System and method for preparing ammonia water from gaseous ammonia

A technology of ammonia water and gaseous ammonia, applied in the preparation/separation of ammonia, chemical instruments and methods, ammonia compounds, etc., can solve the problems of high power consumption and low efficiency, and achieve the effects of reducing power consumption, reducing costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

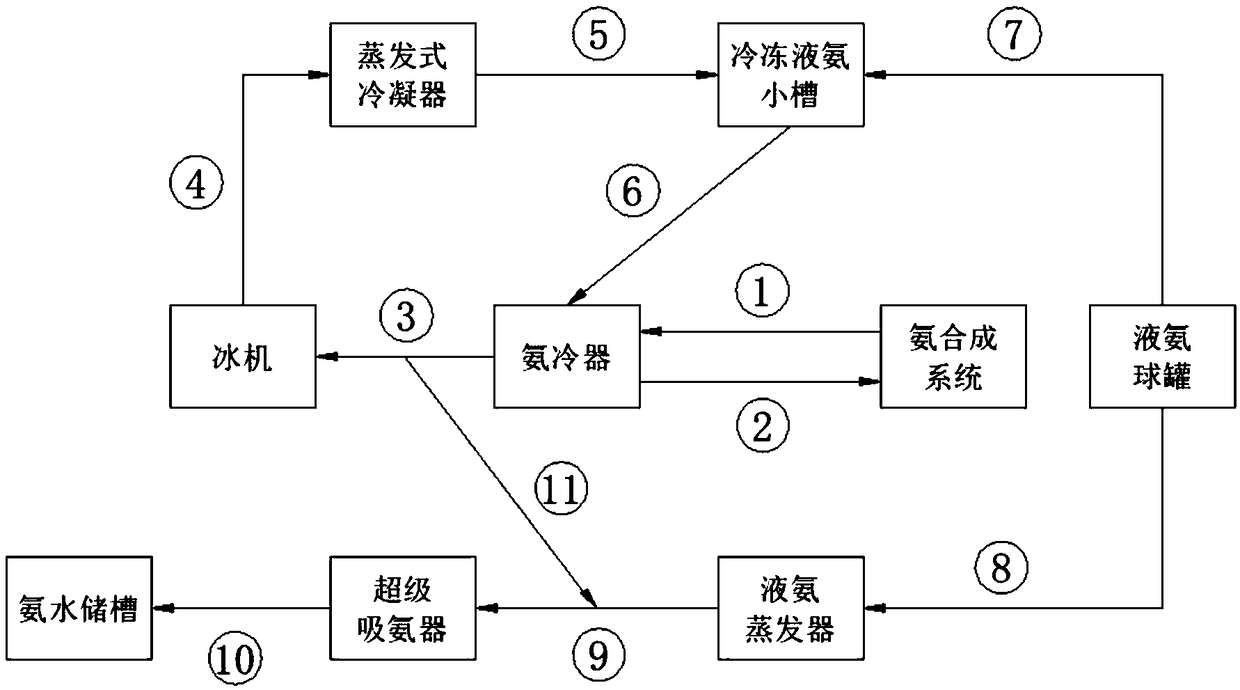

[0026] Embodiment 1: A system for preparing ammonia water from ammonia gas, comprising a synthetic ammonia system, an ammonia cooler, a refrigeration system, a small tank for refrigerated liquid ammonia, an ammonia water system and an ammonia water pipeline from ammonia gas, the process gas of the ammonia synthesis system enters the ammonia cooler, and the ammonia The cooler and the refrigerating system are connected through the gas ammonia pipeline, and the liquefied ammonia produced by the refrigerating system is stored in the small refrigerated liquid ammonia tank; the refrigerated liquid ammonia tank provides condensing agent to the ammonia cooler through the liquid ammonia pipeline; the ammonia water system includes a super ammonia absorber , the inlet of the gas ammonia ammonia water pipeline is on the gas ammonia pipeline, and the outlet communicates with an inlet of the super ammonia absorber. A tap is added on the ammonia gas pipeline from the ammonia cooler to the inl...

Embodiment 2

[0027] Embodiment 2: In order to improve the preparation efficiency of ammonia water, ammonia water system comprises liquid ammonia evaporator and ammonia storage tank, the inlet of liquid ammonia evaporator is connected to liquid ammonia spherical tank, and the outlet of liquid ammonia evaporator is connected to another part of super ammonia absorber One inlet, and the outlet of the super ammonia absorber is connected to the ammonia water storage tank. A fourth regulating valve is arranged on the connecting pipeline of the liquid ammonia evaporator and the liquid ammonia spherical tank. This embodiment combines gaseous ammonia to prepare ammonia water and liquid ammonia to prepare ammonia water.

[0028] When the demand for ammonia water is large, all the gas ammonia from the ammonia cooler is sent to the super ammonia absorber to make ammonia water. If it is not enough to meet the needs at this time, start supplementing liquid ammonia to make ammonia water. Then the ice mac...

Embodiment 3

[0030] Embodiment 3: A system for preparing ammonia water from ammonia gas, the freezing system includes an ice machine and an evaporative condenser connected in sequence, the inlet of the ice machine is connected to the ammonia cooler, and the outlet of the evaporative air cooler is connected to the small tank of refrigerated liquid ammonia, and the evaporation A temperature sensor is installed on the pipeline connecting the type condenser and the small tank of refrigerated liquid ammonia; the first regulating valve is installed on the liquid ammonia pipeline, which can replenish liquid ammonia according to the temperature of the refrigeration system. The small tank of refrigerated liquid ammonia continuously replenishes liquid ammonia to the ammonia cooler, and the amount of ammonia replenishment is controlled by a self-regulating valve according to the temperature of the ammonia cooler;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com