Method for preparing 3-methoxy methyl propionate

A technology of methyl methoxypropionate and methyl acrylate, applied in the field of improvement of the method, can solve the problems of low product yield, large catalyst dosage, complicated refining process, etc., and achieves simple refining process and less catalyst dosage , the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

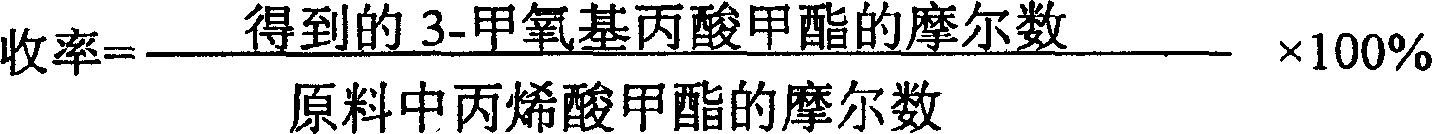

Image

Examples

Embodiment 1

[0018] (1) Synthesis of methyl 3-methoxypropionate

[0019] Add 32g of sodium methoxide with a concentration of 28% and 57g of methanol to a four-neck flask equipped with a stirrer, thermometer, constant pressure funnel, and reflux condenser, and slowly drip 86g of methyl acrylate over 12 hours under strong stirring. Add it into the said flask (methanol:MA=2.5:1mol), continue to react for 2 hours, and the reaction temperature is 55±2°C.

[0020] (2) Neutralization catalyst

[0021] Slowly add 8.3g of 98% concentrated sulfuric acid into the flask under cooling and stirring, and control the temperature of the system to ≤35°C, and the material in the flask is in a state of suspension.

[0022] (3) Recovery of unreacted materials and refining of products

[0023] The above-mentioned suspension was added to the tower kettle of the glass rectification tower (600mm high φ2×2θ mesh ring packing inside, produced by Tianda Tianjiu Technology Co., Ltd.), and the tower kettle was equipp...

Embodiment 2

[0025] 50.4g concentration is that the methyl alcohol of 28% liquid sodium methylate, 59.6g is added in the four-necked flask that stirrer, thermometer, constant pressure funnel, reflux condenser are equipped with, under vigorous stirring, with 10 hours, 86gMA (methanol: MA =3.0: 1mol), then reacted for 2 hours, and the reaction temperature was 45 ± 2°C, and all the other catalysts were neutralized, the recovery of unreacted materials, and the refining of the product were all the same as (2) and (3) in Example 1, and the product The yield was 86.4%.

Embodiment 3

[0027] The concentrated sulfuric acid that removes catalyst with 28% potassium methylate, neutralization catalyst is 6.4g, and all the other are all relevant parts with embodiment 1. The yield of methyl 3-methoxypropionate is 89.0% (the price of potassium methylate is 5 times higher than that of sodium methylate).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com