Thin plate wrinkle-free forming die and forming method using low melting point alloy

A forming mold with low melting point technology, applied in the field of mechanical engineering, to achieve the effect of improving the utilization rate of raw materials, saving design and production, and reducing trimming work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

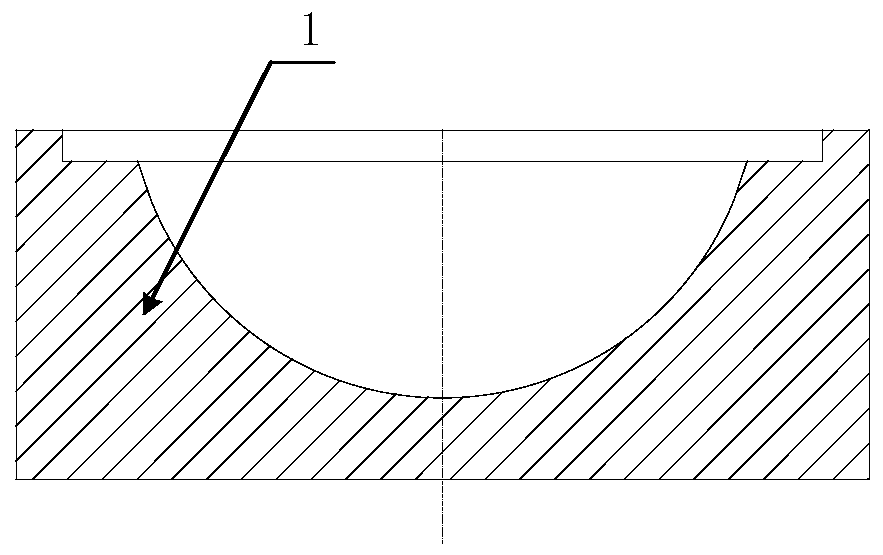

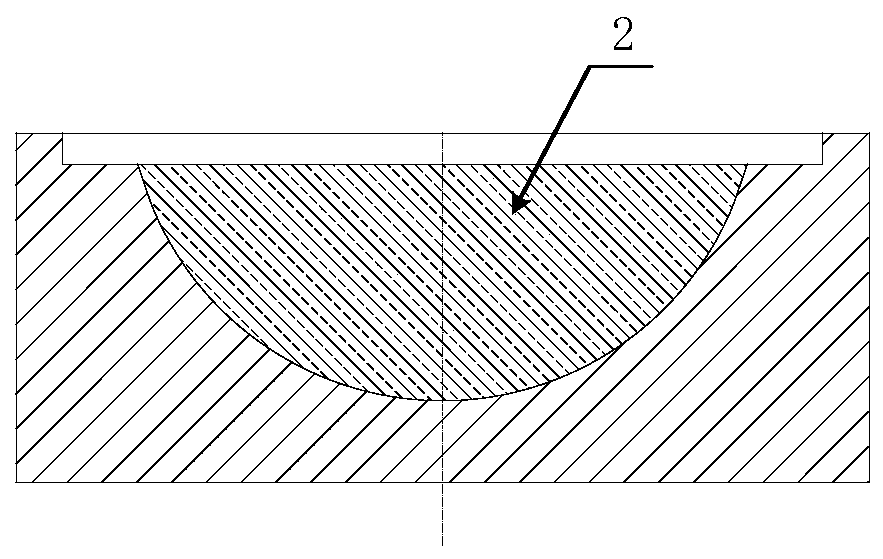

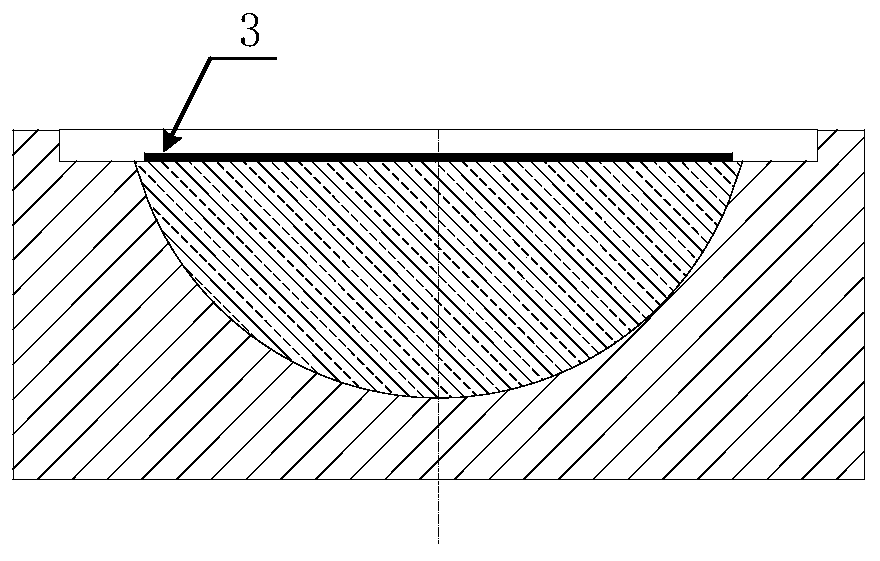

[0029] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0030] The object of the present invention is to provide a wrinkle-free forming die for a thin plate using an alloy with a low melting point. The anti-wrinkle forming die adopts low melting point alloy as the anti-wrinkle forming medium. During the forming process of the sheet, the low-melting-point alloy produces a corresponding flow when the punch is pressed down, and the low-melting-point alloy clings to the upper and lower surfaces of the sheet during the flow process, and at the same time, the shape of the sheet changes continuously. The low-melting-point alloy of the convex and concave molds maintains full contact with the sheet metal and applies forming pressure to the sheet to give the sheet a normal and tangential force to prevent the plastic instability and wrinkling of the sheet during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com