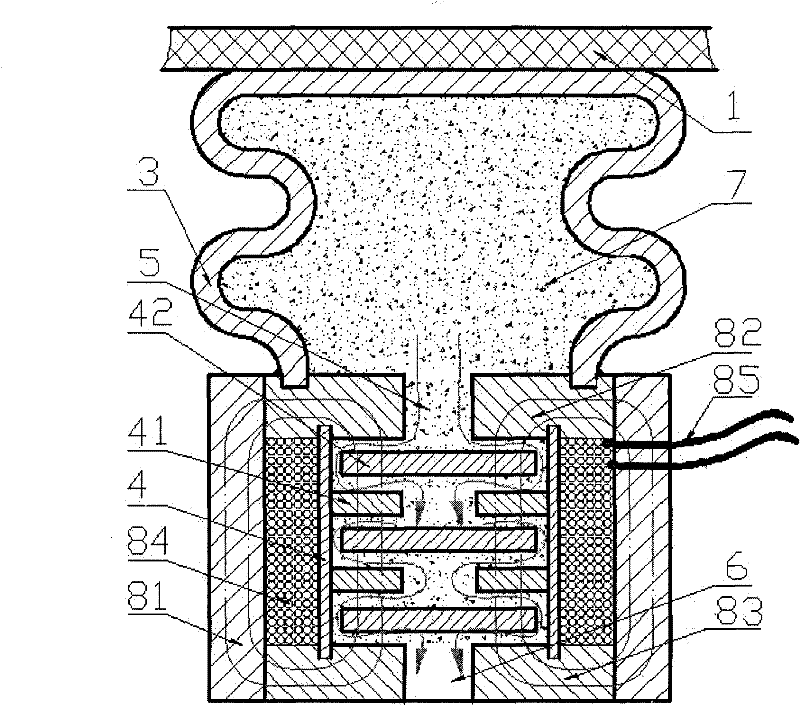

The invention discloses a magnetorheological buffer which comprises an outer cylinder barrel, an inner cylinder barrel, a piston and a piston rod. The inner cylinder barrel and the outer cylinder barrel are in clearance fit. The piston is arranged in the inner cylinder barrel and divides the inner cavity of the inner cylinder barrel into an upper working cavity and a lower working cavity. Inner cavities of the inner cylinder barrel and the outer cylinder barrel are filled with magnetorheological fluid. The inner cylinder barrel comprises a closed end and an open end. The open end communicates with the inner cavity of the outer cylinder barrel. The magnetorheological buffer further comprises a multistage circumferential damping channel arranged in the open end and a magnetic field generator used for adjusting damping force. The magnetorheological buffer can provide different damping forces under different vibrational excitation conditions, can be rapidly applied to a traditional damper structure, is high in extension capacity and rapid in response speed and has good stability and reliability; when the magnetorheological buffer is used, since the open end of the inner cylinder barrel is located at the bottom, the multistage circumferential damping channel of the buffer achieves the effect of a throttle valve, and according to vibrational excitation, under the effect of a controller, different excitation currents are applied, and therefore the damping force is controllable.

Owner:CHONGQING UNIV

Solid powder regulation ball valve

InactiveCN102966752AGuaranteed strength and communicationExtended service lifePlug valvesValve housingsBall valveChromium

The invention discloses a solid powder regulation ball valve, which comprises a valve body, a spool, a valve rod, an upper shaft sleeve, a lower shaft sleeve, a set screw, a stop block, a rear cover, a valve seat assembly, screws and the like. Since the solid powder regulation ball valve adopts the one-piece valve rod, the strength and the communication degree are guaranteed; since the partially spherical spool with a V-shaped notch is adopted, the flow characteristic of the valve is changed, as a result, the valve has regulating performance and an automatic shearing function, and the service life of the valve is prolonged; because belleville springs are adopted for pretightening, the sealing specific pressure of a valve seat is guaranteed; dust-proof pads are adopted to prevent powdery medium from entering the spring holes to cause the failure of the springs; the surface of the spool and the sealing surface of the valve seat are specially treated, i.e., nickel-chromium hard alloy is sprayed or surfaced on the surfaces, the abrasive resistance and corrosion resistance of the valve are effectively enhanced, the service life of the valve is prolonged, and the production cost is reduced.

Owner:ZHEJIANG ZHONGDE AUTOMATIC CONTROL VALVE

Anti-settling multilayer spiral pole plate damper based on giant electrorheological fluid

ActiveCN112901703AChange viscosityChange the damping factorSpringsNon-rotating vibration suppressionSpiral bladeDamper

The invention discloses an anti-settling multilayer spiral pole plate damper based on giant electrorheological fluid, and relates to the technical field of dampers. The damper comprises an outer cylinder, an upper end cover is arranged at the upper end of the outer cylinder, a lower end cover is arranged at the lower end of the outer cylinder, a floating piston connected to the outer cylinder in a sliding mode is arranged in the outer cylinder, a compensation cavity between the floating piston and the lower end cover is filled with compressed air, a working cavity between the upper end cover and the floating piston is filled with the giant electrorheological fluid, a spindle structure is arranged in the outer cylinder, penetrates through the upper end cover and can slide relative to the upper end cover, a plurality of spiral blade pole plates and a plurality of electrode plates are arranged on the spindle structure in the circumferential direction, each spiral blade pole plate is connected to one electrode plate, and an anti-settling structure is arranged at the lower end of the spindle structure. The damper has the advantages of being simple in structure, high in response speed, light in weight, small in size, large in damping force and capable of automatically preventing settling.

