Method for preparing polylactic acid-based high-elasticity copolymer

A technology of polylactic acid-based copolymers, which is applied in the field of preparation of polylactic acid-based high-elastic copolymers, can solve the problems of destroying the equimolar ratio of hydroxyl and carboxyl groups, the molecular weight of the product is not high, and the number of hydroxyl groups is increased, so as to increase efficiency, Simplify the refining process and improve toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

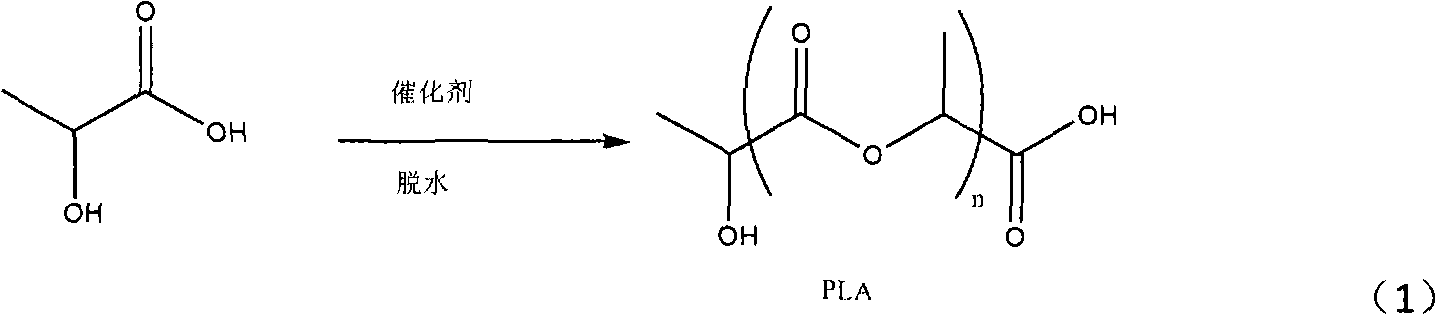

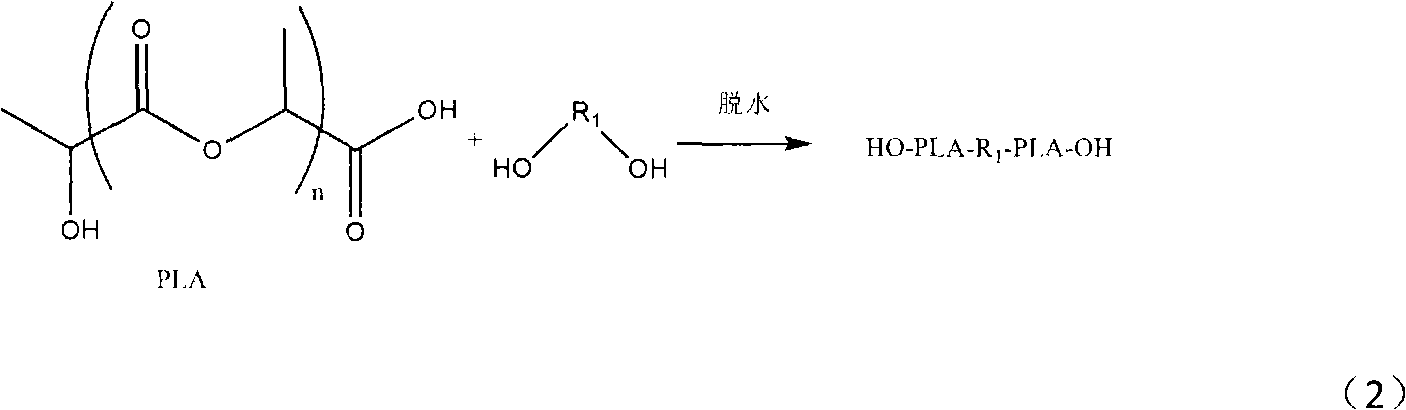

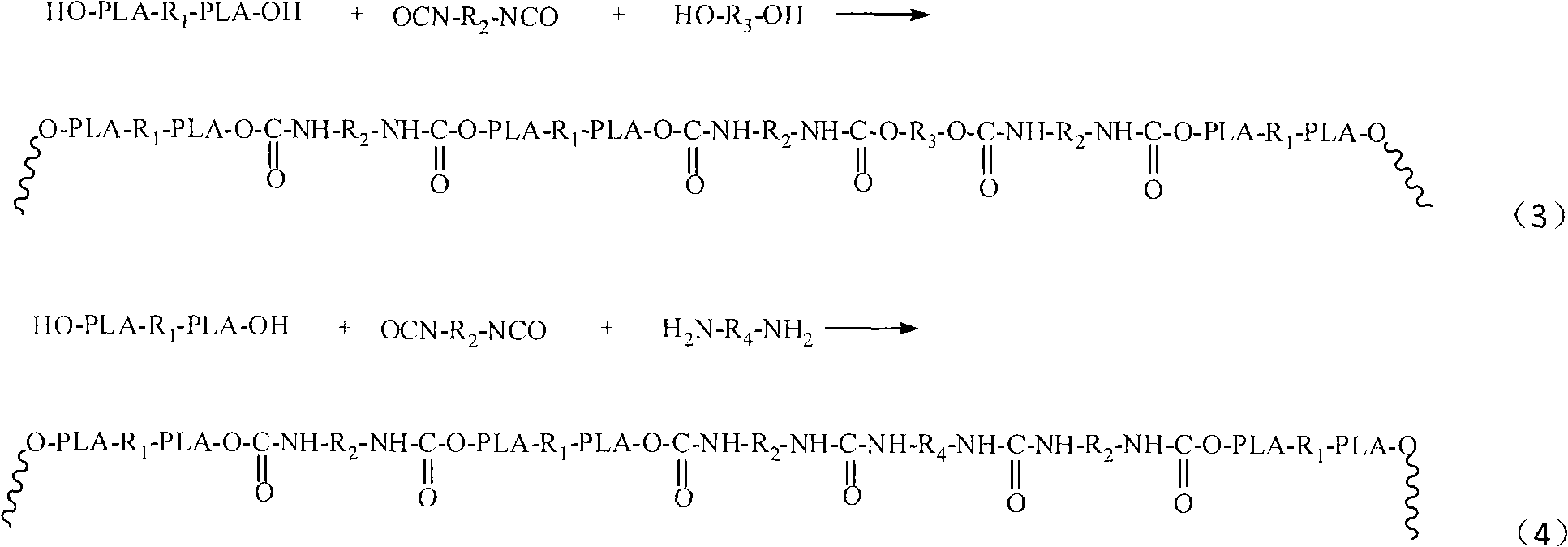

Method used

Image

Examples

Embodiment 1

[0034] (1) Add 800g of L-lactic acid into the vacuum reactor, add 0.5g of stannous chloride catalyst, vacuumize, control the pressure of the reactor at 1.0Kpa, raise the temperature of the reactor to 100°C, and react for 5 hours; then the temperature of the reactor Raise to 165°C, drop the pressure below 100Pa, and continue the reaction for 10 hours to obtain polylactic acid.

[0035] (2) Add 80 g of polytetrahydrofuran glycol (PTMEG) to a vacuum reactor containing polylactic acid, the pressure of the reactor is 1.0 Kpa, the temperature of the reactor is 150° C., and react for 6 hours to obtain a copolymer prepolymer.

[0036] (3) The prepolymer obtained by the reaction in step (2) is mixed with 1,6-hexamethylene diisocyanate (HDI), 1,4-butanediol according to the -NCO of isocyanate: -OH of the copolymer prepolymer: extended -OH (molar ratio) of the chain agent = 1.09: 1.00: 0.05 is added to the reactor, the amount of polyol is 5wt% of the amount of isocyanate, at 140 ° C, rea...

Embodiment 2

