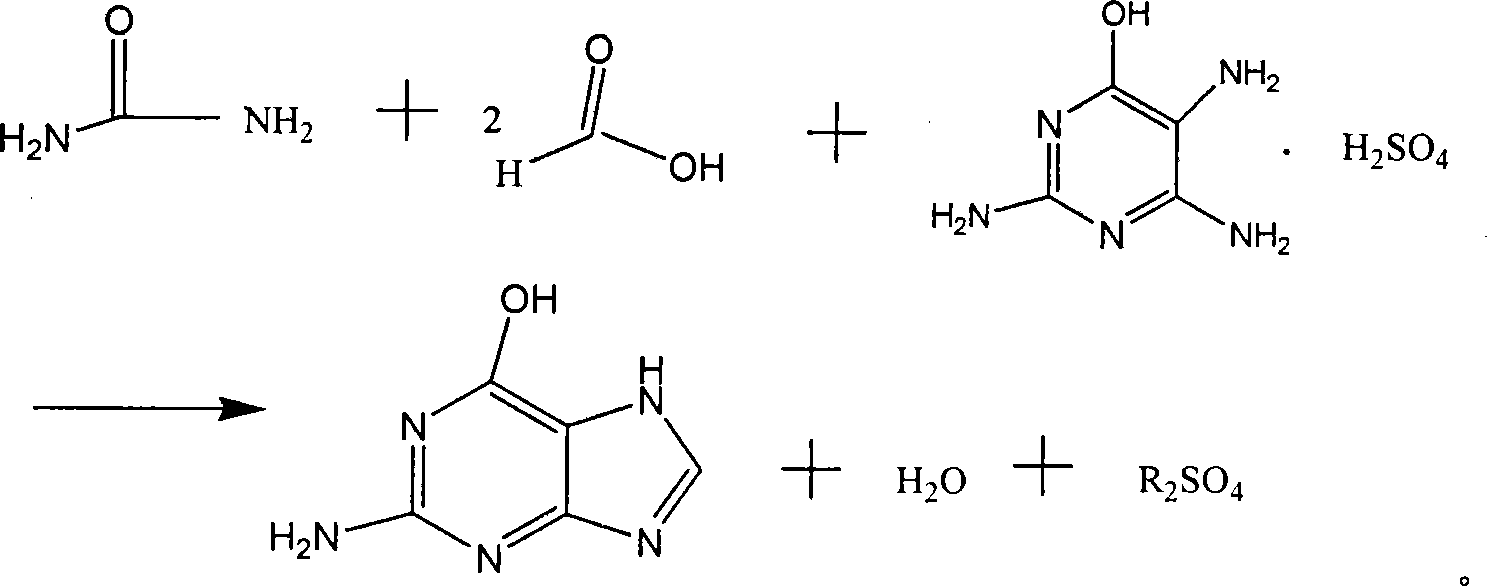

Method for synthesizing guanine from urea

A technology of guanine and urea, applied in the field of chemical industry, achieves the effect of low price and low consumption of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 15 grams of urea to the dried 500 milliliter three-necked bottle, and then add 75 milliliters of formic acid (94% by weight, about 90 grams), and stir at room temperature to make the solution completely clear.

[0022] Continue to add 48 grams of 2,4,5-triamino-6-hydroxypyrimidine sulfate (industrial grade, content 95%) into the three-necked bottle. After casting, heat up to reflux. Add 50 grams of formic acid (content 94%) in the there-necked flask with a constant pressure titration funnel at a faster speed through a spherical condenser, and drop it in about 5 minutes; continue to reflux.

[0023] Reflux and keep warm for 15 hours, first evaporate part of the formic acid at normal pressure, and then evaporate the formic acid to dryness under a negative pressure less than 0.1Mpa.

[0024] Dissolve the solid obtained in the three-necked bottle with an appropriate amount of hydrochloric acid solution, decolorize, and adjust the mother liquor to neutrality with lye to...

Embodiment 2

[0028] Utilize the formic acid that content is 86%, other is with embodiment 1, and the results are shown in Table 1.

Embodiment 3

[0032] Utilize the formic acid that content is 79.5%, other is with embodiment 1, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com