Owner:CHONGQING UNIV

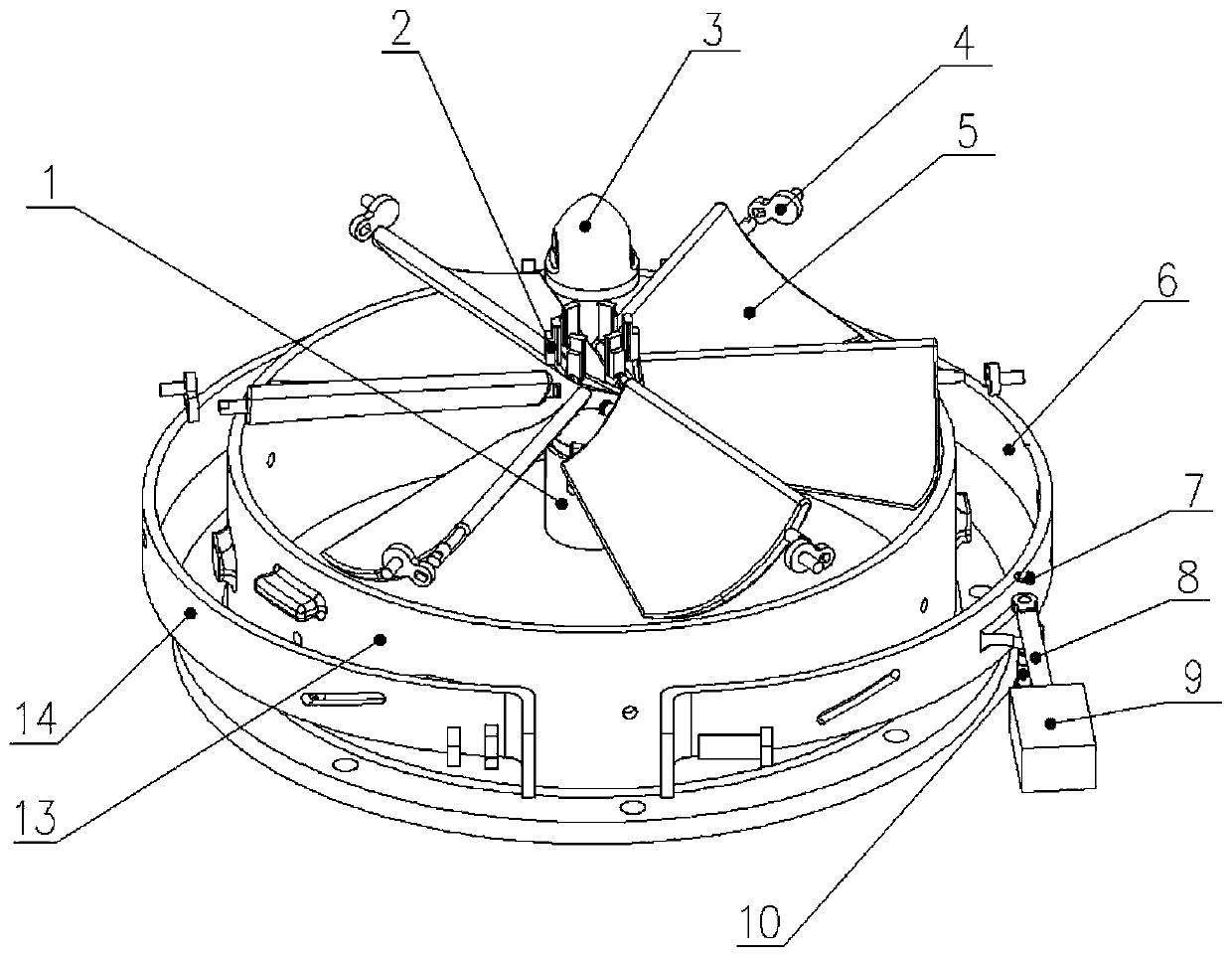

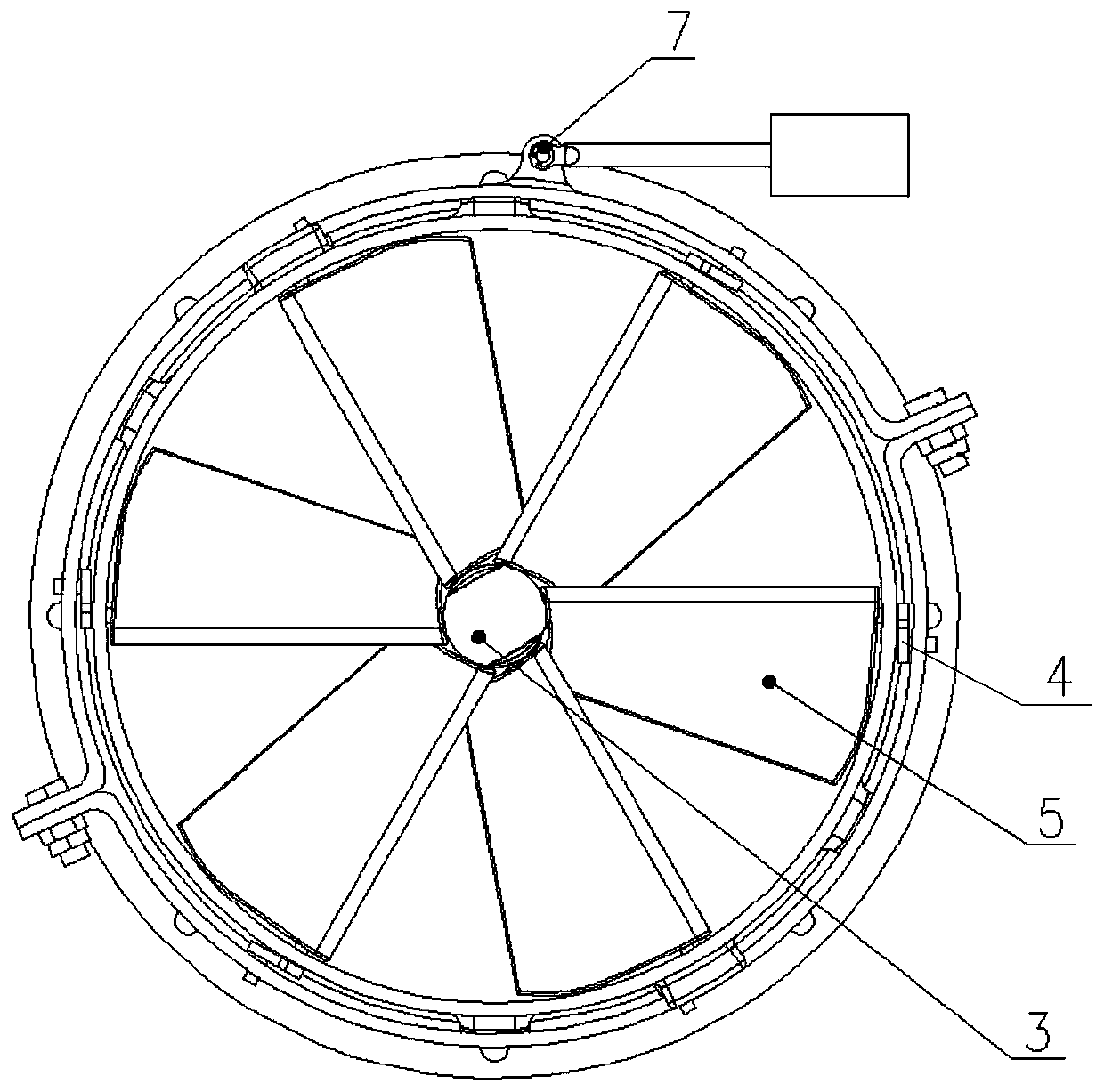

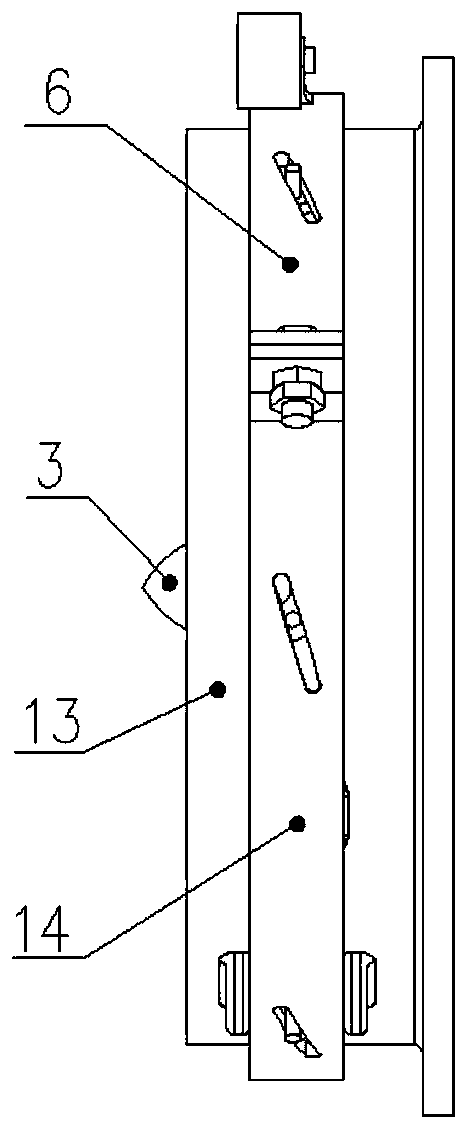

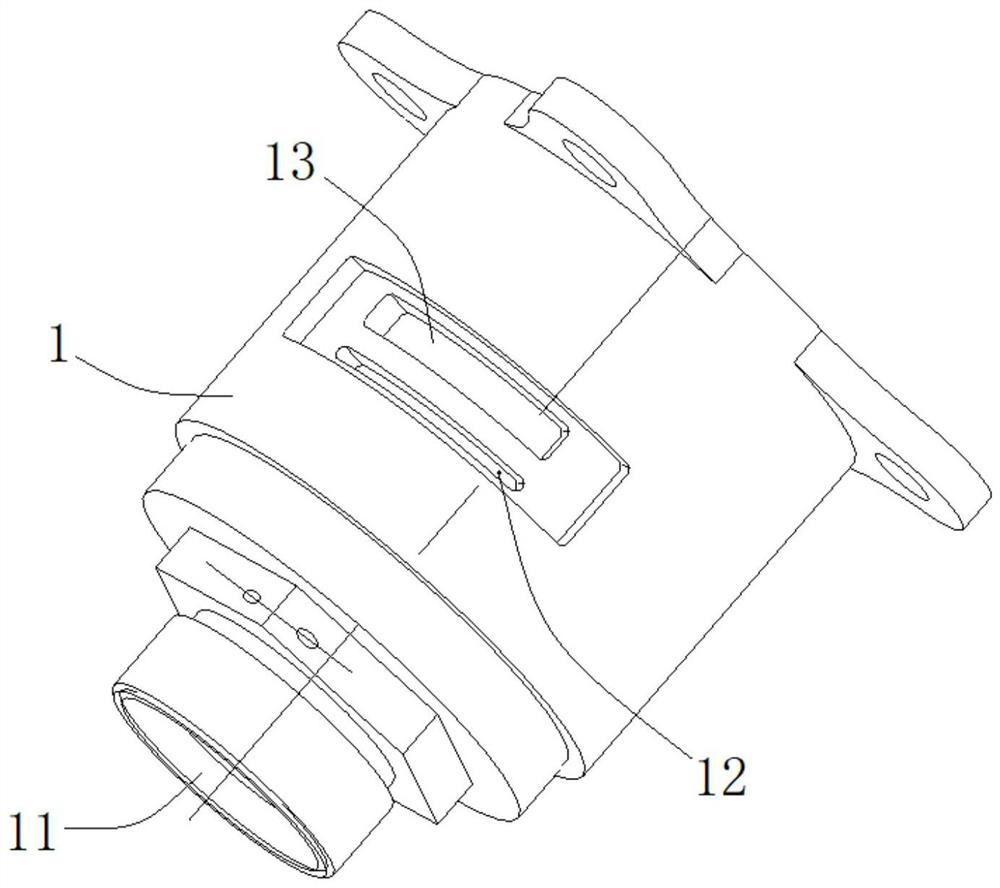

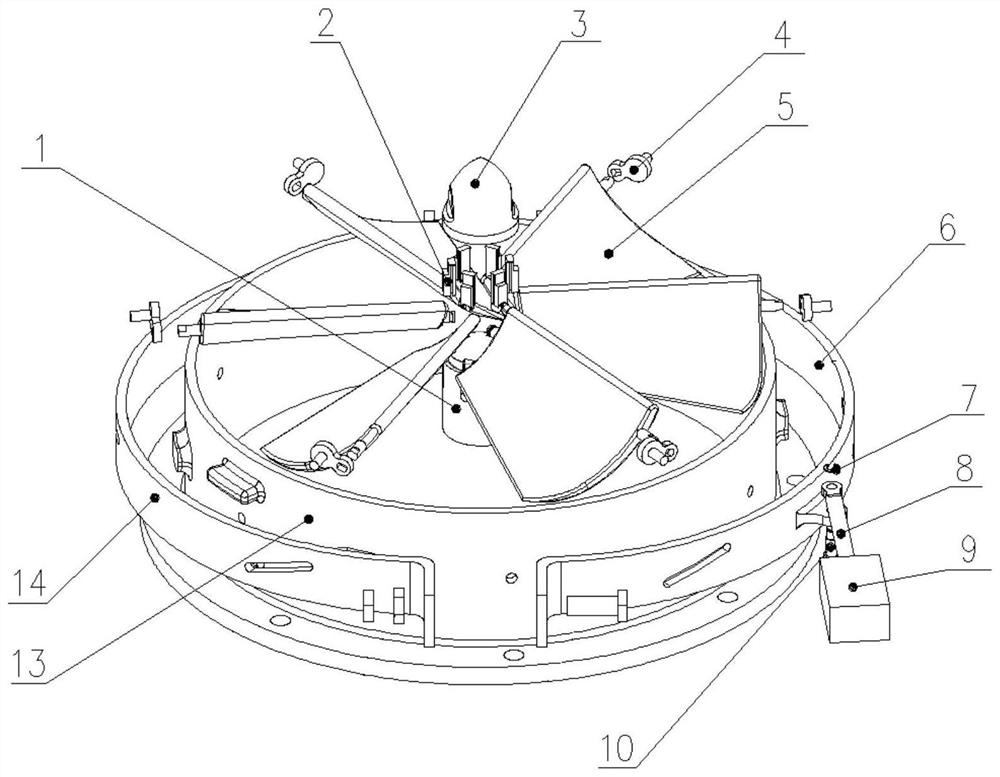

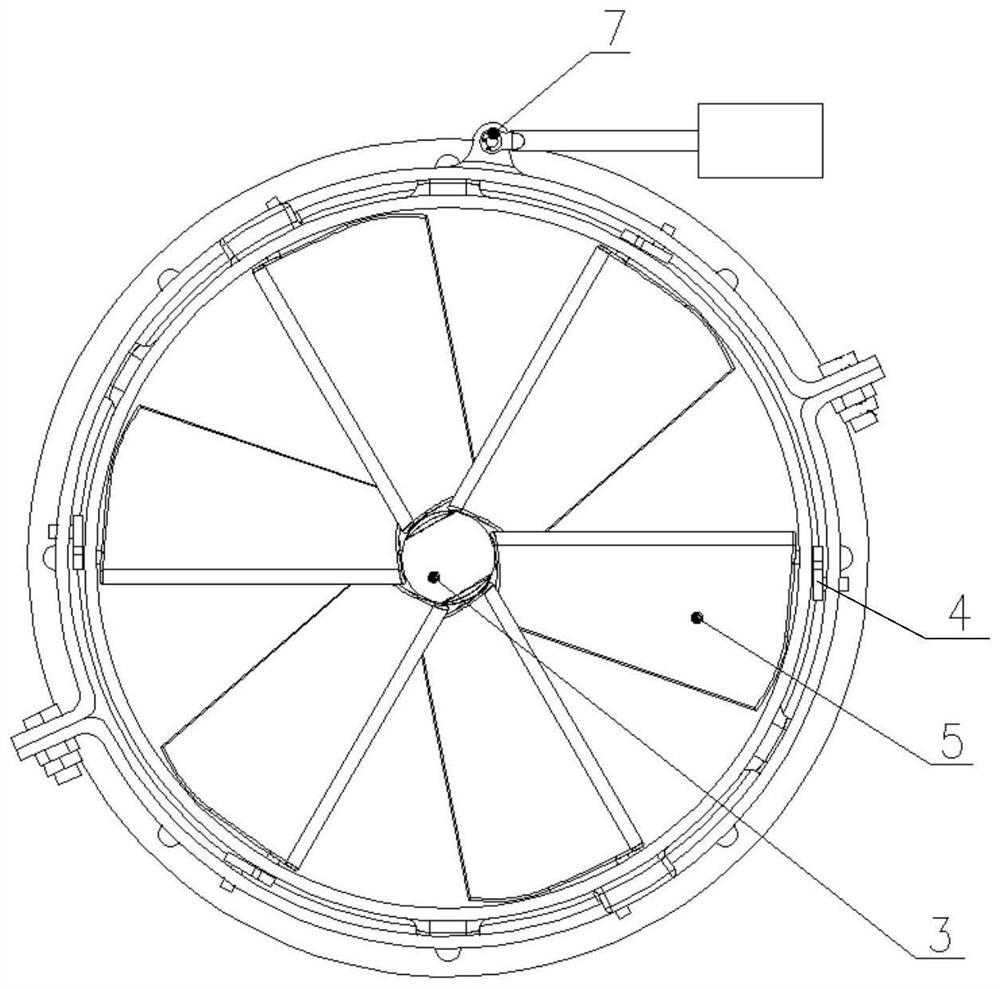

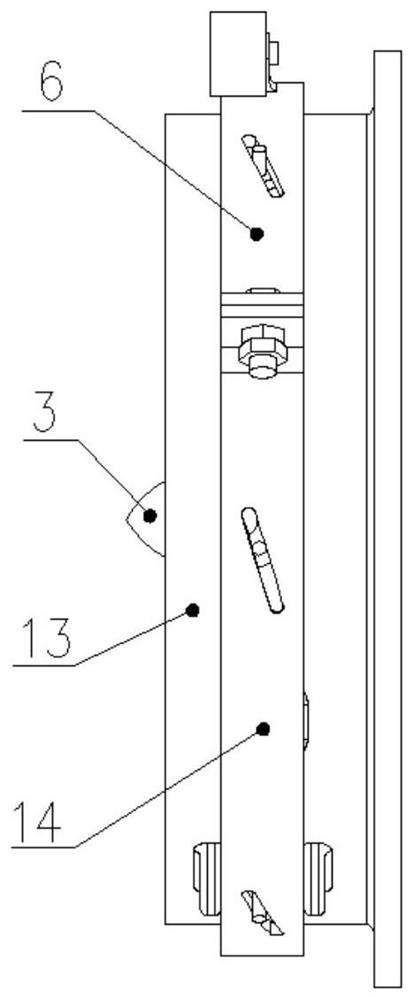

Air inlet prerotator with adjustable blade angle

ActiveCN110594198AChange flow characteristicsSimple structurePump componentsPumpsTurbochargerEngineering

The invention provides an air inlet prerotator with adjustable blade angle, and belongs to the technical field of power machinery. The air inlet prerotator with adjustable blade angle is installed atan air inlet of a compressor of a turbocharger and comprises a wheel hub, a rim and a dial assembly which are arranged coaxially from the inside to the outside; the wheel hub is connected with the airinlet of the compressor; the dial assembly comprises a first dial and a second dial which are connected with each other, the first dial and the second dial are both provided with chutes; the first dial or the second dial is connected with an electric control actuator through a movement connecting rod; one end of the wheel hub is provided with a wheel head which is used for guiding flow and preventing adjustable blades from moving along the axial direction of the wheel hub; the plurality of adjustable blades are uniformly arranged around the wheel hub, one ends of the adjustable blades are connected with the wheel hub, the other ends of the adjustable blades are connected with a deflector rod, and the deflector rod is connected with the chutes in a sliding manner. The air inlet prerotatorwith adjustable blade angle has simple structure, can widen the flow and regulation range of the supercharger compressor, and improve the economy and adaptability of an engine.

Owner:LIAONING TECHNICAL UNIVERSITY

PVC electrostatic flocking glove and processing method thereof

ActiveCN109647674AIncreasing the thicknessGood moisture absorptionPretreated surfacesDomestic articlesCooking & bakingSlurry

The invention relates to the technical field of PVC gloves, in particular to a PVC antibacterial flocking glove. A processing method comprises the steps of hand mold preparing; first-time starching; first-time baking, specifically, a hand mold after the first-time starching is put into a drying oven to be baked for 5-15 minutes with the temperature being 80-150 DEG C; second-time starching, specifically, the hand mold after the step(3) is soaked in starch liquid when the temperature is reduced to 70-110 DEG C; second-time baking, specifically, the hand mold after the second-time starching is put into the drying oven to be subjected to high-temperature plasticizing; third-time starching, specifically, the hand mold is soaked with PVC flocking glue; electrostatic flocking, specifically, fluff used in the electrostatic flocking is composite fiber fluff, and the composite fiber fluff is made of the following raw materials of 70-100 parts of polylactic acid slices, 8-12 parts of micron grade bamboo charcoal powder, 0.6-3 parts of micron grade silver wires and 7-10 parts of micron grade graphene powder; and aftertreating, cooling, flanging demoulding, testing, sorting and packaging are performed on the hand mold after the electrostatic flocking after the hand mold is dried and shaped, wherein the drying shaping temperature is 80-200 DEG C. According to the PVC electrostatic flockingglove and the processing method thereof, the composite fiber fluff is utilized to improve the antibacterial and bactericidal functions of the PVC gloves.

