Zinc negative electrode provided with electrolyte flow distribution component and application thereof

An electrolyte and zinc negative electrode technology, which is applied in the field of zinc negative electrodes, can solve the problems of increasing battery internal resistance and decreasing battery charge and discharge efficiency, and achieves the effect of optimizing the electrolyte flow channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

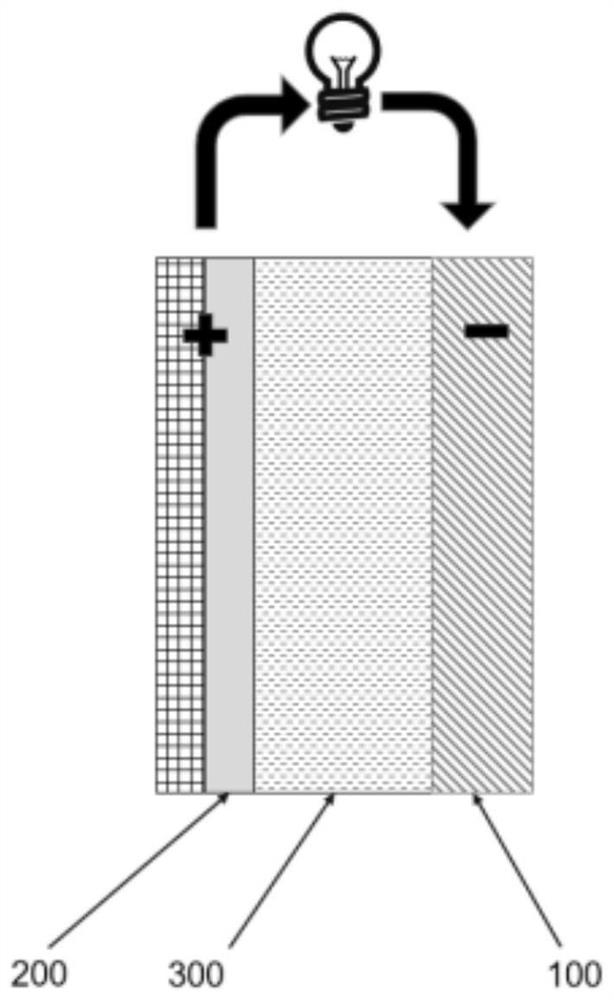

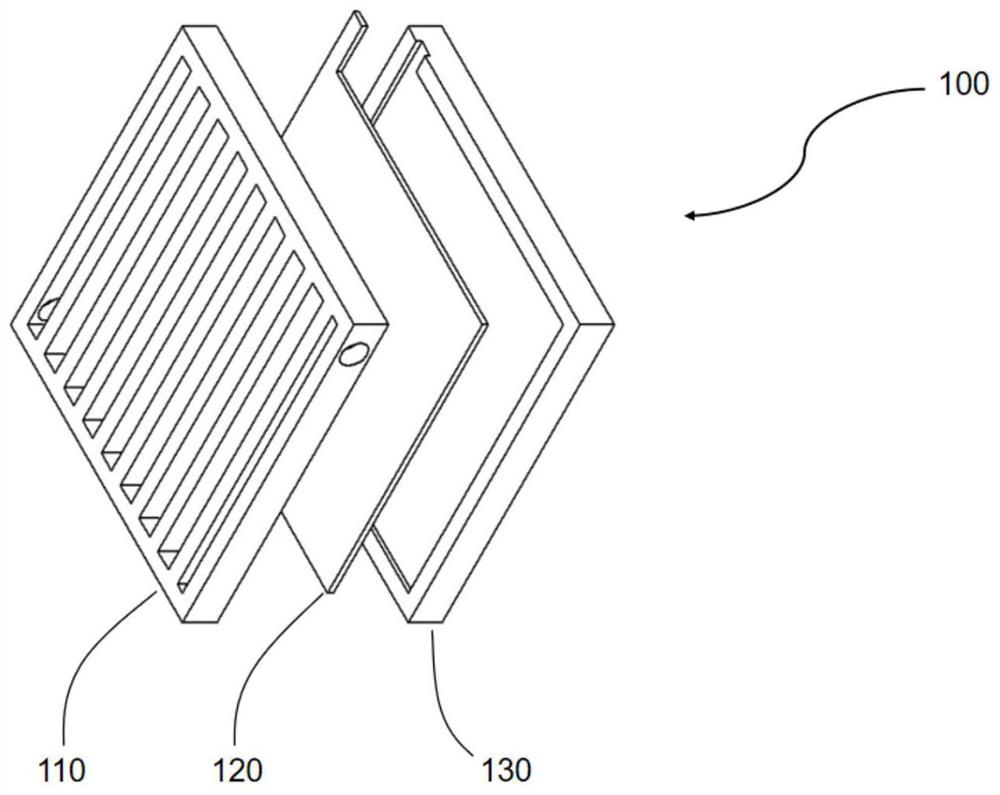

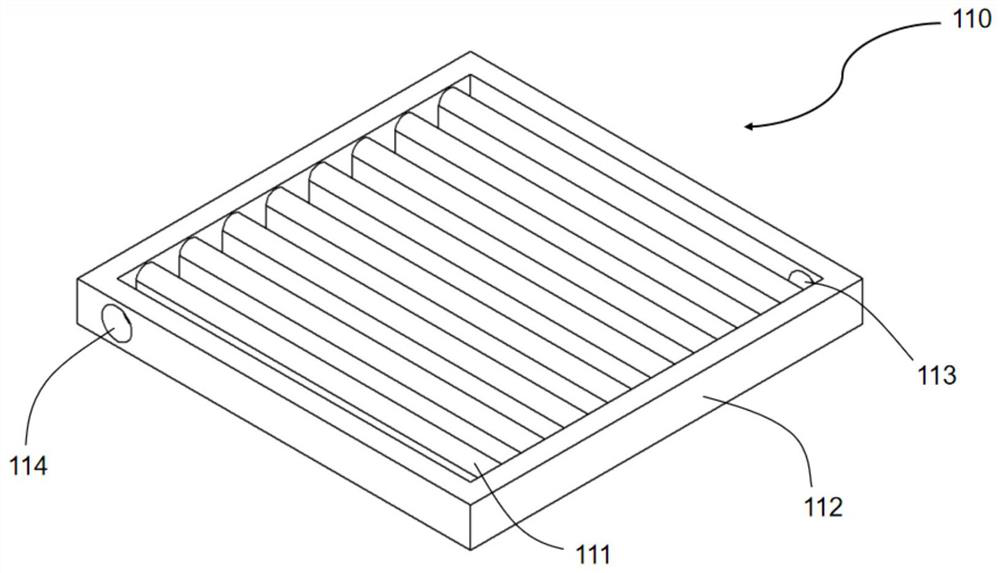

[0033] A zinc-air secondary battery, such as figure 1 As shown, it includes a zinc negative electrode 100 , an air positive electrode 200 and an electrolyte 300 . The zinc negative electrode 100 is a zinc plate provided with electrolyte flow distribution parts, the air positive electrode 200 is a metal mesh provided with a catalyst, the metal mesh acts as a current collector, and the electrolyte solution 300 can be sodium hydroxide or potassium hydroxide to provide hydrogen and oxygen Root ions participate in battery reactions. In addition, in the battery structure, end plates are usually provided on both sides of the positive and negative electrodes. The specific structure of the zinc negative electrode 100 is as follows: figure 2 As shown, it includes a zinc plate 120 with a current collection function, and one side of the zinc plate 120 is provided with an electrolyte flow distribution part 110, and the electrolyte flow distribution part 110 is a grid structure with a fr...

Embodiment 2

[0037] The structure of the zinc-air secondary battery of this embodiment is the same as that of Embodiment 1, the difference is that in the electrolyte flow distribution part 110 of this embodiment, the guide column 111 is close to the zinc plate 120, and the guide column 111 has only One end is connected to the frame 112 and the ends of the adjacent guide columns connected to the frame 112 are staggered, so the electrolyte 300 has a serpentine flow channel when flowing on the surface of the zinc plate 120, and the electrolyte 300 flows when flowing through the surface of the zinc plate 120 The direction will be constantly changing, as in Figure 6 indicated by the arrow in .

[0038] The battery system is placed vertically. When the battery is charging and discharging, the electrolyte 300 enters the electrolyte flow distribution part 110 from the inlet 113 of the frame and fills the gap of the grid structure, and then flows out from the electrolyte outlet 114, and the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com