Deep processing device and method for chloropropene co-product

A joint product and deep processing technology, applied in the field of separation and purification of chemical substances, to achieve the effect of convenient production, simple and easy refining process, and expanded production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

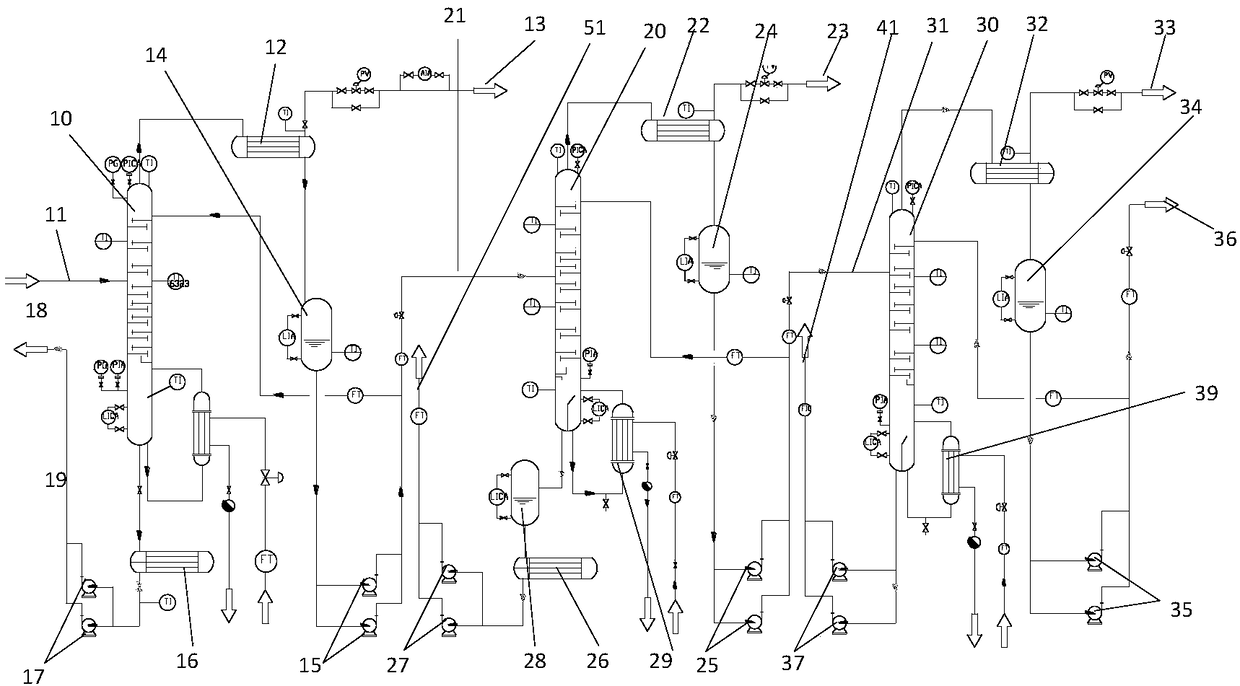

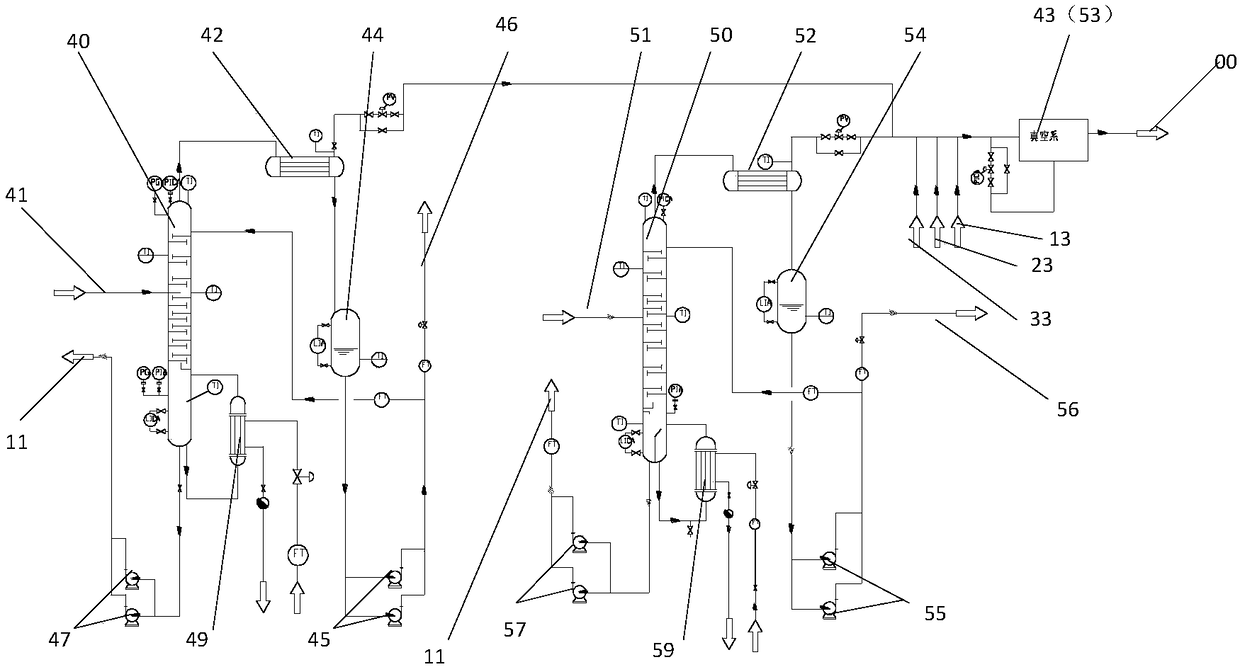

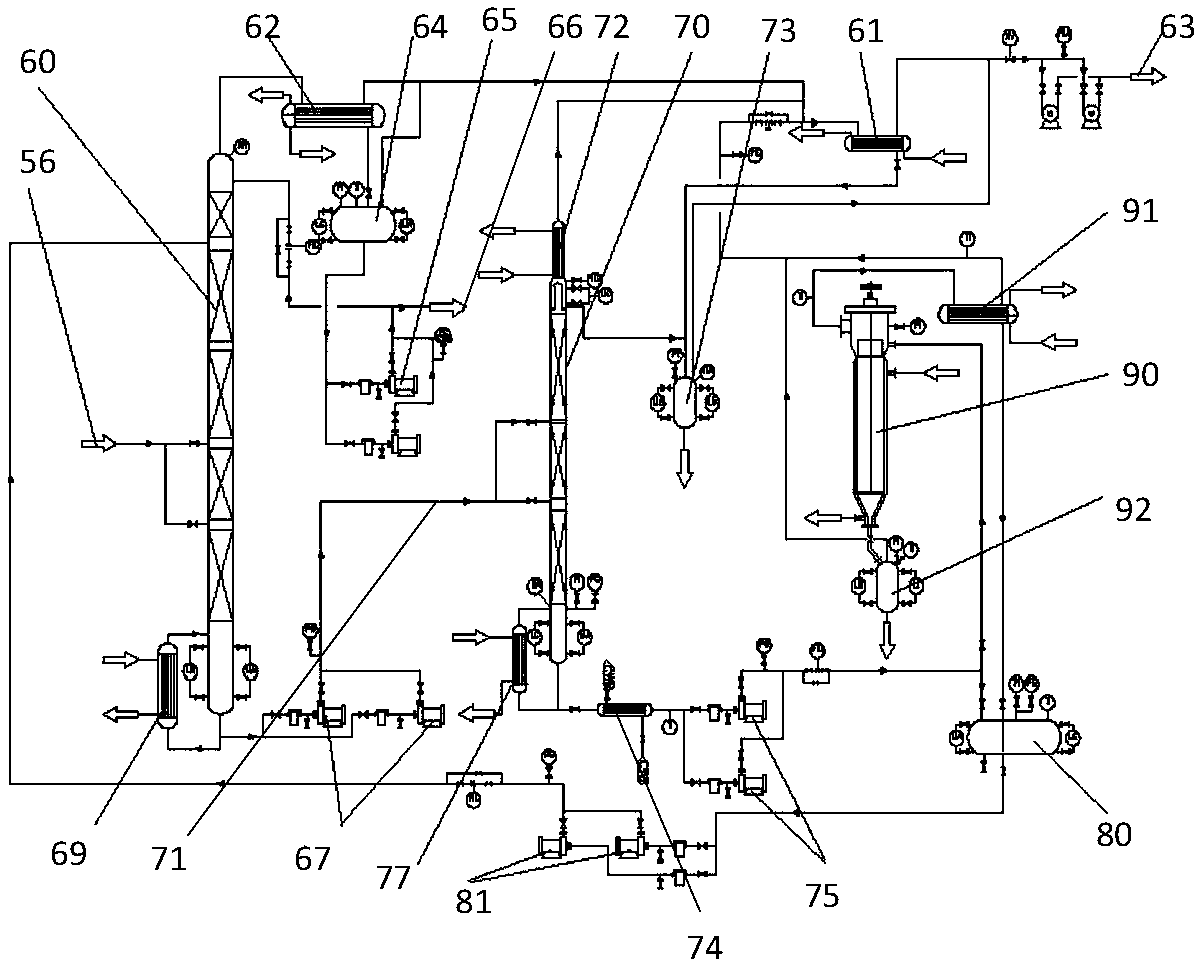

[0040] Such as figure 1 and figure 2 As shown, the first part and the second part of a chloropropene co-product deep processing device provided by the present invention are continuous vacuum rectification separation devices, including a first rectification tower 10, a second rectification tower 20, and a third rectification tower 30. The fourth rectification tower 40 and the fifth rectification tower 50, specifically:

[0041] The feed inlet of rectification first tower 10 is connected with rectification first tower feed pipeline 11, and the air outlet on the top of the tower is connected with the air inlet of rectification first tower top condenser 12, and the gas outlet of rectification first tower top condenser 12 Connected to the first rectification tower vacuum pump 13; the outlet of the first rectification tower overhead condenser 12 is connected to the feed port of the first rectification tower reflux tank 14; the outlet of the first rectification tower reflux tank 14...

Embodiment 2

[0052] The present invention also provides a method for deep processing of allyl chloride co-products, comprising the following steps:

[0053] (1) The DD mixture enters the first rectification tower through the feed pipeline, and after rectification and separation, the gas phase at the top of the tower enters the top condenser of the first rectification tower, and after being condensed with circulating water, the liquid phase enters the reflux tank of the first rectification tower , the uncondensed gas phase enters the first rectification tower vacuum pump to ensure the stability of the negative pressure in the tower; the material in the first rectification tower reflux tank is pressurized by the first rectification tower reflux pump, and part of it returns to the first rectification tower, and the other Part of it is used as the feed to the second rectification tower, and the feed amount is controlled by the feed regulating valve; the high boiler residue is produced from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com