Owner:三门县旭月日用品有限公司

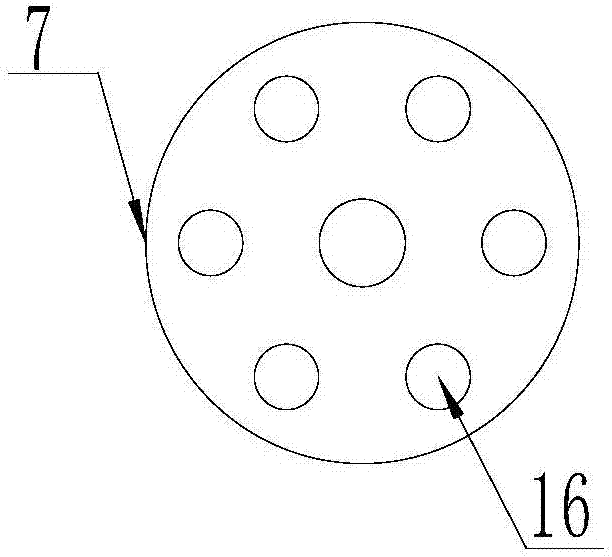

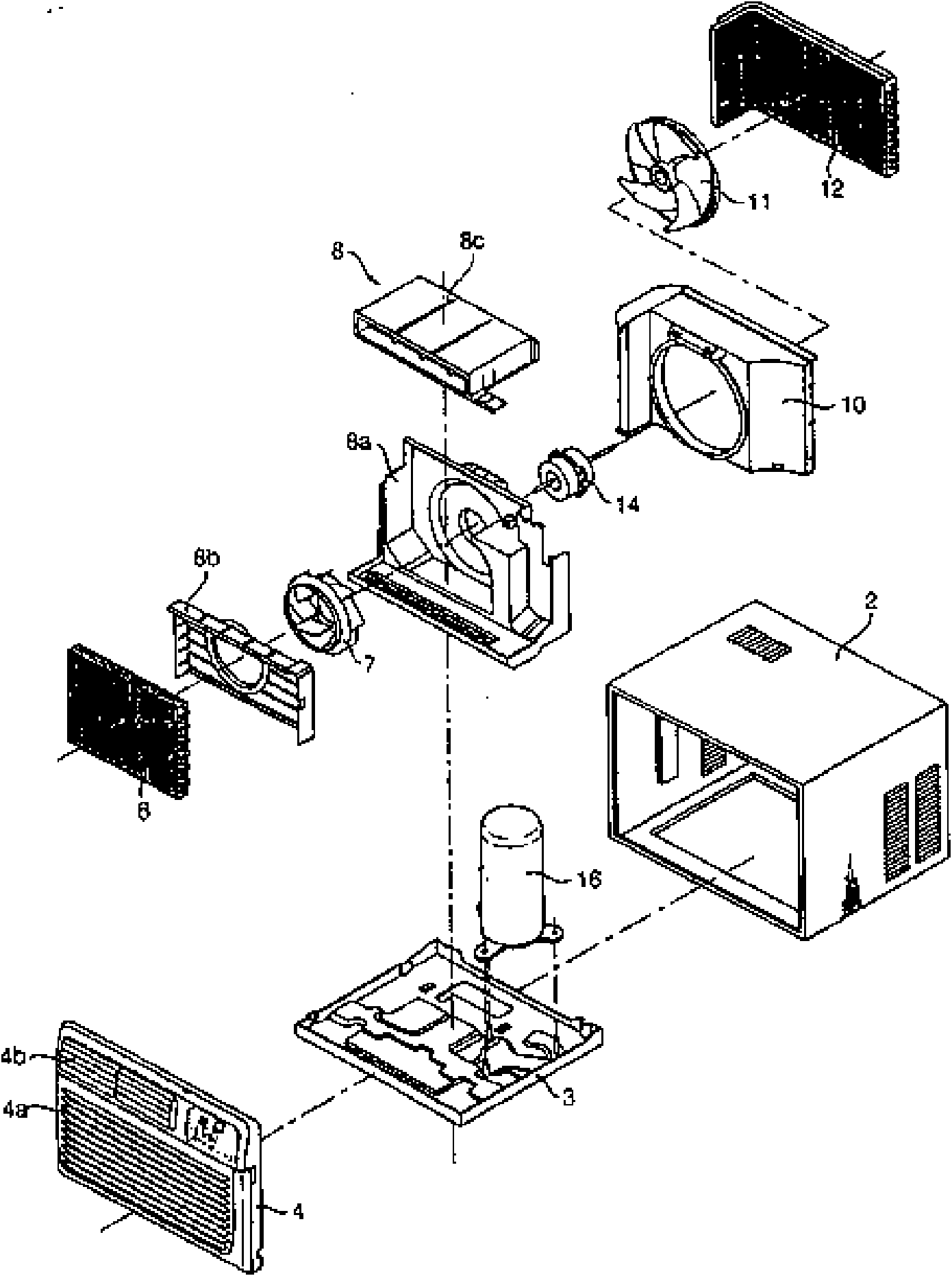

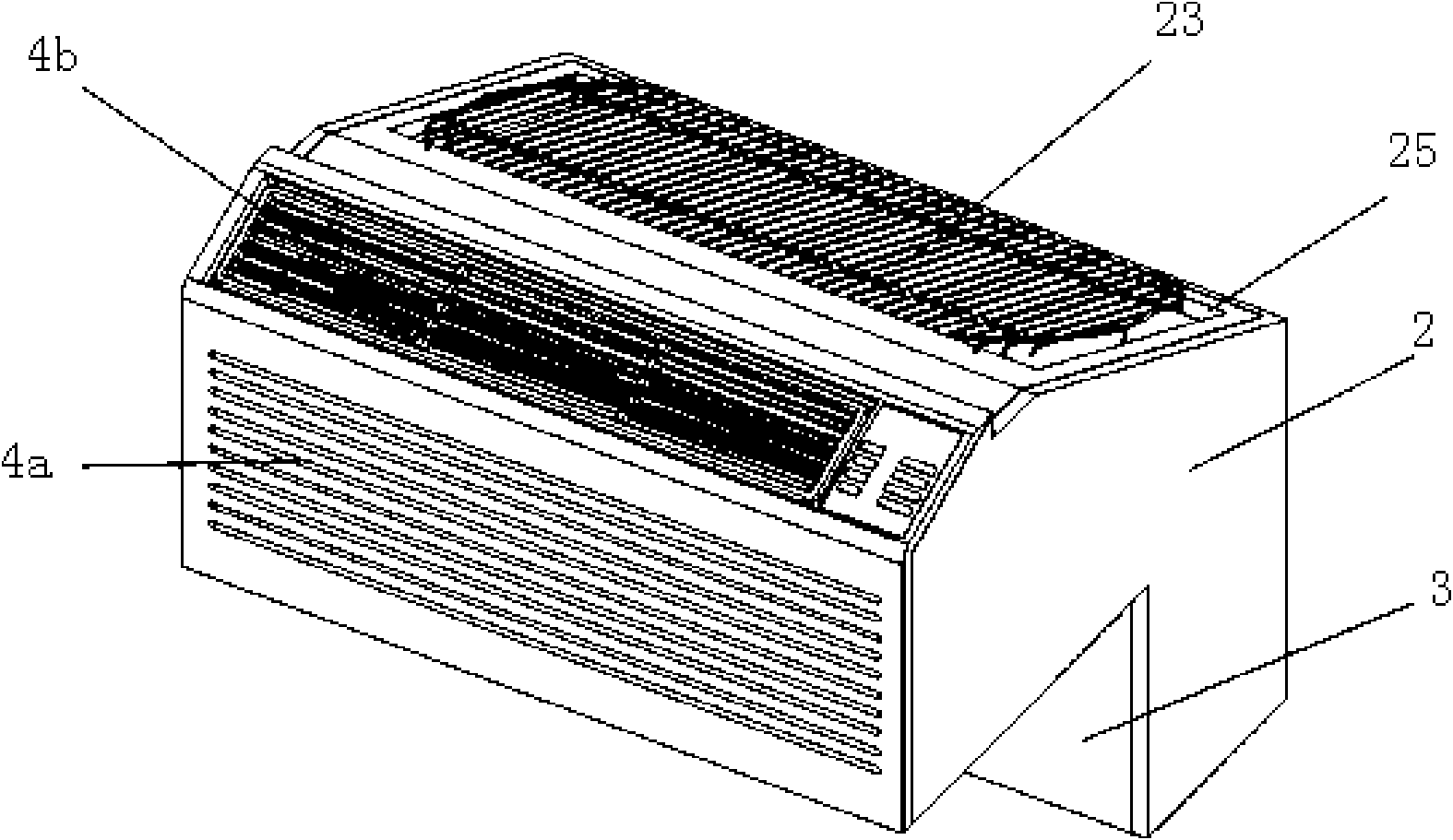

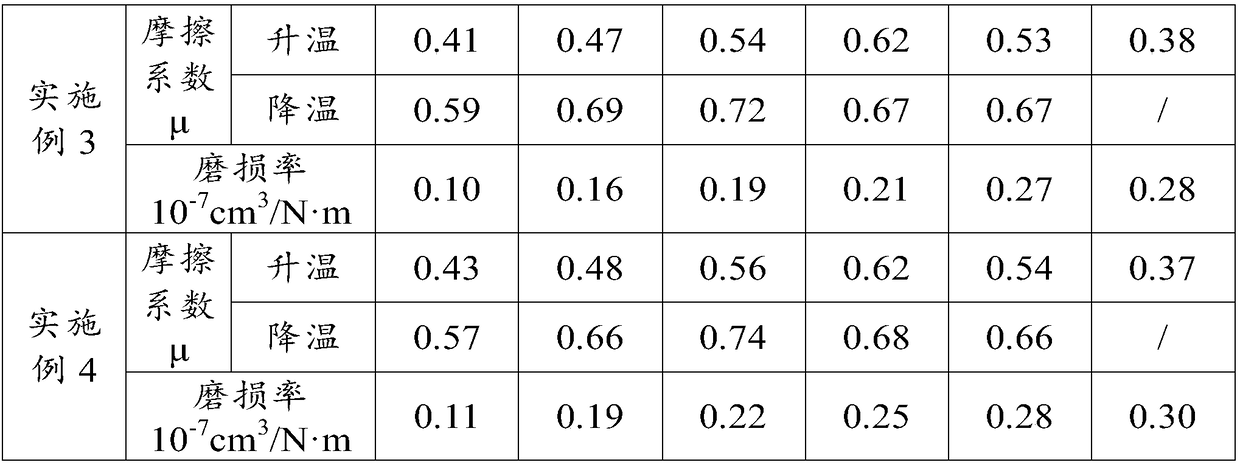

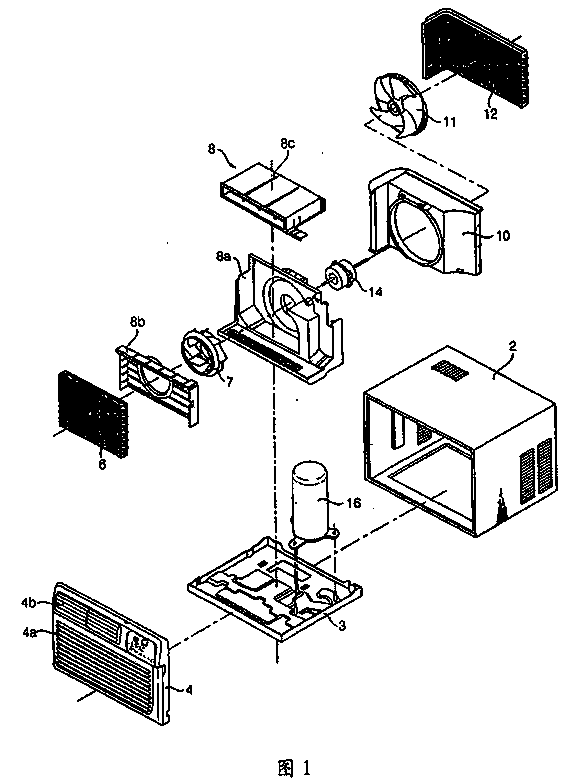

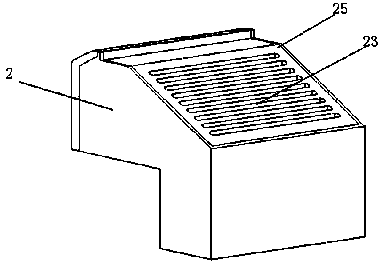

Window air conditioner

InactiveCN102003786AImprove comfortImprove user experienceNoise suppressionAir-flow control membersThe chokesEvaporator

The invention discloses a window air conditioner which comprises an indoor panel, a case, an evaporator, an indoor fan, a condenser, an outdoor fan, a compressor and a chassis, wherein a noise filtering device is arranged at the exhaust port of the air conditioner, and comprises an exhaust plate and a choke plate; multiple round vent holes are arranged on the exhaust plate in order, and the choke plate is arranged at the inner side of the exhaust plate; the choke plate is formed by mutually connecting multiple round choke pieces the diameters of which are larger than those of the round vent holes on the exhaust plate, and the positions of the choke pieces are in one-to-one correspondence with the positions of the vent holes; and the included angle of the choke plate and the exhaust plate is adjustable, i.e. the included angle of each choke piece and the air-out direction of the corresponding vent hole can be changed at the same time, thus the flow characteristic of air which is discharged along the indoor direction is changed, thereby changing the sound quality of the noise formed when the air rubs with the exhaust plate. Users can set the open angles of the choke pieces according to the judgment on the noise, so that products can obtain sound characteristics adaptive to different requirements of the users.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

