Aero-engine lubricating oil system multi-way flow distribution valve

A technology of aero-engine and lubricating oil system, which is applied in the direction of engine lubrication, engine components, distribution devices, etc., to achieve the effect of compact structure, guaranteed rotor blade tip clearance, good shock absorption and damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

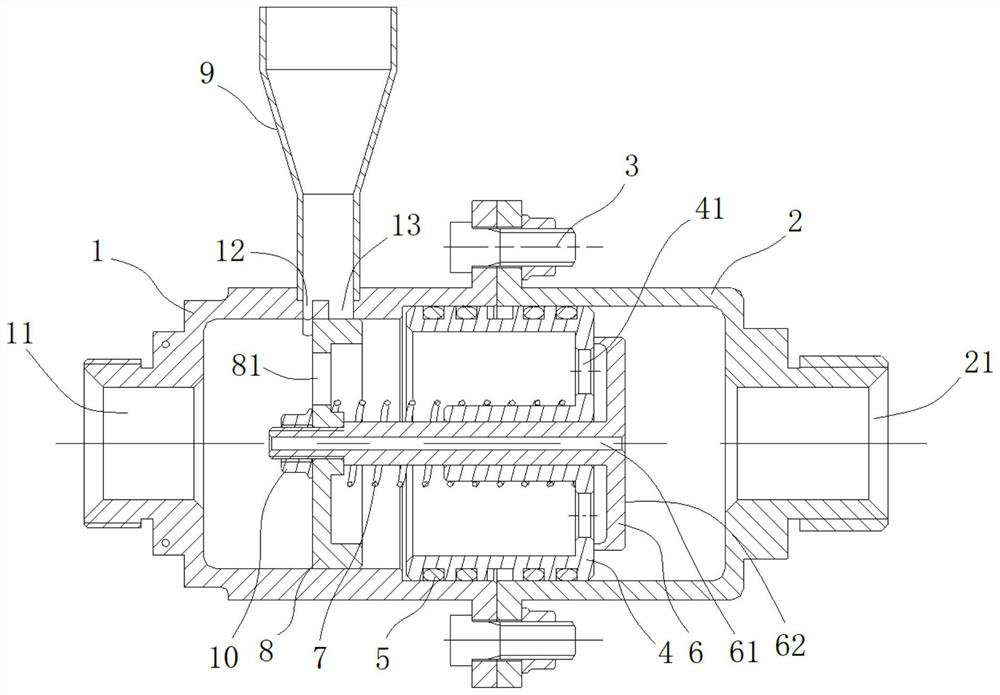

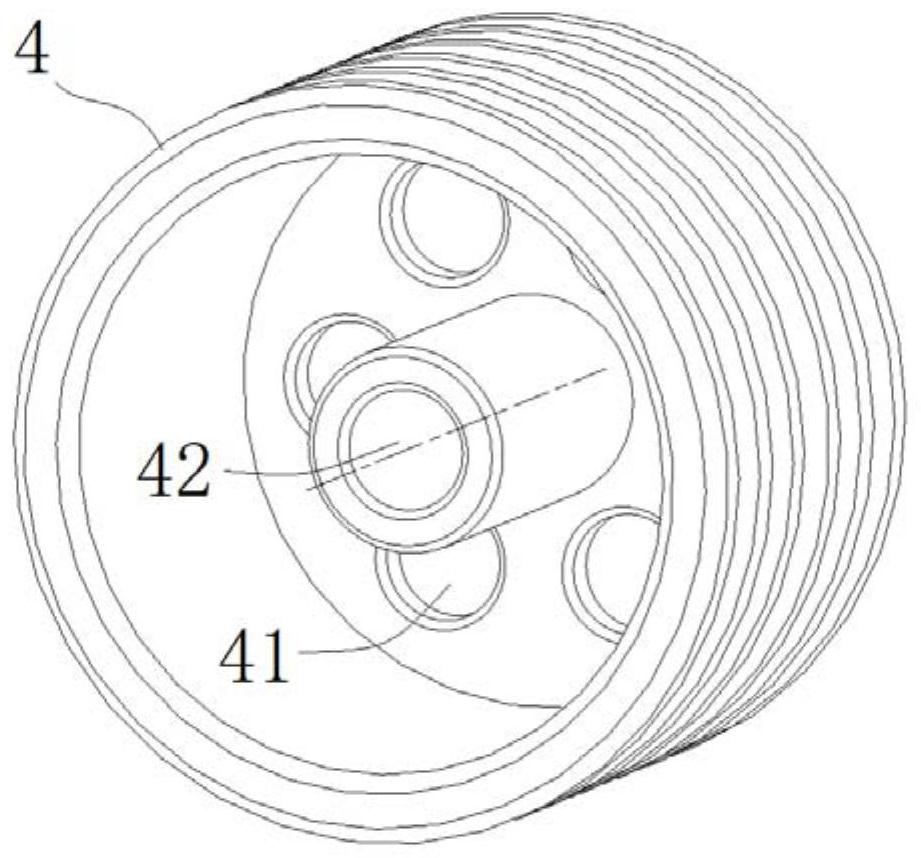

[0055] Such as figure 1 As shown, the multi-way flow distribution valve of the aero-engine lubricating oil system provided by the present application mainly includes