Preparation method of biological diesel oil

A biodiesel and oil technology, which is applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, biofuels, etc., can solve the problems of complex process, waste lye discharge, high cost, etc., and achieves simple and safe process route, mild reaction conditions, and high cost. The effect of reducing waste residue discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

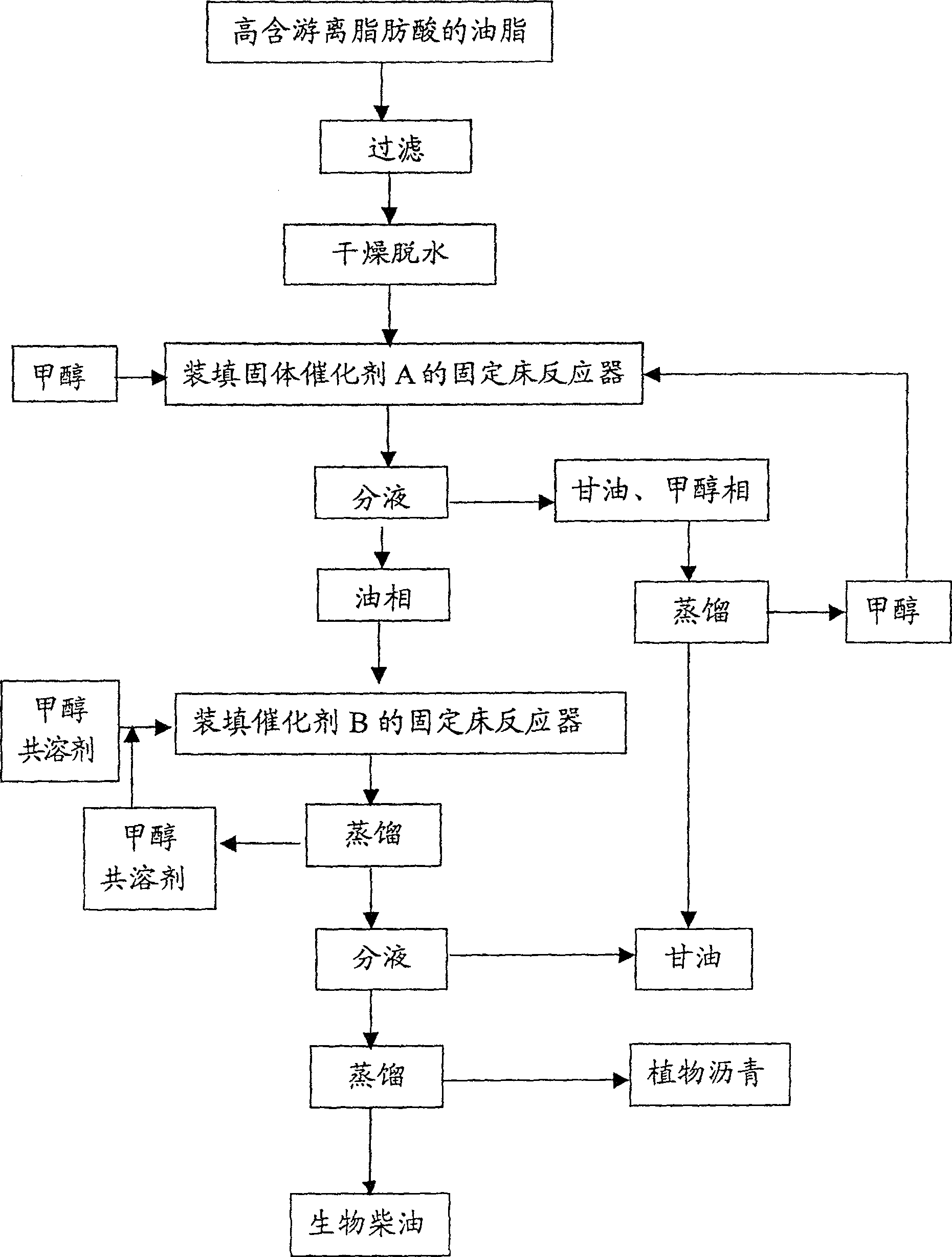

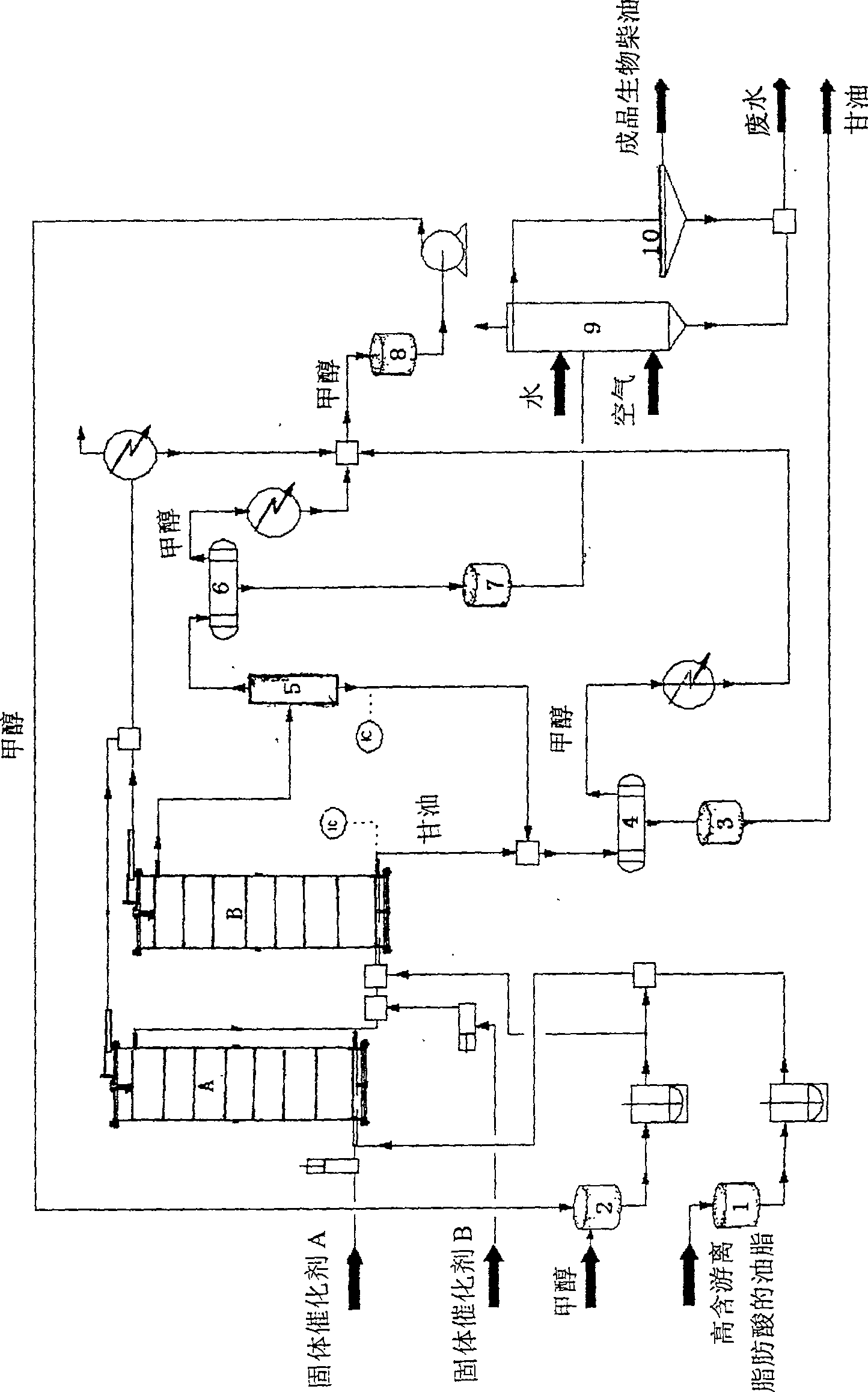

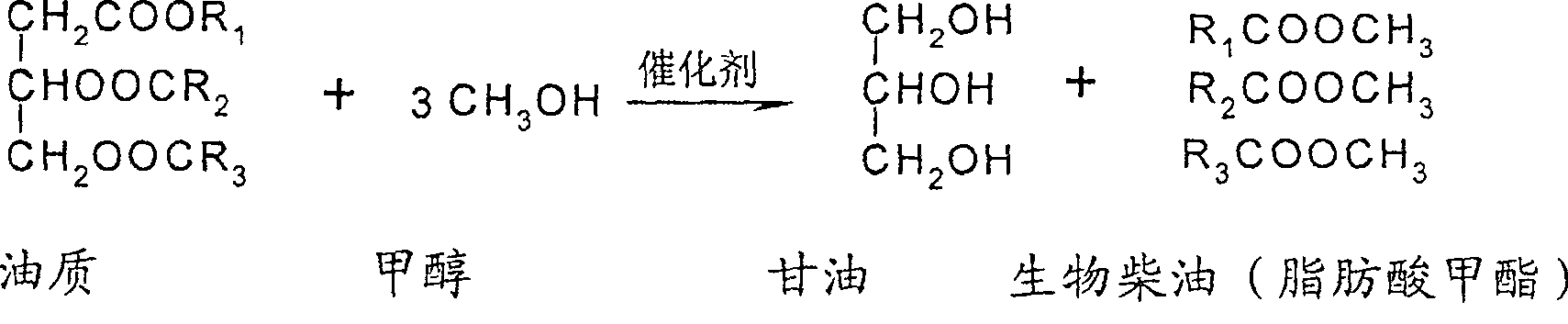

Method used

Image

Examples

Embodiment 1

[0038] Preparation of solid catalyst A:

[0039] Mix titanium tetrachloride and aluminum trichloride with a molar ratio of 1:2 to make a 30% solution, 1kg of catalyst A requires 435g titanium tetrachloride and 584g aluminum trichloride, use 28% ammonia water as a precipitant, and control the pH The value is 7~8, the precipitate is filtered, washed, ground, passed