Continuous production method for preparing fatty acid butyl ester based on biodiesel

A technology of fatty acid butyl ester and biodiesel, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of ester groups and hydroxyl groups, etc., can solve the problems of low utilization rate of butanol, decreased yield, equipment corrosion, etc. The effect of reducing the consumption of butanol, reducing the energy consumption of rectification and running stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

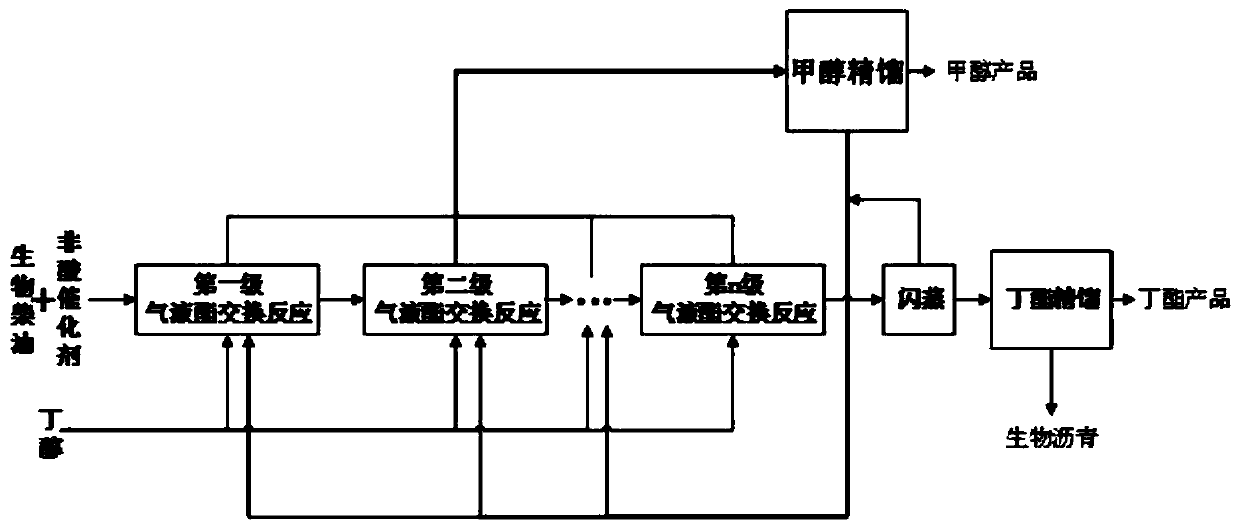

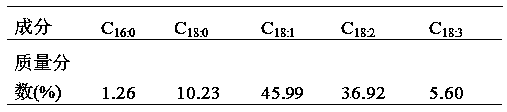

[0032] The fatty acid methyl ester content distribution of raw material biodiesel is shown in Table 1:

[0033] Table 1 Content table of each fatty acid methyl ester in raw material biodiesel

[0034]

[0035]The raw material biodiesel and sodium methoxide catalyst are mixed at a mass ratio of 1000:5 and then mixed with 2m 3 Feed at the flow rate of / h, the gas-liquid transesterification reaction section is composed of four-stage tower reactors, the temperature of the four-stage tower reactors is controlled at 190°C, and the fresh reactant butanol is respectively charged at 0.8m 3 / h, 0.2m 3 / h, 0.2m 3 / h, 0.6m 3 / h flow rate feed to start the reaction. After the whole production system is stabilized, fresh butanol feed will no longer be maintained in the first three tower reactors, and the first, second and third tower reactors will be switched to recover butanol product feed respectively. , The flow rate of the recovered butanol product passed into the three-stage to...

Embodiment 2

[0041] The fatty acid methyl ester content distribution of the raw material biodiesel is shown in Table 1. The raw material biodiesel and sodium methoxide catalyst are mixed at a mass ratio of 1000:5 and then mixed with 3m 3 / h flow rate feed, the gas-liquid transesterification reaction section is composed of six tower reactors, the temperature of the six tower reactors is controlled at 165 °C, and the fresh reactant butanol is 1.4m 3 / h, 0.5m 3 / h, 0.5m 3 / h, 0.5m 3 / h, 0.5m 3 / h, 0.9m 3 / h flow rate feed to start the reaction. After the entire production system is stabilized, the first five tower reactors will no longer maintain fresh butanol feed, and the first to fifth tower reactors will be switched to recycled butanol product feeds, and the first to fifth The flow rate of the recovered butanol product passed into the fifth-stage tower reactor is maintained at 1.4m 3 / h, 0.5m 3 / h, 0.5m 3 / h, 0.5m 3 / h, 0.5m 3 / h; the sixth stage tower reactor maintains fresh b...

Embodiment 3

[0047] The fatty acid methyl ester content distribution of the raw material biodiesel is shown in Table 1. The raw material biodiesel and sodium methoxide catalyst are mixed at a mass ratio of 1000:5 and then mixed with 1.5m 3 / h flow feed, the gas-liquid transesterification reaction section is composed of eight-stage tower reactors, the temperature of the eight-stage tower reactors is controlled at 130 ° C, and the fresh reactant butanol is divided into 0.6m 3 / h, 0.16 m 3 / h, 0.16m 3 / h, 0.16 m 3 / h, 0.16m 3 / h, 0.16 m 3 / h, 0.16m 3 / h, 0.45m 3 / h flow rate feed to start the reaction. After the entire production system is stabilized, fresh butanol feed will no longer be maintained in the first seven tower reactors, and the first to seventh tower reactors will be switched to recycled butanol product feeds. The flow rate of the recovered butanol product passed into the seventh-stage tower reactor was maintained at 0.6 m 3 / h, 0.16 m 3 / h, 0.16m 3 / h, 0.16 m 3 / h, 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com