Magnetorheological buffer

A magnetorheological buffer and outer cylinder technology, applied in the buffer field, can solve the problems of limited range of damping force, low magnetic field utilization, poor manufacturability, etc., and achieve the effects of compact layout, good structure matching and small structural changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

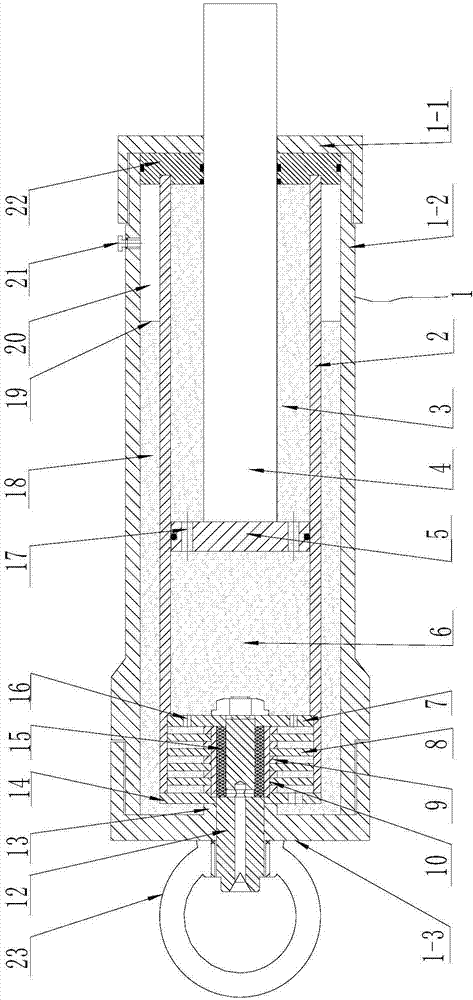

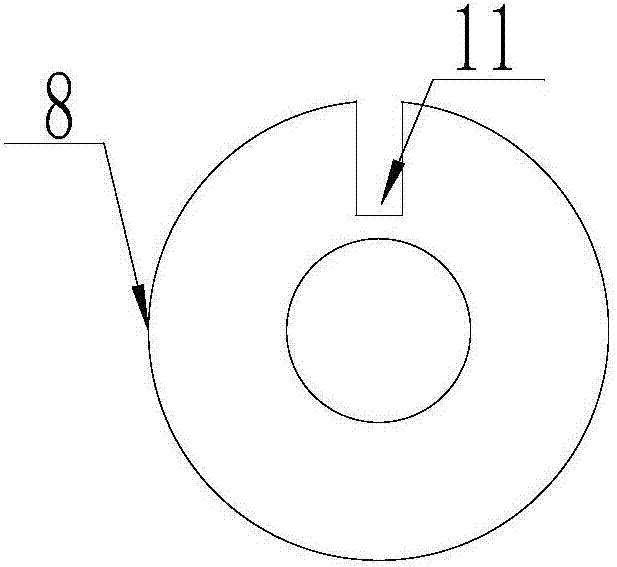

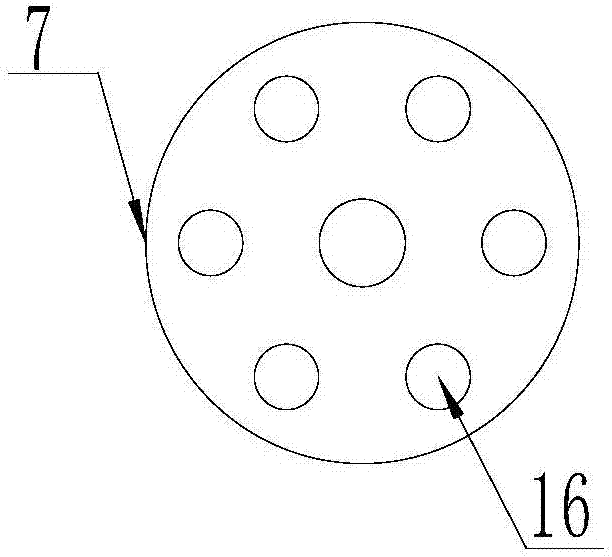

[0021] figure 1 Is a schematic diagram of the structure of the present invention, figure 2 It is a schematic diagram of the annular partition structure in the present invention, image 3 It is a schematic diagram of the upper positioning plate structure in the present invention, Figure 4 It is a schematic diagram of the structure of the lower positioning plate in the present invention, as shown in the figure: the magnetorheological damper of this embodiment includes an outer cylinder 1, an inner cylinder 2, a piston rod 4, and a piston 5, and the inner cylinder 2 is arranged at The outer cylinder tube 1 is in clearance fit with the inner wall of the outer cylinder tube 1, the piston 5 is placed in the inner cylinder tube 2, and the inner cavity of the inner cylinder tube 2 is divided into an upper working chamber 3, a lower working chamber 6, and the piston rod 4 and The piston 5 is fixedly connected and penetrates the inner cylinder 2 from the upper working chamber 3, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com