An axial-flow fan blade and an air conditioner having the same

A technology of axial flow blades and blades, which is applied in the field of axial flow blades and air conditioners with them, can solve the problems that plague designers, noise deterioration, and power consumption increase, and achieve improved air volume performance, improved operating noise, and low Effects of Noise and Power Consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

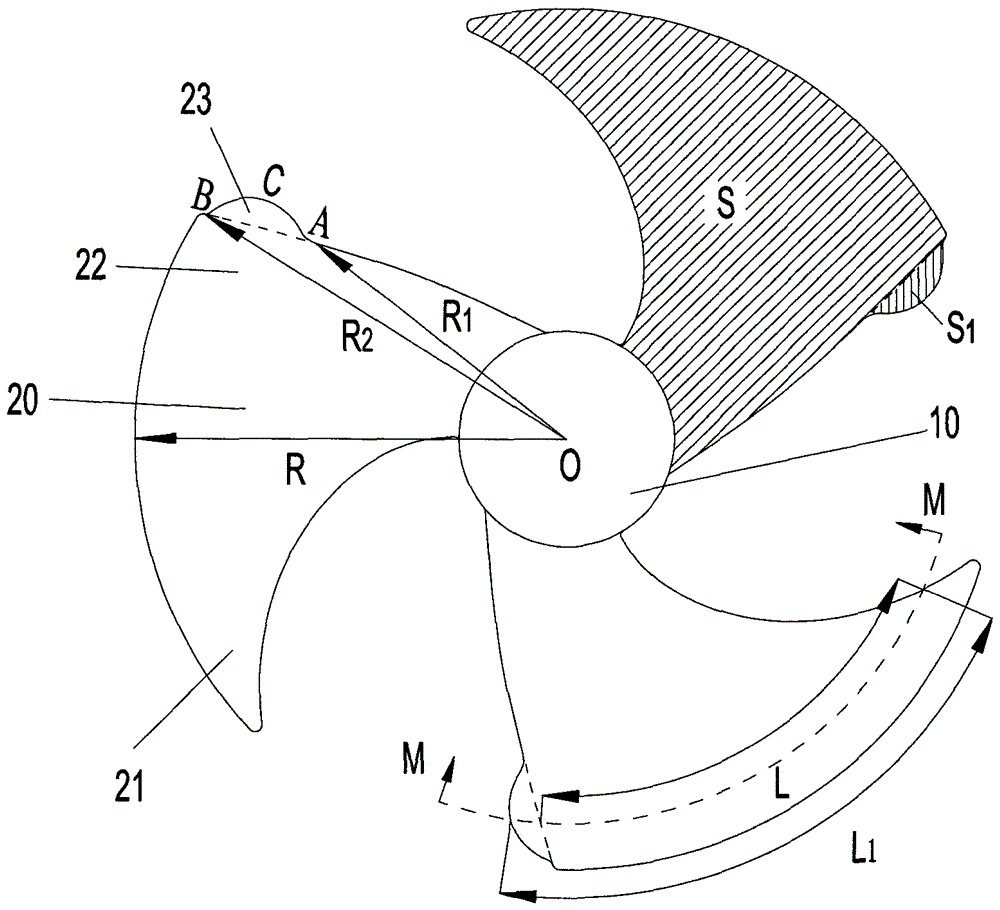

[0043] Such as Figure 5 As shown, the distance R from the starting point A of the empennage 23 to the hub axis O 1 Equal to 0.77R, the distance R from the end point B of the empennage 23 to the hub axis O 2 Equal to R, the distance R between the end C of the empennage 23 and the hub axis O 3 Equal to 0.98R, the length of the chord line from the leading edge 21 to the end C of the empennage 23 is L C Equal to 1.12L, the surface area of empennage 23 is S 1Equal to 0.04S, the angle α between the centerline of the empennage 23 in the thickness direction and the normal line of the tailing edge 22 ranges from 88° to 92°, the thickness of the empennage 23 is equal to the thickness of the tailing edge 22, and the outer edge contour of the empennage 23 Consists of multiple smooth transition arcs.

Embodiment 2

[0045] Such as Figure 6 As shown, the distance R from the starting point A of the empennage 23 to the hub axis O 1 Equal to 0.8R, the distance R from the end point B of the empennage 23 to the hub axis O 2 Equal to R, the distance R between the end C of the empennage 23 and the hub axis O 3 Equal to 0.88R, the length of the chord line from the leading edge 21 to the end C of the empennage 23 is L C Equal to 1.15L, the surface area of empennage 23 is S 1 Equal to 0.06S, the angle α between the centerline of the empennage 23 in the thickness direction and the normal line of the trailing edge 22 ranges from 90° to 94°, the thickness of the empennage 23 is slightly greater than the thickness of the tailing edge 22, and the outer edge profile It is in the form of a spline curve, that is, given multiple fixed points, two adjacent fixed points are connected by a curve.

[0046] According to the above parameters, use the same material and process to manufacture the axial flow f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com