Galvanic bath

A technology of electroplating bath and electrolyte, applied in electrodes, electrolysis components, electrolysis process, etc., can solve the problems of consumption of reactants, uneconomical, etc., and achieve the effect of delaying oxidation treatment, increasing working time, and improving layer thickness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

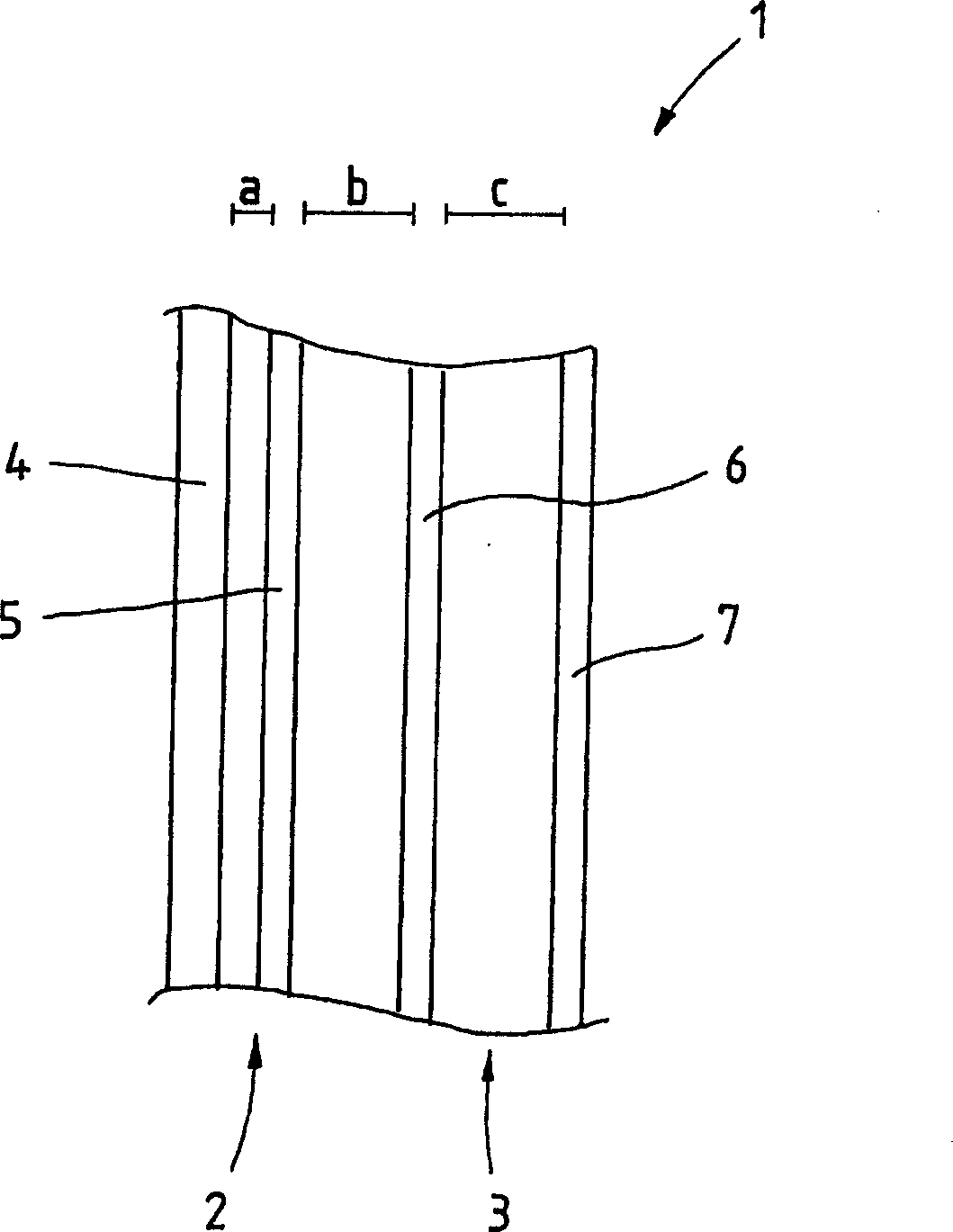

[0052] The anode base body 2 itself consists of a carrier material 4 and a coating 5, ie the active layer. The carrier material 4 is preferably stainless steel, titanium or the like, while the coating 5 is preferably made of iridium mixed oxides, platinum or the like. The coating 5 can be applied directly on the carrier material 4 or spaced apart from the carrier material 4 . in accordance with figure 1 In an exemplary embodiment, the coating 5 is spaced apart from the carrier material 4, wherein the distance between the carrier material 4 and the coating 5 is denoted by a. This distance can be, for example, a few tenths of a millimeter. in accordance with figure 1 In an exemplary embodiment, the coating 7 is applied to a substrate, which may be made of stainless steel, titanium, or the like.

[0053] Depend on figure 1 It can be seen that the separator 3 of the anode 1 is a two-part piece. The first part of the separator 3 is formed by a tissue 6 consisting of a non-con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com