Method utilizing supercritical catalysis process to continuously prepare biodiesel

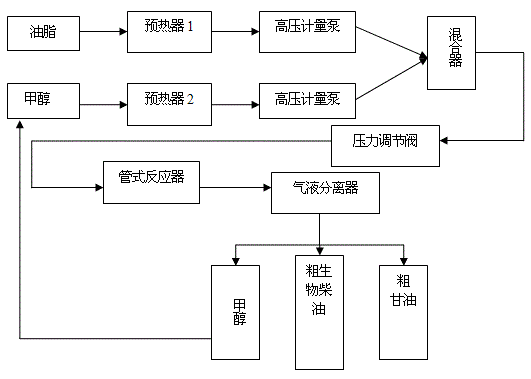

A biodiesel and supercritical technology, applied in biofuels, petroleum industry, fatty acid esterification, etc., can solve problems such as harsh operating conditions, increased costs, and complicated operation of the separation catalyst process, and achieve stable product quality and high production efficiency High, high output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preheat the sorbifolia oil to 35°C, heat the tubular reactor to 350°C through a heating furnace, and adjust the pressure to 20MPa. After filtering out the solid impurities in the oil, use a high-pressure metering pump to pump soybean oil and methanol into the mixer at a volume ratio of 1:2.5 (molar ratio is about 1:60). After mixing, they enter the reaction tube for reaction, and the materials stay in the tube. The time was 3 minutes, and the sample was collected after the reaction was stable, and residual methanol was distilled off under reduced pressure. The conversion rate of soybean oil was measured to be 100%.

Embodiment 2

[0046] Preheat the sorbifolia oil to 35°C, heat the tubular reactor to 350°C through a heating furnace, and adjust the pressure to 20MPa. After filtering out the solid impurities in the oil, use a high-pressure metering pump to pump soybean oil and methanol into the mixer at a volume ratio of 1:2 (molar ratio is about 1:48). After mixing, they enter the reaction tube for reaction, and the materials stay in the tube. The time was 3 minutes, and the sample was collected after the reaction was stable, and residual methanol was distilled off under reduced pressure. The conversion rate of soybean oil was measured to be 97%.

Embodiment 3

[0048] Preheat the sorbifolia oil to 35°C, heat the tubular reactor to 350°C through a heating furnace, and adjust the pressure to 20MPa. After filtering out the solid impurities in the oil, use a high-pressure metering pump to pump soybean oil and methanol into the mixer at a volume ratio of 1:1.5 (molar ratio is about 1:36). After mixing, they enter the reaction tube for reaction, and the materials stay in the tube. The time was 3 minutes, and the sample was collected after the reaction was stable, and residual methanol was distilled off under reduced pressure. The conversion rate of soybean oil was measured to be 94%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com