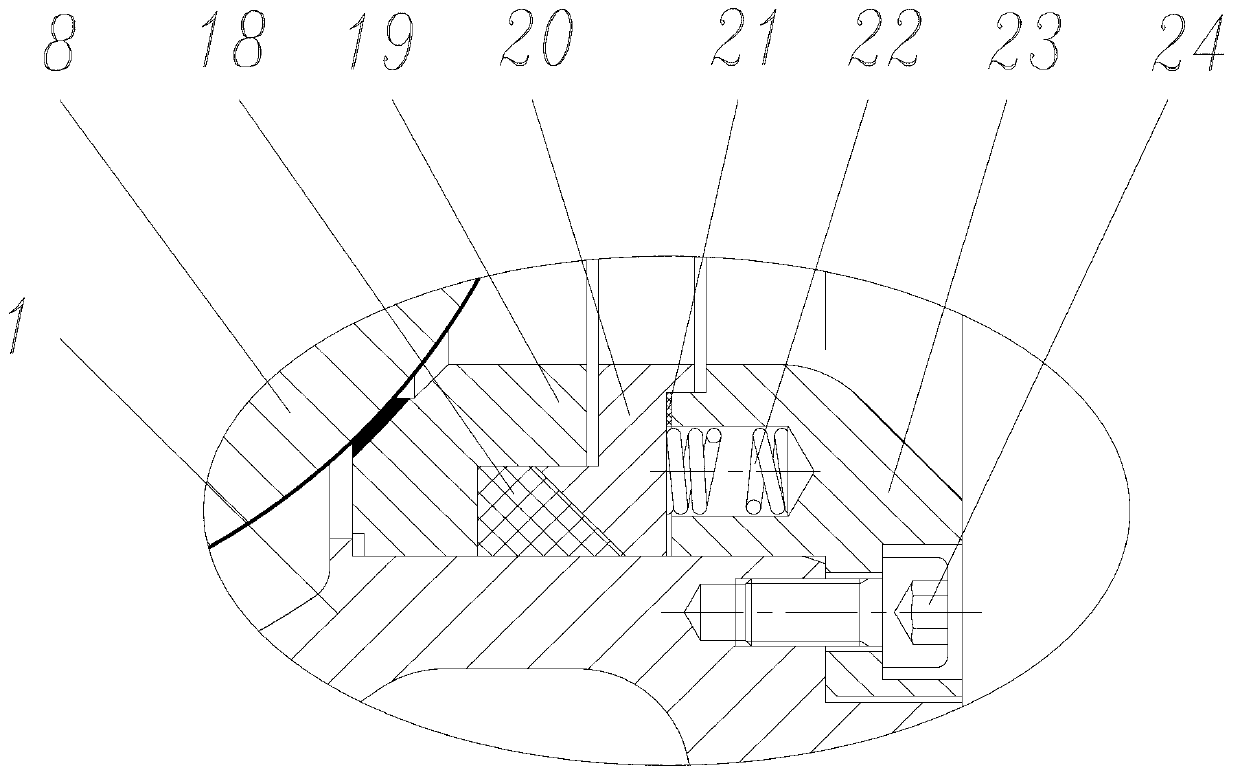

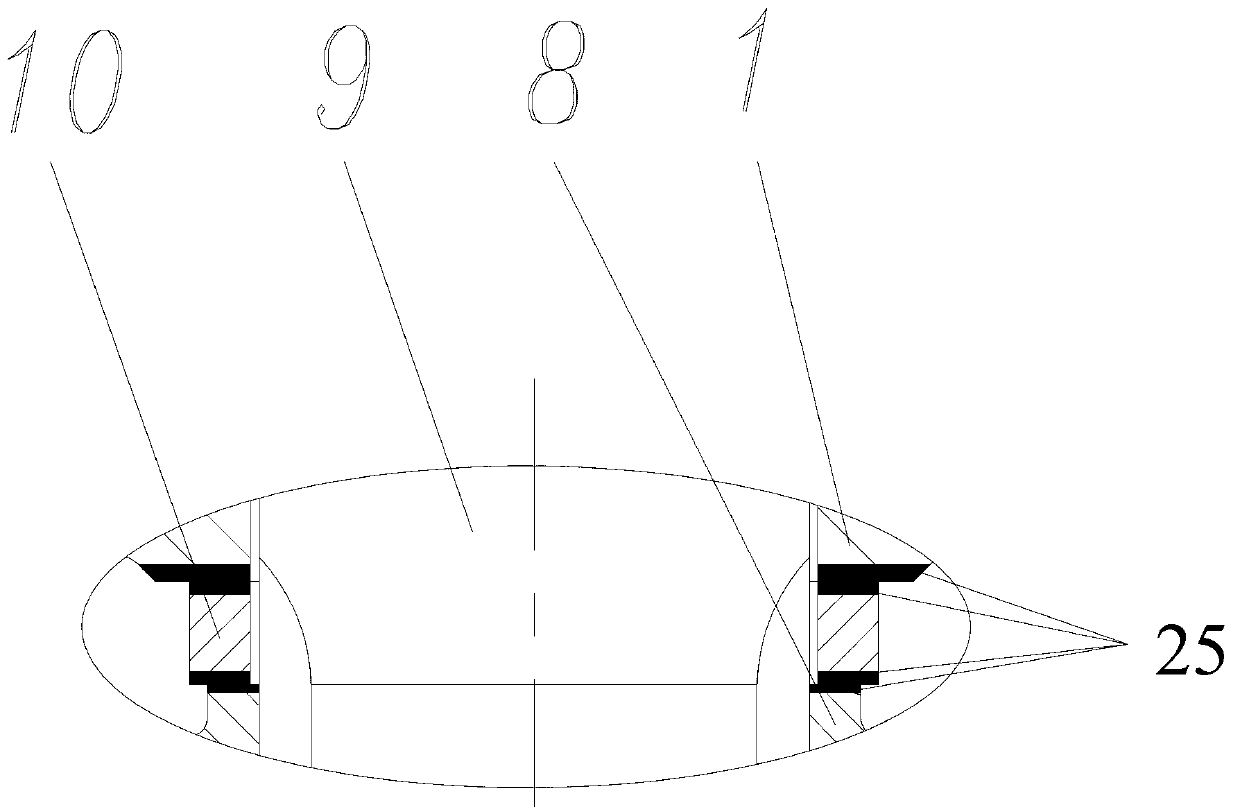

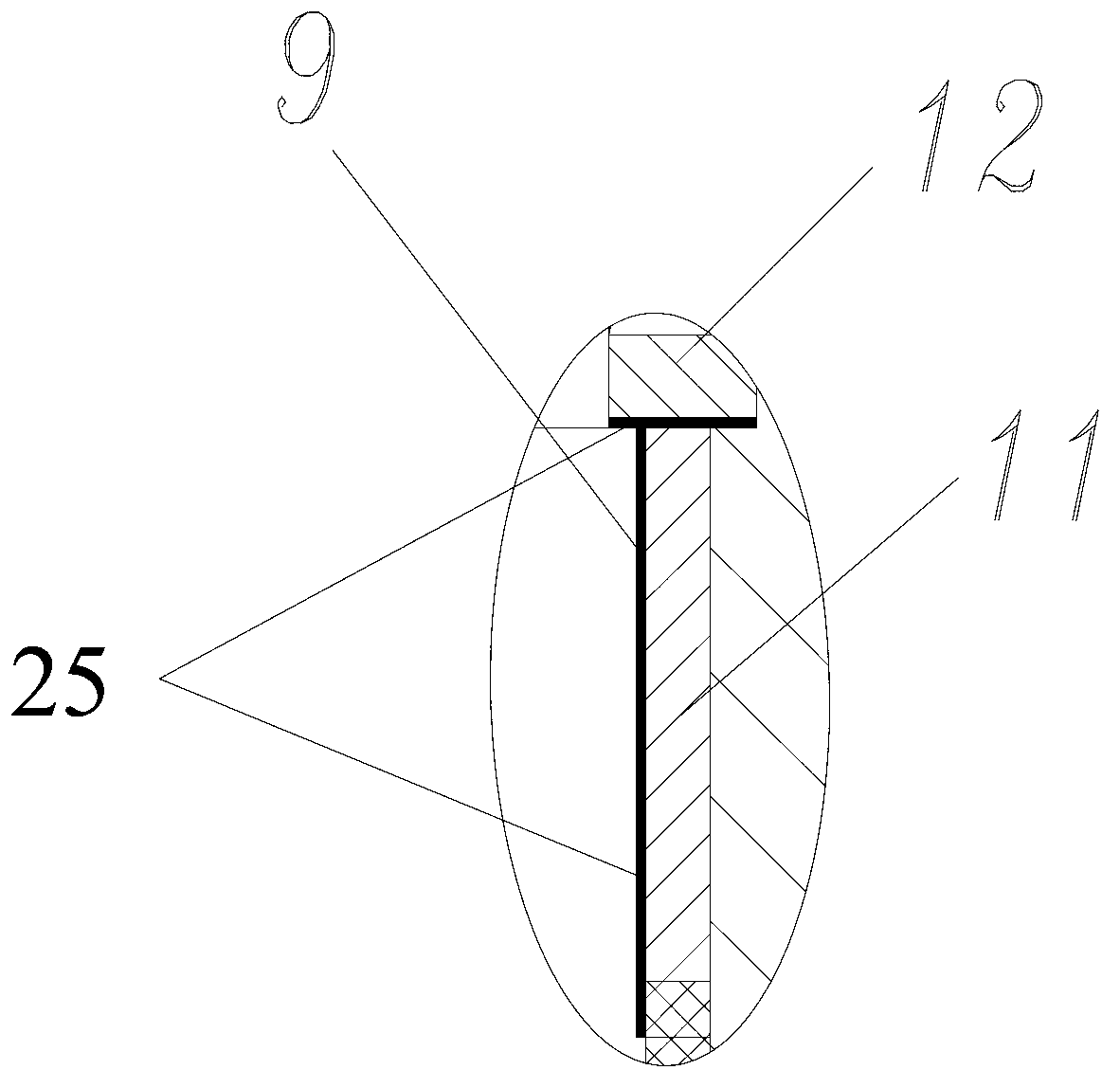

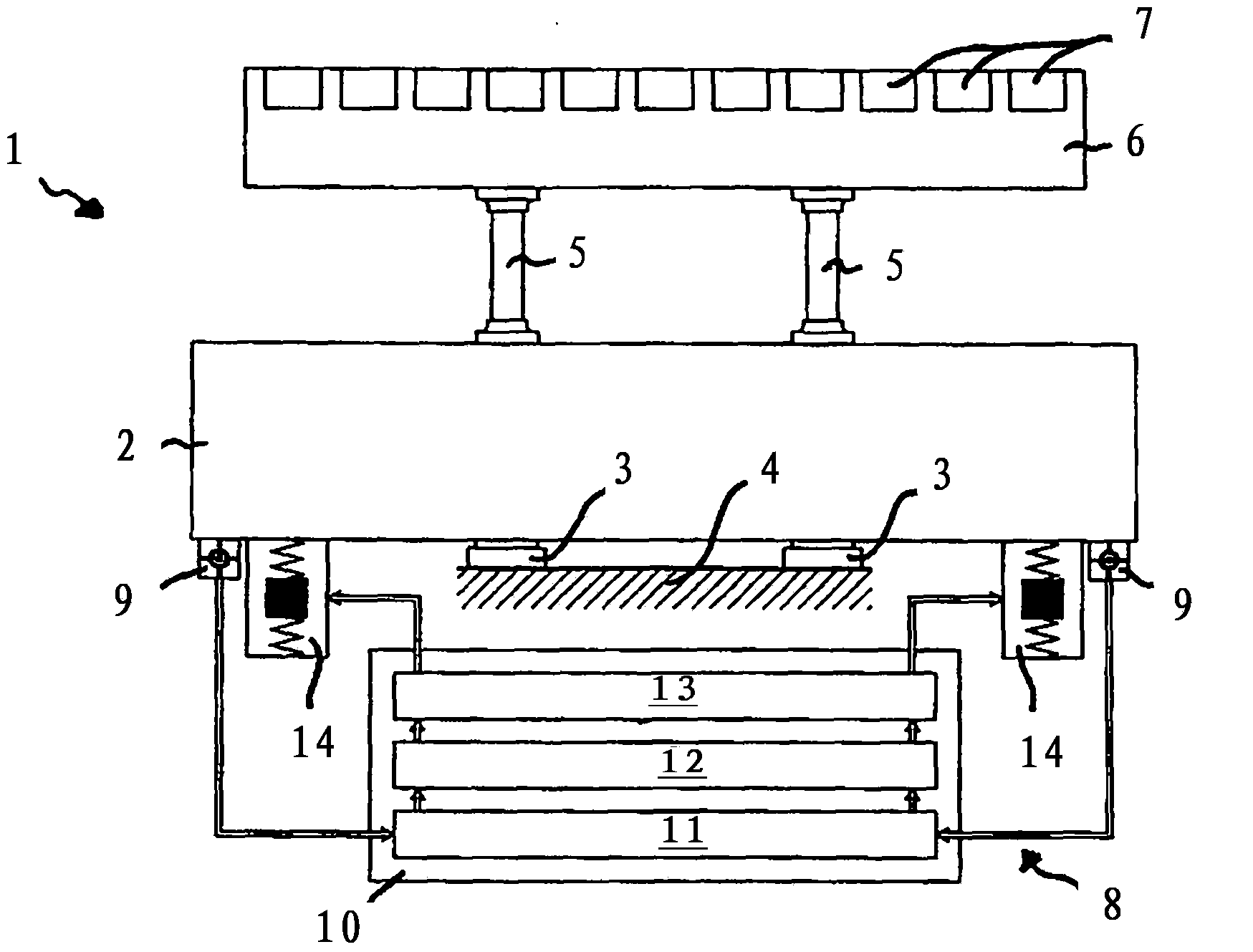

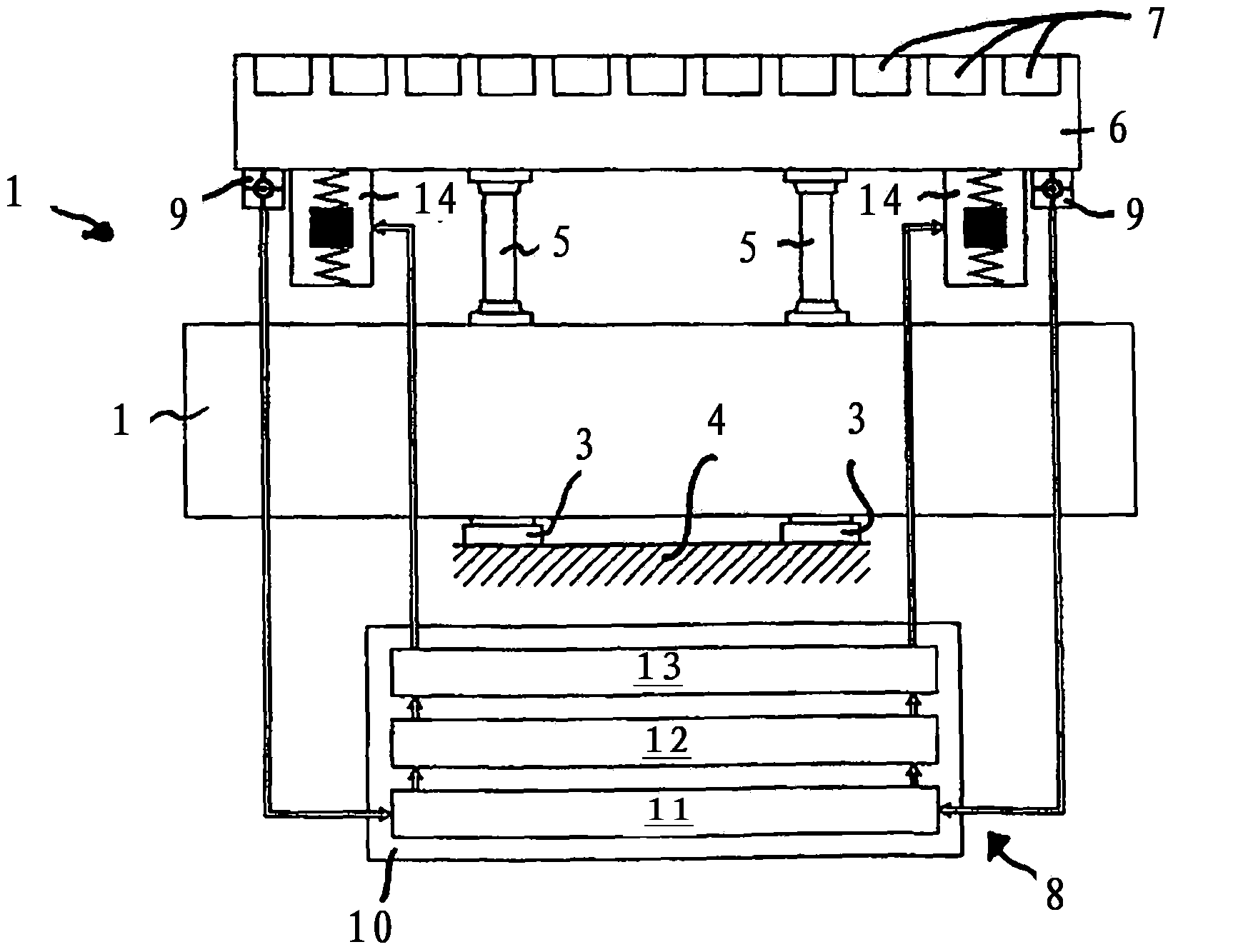

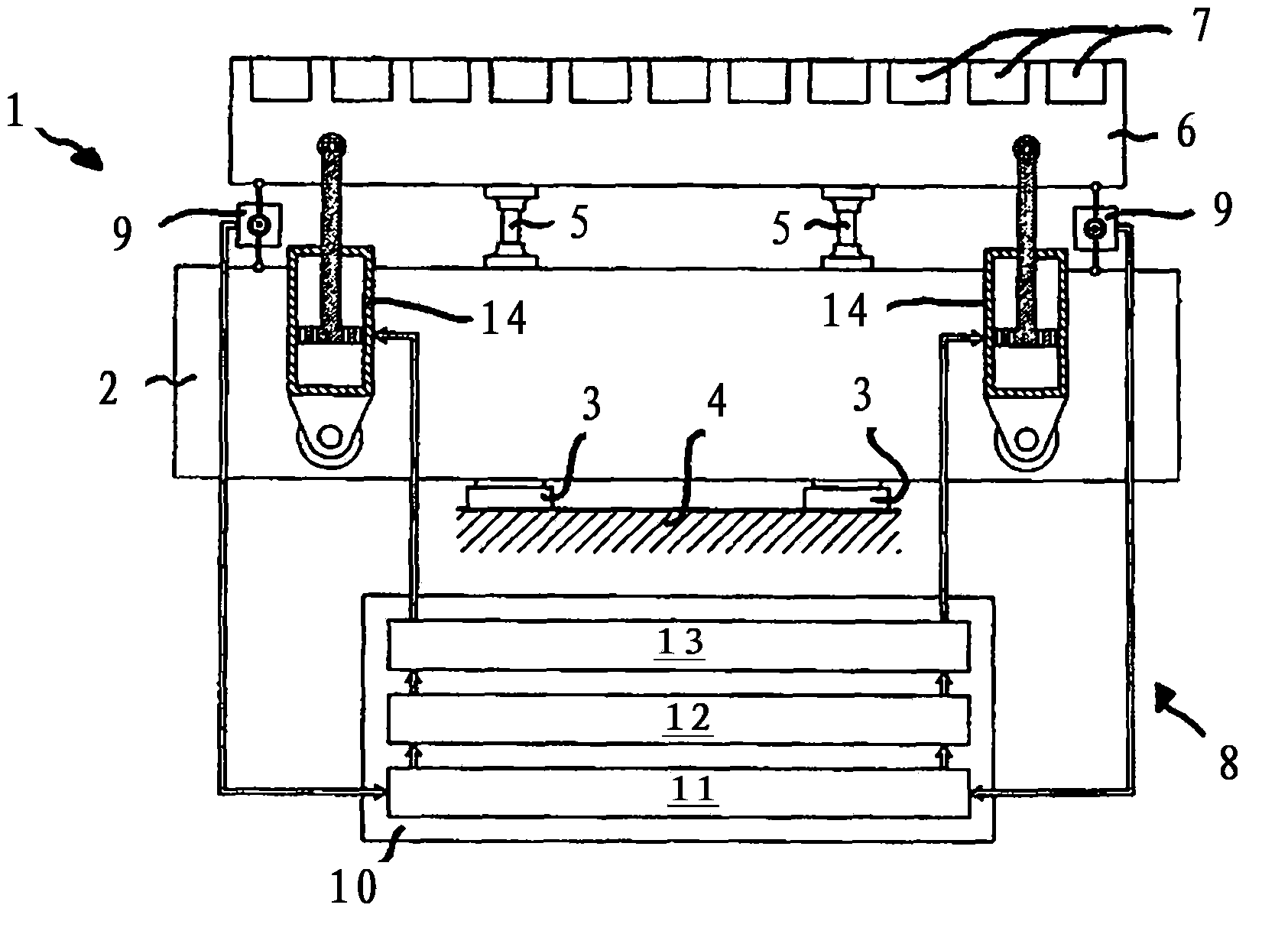

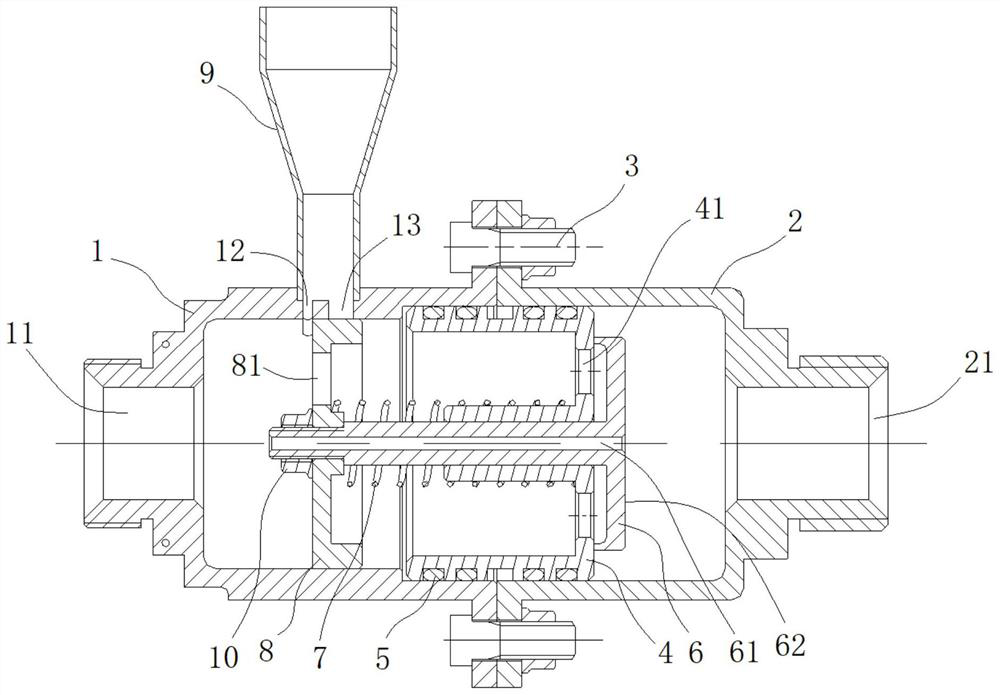

Brush making machine and method used for reducing vibration

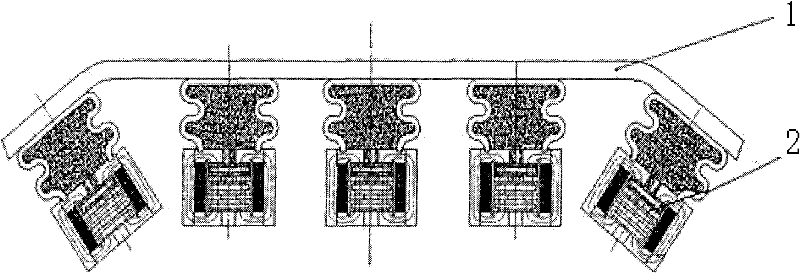

InactiveCN103671691ASmall space requirementOptimizing Vibration Reduction ResultsBrush bodiesNon-rotating vibration suppressionControl engineering

The present invention relates to a brush making machine (1), comprising at least one movable function part (7) and a device (8) used for reducing vibration caused by movement of the function part (7). The device (8) is configured for actively eliminating and / or actively damping vibration. The present invention also relates to a method used for reducing vibration caused by movement of the function part (7) of the brush making machine (1), so as to reduce the vibration by actively eliminating and / or actively damping the vibration.

Owner:ZAHORANSKY AG

Method for producing filter tip addition liquid and its filter tip

InactiveCN1857130AChange flow velocityChange flow characteristicsTobacco smoke filtersMentholChinese-olive

The present invention relates to a production process of filter tip additive liquid and filter tip capable of filtering out tar and nicotine components from cigarette. The production process of the filter tip additive liquid includes the following steps: preparing material including licorice, wild chrysanthemum flower, menthol, honeysuckle, fructus momordicae, Chinese olive, loquat leaf, adenophora root and tea in certain weight proportion; stamping material; soaking the stamped material in active water to swell; and squeezing the swelled material to obtain the additive liquid. Dropping the additive liquid to filter tip of cigarette can increase the adsorption area, strength the attachment and separate harmful matter from cigarette, while producing some health functions of moistening throat, cleaning teeth, etc.