a front housing 1 , a rear housing 2 , a valve seat 4 , a main valve 6 , an auxiliary valve 8 and a spring 7 .

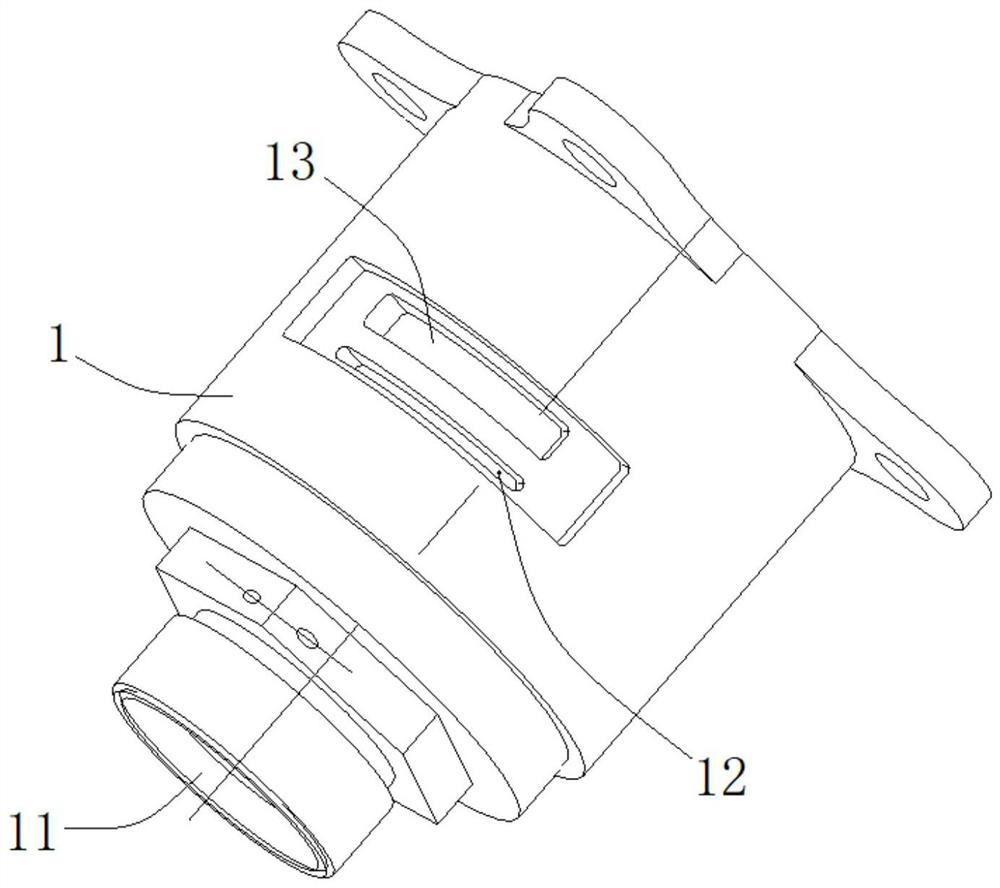

[0056] The front housing 1 has an extruding oil film interface 11 and an opening of the first lubricating oil chamber. The extruding oil film interface 11 is used to connect with the extruding oil film pipeline 30 or the lubricating oil supply pipeline 30. The opening of the first lubricating oil chamber is set On the side wall of the front housing 1, it is used to communicate with the first lubricating oil chamber. Wherein, the open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com