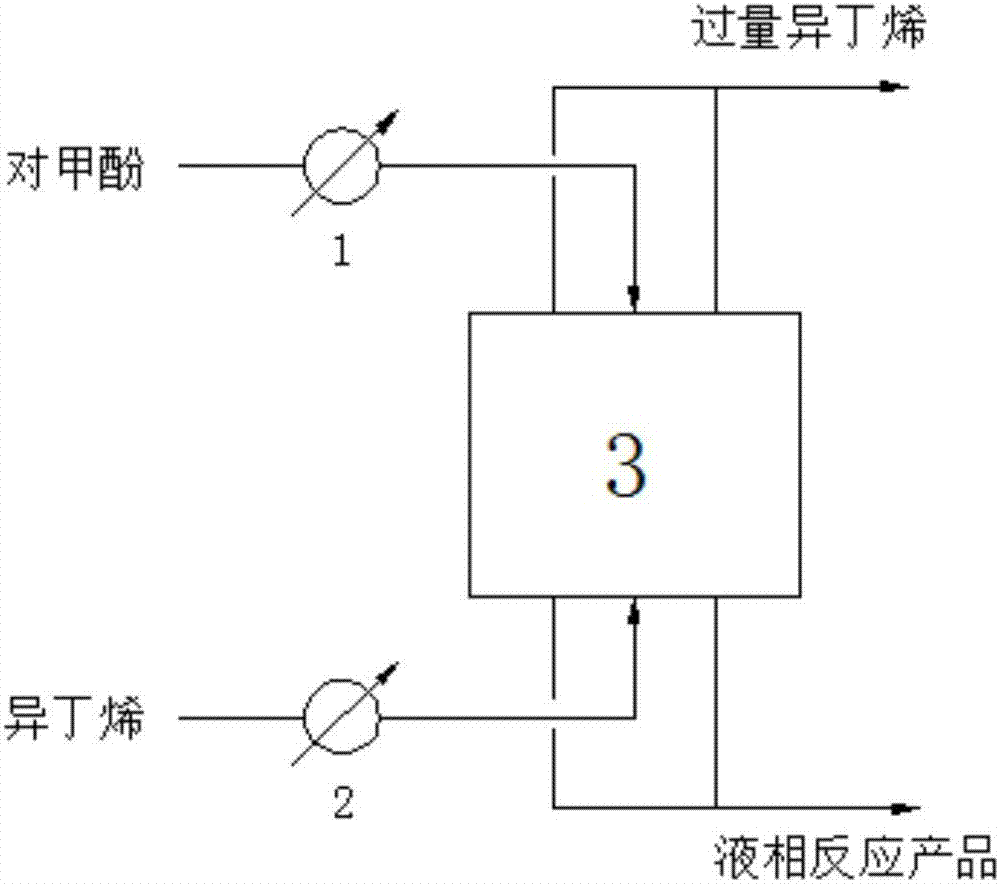

Method for preparing 2,6-ditertbutyl-4 methylphenol by using micro-reaction rectifying plate and device thereof

A di-tert-butyl and micro-reaction technology, which is applied in the field of preparation of 2,6-di-tert-butyl-p-cresol, can solve the problems of not being able to meet complex and diverse actual chemical production needs, and achieve simplified product refining process and heat transfer area Great, conversion-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Use above-mentioned equipment and process method to prepare 2,6-di-tert-butyl-p-cresol, wherein:

[0038] The preheating temperature of p-cresol preheater and isobutylene preheater is 70°C;

[0039] Raw material feed pressure is 0.5MPa;

[0040] Catalyst V 2 o 5 The mass fraction is 0.1%

[0041] The catalyst coating thickness is 2 μm;

[0042] The space velocity of p-cresol is 1.0h -1 ;

[0043] The molar ratio of p-cresol to isobutylene feed is 1:3.