Owner:胡晓宇

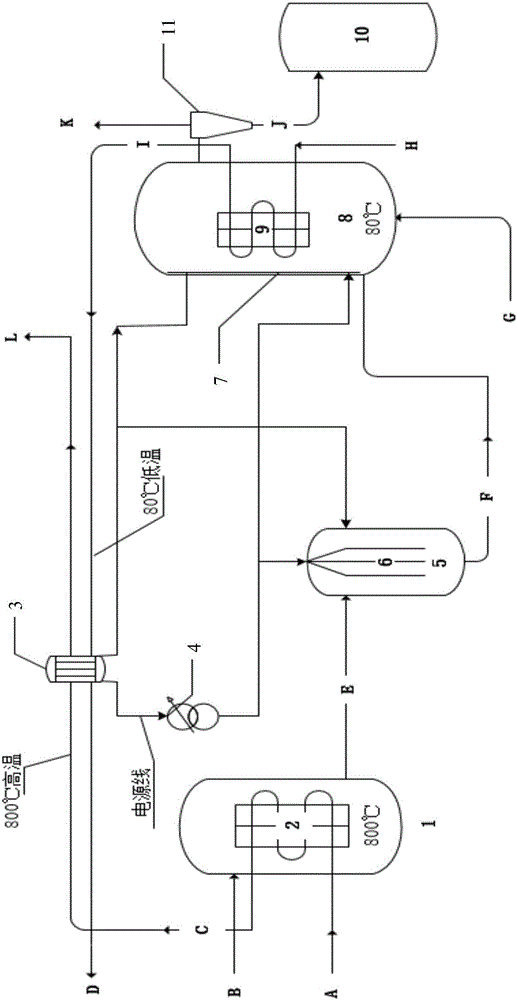

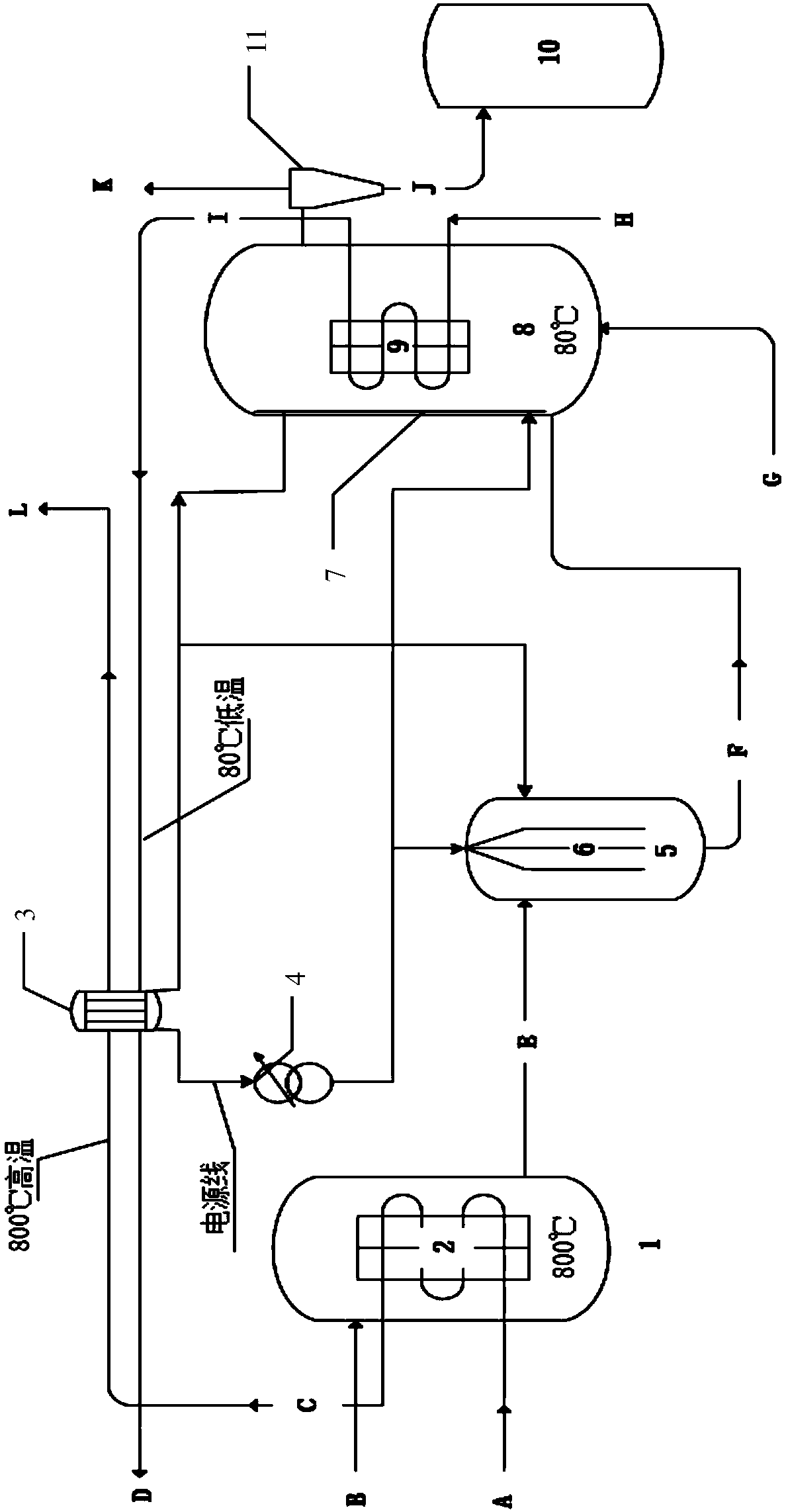

Device and method for removing CO2 from flue gas in power plant by using fly ash

ActiveCN106474912ARealize resource utilizationLow costGas treatmentDispersed particle separationCold airFluidized bed

The invention discloses a device for removing CO2 from flue gas in a power plant by using fly ash. The device comprises an activation reactor, a charging device, a fluidized bed, a cyclone separator and a waste material bin, wherein the output end of the activation reactor is connected with the charging device; the output end of the charging device is connected with the fluidized bed; the output end of the fluidized bed is connected with the cyclone separator; and the output end of the cyclone separator is connected with the waste material bin. The invention also discloses a method for removing the CO2 from the flue gas in the power plant by using the fly ash. The method comprises the following steps: conveying the fly ash into the activation reactor and carrying out activation treatment, then carrying out conveying into the charging device and carrying out charging treatment, then carrying out conveying into the fluidized bed so as to remove the CO2 in the flue gas, and finally carrying out conveying into the waste material bin. According to the invention, the device organically combines with a coal-fired power generating system; the flue gas and cold air in the coal-fired power plant can be utilized to provide a heat source and a cold source for the device; meanwhile, needed electric energy is provided for the device through a thermoelectric power generation technology; thus, an optimization scheme capable of reducing cost and energy consumption is realized.

Owner:NANJING NORMAL UNIVERSITY

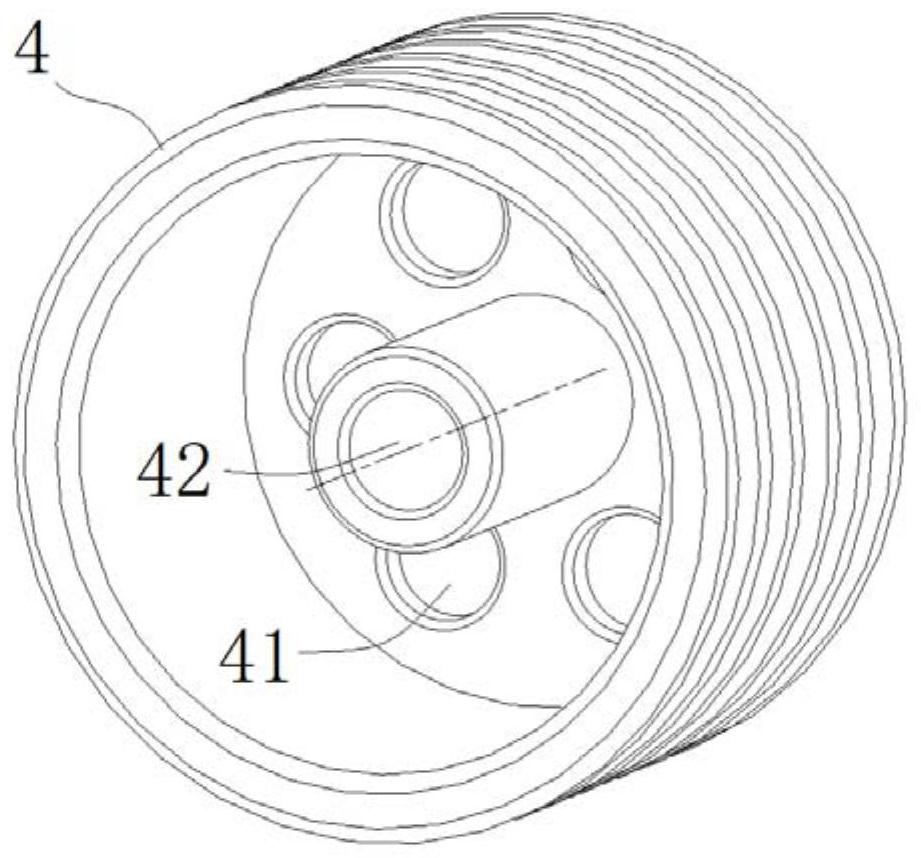

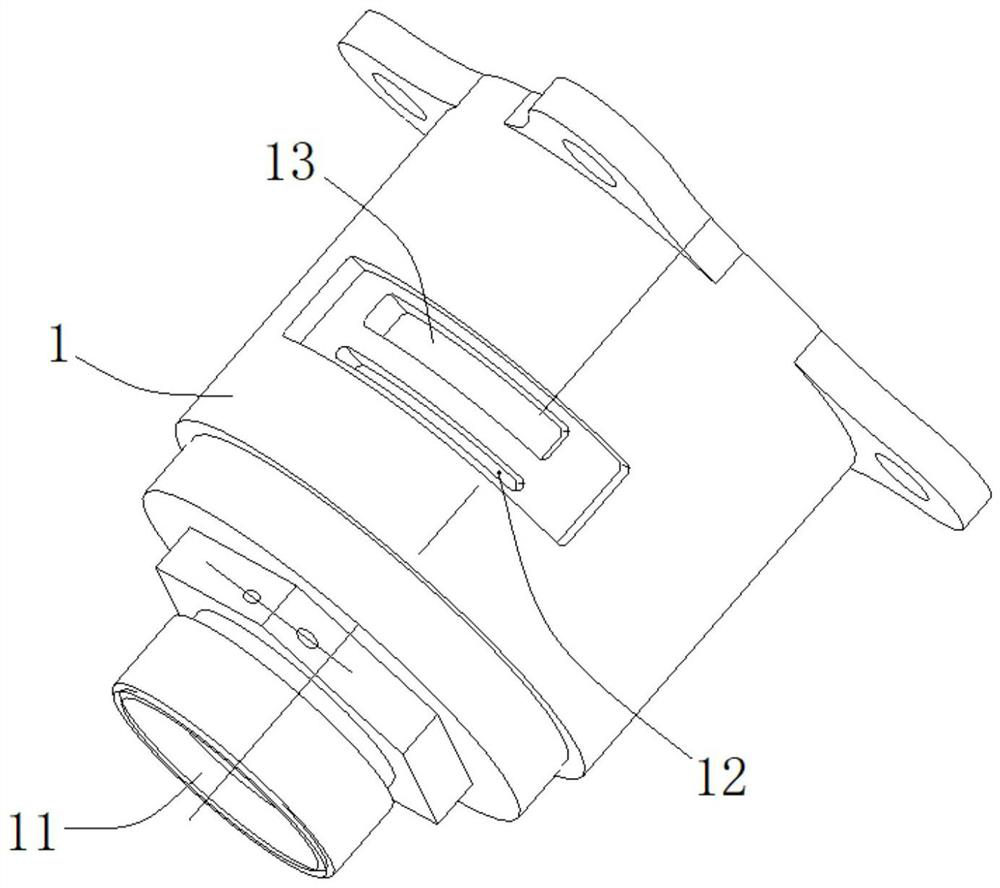

Aero-engine lubricating oil system multi-way flow distribution valve

ActiveCN112648523AGuaranteed clearanceImprove shock absorptionWeight reductionTurbine/propulsion lubricationMechanicsValve seat

The invention provides an aero-engine lubricating oil system multi-way flow distribution valve. The flow distribution valve comprises a front shell, a rear shell, a valve seat, a main valve and an auxiliary valve, wherein the front shell is provided with an extrusion oil film connector and a first lubricating oil cavity opening formed in the wall of the front shell and used for communicating with the first lubricating oil cavity, the first lubricating oil cavity opening at least comprises a first lubricating oil cavity low-state flow channel and a first lubricating oil cavity high-state flow channel which are arranged in the axis direction of the front shell, the rear shell is fixedly connected with the front shell and provided with a second lubricating oil cavity connector used for communicating with a second lubricating oil cavity, the valve seat is arranged in a containing cavity formed by the front shell and the rear shell, a valve flow channel is arranged on the valve seat, the main valve and the auxiliary valve can move relative to the valve seat, the main valve is supported by the valve seat and covers the valve flow channel, a spring is arranged between the valve seat and the auxiliary valve, the main valve is provided with a main valve flow channel communicating with the extrusion oil film connector and the second lubricating oil cavity connector, and the auxiliary valve is provided with an auxiliary valve flow channel for communicating the extrusion oil film connector with the valve flow channel.

Owner:AECC SHENYANG ENGINE RES INST

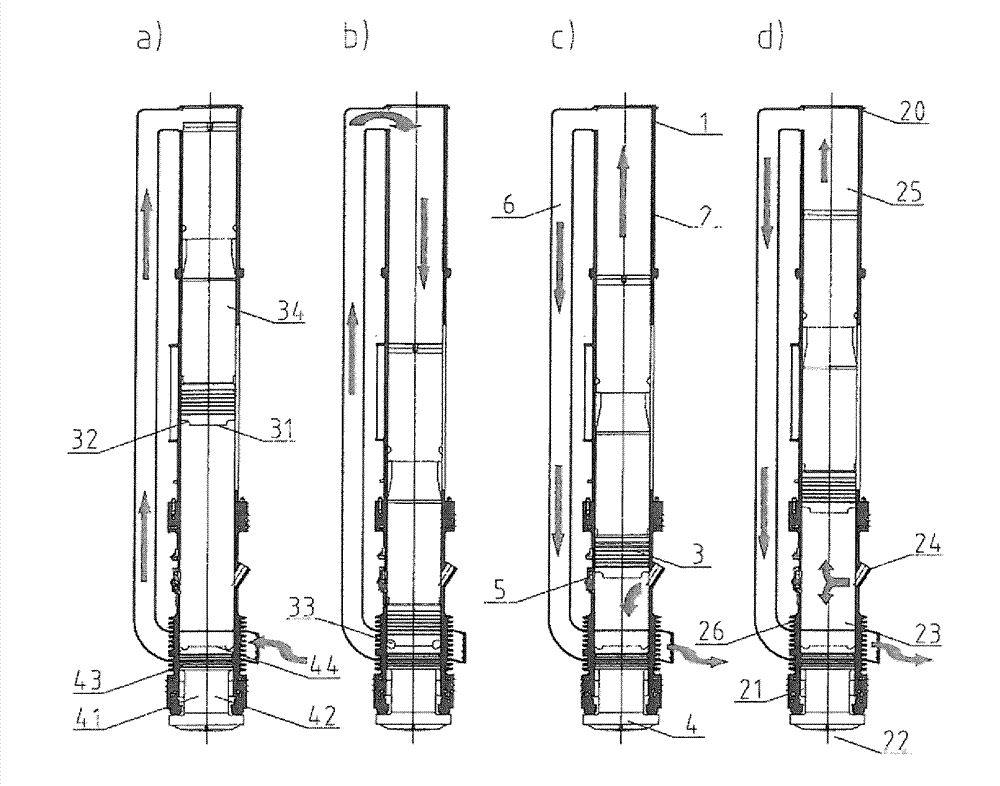

Tamping device

InactiveCN102953380AEasy to passIncrease cooling powerBulkheads/pilesSoil preservationEngineeringPiston

The invention relates to a tamping device, particularly to a diesel tamping device. The tamping device is provided with a cylinder having a movably supported piston therein and a tamping block arranged under the piston during the operating state, wherein a working cavity is limited in the axial direction between the end face of the tamping block inside the cylinder and the end face of the piston. With the arranged fuel jet apparatus, the fuel with regulated amount can be led to the working cavity. The cylinder (2) is sealed via a cover plate (20) at its upper side face opposite to the tamping block (4). A replacing chamber is arranged between the cover plate (20) and the piston (3) as well as between the piston (3) and the cover plate (20) when the phase step height of the piston (3) is at the maximum degree. The replacing chamber is connected with the air cooling apparatus applicable to the tamping device (1).