through a 100-mesh sieve, impregnated with 0.5mol / L sulfuric acid for 2 hours, filtered with suction, dried at 110°C, activated at 430°C for 3h, cooled, and placed in a desiccator After medium drying, the composite titanium sulfate super strong solid acid SO 4 2- / TiO 2 —Al 2 o 3 . The solid catalyst A is loaded in the fixed-bed reactor A, and the amount of the solid catalyst A is 2% of the mass of the cottonseed oil, which is supplemented with the reaction.

[0040] Preparation of solid catalyst B: 1020g Al 2 o 3 1kg of solid catalyst B can be produced.

[0041] With 20% KNO 3 solution, the Al 2 o 3 Powde...

Embodiment 2

[0054] Preparation of solid catalyst A:

[0055] Make a 30% solution of chromium tetrachloride and aluminum trichloride according to the molar ratio of chromium and aluminum at 1:2, use 28% ammonia water as a precipitant, control the pH value to 7-8, and filter and wash the precipitate , grind, pass through a 100-mesh sieve, impregnate with 0.5mol / L sulfuric acid for 2 hours, filter with suction, dry at 110°C, activate at 480°C for 3 hours, cool, and dry in a desiccator to obtain a composite titanium sulfate super solid acid SO 4 2- / ZrO 2 —Al 2 o 3

[0056] The rapeseed oil enters the raw material storage tank after removing mechanical impurities, and enters the raw material storage tank after being heated to 80°C with a vacuum degree of -0.095Mpa and a dehydrator at a temperature of 130°C. effect on catalyst activity.

[0057] Ethanol and co-solvent tetrahydrofuran were prepared according to the volume ratio of 1:1.25, and put into No. 2 raw material tank for standby.

...

Embodiment 3

[0065] The preparation method is the same as that of Example 1, the raw material is agricultural seed oil, the activation condition of solid catalyst A is 450° C. for 3 hours, and other process conditions are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com