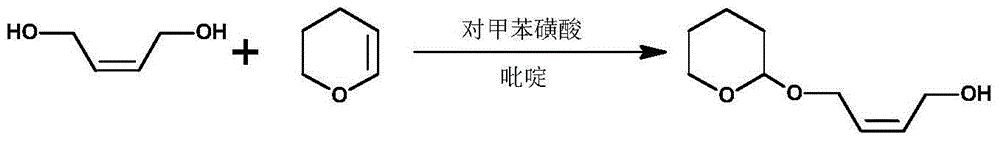

Synthetic method of cis-4-(tetrahydropyrane-2-oxy)-2-butylene-1-ol

A technology of tetrahydropyran and a synthesis method, applied in the direction of organic chemistry and the like, can solve the problems of energy consumption, solvent recovery and environmental protection increase large cost, unsuitable for industrial production, affecting industrial production and other problems, and achieves widening raw material sources and reducing residues. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1, refining of 1,4-butenediol

[0032] 394.25 g of crude 1,4-butenediol (89.16% cis content detected by GC) and 1193.47 g of acetone were put into a 2000 mL four-necked flask. Use an ethanol refrigeration system to cool down the solution to -16°C, keep stirring and crystallize for about 4 hours, then quickly filter with suction and rinse with 41g of cold acetone at -6°C (wash the filter funnel with another portion of cold acetone first). Put the filtered crystals into a 1000mL four-neck flask, connect to the vacuum and heat, and distill to the liquid temperature of 65°C under the vacuum of -0.085Mpa, and continue until there is no distillation. Then pump in about 200g of toluene, continue to distill at -0.085Mpa to a liquid temperature of 85°C, and continue until there is no distillation. Cool to room temperature and set aside. GC detection showed that the cis content was 99.76% excluding the residual toluene, and the residual toluene was 4.31%.

[0033] Step 2....

Embodiment 2

[0036] Step 1, refining of 1,4-butenediol

[0037] Put 203.78 g of crude 1,4-butenediol (88.34% cis content as detected by GC) and 613.09 g of acetone into a 2000 mL four-necked flask. Use an ethanol refrigeration system to cool the solution down to -17°C, keep stirring and crystallize for about 4 hours and 30 minutes, then quickly filter it with suction, and rinse it with 23g of cold acetone at -8°C (the filter funnel is first washed with another cold acetone). Put the filtered crystals into a 1000mL four-neck flask, connect to the vacuum and heat, and distill to the liquid temperature of 65°C under the vacuum of -0.085Mpa, and continue until there is no distillation. Then pump in about 100g of toluene, continue to distill at -0.085Mpa to a liquid temperature of 85°C, and continue until there is no distillation, then cool to room temperature for later use. GC detection showed that the cis content was 99.62% excluding the residual toluene, and the residual toluene was 3.59%. ...

Embodiment 3

[0041] Step 1, refining of 1,4-butenediol

[0042]Put 400.97 g of crude 1,4-butenediol (85.42% cis content as detected by GC) and 1206.85 g of acetone into a 2000 mL four-necked flask. Use an ethanol refrigeration system to cool the solution down to -16°C, insulate and stir to crystallize for about 4 hours, then quickly filter it with suction and wash it with 43g of cold acetone at -6°C (the filter funnel is first washed with cold acetone). Put the filtered crystals into a 1000mL four-neck flask, connect to the vacuum and heat, and distill to the liquid temperature of 65°C under the vacuum of -0.085Mpa, and continue until there is no distillation. Then pump in about 200g of toluene, continue to distill at -0.085Mpa to a liquid temperature of 85°C, and continue until there is no distillation. Cool to room temperature and set aside. GC detection showed that the cis content was 99.89% excluding the residual toluene, and the residual toluene was 3.44%.

[0043] Step 2. Addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com