Method for producing xylosic acid through xylose whole-cell catalysis by direct oxygen introduction and pressurization

A xylonic acid, whole cell technology, applied in the fields of bioengineering and chemical engineering, can solve problems such as overflow, production operation and product quality impact, foam, etc., achieve simple production operation and control, eliminate foam phenomenon, and improve reaction rate. and the effect of reaction concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

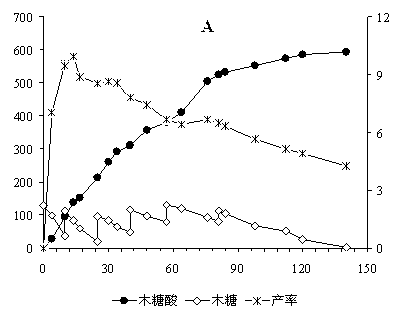

Embodiment 1

[0024] In a 3.0L mechanically ventilated reaction tank, add 1.0L xylose solution to an initial monosaccharide concentration of 150g / L, add 40g / L calcium carbonate to adjust the pH of the reaction system to 5.0~7.5, start the stirring speed at 500r / min, then Inject activated Gluconobacter oxydans to a cell concentration of OD 600nm =1.0. Open the exhaust gas discharge valve, directly feed oxygen (volume concentration not less than 90%) for 10 minutes to replace the air in the reaction system, and then seal the reaction system for catalytic reaction. Adjust the oxygen supply pressure of the oxygen source to maintain the internal pressure of the reaction system at 0.01~0.10MPa.

[0025] Real-time monitoring of reaction system CO 2 concentration, to CO 2 When the concentration in the exhaust gas of the reaction system reaches 5% (volume ratio), reduce the stirring speed to 80r / min, open the exhaust valve of the reaction tank, and pass oxygen for 5~15min to replace the CO in the...

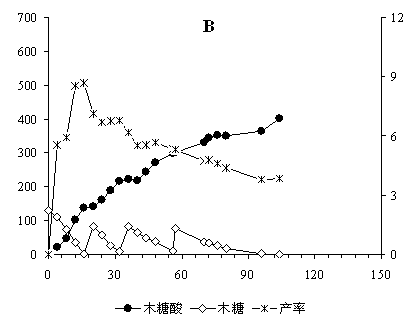

Embodiment 2

[0028] In a 100 L mechanically ventilated reaction tank, add 60 L of xylose solution to an initial monosaccharide concentration of 100 g / L, add 35 g / L of calcium carbonate to adjust the pH of the reaction system to 5.0~7.5, start the stirring speed at 500 r / min, and insert Activated Gluconobacter oxydans to a cell concentration of OD 600nm = 1.0. Open the exhaust gas discharge valve, directly introduce oxygen (volume concentration not less than 90%) for 15 minutes to replace the air in the reaction system, and then seal the reaction system for catalytic reaction. Adjust the oxygen supply pressure of the oxygen source to maintain the internal pressure of the reaction system at 0.01~0.03MPa.

[0029] Real-time monitoring of reaction system CO 2 concentration, to CO 2 When the concentration in the exhaust gas of the reaction system reaches 5% (volume ratio), reduce the stirring speed to 50r / min, open the exhaust valve of the reaction tank, and discharge the CO in the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com