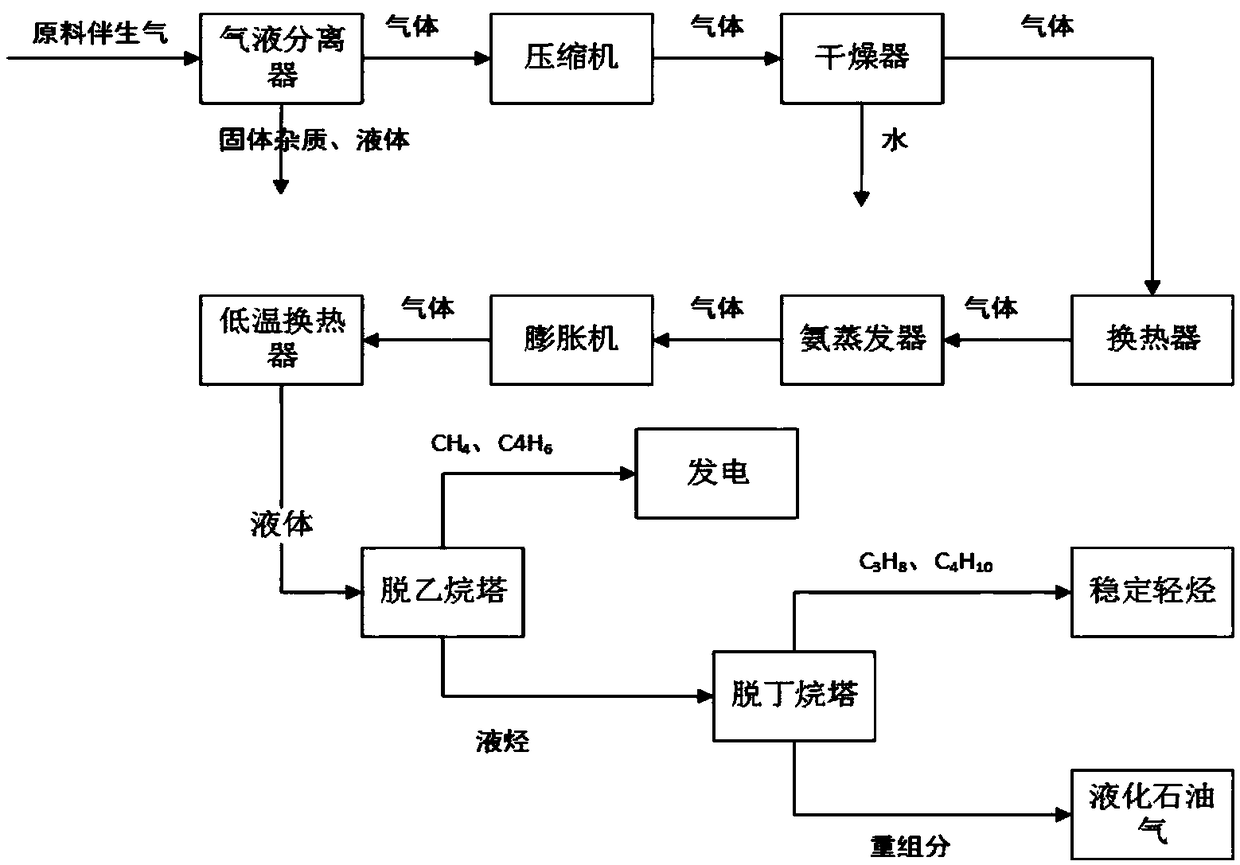

Treatment technology for petroleum associated gas

A technology of oil associated gas and treatment process, which is applied in the direction of petroleum industry, gas fuel, fuel, etc., can solve the problems of unsuitable associated gas, high gas permeation rate, unfavorable oil associated gas treatment process simplification, etc., to achieve simplified drying steps, The effect of high gas flux and fast dehydration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the preparation one of composite film:

[0031] The preparation steps of this embodiment are as follows:

[0032] Bottom membrane preparation: stainless steel fiber and glass fiber are mixed and woven into a mesh bottom membrane;

[0033] Film compact: mix 50g of alumina, 25g of γ-Al 2 o 31. After mixing 50g of silicon dioxide with 250ml of 45wt% ethanol solution, the mixture was dispersed by 30kHz ultrasonic treatment for 0.5h at room temperature. After mixing the mixture with 100ml of acetone, it was placed in a ball mill with a rotating speed of 200rpm for 25h. The medium is alumina balls. After ball milling, the mixture is taken out and dried at 90°C to form a mixed powder. The mixed powder is pre-sintered in vacuum at 1500°C and 10MPa for 2 hours and then taken out to obtain a composite powder. Mix 40g of the composite powder with 20g of silicon Gel, 5g of sodium bicarbonate powder, and 15g of polyimide powder are prepared by stirring with a high-s...

Embodiment 2

[0035] Embodiment 2: the preparation two of composite film:

[0036] The preparation steps of this embodiment are as follows:

[0037] Bottom membrane preparation: stainless steel fiber and glass fiber are mixed and woven into a mesh bottom membrane;

[0038] Film compact: mix 50g of alumina, 25g of γ-Al 2 o 3 1. After mixing 50g of silicon dioxide with 250ml of 50wt% ethanol solution, use 30kHz ultrasonic treatment to disperse for 0.5h at room temperature to obtain the mixture. After mixing the mixture with 100ml of acetone, place it in a ball mill with a rotation speed of 250rpm for 23h. The medium is alumina balls. After ball milling, the mixture is taken out and dried at 95°C to form a mixed powder. The mixed powder is pre-sintered in vacuum at 1600°C and 9MPa for 2 hours and then taken out to obtain a composite powder. Mix 40g of the composite powder with 32g of silicon Gel, 20g of sodium bicarbonate powder, and 60g of polyimide powder were prepared by stirring with an...

Embodiment 3

[0040] Embodiment 3: the preparation three of composite film:

[0041] The preparation steps of this embodiment are as follows:

[0042] Bottom membrane preparation: stainless steel fiber and glass fiber are mixed and woven into a mesh bottom membrane;

[0043] Film compact: 80g of alumina, 40g of γ-Al 2 o 3 1. After mixing 80g of silicon dioxide with 400ml of 65wt% ethanol solution, 30kHz ultrasonic treatment was used at room temperature to disperse for 0.5h to obtain the mixture. After the mixture was mixed with 100ml of acetone, it was placed in a ball mill with a rotating speed of 200rpm for 25h. The medium is alumina balls. After ball milling, the mixture is taken out and dried at 100°C to form a mixed powder. The mixed powder is pre-sintered in vacuum at 1800°C and 8MPa for 1 hour and then taken out to obtain a composite powder. Mix 60g of the composite powder with 30g of silicon Gel, 7.5g sodium bicarbonate powder, and 22.5g polyimide powder were prepared by stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com