[0039] (1) Put 800g of L-lactic acid into the vacuum reactor, add catalyst 0.5g stannous octoate, vacuumize, control the pressure of the reactor at 1.0Kpa, raise the temperature of the reactor to 100°C, and react for 5 hours; then the temperature of the reactor rises To 165°C, the pressure drops below 100Pa, and the reaction is continued for 10 hours to obtain polylactic acid.

[0040] (2) Add 80g of polycaprolactone diol (PCL) to the vacuum reactor containing polylactic acid, the reactor pressure is 1.0Kpa, the reactor temperature is 150°C, react for 6 hours to obtain the copolymer prepolymer .

[0041](3) The prepolymer obtained by the reaction in step (2) is prepolymerized with diphenylmethane-4,4'-diisocyanate (MDI), 1,4-butanediol, and isocyanate-NCO: copolymer The -OH of the body: the -OH of the chain extender (molar ratio) = 1.05: 1.00: 0.03 is added to the reactor, the amount of polyol is 5wt% of the amount of isocyanate, at 140 ° C, reacted for 15 minutes, and releas...

Embodiment 3

[0044] (1) Add 500g of D-lactic acid and 300g of L-lactic acid into the vacuum reactor, add catalyst 0.5g tetrabutyl titanate, vacuumize, control the pressure of the reactor at 2.0Kpa, raise the temperature of the reactor to 120°C, and react 5 hours; then the temperature of the reactor was raised to 180° C., the pressure dropped below 100 Pa, and the reaction was continued for 8 hours to obtain polylactic acid.

[0045] (2) Add 160g of polyethylene adipate diol (PEA) to a vacuum reactor containing polylactic acid, the pressure of the reactor is 1.0Kpa, the temperature of the reactor is 200°C, and the reaction is carried out for 5 hours to obtain a copolymerized prepolymers.

[0046] (3) react the prepolymer obtained in the step (2) with toluene diisocyanate (TDI), trimethylolpropane according to the -NCO of isocyanate: the -OH of the copolymer prepolymer: the -OH of the chain extender ( Molar ratio) = 1.05: 0.99: 0.05 into the reactor, the amount of polyol is 7wt% of the amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com