Method for adding crude anhydride in maleic anhydride production process

A technology of maleic anhydride and crude anhydride, applied in the field of maleic anhydride production, can solve the problems of shortening the washing cycle, increasing environmental pollution, increasing enterprise costs, etc., and achieves the effect of convenient refining process, increasing economic benefits and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

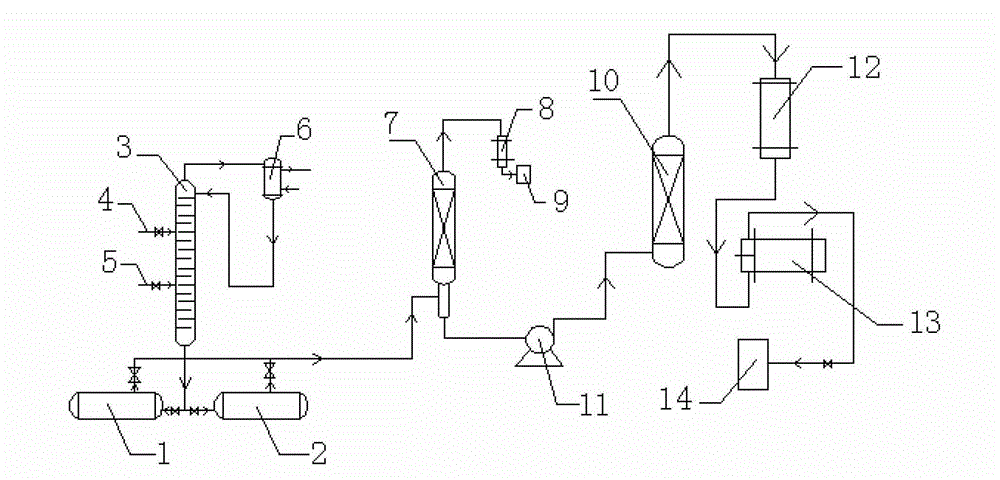

[0011] A method for thickening anhydride in the process of producing maleic anhydride, the refining system for producing maleic anhydride adopts a continuous refining system of three towers and two kettles consisting of two refining kettles, an azeotropic dehydration tower, a solvent recovery tower and a refining tower, and is characterized in that : The crude anhydride is directly added to the azeotropic dehydration tower, and the crude anhydride is added from the middle of the azeotropic dehydration tower.

[0012] Such as figure 1 As shown, a refining system for the method of thickening anhydride in the production of maleic anhydride as described above is characterized in that it includes a first refining kettle 1, a second refining kettle 2, an azeotropic dehydration tower 3, and a solvent recovery Tower 7 and refining tower 10, described azeotropic dehydration tower 3 is provided with acid inlet pipe 4 and thickening anhydride pipe 5, the first refining still 1 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com