Owner:DELMAG

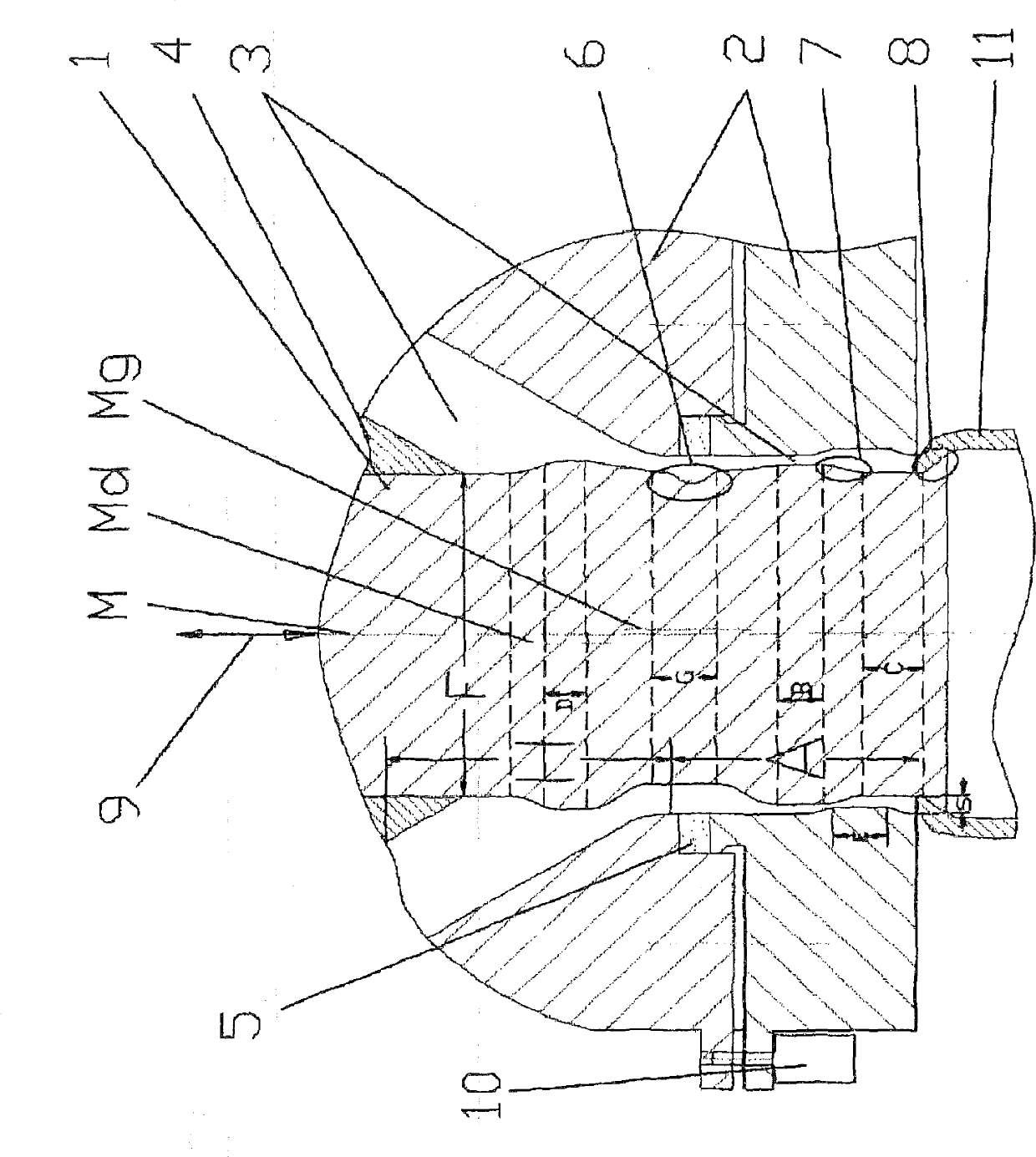

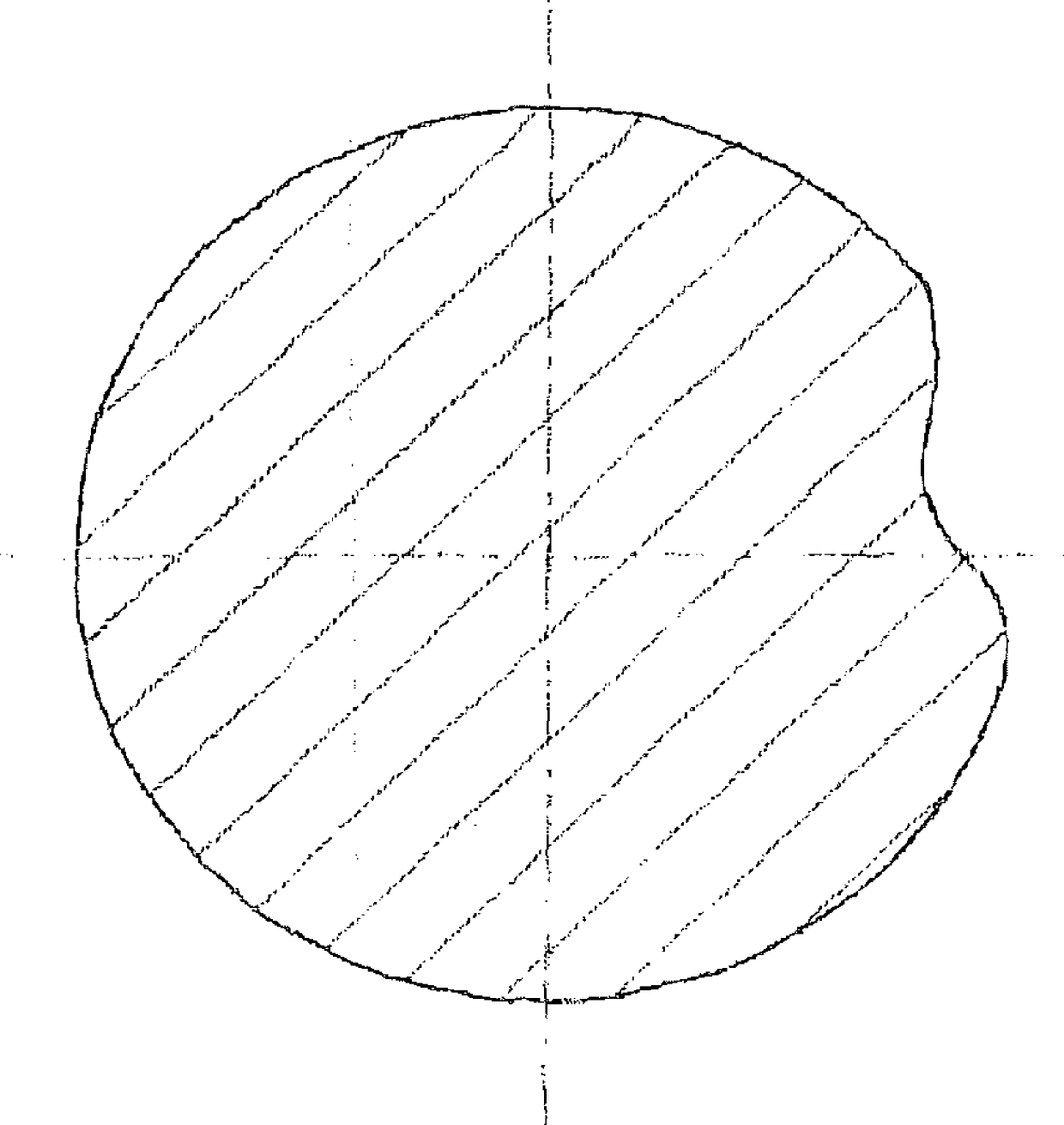

Extrusion head and method for producing hollow bodies

InactiveCN104010791AUniform discharge speedAffect discharge speedDomestic articlesTubular articlesEngineeringExtrusion

The invention relates to an extrusion head and to a method, by way of which for example the thickness distribution of hollow bodies can be further improved. To this end, the extrusion head consists of at least one mandrel (1) and a nozzle (2), which mandrel (1) and nozzle (2) may be geometrically rigid and thus not changeable or else deformable in a regionally flexible manner and which form a flow duct (3), wherein the mandrel (1) and the nozzle (2) are positionally changeable in relation to one another, as a result of which the geometry of an outlet gap (s) of the flow duct (3) is changeable during the discharge of a melt, wherein each head part has at least one head section having a constant cross-sectional area in an outlet region (A) of the extrusion head, and wherein at least one head part has at least two head sections (B) and (C); which each have predominantly constant cross-sectional areas within the head section (B), (C), are axially spaced apart and have different cross-sectional areas from one another.

Owner:海因茨·格罗斯

Plasticizing enhancement nylon 6 composite material with good apparent mass and preparation method thereof

Owner:CHONGQNG PRET NEW MATERIAL +2

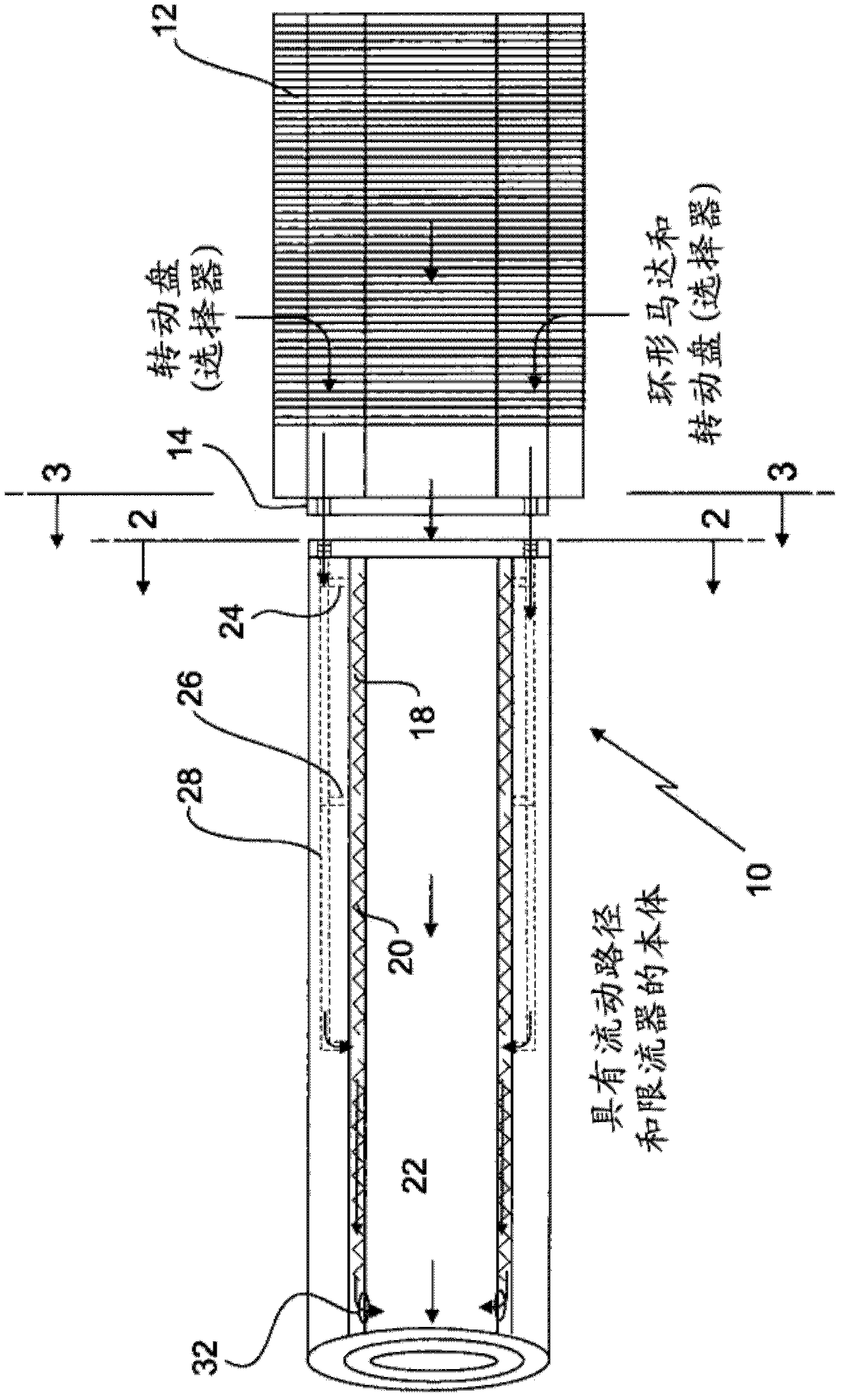

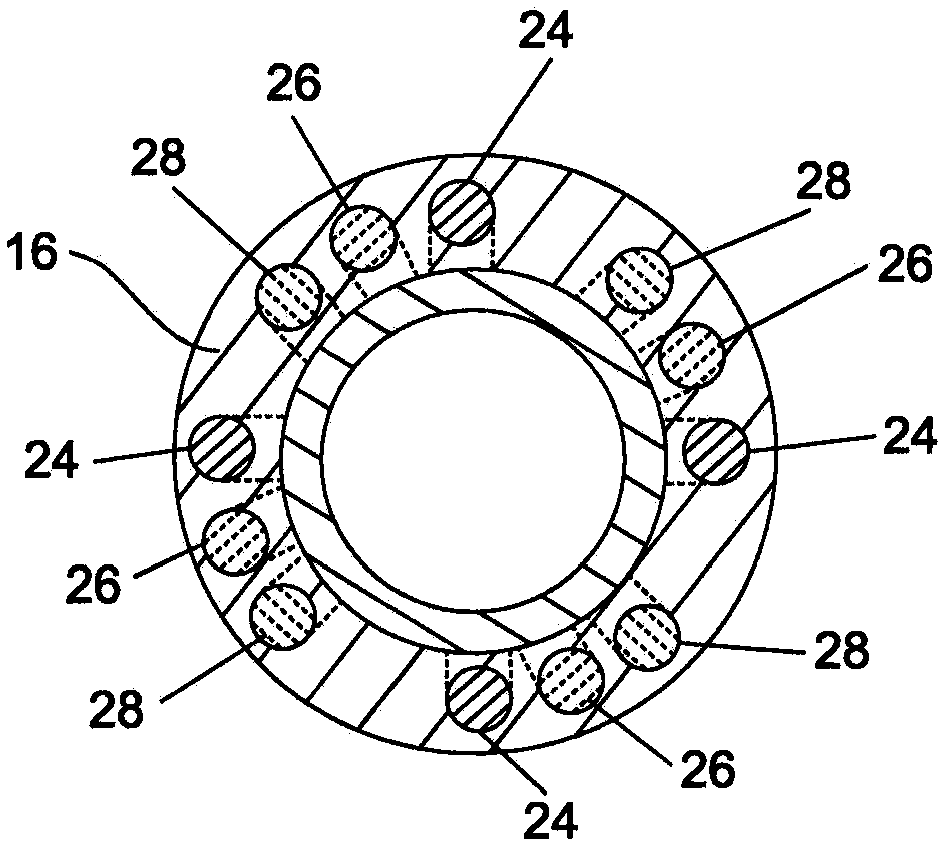

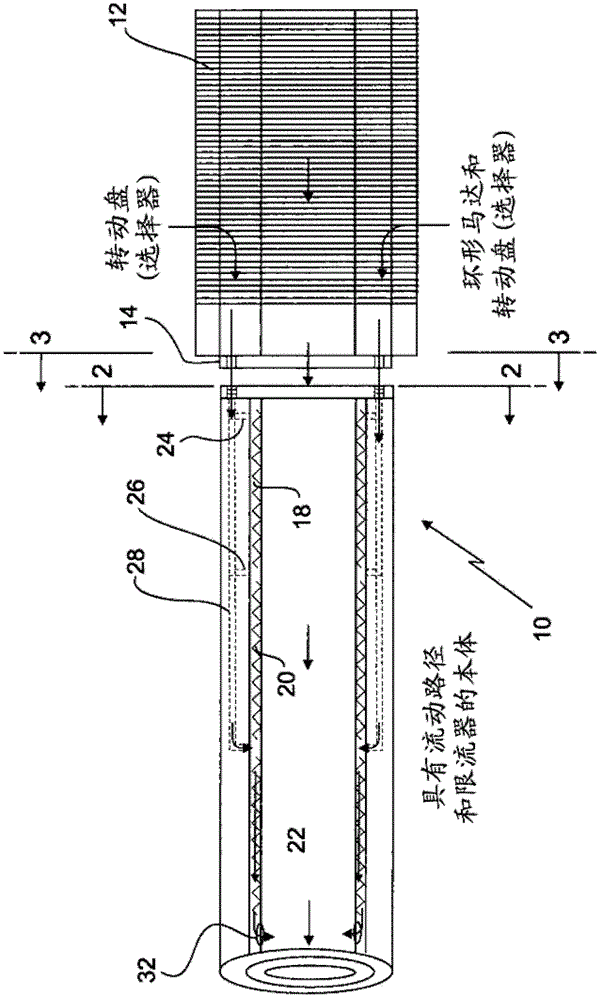

Remotely controllable variable flow control configuration and method

ActiveCN102472087AChange flow characteristicsFluid removalWell/borehole valve arrangementsMechanical engineeringEngineering

Owner:BAKER HUGHES INC

A multi-way flow distribution valve for aero-engine lubricating oil system

ActiveCN112648523BGuaranteed clearanceImprove shock absorptionWeight reductionTurbine/propulsion lubricationMechanicsValve seat

The present application provides a multi-way flow distribution valve for the lubricating oil system of an aero-engine, which includes: a front casing, which has an extruded oil film interface and a first valve arranged on the wall of the front casing and used to communicate with the first lubricating oil chamber. A lubricating oil chamber opening, the first lubricating oil chamber opening at least includes a first lubricating oil chamber low-state flow channel and a first lubricating oil chamber high-state flow channel arranged along the axial direction of the front housing; The casing has a second lubricating oil chamber interface for connecting with the second lubricating oil chamber; the valve seat is arranged in the cavity formed by the front casing and the rear casing, and the valve flow channel is arranged on it; The main valve and the auxiliary valve that can move relative to the valve seat. The main valve is supported by the valve seat and covers the valve flow channel. A spring is arranged between the valve seat and the auxiliary valve. The main valve flow channel of the lubricating oil chamber interface, and the auxiliary valve has an auxiliary valve flow channel connecting the extrusion oil film interface and the valve flow channel.

