Brush making machine and method used for reducing vibration

A brush making machine and movement technology, applied in the field of vibration caused by movement, can solve problems such as limited vibration bandwidth, and achieve the effect of eliminating vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

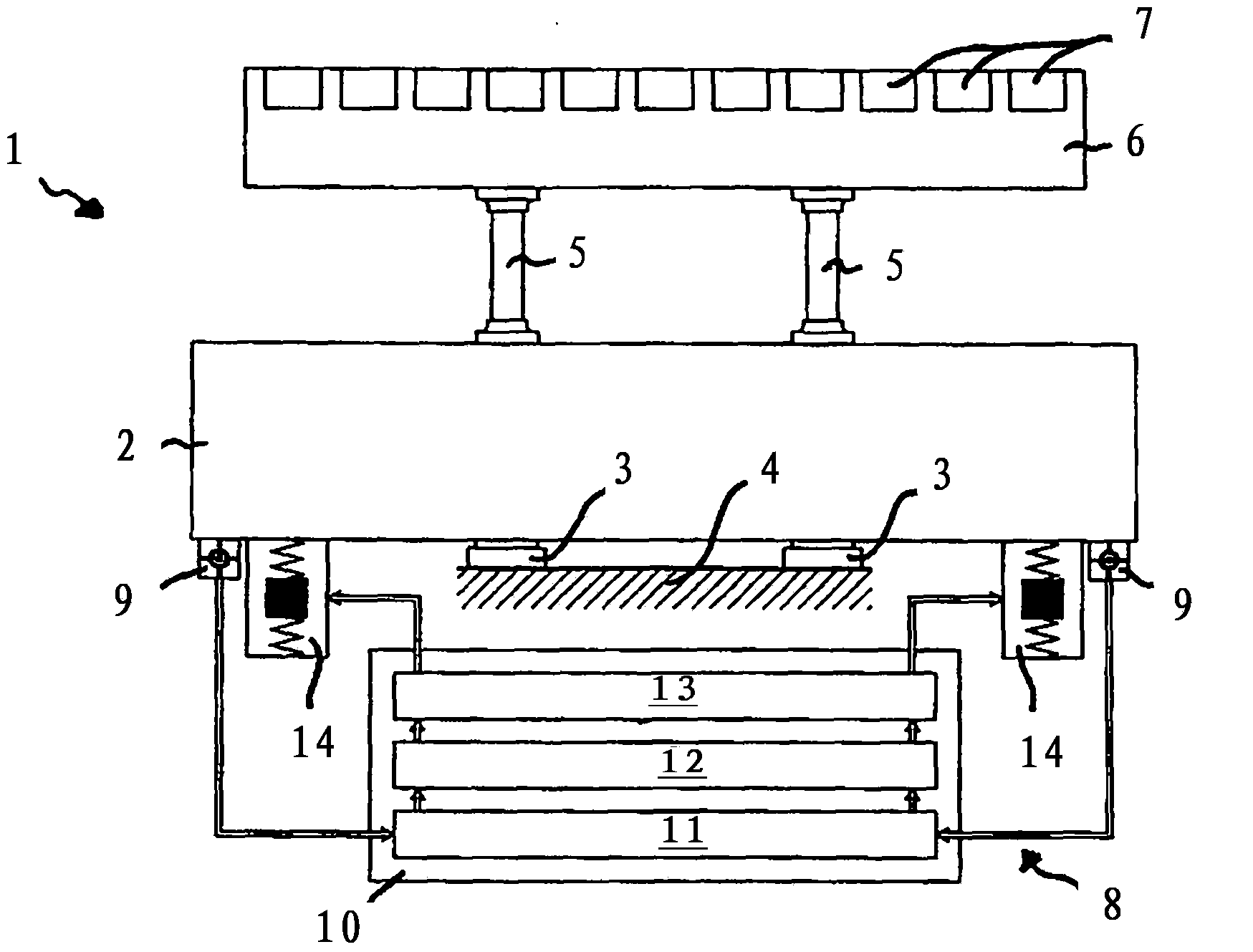

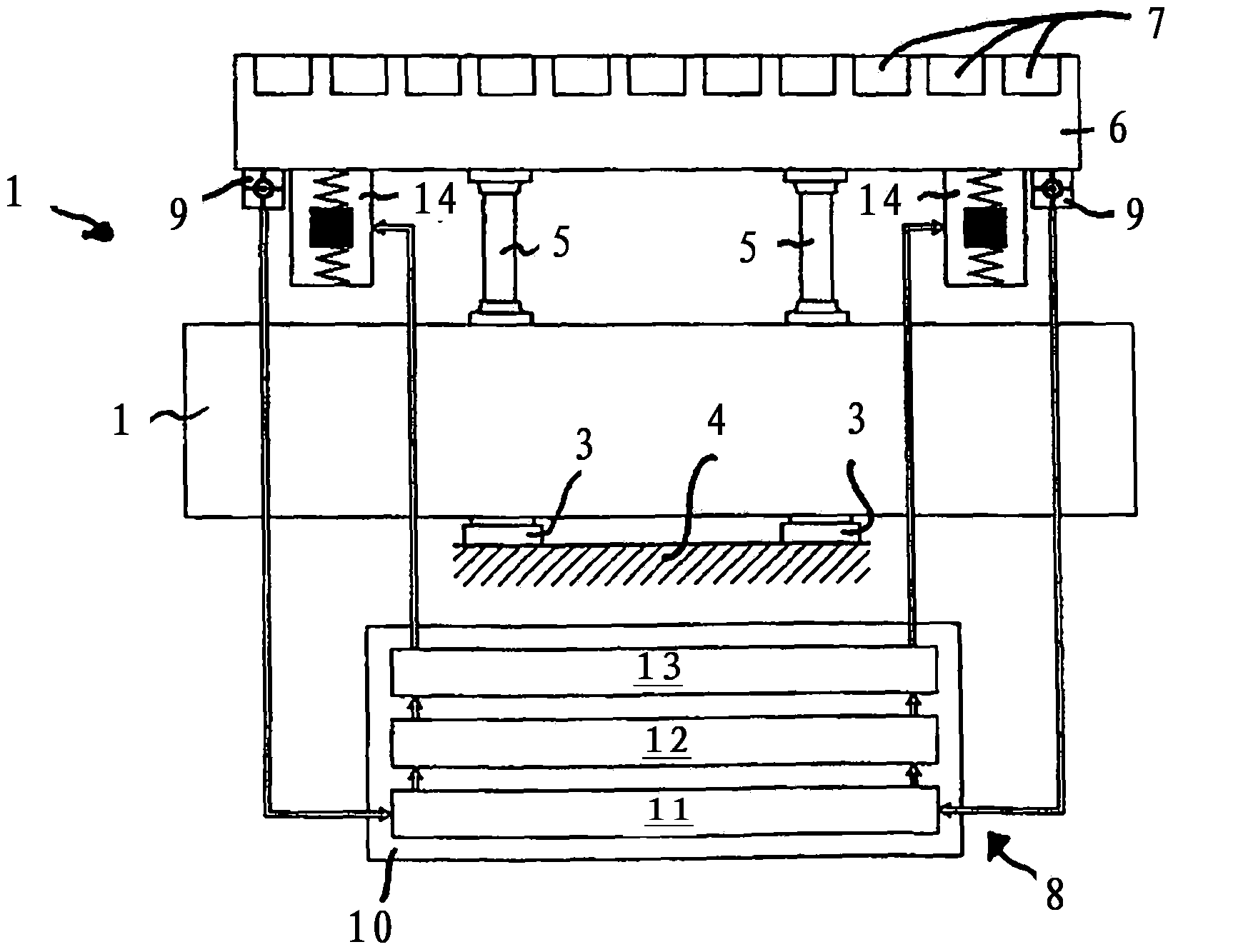

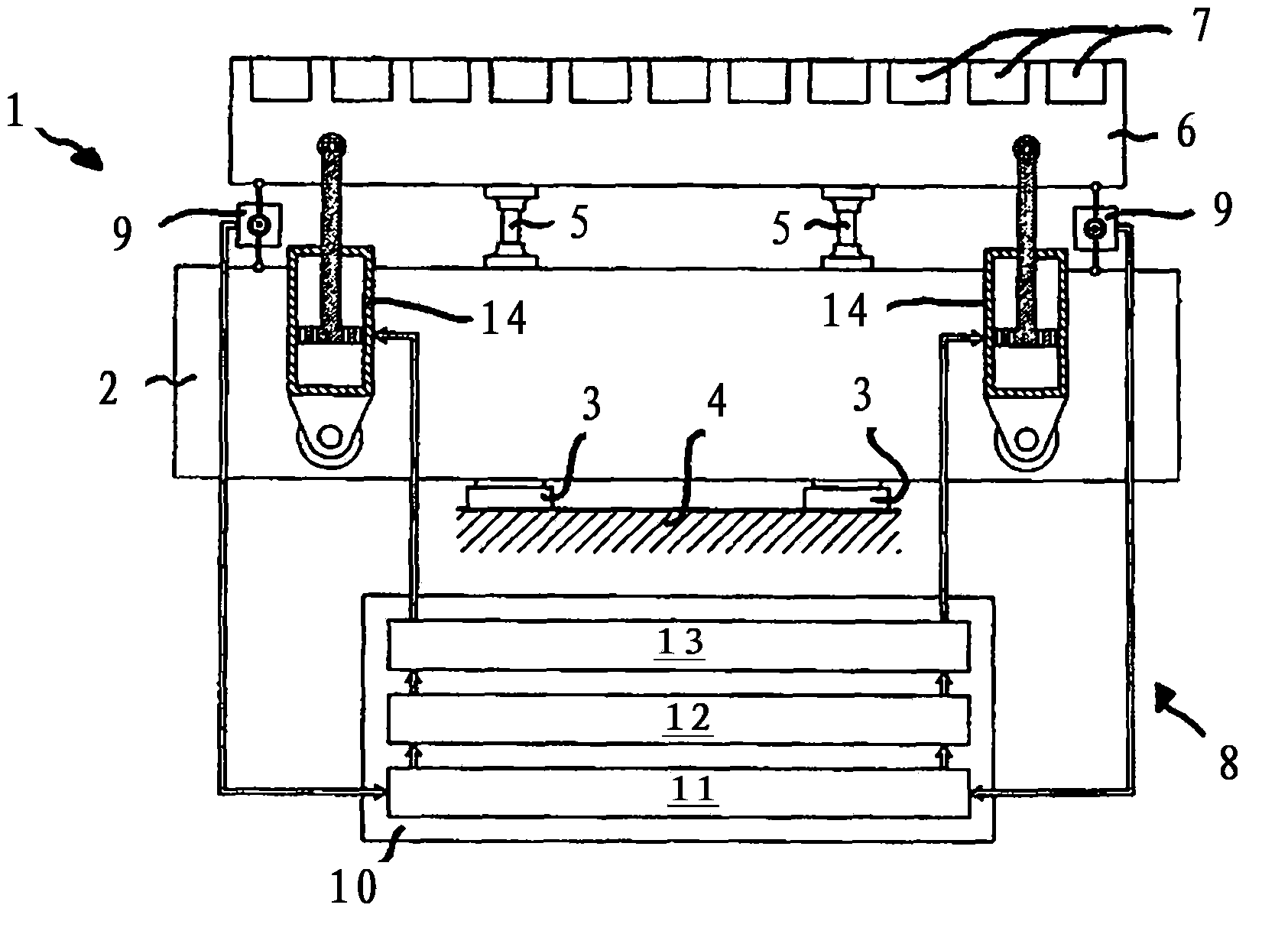

[0022] according to figure 1 The brush-making machine denoted as a whole by the reference numeral 1 comprises a base part 2 which is set up on the ground 4 by means of feet 3 . The base part 2 is connected via connecting elements 5 to a functional unit 6 which has a plurality of functional elements 7 . The respective functional part 7 forms a differently movable part of the brush making machine 1 , for example a caulking tool or a positioning device for the brush body. Various vibrations generated by each functional part 7 are transmitted to the functional unit 6 . Depending on the stiffness of the connection part 5 , these vibrations are damped or transmitted to the base part 2 between the functional unit 6 and the base part 2 . A part of the transmitted vibration is in turn damped by the foot 3 relative to the ground 4 . The remaining vibrations are absorbed and eliminated or at least reduced by the device 8 . For this purpose, the device 8 has sensors 9 arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com