Catalyst with functionalized carbon nanotubes as carrier, and preparation method and application thereof

A technology of carbon nanotubes and catalysts, applied in the field of catalysts, functionalized carbon nanotube-supported catalysts and their preparation, can solve the problems of low conversion efficiency, achieve excellent catalytic performance and selectivity, simple production and refining process, The effect of uniform metal dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

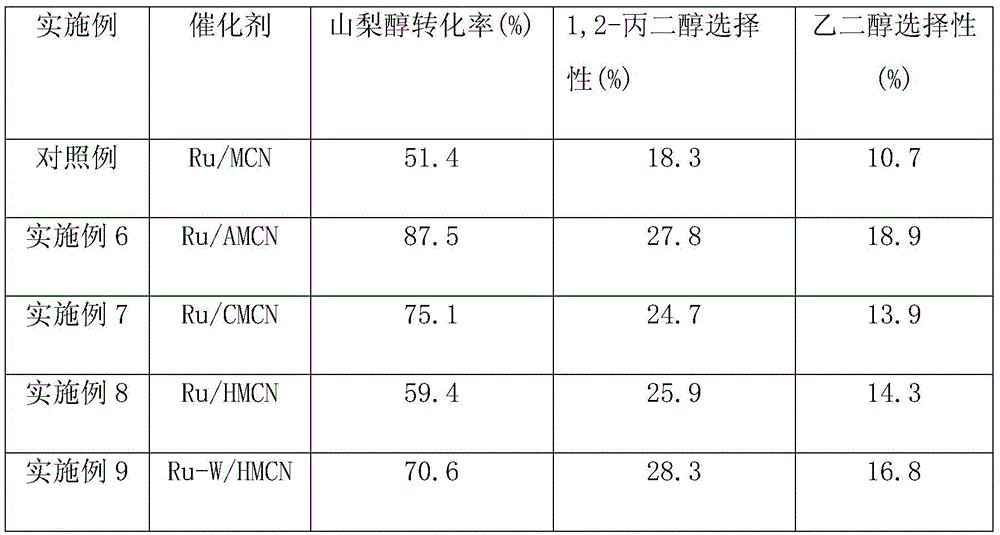

Examples

Embodiment 1

[0031] The preparation of embodiment 1 aminated carbon nanotube supported Ru catalyst (Ru / AMCN)

[0032] Weigh 0.4186gRuCl 3 ·xH 2 O precursor (Ru content 38-42%), dissolved in 30mL distilled water to prepare RuCl 3 aqueous solution, add 5.0g unfunctionalized carbon nanotubes (AMCN,-NH 2 : 0.45wt%, OD: 8 ~ 18nm, Length: ~ 50μm). After ultrasonication for 3 hours, impregnation overnight with stirring at room temperature, and drying in a vacuum oven at 120° C. for 12 hours, an aminated carbon nanotube-supported Ru catalyst (Ru / AMCN) was obtained.

[0033] Put the above catalyst at 250℃~350℃, H 2 Reduction was carried out for 2 hours at a flow rate of 30 mL / min to obtain reduction-activated carbon nanotube-supported Ru catalysts (Ru / AMCN-250R and Ru / AMCN-350R).

Embodiment 2

[0034]The preparation of embodiment 2 carboxylated carbon nanotube supported Ru catalyst (Ru / CMCN)

[0035] The specific implementation process is the same as in Example 1, but the difference is that RuCl 3 ·xH 2 O was dissolved in 32 mL of distilled water, and the carrier used was aminated carbon nanotubes (CMCN, -COOH: 2.56 wt%, OD, 8-18 nm, Length: ~50 μm).

Embodiment 3

[0036] Preparation of Example 3 Hydroxylated Carbon Nanotube-supported Ru Catalyst (Ru / HMCN)

[0037] The specific implementation process is the same as in Example 1, but the difference is that RuCl 3 ·xH 2 O was dissolved in 32 mL of distilled water, and the carrier used was hydroxylated carbon nanotubes (HMCN, -OH: 3.70 wt%, OD: 8-18 nm, Length: ~ 50 μm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com