Owner:AECC SHENYANG ENGINE RES INST

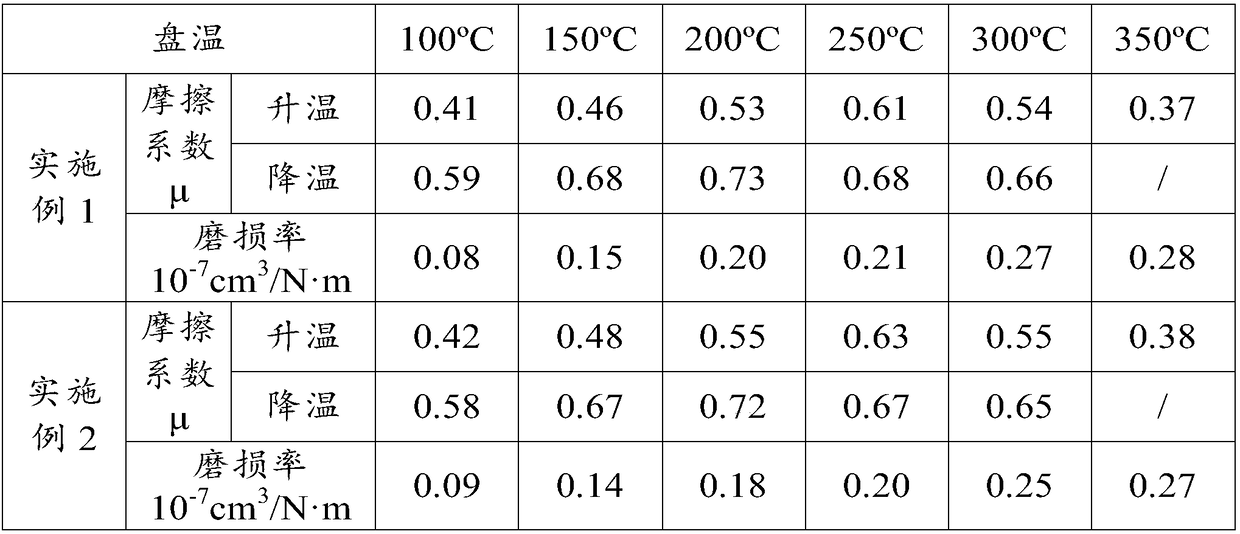

A brake pad for a disc brake

ActiveCN106810816BStable, tough and heat-resistant structureEasy to brakeOther chemical processesFriction liningEpoxyPolyester

The invention discloses a brake block for a disc brake. The brake block consists of a back plate, a thermal insulating layer and a friction material, wherein the back plate is made of a stainless steel material; the thermal insulating layer is prepared from foamed polyurethane, polyimide, glass cotton, silica-rich cotton and aluminum polyester; the friction material is prepared from thermosetting phenolic resin, thermosetting epoxy resin, short carbon fiber, aramid fiber, kaolin, graphite, molybdenum disulfide, sodium polyacrylate and polytetrafluoroethylene. The brake block for the disc brake, disclosed by the invention, is good in friction stability, low in cost, low in density, good in brake property, good in abrasion resistance, low in brake noise and good in environment resistance, and product standards which are improved day by day in the automobile manufacturing industry can be met.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

Window air conditioner

InactiveCN102003786BImprove comfortImprove user experienceNoise suppressionAir-flow control membersEngineeringSound quality

The invention discloses a window air conditioner which comprises an indoor panel, a case, an evaporator, an indoor fan, a condenser, an outdoor fan, a compressor and a chassis, wherein a noise filtering device is arranged at the exhaust port of the air conditioner, and comprises an exhaust plate and a choke plate; multiple round vent holes are arranged on the exhaust plate in order, and the choke plate is arranged at the inner side of the exhaust plate; the choke plate is formed by mutually connecting multiple round choke pieces the diameters of which are larger than those of the round vent holes on the exhaust plate, and the positions of the choke pieces are in one-to-one correspondence with the positions of the vent holes; and the included angle of the choke plate and the exhaust plate is adjustable, i.e. the included angle of each choke piece and the air-out direction of the corresponding vent hole can be changed at the same time, thus the flow characteristic of air which is discharged along the indoor direction is changed, thereby changing the sound quality of the noise formed when the air rubs with the exhaust plate. Users can set the open angles of the choke pieces according to the judgment on the noise, so that products can obtain sound characteristics adaptive to different requirements of the users.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

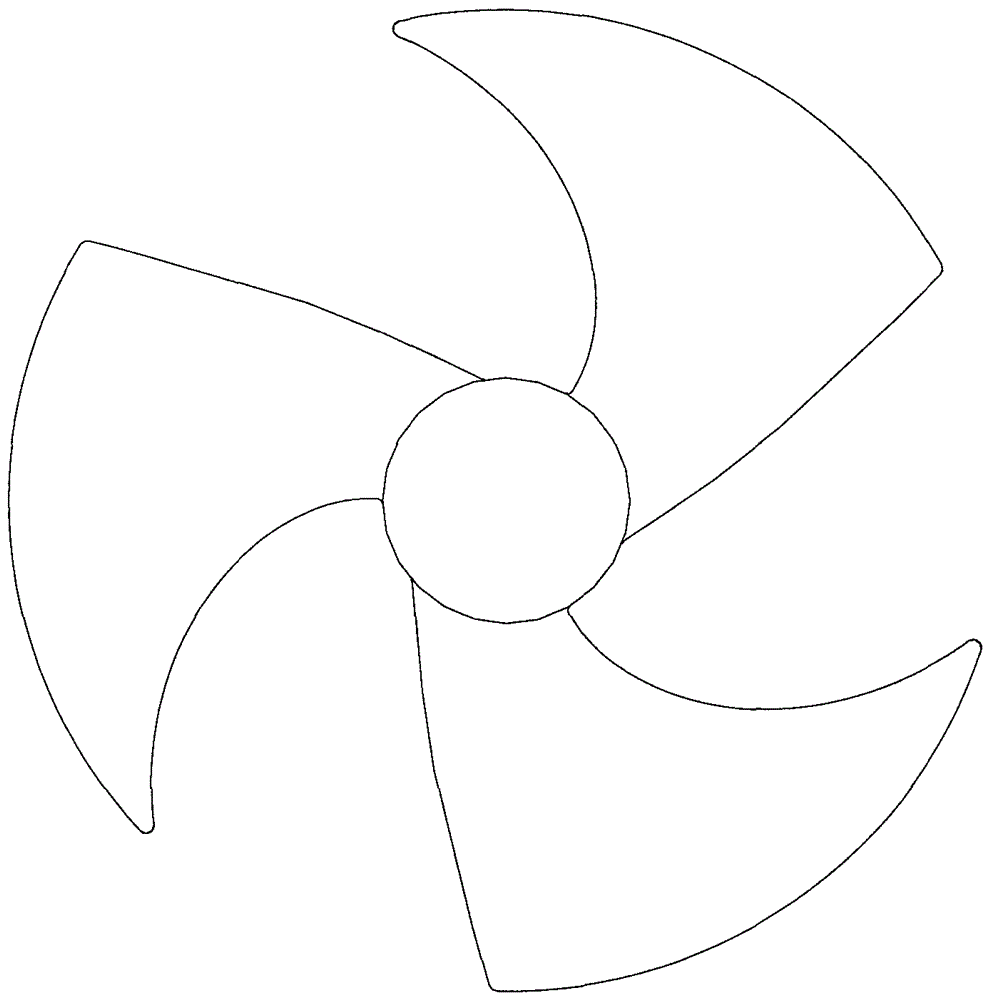

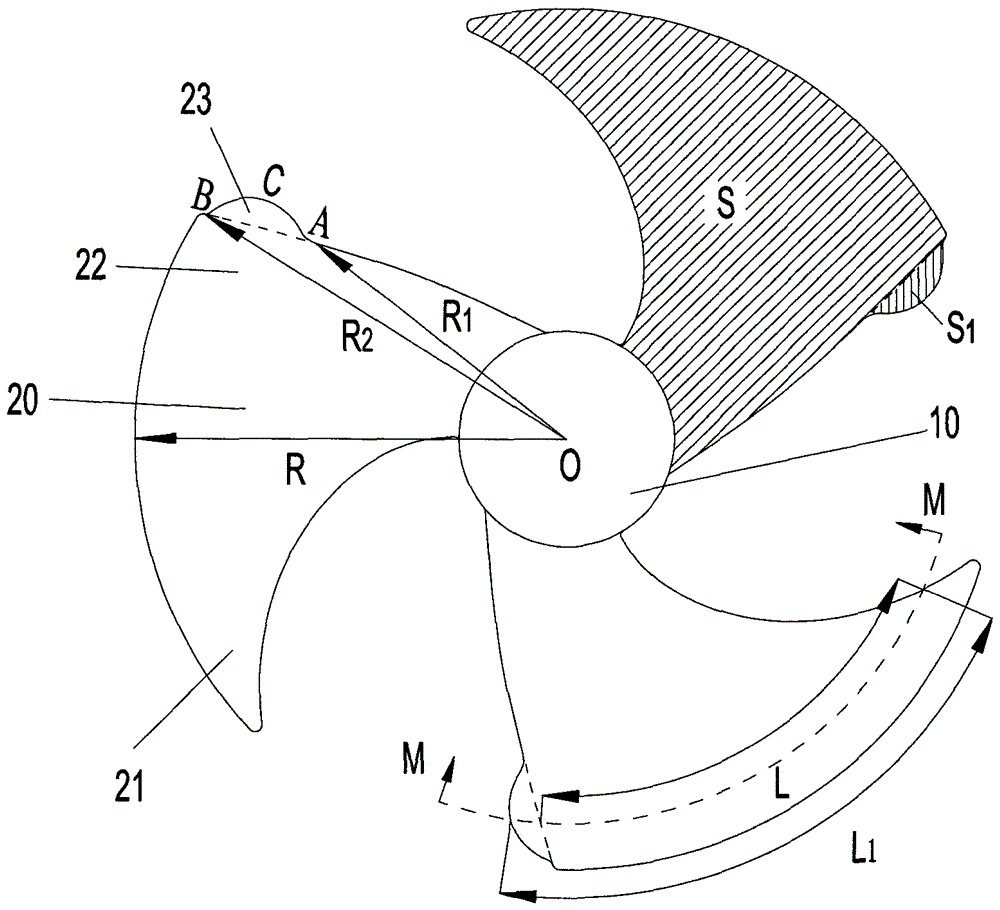

An axial-flow fan blade and an air conditioner having the same

Owner:GREE ELECTRIC APPLIANCES INC

Method for producing filter tip addition liquid and its filter tip

InactiveCN100548163CChange flow velocityChange flow characteristicsTobacco smoke filtersMentholChinese-olive

The present invention relates to a production process of filter tip additive liquid and filter tip capable of filtering out tar and nicotine components from cigarette. The production process of the filter tip additive liquid includes the following steps: preparing material including licorice, wild chrysanthemum flower, menthol, honeysuckle, fructus momordicae, Chinese olive, loquat leaf, adenophora root and tea in certain weight proportion; stamping material; soaking the stamped material in active water to swell; and squeezing the swelled material to obtain the additive liquid. Dropping the additive liquid to filter tip of cigarette can increase the adsorption area, strength the attachment and separate harmful matter from cigarette, while producing some health functions of moistening throat, cleaning teeth, etc.

Owner:胡晓宇

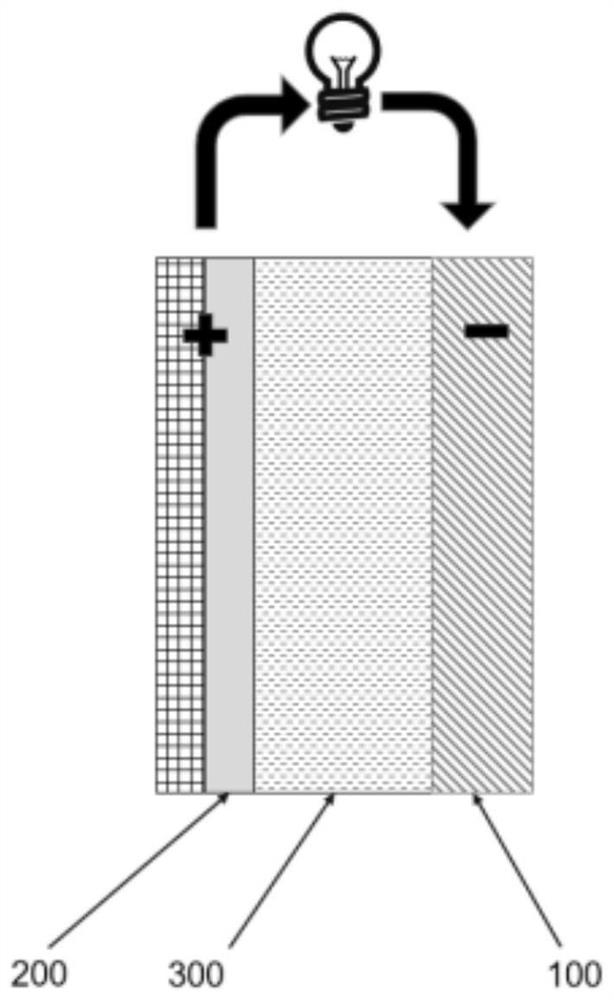

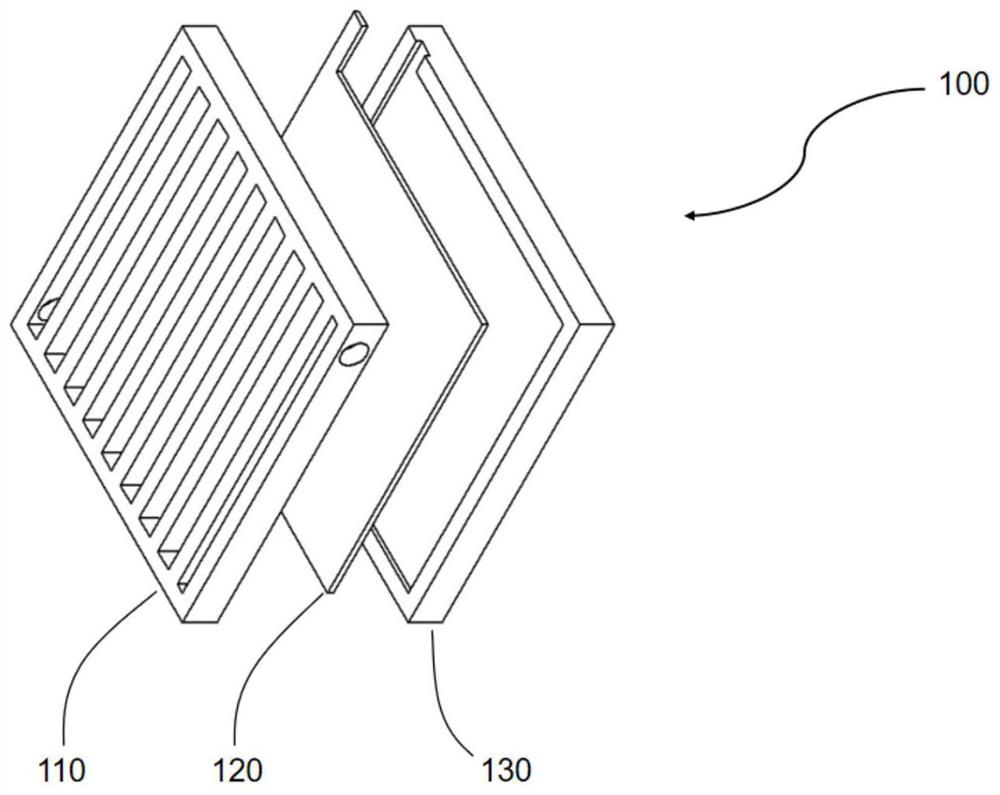

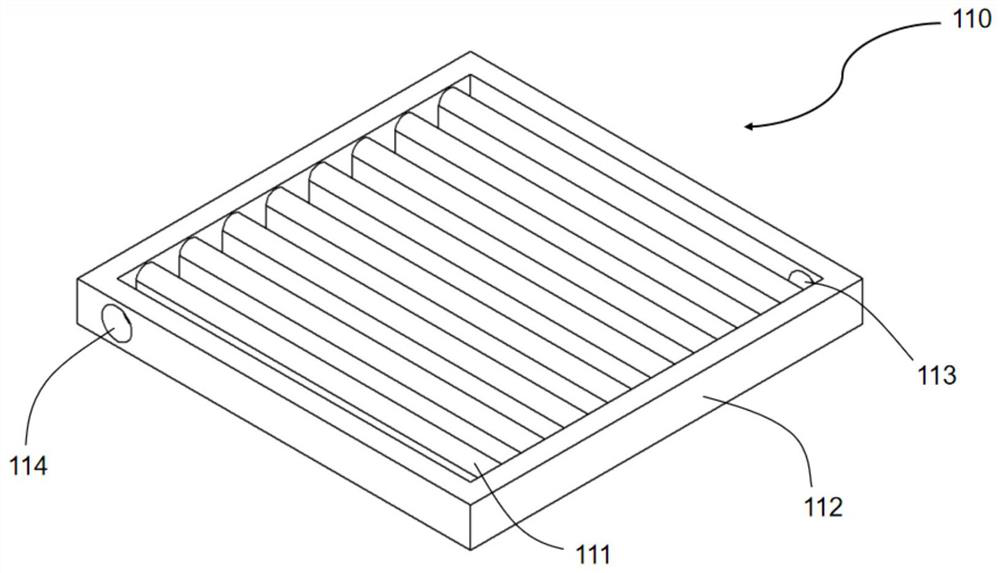

Zinc negative electrode provided with electrolyte flow distribution component and application thereof

InactiveCN112909287AChange flow rateChange flow characteristicsFuel and secondary cellsSecondary cells servicing/maintenanceElectrolytic agentInternal resistance

The invention discloses a zinc negative electrode provided with an electrolyte flow distribution component and application thereof. The zinc negative electrode comprises a zinc plate (120) with a current acquisition function, one side of the zinc plate (120) is provided with an electrolyte flow distribution part (110), the electrolyte flow distribution part (110) comprises a plurality of diversion columns (111) and a frame (112), the diversion columns (111) are arranged in the frame (112), and the opposite angles of the frame (112) are respectively provided with an electrolyte inlet (113) and an electrolyte outlet (114) higher than the electrolyte inlet (113). The electrolyte flow distribution part changes the flow mode of the electrolyte on the surface of the zinc plate, so that dendritic crystals are not easy to gather on the surface of the zinc electrode, and meanwhile, the internal resistance of a battery is not increased; and therefore, the stability and utilization rate of the battery are effectively improved.

