Film forming device and partition wall structure of same

A film-forming device and a technology for partition walls, which are applied in ion implantation plating, gaseous chemical plating, coating, etc., can solve problems such as difficulty in improving thin films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

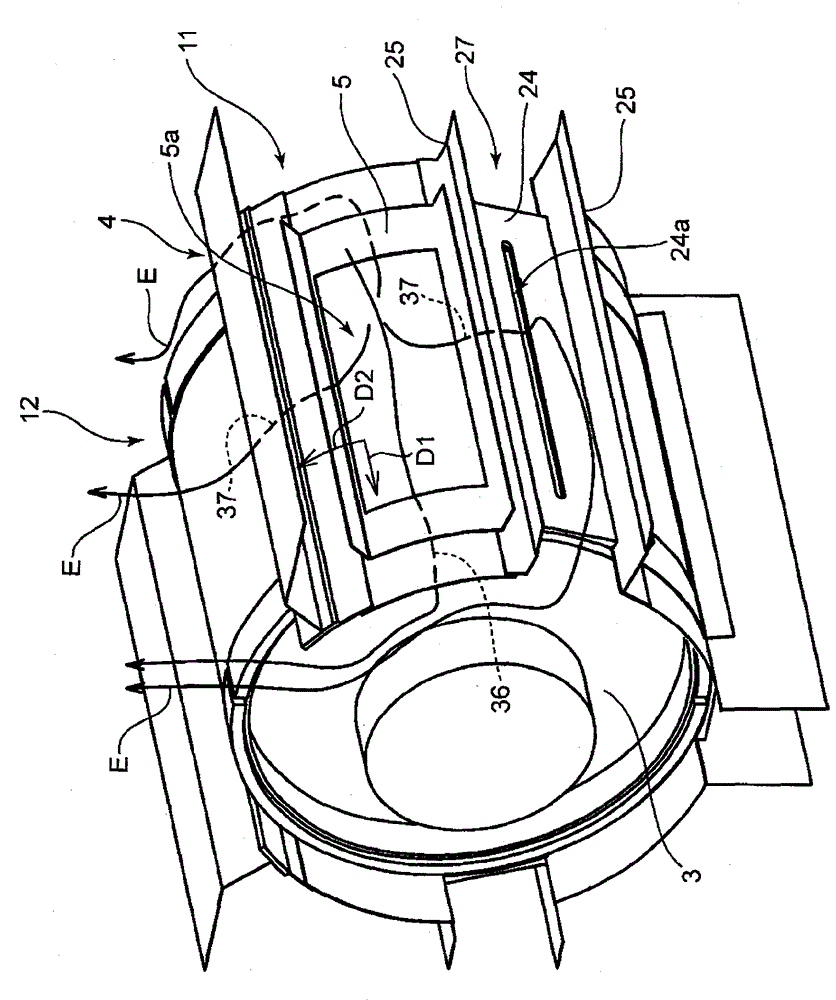

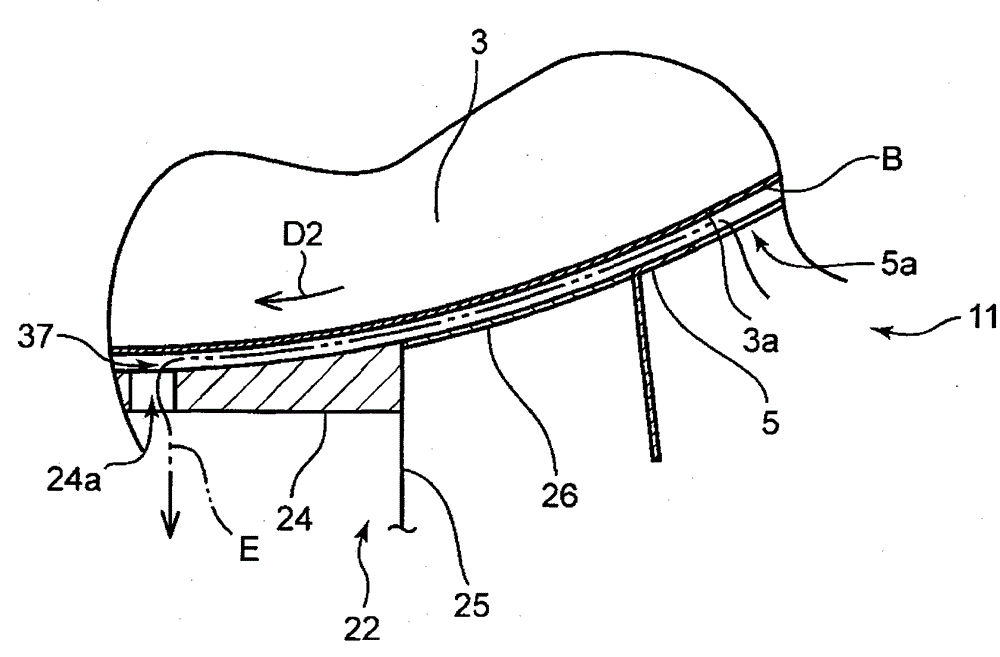

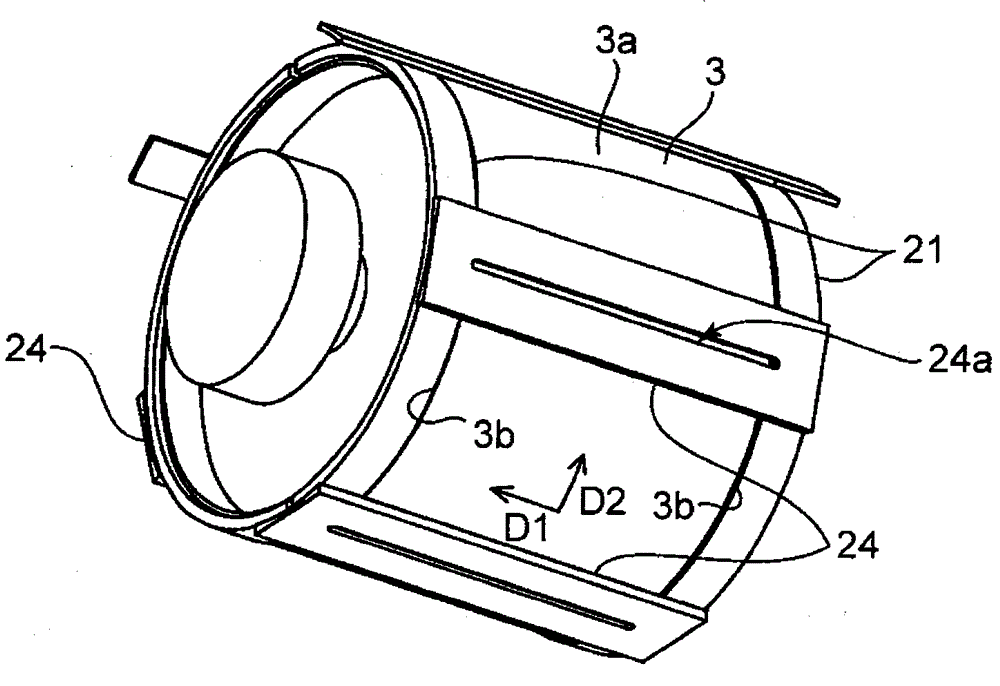

[0066] Hereinafter, embodiments of the partition wall structure and the film forming apparatus including the partition wall structure of the present invention will be described in further detail with reference to the drawings.

[0067] Figure 1 ~ Figure 2 The shown film forming device 1 is formed on at least one partition wall structure 4 (in figure 1 4 in the middle) A device for continuously forming a thin film on the surface of the strip-shaped substrate B using the gas G in the film forming area 11 . As the film forming apparatus 1, any apparatus that continuously forms a thin film on the surface of the substrate B using the gas G may be used, and a film forming apparatus that performs sputtering, vacuum deposition, plasma CVD, or the like is used. In the following embodiments, the film formation apparatus 1 that performs sputtering will be described as an example.

[0068] This film forming apparatus 1 includes a chamber 2 , a film forming roll 3 rotatably mounted insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com