Solanesol refining method

A refining method and technology of solanesol, applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve the problems of complicated operation process, low production efficiency, large solvent consumption, etc., and achieve simplified refining process, increase product yield, and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1. Put the solanesol crude paste extracted from tobacco leaves into a saponification tank, add 10% KOH aqueous solution for saponification treatment for 30 minutes under the condition of heating to 80°C and stirring vigorously, release the water layer after the end, and keep the oil layer , to obtain crude paste saponification;

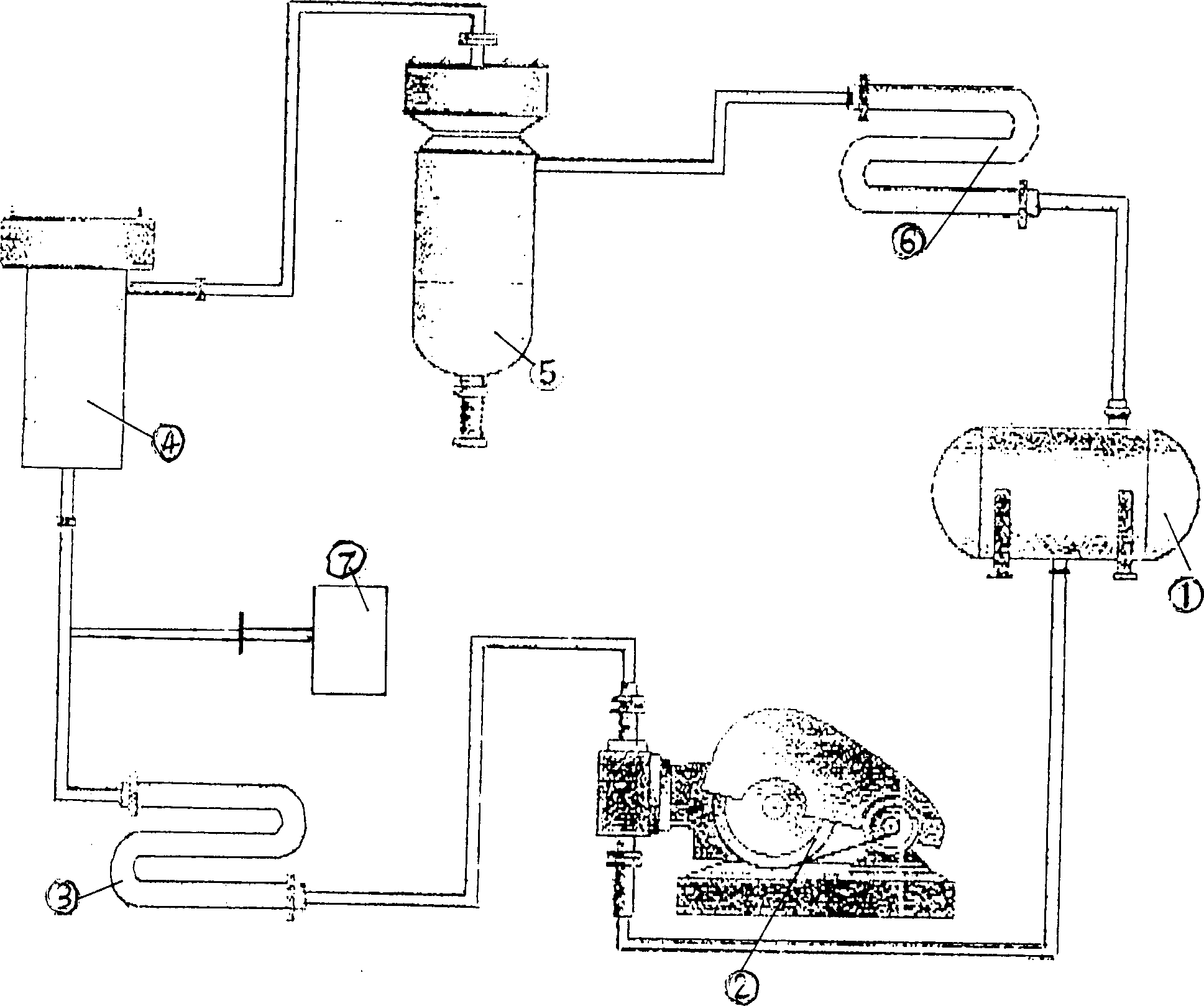

[0017] 2. Put 10 kg of saponified solanesol crude paste into the extraction tank 4, turn on the heat exchanger 3, adjust the heating temperature to 50°C, turn on the compressor 2, and set the temperature at 30 m / min 3 The flow rate is passed into the extraction tank 4 with carbon dioxide fluid in a super-immediate state, so that the pressure in the extraction tank 4 reaches 14Mpa, and the pressure reducing valve is opened to extract the substances with molecular weight and polarity lower than solanesol in the phase paste and then extract them with the super The intermediary carbon dioxide fluid flows into the separation tank 5, and the extract ...

Embodiment 2

[0021] 1, the process is the same as embodiment 1;

[0022] 2. Put 10 kg of saponified solanesol crude paste into the extraction tank 4, turn on the heat exchanger 3, adjust the heating temperature to 80°C, turn on the compressor 2, and set the temperature at 100m / min 3 The flow rate is fed into the extraction tank 4 with carbon dioxide fluid in a super-immediate state, so that the pressure in the extraction tank 4 reaches 16Mpa, and the pressure reducing valve is opened to extract the substances with molecular weight and polarity lower than solanesol in the thick paste and then extract them with the super The intermediary carbon dioxide fluid flows into the separation tank 5, and the extract is precipitated after decompression. The pressure of the separation tank 5 is maintained at 4MPa, so that the supercritical carbon dioxide becomes gaseous carbon dioxide and enters the condenser 6, where it is continuously liquefied and then flows back The liquid storage tank 1 is re-inje...

Embodiment 3

[0026] 1, saponification process is with embodiment 1;

[0027] 2. Put 10 kg of saponified crude solanesol paste into the extraction tank 4, turn on the heat exchanger 3, adjust the heating temperature to 40°C, turn on the compressor 2, and set the temperature at 10 m / min 3 The flow rate is passed into the extraction tank 4 with carbon dioxide fluid in a super-immediate state, so that the pressure in the extraction tank 4 reaches 75Mpa, and the pressure reducing valve is opened to extract the substances with molecular weight and polarity lower than solanesol in the thick paste and then extract them with the super The intermediary carbon dioxide fluid flows into the separation tank 5, and the extract is precipitated after decompression. The pressure of the separation tank 5 is maintained at 5Pma, so that the supercritical carbon dioxide becomes gaseous carbon dioxide and enters the condenser 6, where it is continuously liquefied and then flows back The liquid storage tank 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com