Owner:上海簇睿低碳能源技术有限公司

Remotely controllable variable flow control configuration and method

InactiveCN102472087BChange flow characteristicsFluid removalWell/borehole valve arrangementsMechanical engineering

Owner:BAKER HUGHES HLDG LLC

Device and method for removing CO2 from power plant flue gas with fly ash

ActiveCN106474912BRealize resource utilizationLow costGas treatmentDispersed particle separationCold airFluidized bed

The invention discloses a device for removing CO2 from flue gas in a power plant by using fly ash. The device comprises an activation reactor, a charging device, a fluidized bed, a cyclone separator and a waste material bin, wherein the output end of the activation reactor is connected with the charging device; the output end of the charging device is connected with the fluidized bed; the output end of the fluidized bed is connected with the cyclone separator; and the output end of the cyclone separator is connected with the waste material bin. The invention also discloses a method for removing the CO2 from the flue gas in the power plant by using the fly ash. The method comprises the following steps: conveying the fly ash into the activation reactor and carrying out activation treatment, then carrying out conveying into the charging device and carrying out charging treatment, then carrying out conveying into the fluidized bed so as to remove the CO2 in the flue gas, and finally carrying out conveying into the waste material bin. According to the invention, the device organically combines with a coal-fired power generating system; the flue gas and cold air in the coal-fired power plant can be utilized to provide a heat source and a cold source for the device; meanwhile, needed electric energy is provided for the device through a thermoelectric power generation technology; thus, an optimization scheme capable of reducing cost and energy consumption is realized.

Owner:NANJING NORMAL UNIVERSITY

A magnetorheological semi-active stiffness adjustable shock absorber

ActiveCN109235688BChange flow characteristicsGood vibration dampingProtective buildings/sheltersShock proofingSemi activeAdjustable stiffness

The invention discloses a magneto-rheological semi-active damper with adjustable stiffness. The damper comprises an outer annular cylinder fixed on the inner wall of a container and an inner cylinder;scrollable balls are arranged between the lower portion of the inner cylinder and a bottom plate of the device, and the inner cylinder and the outer annular cylinder are filled with a magneto-rheological liquid respectively; hollow spring pipes are connected between the cylinder walls of the inner cylinder and outer annular cylinder, the inner cylinder and the outer annular cylinder are communicated with each other through the hollow spring pipes, the magneto-rheological liquid can flow in the inner cylinder and the outer annular cylinder through the hollow spring pipes, the outer portions ofthe spring pipes are provided with magnet exciting coils, the magnet exciting coils, controllers and a solar panel arranged at the outer side of the upper portion of the container are connected in series to form a closed loop circuit, the controllers receive signals of acceleration sensors to control the current in the magnet exciting coils, thereby adjusting the stiffness of the hollow spring pipes and achieving the horizontal damping control; limiting plates are arranged between the outer annular cylinder and the inner cylinder to prevent the inner cylinder from being displaced too much; damping nets are arranged in the outer annular cylinder, and the torsion damping control is achieved through damping force.

Owner:SHANDONG UNIV

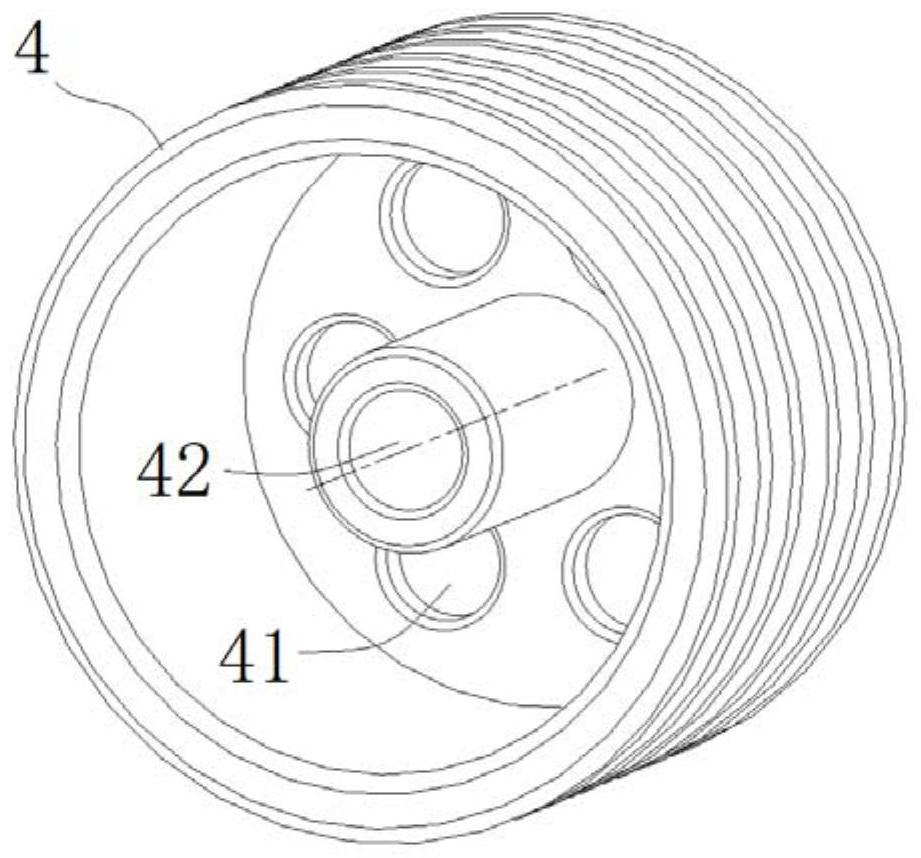

Collision energy dissipation component based on magnetorhrologic grease and device

InactiveCN101797910BImproved dissipation capacitySimple structureBumpersMagneto rheologicalMechanical engineering

The invention relates to a collision energy dissipation component based on magnetorhrologic grease and a device; the collision energy dissipation component comprises an oil sac and an oil cylinder which are sequentially arranged along the axial direction vertical to a bumper rail, the closed and of the oil sac is arranged on the back surface of the bumper rail, the opening end thereof is communicated with the oil cylinder, and damping material is filled in the oil sac and the oil cylinder; a multi-level radial annular damping channel is arranged in the oil cylinder along the axial direction; in the invention, the oil sac communicated with the oil cylinder is arranged in front of the oil cylinder, and a linear type damping channel is changed into the multi-level radial annular damping channel, the effective length of the damping channel is increased and the dissipation ability of a collision energy dissipation device to collision energy is enhanced; the invention adopts the damping channel formed by an annular damping segregation board and a central segregation board, the structure is simple and the operation is convenient.

Owner:CHONGQING UNIV

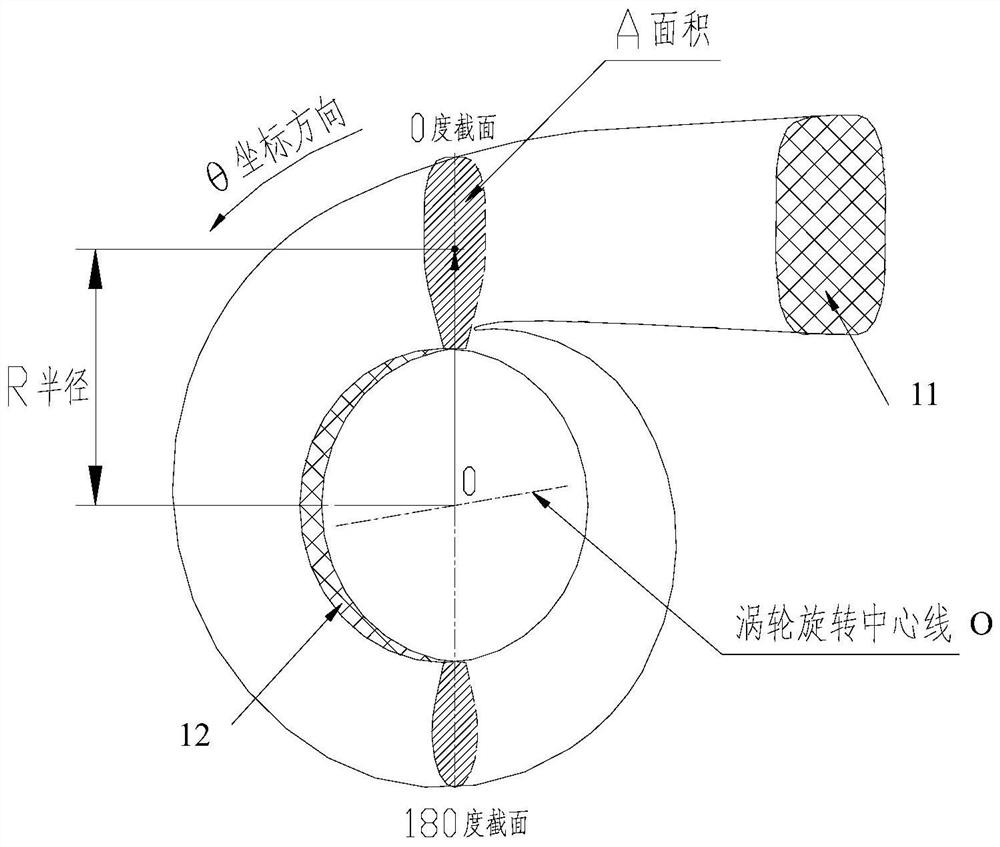

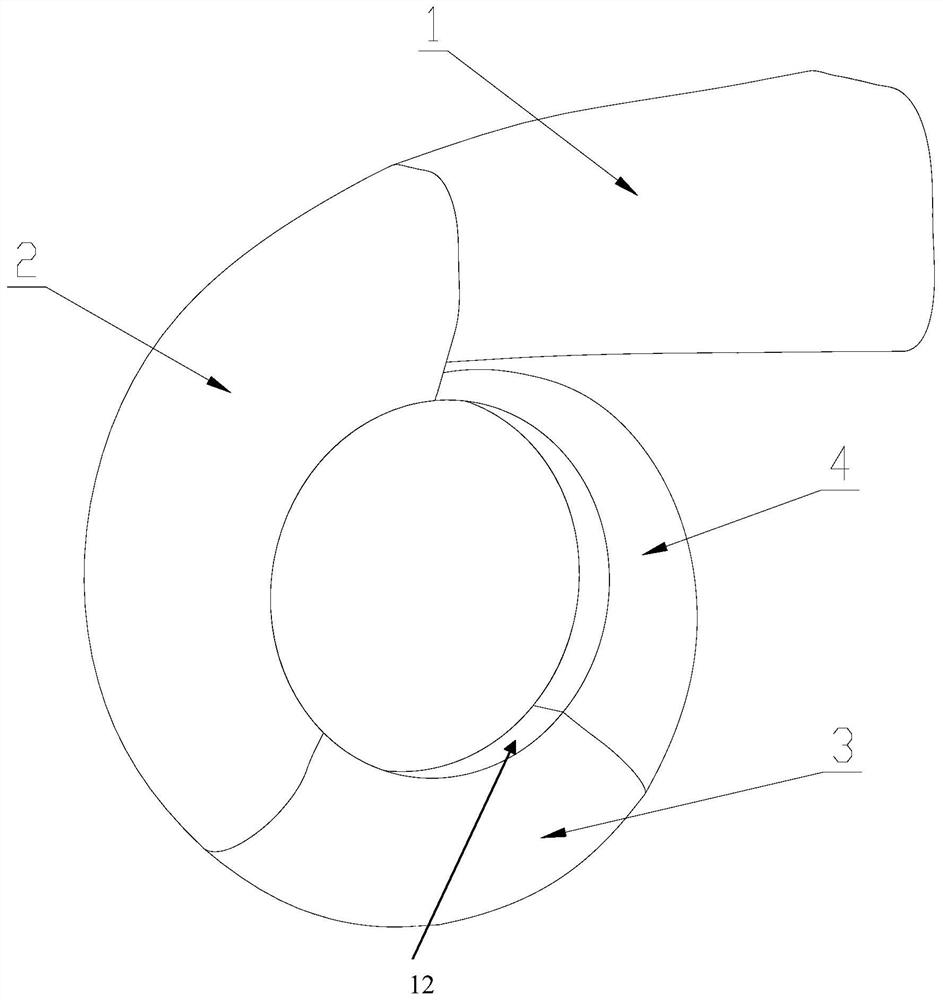

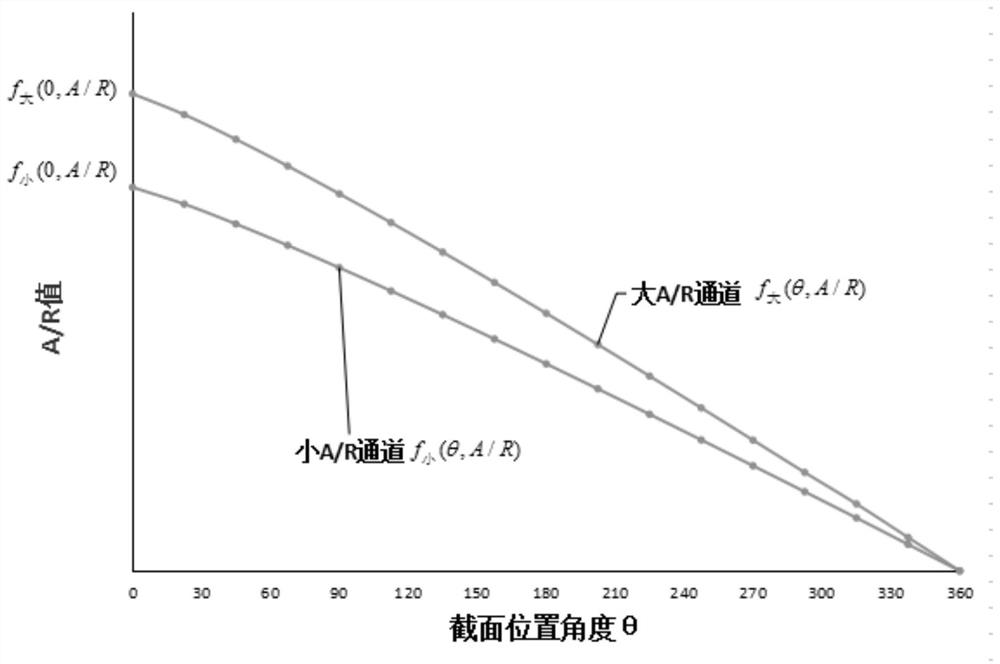

Turbocharger turbine box with channel section two-section feature

PendingCN112554971AStructural Design ScienceChange flow characteristicsMachines/enginesEngine componentsStructural engineeringMarine engineering

The invention discloses a turbocharger turbine box with a channel section two-section feature. The turbocharger turbine box comprises a turbine box inlet channel section, a first channel section, a mixed transition channel section and a second channel section. A turbine box air inlet is formed in the right end of the turbine box inlet channel section. A left end opening of the turbine box inlet channel section communicates with an upper end opening of the first channel section in a sealed manner. A lower end opening of the first channel section communicates with a left end opening of the mixedtransition channel section in a sealed manner. A right end opening of the mixed transition channel section communicates with a lower end opening of the second channel section in a sealed manner. An upper end opening of the second channel section communicates with an upper end opening of the first channel section in a sealed manner. The turbine box inlet channel section, the first channel section,the mixed transition channel section and the second channel section are all hollow and bent smooth continuous channel sections. The first channel section and the second channel section have differentA / R values. According to the turbocharger turbine box, the flowing feature of airflow in the turbine box is changed, and the flowing property of the airflow in the turbine box is enhanced.

Owner:天津北方天力增压技术有限公司

injector

ActiveCN103256098BHigh trafficChange flow characteristicsInternal combustion piston enginesNon-fuel substance addition to fuelWorking fluidDecompression chamber

An ejector includes: a decompression chamber in an outer pipe on an air entrance side; a throat in the outer pipe on an air exit side; a nozzle in the outer pipe on the air entrance side, the nozzle having a leading end portion placed in a decompression chamber to inject air; and a suction port in the decompression chamber to suck blow-by gas into the decompression chamber. The air injected from the nozzle generates negative pressure in the decompression chamber to suck in blow-by gas through the suction port, and the sucked gas is discharged together with air through a throat. The valve in the nozzle includes a valve seat, a valve element, and a spring to press the valve element in a direction to separate from the valve seat. The valve element is formed with a bottom-closed cavity opening toward an upstream side of an air flow.

Owner:AISAN IND CO LTD +1

A kind of intake prerotator with adjustable blade angle

ActiveCN110594198BChange flow characteristicsSimple structurePump componentsPumpsTurbochargerElectric control

Owner:LIAONING TECHNICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com