Method for hydrofining caprolactam in magnetically stabilized bed

A caprolactam, magnetically stabilized bed technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc., can solve the problems of large catalyst dosage, low reactant concentration and high energy consumption, Achieve the effect of reducing energy consumption, optimizing refining process and improving processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The preparation of embodiment 1 catalyst carrier

[0015] (1), 250 grams of magnetic granular material and 1000 grams of Al 2 o 3 The sol (Al 2 o 3 The mass ratio is 40%), 30 grams of 20 nanometers of CaCO 3 Mix in a stirred mixer, where SiO in the magnetic granular material 2 The coating layer is uniformly dispersed in it with Fe with an average particle size of 108 nm 3 o 4 The ratio of magnetic particles is 0.3:1. Control the stirring speed to be greater than 500 rpm and mix for 1 hour, prepare micron-sized pellets in a nitrogen flow at 600°C by spray drying method, and soak the pellets in excess hydrochloric acid (10% mass concentration) at 40°C for 30 minutes , washed several times to remove CaCO 3 . Then calcined at 500° C. for 2 hours to obtain spherical particles, and sieved to obtain small balls with a diameter of 50-70 microns as spherical catalyst carriers for later use, namely Carrier-1.

[0016] (2), 250 grams of magnetic granular material and 100...

Embodiment 2

[0017] The preparation of embodiment 2 catalyst.

[0018] (1), according to the weight of palladium being 1% calculation of catalyst support weight, take by weighing an appropriate amount of Pd (NO 3 ) 2 , the palladium is loaded on the surface of the carrier-1 by impregnation method, the catalyst carrier loaded with palladium decants the liquid, puts it into a muffle furnace after drying, and bakes at 550° C. for 2 hours. The calcined catalyst was reduced with hydrogen at 500° C. for 4 hours, the heating was stopped, and the temperature was lowered to room temperature in a hydrogen atmosphere to obtain Catalyst-1.

[0019] (2), according to the weight of platinum is 1% calculation of catalyst carrier weight, take by weighing an appropriate amount of chloroplatinic acid, platinum is loaded on the surface of carrier-1 by dipping method, the catalyst carrier after loading platinum is decanted liquid, air After drying, put it into a muffle furnace and bake at 550°C for 2 hours....

