Solid powder regulation ball valve

A technology for regulating balls and solid powders, applied to valve details, valve devices, valve housing structures, etc., can solve problems that cannot be used for regulating occasions, achieve strength and communication, improve wear resistance and corrosion resistance, The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

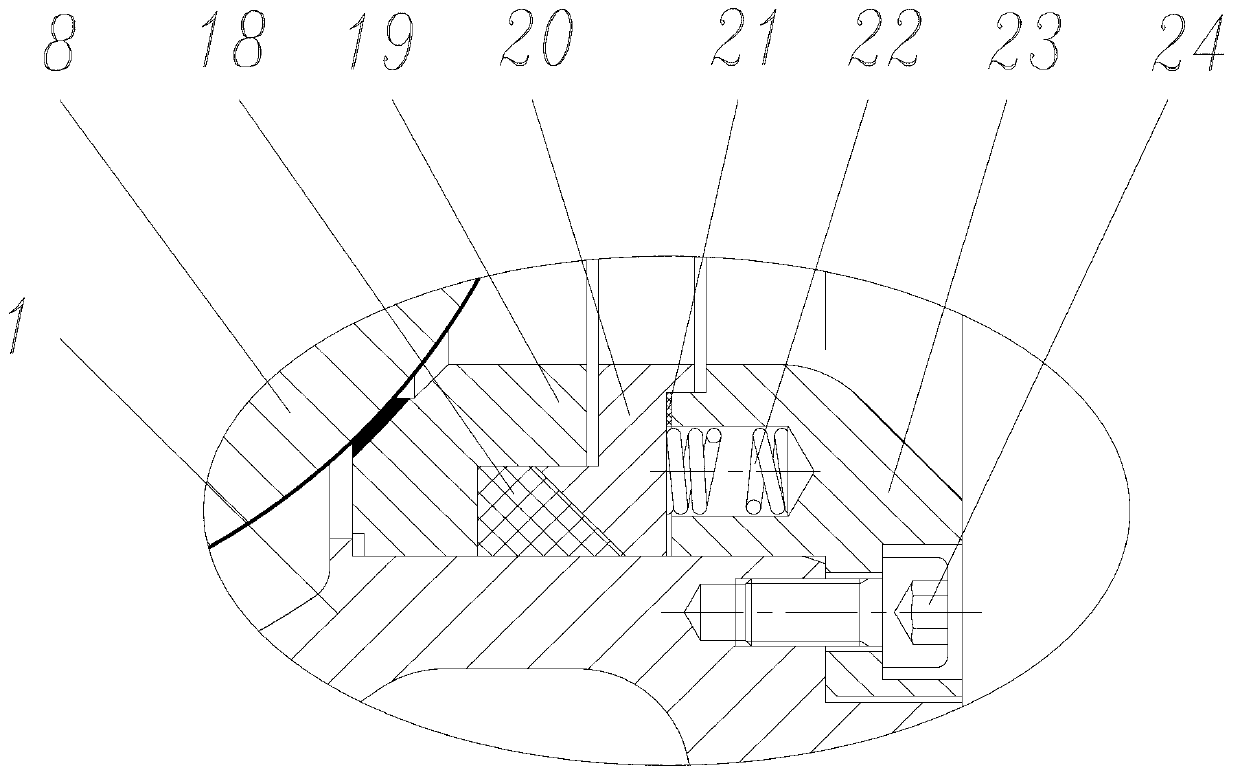

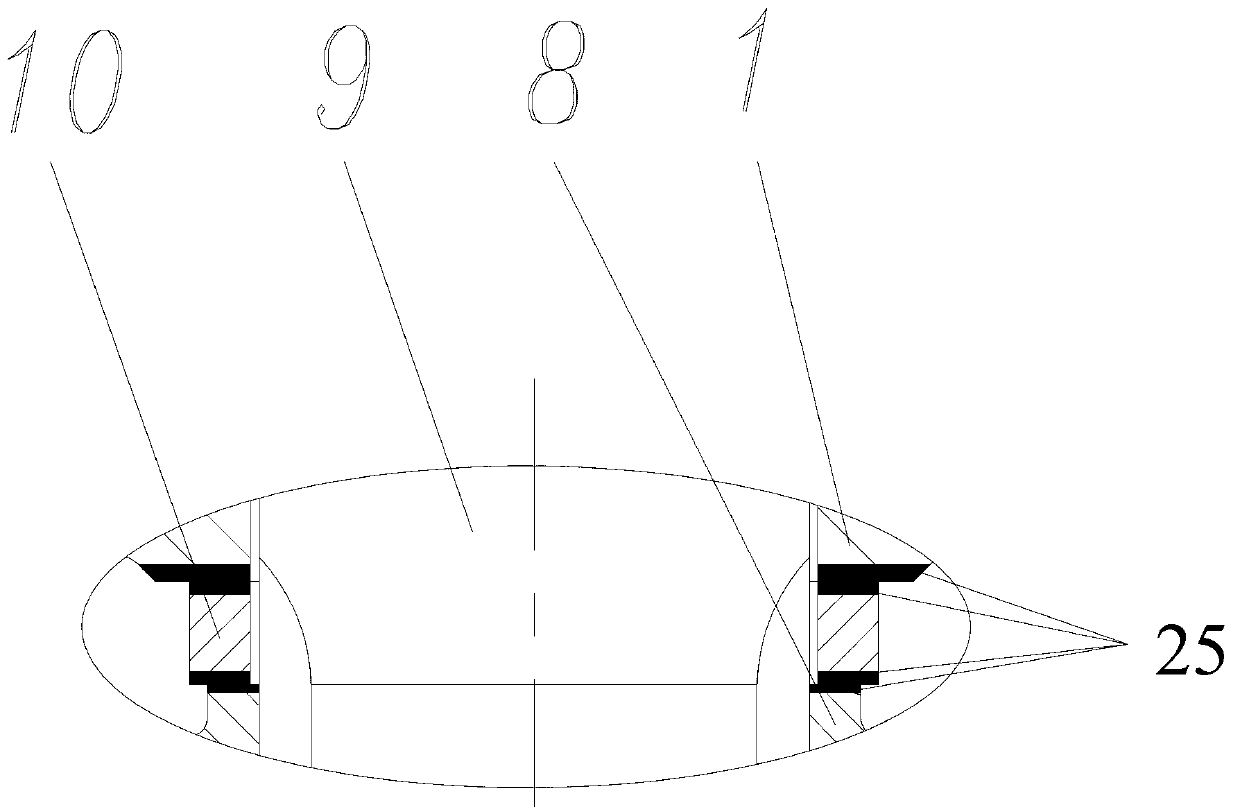

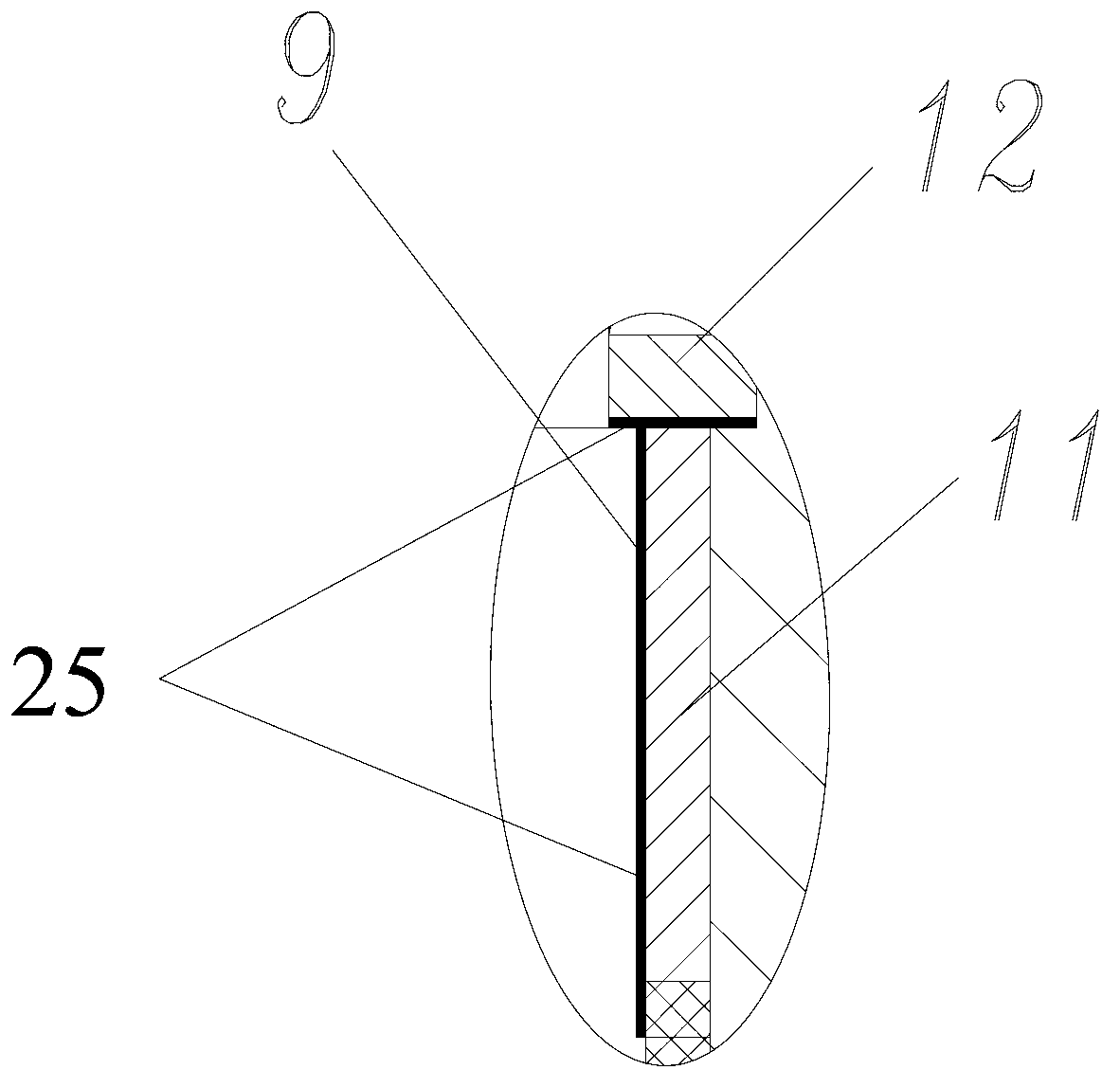

[0019] refer to figure 1 , figure 2 , the solid powder regulating ball valve of the present invention includes a valve body 1, a valve core 8, a valve stem 9, an upper sleeve 11, a lower sleeve 5, a set screw 6, a limit block 10, a rear cover 3, and a valve seat assembly 7 , screw 24, the valve body 1 is an integral structure, the upper part is equipped with an upper bushing 11, the lower part is installed with a lower bushing 5, one side of the valve core 8 is spherical, and the other side is opened with a "V" Type opening, the valve stem 9 is integrated, and fixed with the valve core 8 by the set screw 6, the limit block 10 is located between the valve body 1 and the valve core 8, and the valve core can be made by adding the limit block 10 8 is always concentric with the valve seat 19 to provide sealing and prevent the valve stem 9 from flying out of the valve body 1 under high pressure. The rear cover 3 is located at the tail of the valve body 1 .

[0020] The valve seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com