Preparation method of herbal elsholtzia essential oil

A technology of incense and incense, which is applied in the directions of essential oils/spice, fat production, etc., can solve the problems of high production cost, inflammable and explosive, long production process, etc., and achieves avoiding high peroxide value, simple refining process, The effect of reducing the heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

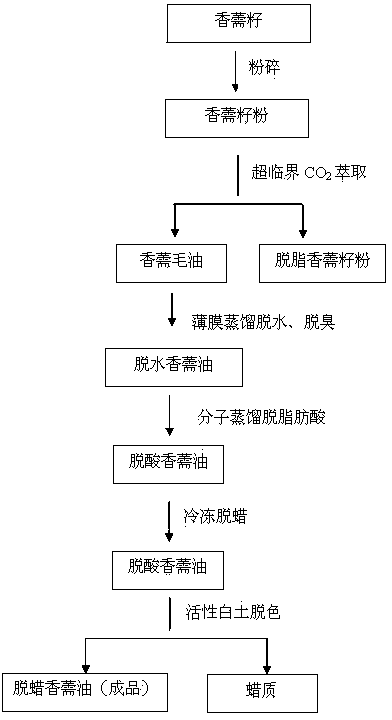

Method used

Image

Examples

Embodiment 1

[0033] 1. Supercritical CO 2 extraction

[0034] 2.0kg is crushed to 50 mesh fenugreek seed powder and is packed in the supercritical 5L barrel, and is placed in the extraction kettle to carry out supercritical CO 2 Extraction, every 30min emits the hairy oil of yarrow from separation kettle 1 once, obtains the hairy oil of yarrow 607.3g after 4h, wherein supercritical CO 2 The extraction pressure is 20.5MPa, the extraction temperature is 45.0°C, the separation I pressure is 7.1MPa, the separation II pressure is 5.2MPa, the separation I temperature is 30.0°C, the separation II temperature is 30.0°C, CO 2 The flow rate is 44.6L / h.

[0035] 2. Dehydration and degassing by thin film distillation

[0036] Pump 607.3g of elixir crude oil into a thin-film distiller for dehydration and deodorization. The vacuum degree of thin-film distillation is 510Pa, the distillation temperature is 70.0°C, the condensation temperature is 10.0°C, the speed of scraping film is 226rpm, and the fee...

Embodiment 2

[0050] 1. Supercritical CO 2 extraction

[0051] 2.0kg is crushed to the 80 mesh fenugreek seed powder and is packed into a supercritical 5L barrel, and placed in an extraction kettle for supercritical CO 2 Extraction, every 30min emits the hairy oil of fenugreek from separation kettle 1 once, supercritical CO 2 After extraction for 3 hours, 613.1 g of fenugreek hair oil was obtained, supercritical CO 2 Extraction pressure is 30.2MPa, extraction temperature is 50.0°C, separation I pressure is 7.9MPa, separation II pressure is 5.5MPa, separation I temperature is 40.0°C, separation II temperature is 40.0°C, CO 2 The flow rate is 40.3L / h.

[0052] 2. Dehydration and degassing by thin film distillation

[0053] Pump 613.1g of elixir crude oil into a thin-film distiller for dehydration and deodorization. The vacuum degree of thin-film distillation is 2100Pa, the distillation temperature is 80.0°C, the speed of scraping film is 298rpm, the condensation temperature is 20.0°C, and...

Embodiment 3

[0067] 1. Supercritical CO 2 extraction

[0068] 2.0kg is crushed to the 100 mesh fenugreek seed powder and is packed into a supercritical 5L barrel, and placed in an extraction kettle for supercritical CO 2 Extraction, every 30min emits the hairy oil of yarrow from separation kettle 1 once, obtains the hairy oil of yarrow 596.9g after 2h, wherein supercritical CO 2 The extraction pressure is 34.8MPa, the extraction temperature is 55.0°C, the separation I pressure is 8.7MPa, the separation II pressure is 6.2MPa, the separation I temperature is 50.0°C, the separation II temperature is 50.0°C, CO 2 The flow rate is 31.8L / h.

[0069] 2. Dehydration and degassing by thin film distillation

[0070] Pump 596.9g of fenugreek crude oil into a thin-film distiller for dehydration and deodorization. The vacuum degree of thin-film distillation is 4800Pa, the distillation temperature is 90.0°C, the speed of scraping film is 348rpm, the condensation temperature is 30.0°C, and the feed fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| peroxide value | aaaaa | aaaaa |

| peroxide value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com