Gravity-flow membrane bioreactor with low energy consumption

A membrane bioreactor, energy-consuming self-flow technology, applied in the field of mechanical equipment, can solve the problems of reduced floor space, low oxygen transfer efficiency, etc., and achieve the effects of saving floor space, high oxygen transfer efficiency, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

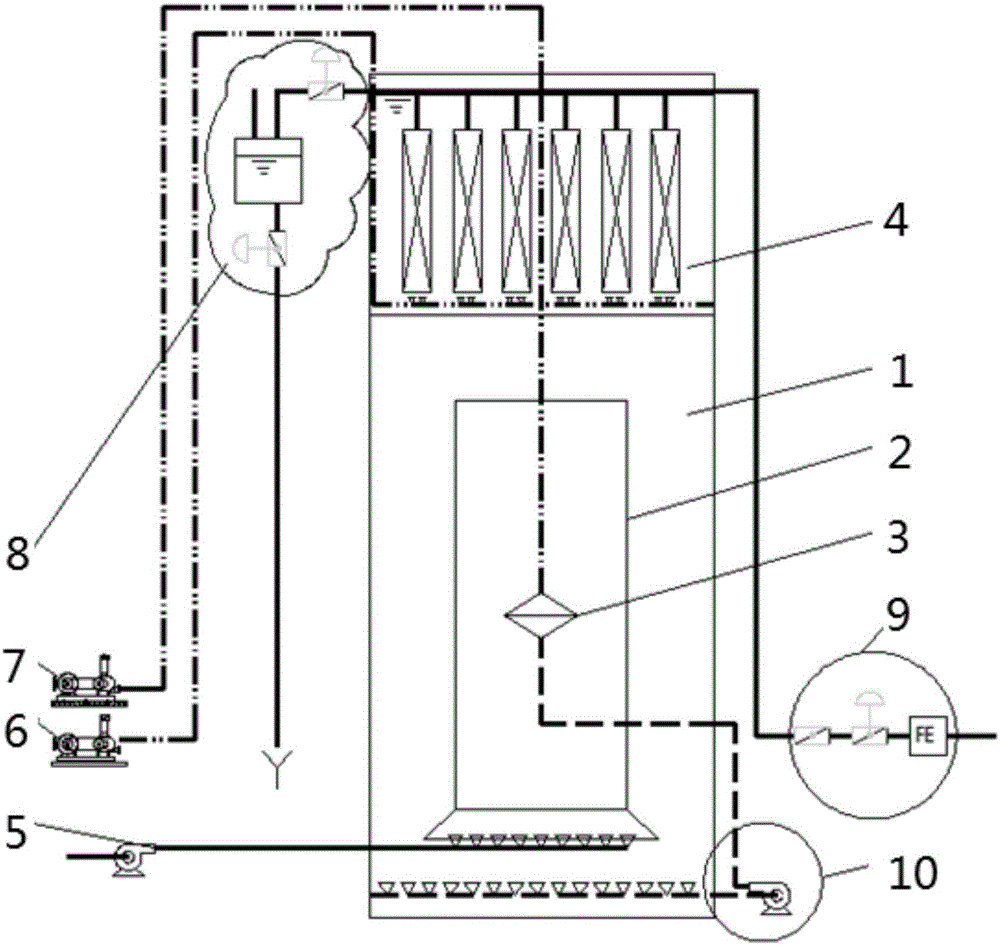

[0050] see figure 1 , the low-energy self-flowing membrane bioreactor of the present invention includes a reactor tank 1, a guide cylinder 2, an aerator 3, an MBR membrane module 4, an inlet water distribution system 5, an MBR fan 6, a process fan 7, Vacuum suction system 8, constant flow automatic adjustment system 9 and sludge internal circulation system 10; the diversion cylinder is set in the lower part of the reactor tank, the aerator is set in the middle of the diversion cylinder, and the MBR membrane module is set in the reactor tank. In the upper part of the tank body, the water inlet and distribution system sends the pretreated sewage evenly from the lower part of the guide tube to the guide tube through the inlet pump and water distributor, and the MBR fan sends air from the bottom of the MBR membrane module through the air distribution pipe. The air is evenly sent into the MBR membrane module, the process fan sends air into the aerator through the air supply pipe, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com