Honeycombed section biological fluidized composite reactor

A biological fluidization and reactor technology, applied in the direction of sustainable biological treatment, aerobic process treatment, etc., can solve the problems of increased construction cost and construction difficulty, insufficient structural strength, impact on surrounding landscape, etc., to improve oxygen transfer efficiency, Effects of reducing energy consumption and controlling biofilm thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

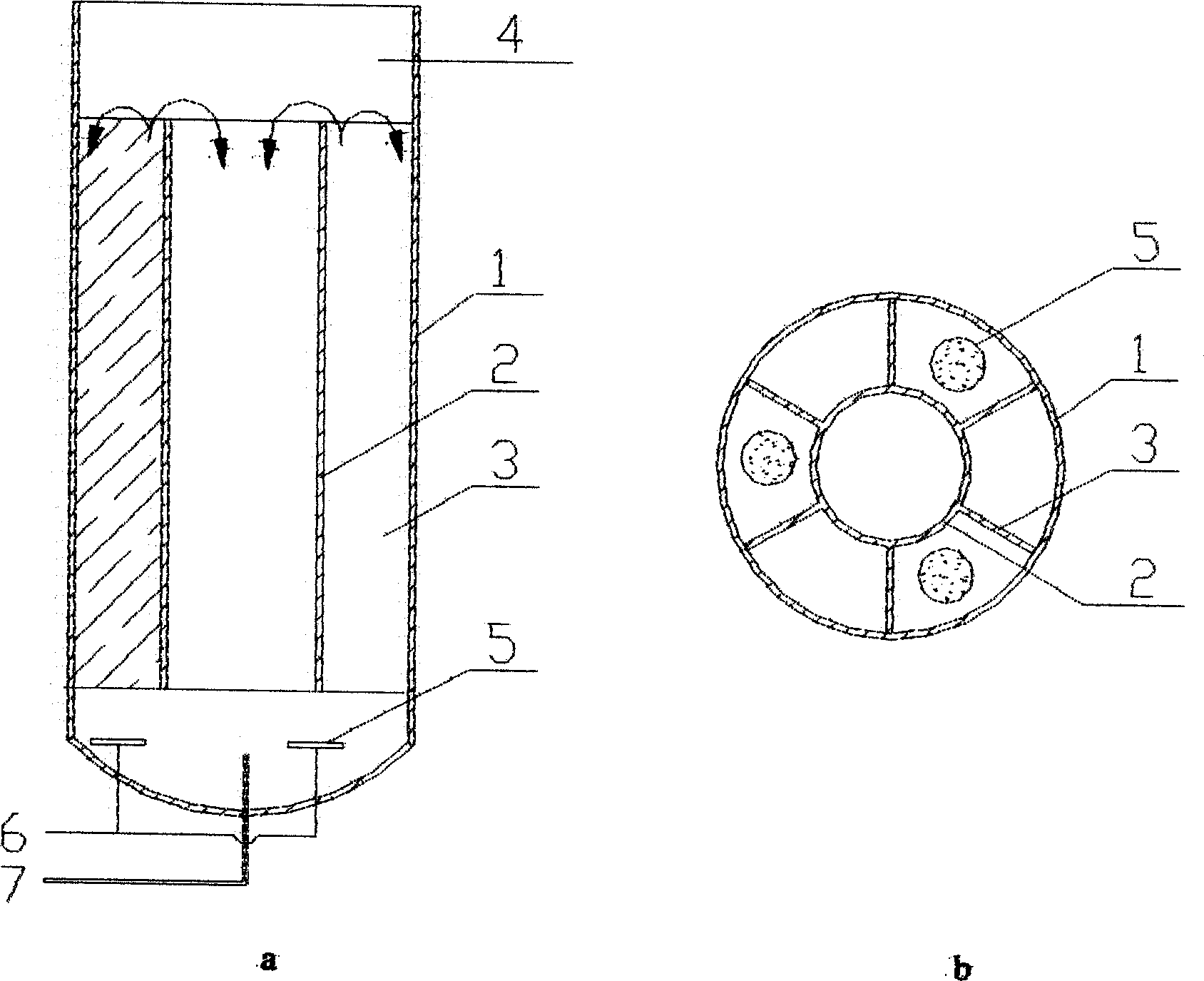

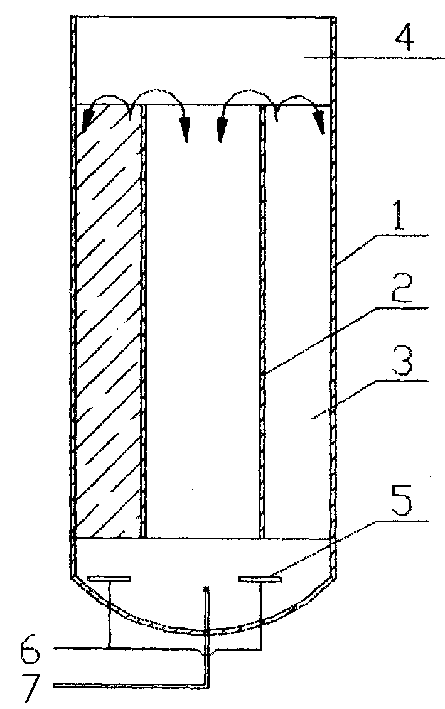

[0010] The present invention relates to a biological fluidization composite reactor with a honeycomb cross-section. The composite biological fluidization reactor adopts a honeycomb cross-section structure. The reactor inner cylinder 2 is located at the center of the reactor outer cylinder 1, and the reactor outer cylinder 1 and A partition 3 is added in the annular gap between the reactor inner cylinders 2, and the annular gap is evenly separated by the partition 3, and the number of partitions is an even number (such as figure 1 a), figure 1 As shown in (b), there are generally 4, 6, 8, and 10; the separated adjacent annulus areas are sequentially set as upflow areas and downflow areas. The internal structure composed of the entire inner cylinder and the partition is installed at a certain distance from the bottom of the reactor to ensure the circulation of the internal gas-liquid-solid mixture; the internal structure is also at a certain height from the top of the reactor, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com