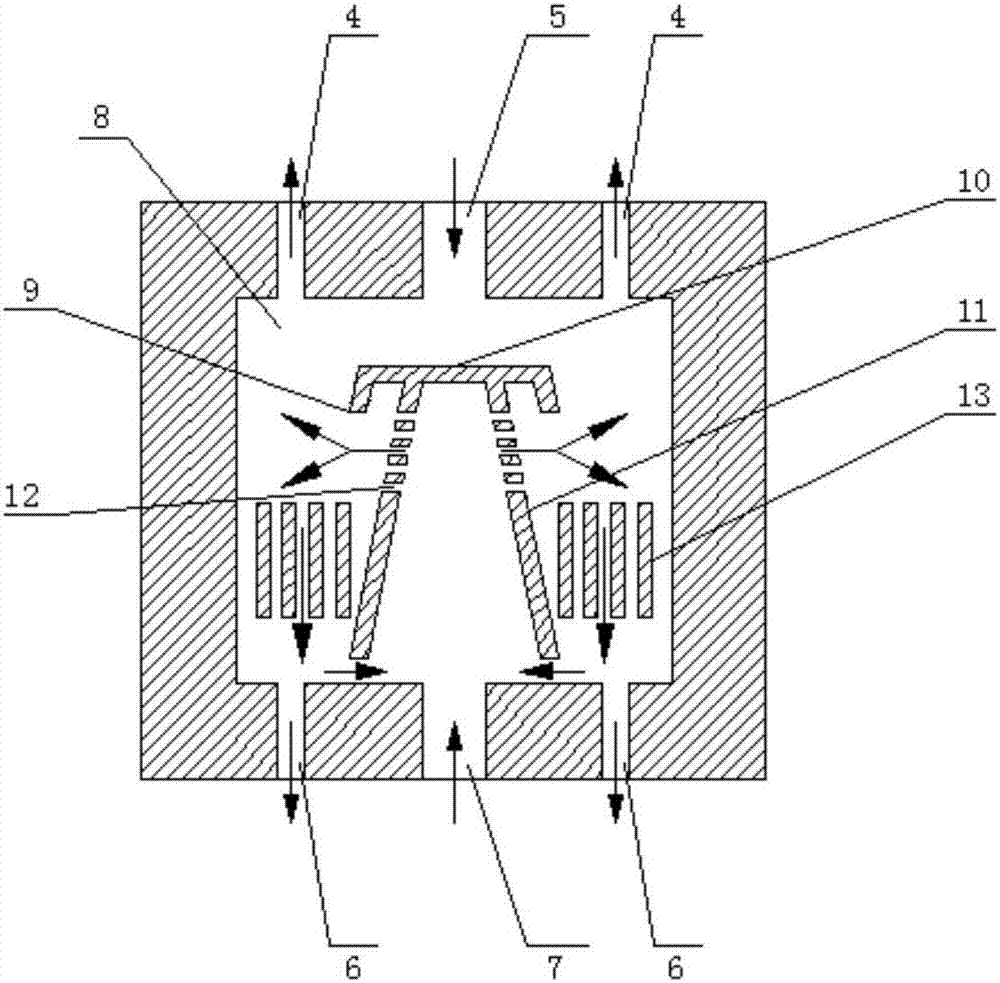

[0044] The side length of the central chamber is 2200 μm;

[0045] The depth of the central chamber is 100 μm;

[0046] The upper and lower four side channels of the microchamber have a width of 100 μm;

[0047] The upper and lower central channels of the microchamber have a width of 200 μm;

[0048] The height of the π-shaped partition is 1500 μm;

[0049] The two legs of the π-shaped partition are at 80° to the top plate of the π-shaped partition;

[0050] The length of the top plate is 400 μm...

Embodiment 2

[0065] Embodiment 2: use above-mentioned equipment and process method to prepare 2,6-di-tert-butyl-p-cresol, wherein:

[0066] The preheating temperature of p-cresol preheater and isobutylene preheater is 70°C;

[0067] Raw material feed pressure is 0.5MPa;

[0068] Catalyst V 2 o 5 The mass fraction is 0.1%

[0069] The catalyst coating thickness is 2 μm;

[0070] The space velocity of p-cresol is 1.0h -1 ;

[0071] The molar ratio of p-cresol to isobutylene feed is 1:4.

[0072] The side length of the central chamber is 2200 μm;

[0073] The depth of the central chamber is 100 μm;

[0074] The upper and lower four side channels of the microchamber have a width of 100 μm;

[0075] The upper and lower central channels of the microchamber have a width of 200 μm;

[0076] The height of the π-shaped partition is 1500 μm;

[0077] The two legs of the π-shaped partition are at 80° to the top plate of the π-shaped partition;

[0078] The length of the top plate is 400 μm...

Embodiment 3

[0093] Embodiment 3: use above-mentioned equipment and process method to prepare 2,6-di-tert-butyl-p-cresol, wherein:

[0094] The preheating temperature of p-cresol preheater and isobutylene preheater is 70°C;

[0095] Raw material feed pressure is 0.5MPa;

[0096] Catalyst V 2 o 5 The mass fraction is 0.1%

[0097] The catalyst coating thickness is 2 μm;

[0098] The space velocity of p-cresol is 0.5h -1 ;

[0099] The molar ratio of p-cresol to isobutylene feed is 1:4.

[0100] The side length of the central chamber is 2200 μm;

[0101] The depth of the central chamber is 100 μm;

[0102] The upper and lower four side channels of the microchamber have a width of 100 μm;

[0103] The upper and lower central channels of the microchamber have a width of 200 μm;

[0104] The height of the π-shaped partition is 1500 μm;

[0105] The two legs of the π-shaped partition are at 80° to the top plate of the π-shaped partition;

[0106] The length of the top plate is 400 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com