Embodiment 3

[0022] Embodiment 3 crude caprolactam hydrogenation test

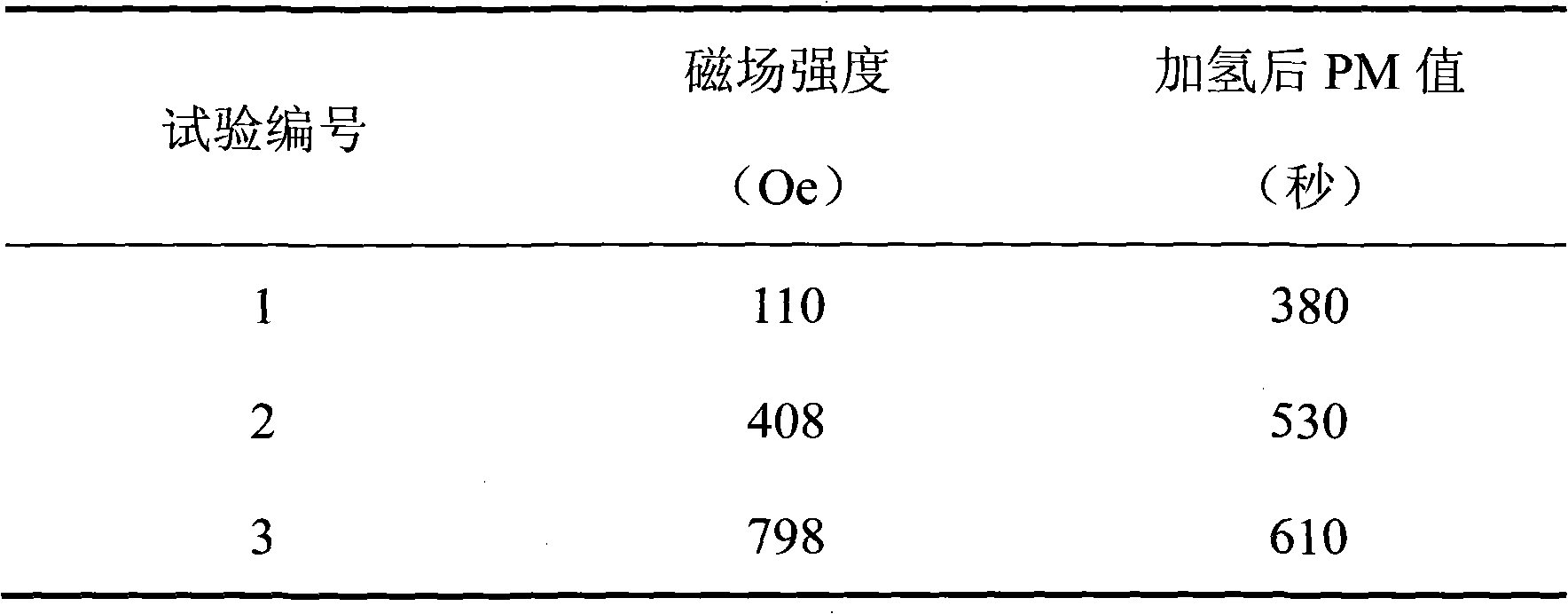

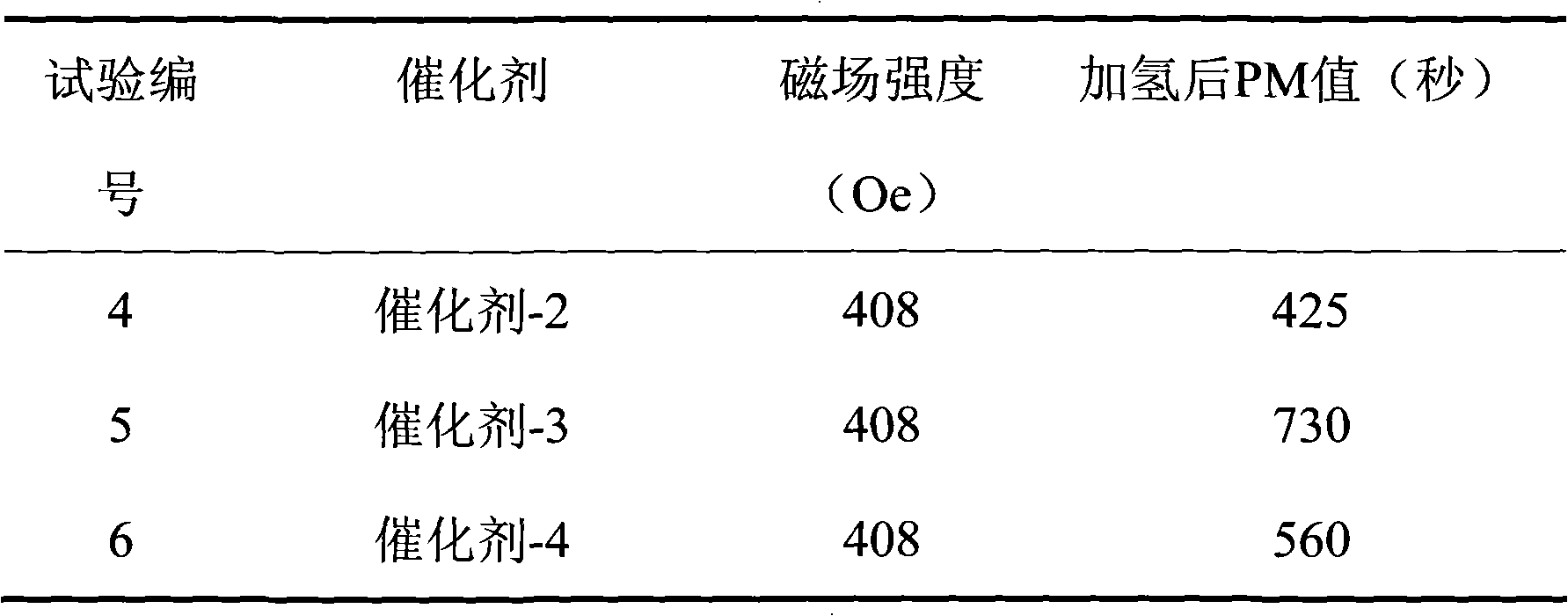

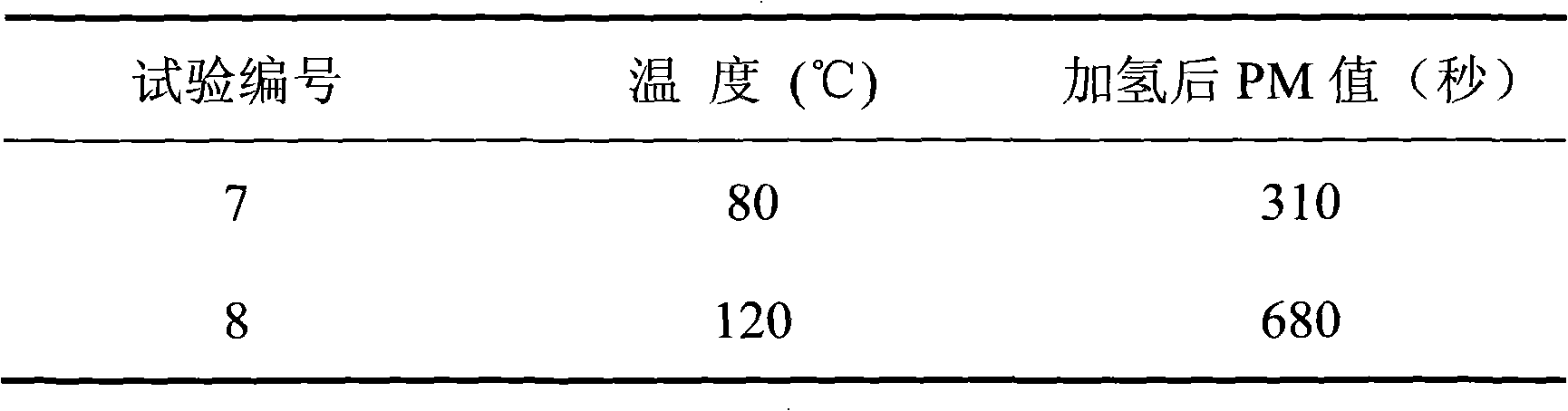

[0023] 10 milliliters of catalyst-1 with a particle size of 50-70 microns is loaded into a reactor with an inner diameter of 14 mm; seven coils with an inner diameter of 55 mm, an outer diameter of 165 mm, a height of 35 mm and a number of turns of 370 are reacted along the The device is axially arranged to provide a uniform magnetic field, and the distance between the coils is 27.5 millimeters; the reaction raw materials and hydrogen enter from the lower part of the magnetically stable bed reactor and flow out from the upper part, and the hydrogen / material ratio (volume ratio) is 6.0. 100℃, pressure 1.2MPa, liquid space velocity 30 hours -1 Hydrofining reaction is carried out under the condition of , the reaction raw material is caprolactam crude product containing impurities (PM value is 110 seconds), table 1 is the effect of caprolactam hydrofinishing under different magnetic field strengths.

[0024] Table 1 Effects...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com